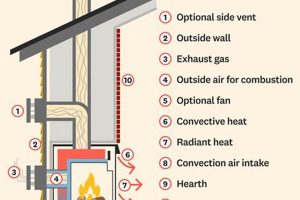

A crucial component of a gas fireplace system facilitates the safe expulsion of combustion byproducts, like carbon dioxide and water vapor, from the appliance to the exterior environment. This specialized ductwork is designed and installed to meet specific safety standards, ensuring efficient ventilation. For example, a properly installed system prevents the accumulation of dangerous gases within a dwelling.

Effective removal of these byproducts protects indoor air quality and helps to prevent potential health hazards associated with carbon monoxide exposure. Historically, inefficient or poorly designed systems led to significant safety concerns, prompting the development of stringent building codes and improved venting technologies. The implementation of these advancements enhances the reliability and safety of gas fireplaces in residential and commercial settings.

Subsequent sections will delve into the types of venting systems available, installation guidelines, maintenance procedures, and troubleshooting common issues. Further discussion will also address relevant safety regulations and best practices for ensuring optimal performance and longevity of the appliance and its accompanying exhaust system.

Essential Guidance

The following points provide crucial information for homeowners utilizing gas fireplaces. Adherence to these recommendations will contribute to a safer and more efficient heating experience.

Tip 1: Regular Inspection: Routine visual checks of the exhaust system are essential. Examine for signs of corrosion, blockages, or physical damage, particularly at joints and termination points. Documented inspections can aid in tracking potential issues over time.

Tip 2: Professional Servicing: Schedule professional servicing by a qualified technician annually. This service should include a comprehensive inspection of the system, including pressure testing, burner cleaning, and verification of proper draft.

Tip 3: Carbon Monoxide Detectors: Install and maintain carbon monoxide detectors on every level of the dwelling, particularly near sleeping areas. Test the detectors regularly and replace batteries as recommended by the manufacturer.

Tip 4: Clearance Requirements: Ensure adequate clearance is maintained between the system and combustible materials. Refer to the manufacturer’s specifications for minimum clearance requirements and adhere to local building codes.

Tip 5: Proper Termination: Verify that the termination point adheres to code requirements, ensuring it is adequately spaced from windows, doors, and air intakes. Improper termination can lead to re-entrainment of exhaust gases into the building.

Tip 6: Vent Material Compatibility: Ensure that the venting components are compatible with the specific type of gas fireplace being used. Using incompatible materials can result in corrosion, leaks, and potential safety hazards. Consult the fireplace manufacturer’s documentation for approved venting systems.

Tip 7: Sealing Integrity: Proper sealing of vent connections is crucial to prevent exhaust leaks. Use approved sealant materials and techniques to ensure a gas-tight seal at all joints and connections.

These recommendations serve as a foundation for safe operation. Diligent attention to these guidelines helps to mitigate risks and maintain the efficiency of the system.

The subsequent sections will further elaborate on specific aspects of gas fireplace operation and maintenance, providing a comprehensive resource for homeowners and professionals alike.

1. Material Durability

The long-term operational safety and efficiency of a gas fireplace’s exhaust system are intrinsically linked to the durability of the materials used in its construction. Material selection directly impacts the system’s resistance to corrosion, thermal stress, and physical degradation, thereby influencing its ability to safely and effectively vent combustion byproducts over time.

- Corrosion Resistance

Exhaust gases from gas fireplaces contain water vapor and acidic compounds that can corrode certain metals. Stainless steel and specialized alloys offer superior resistance to these corrosive elements compared to galvanized steel or aluminum. Premature corrosion can lead to leaks, structural weakening, and the release of harmful gases into the dwelling. Proper material selection mitigates this risk.

- Thermal Stability

Exhaust systems experience significant temperature fluctuations during fireplace operation. Materials must exhibit thermal stability, maintaining their structural integrity and dimensional stability across a wide temperature range. Expansion and contraction due to temperature changes can stress joints and connections, potentially leading to leaks or component failure. Materials with low thermal expansion coefficients are preferable.

- Weather Resistance

The exterior portion of the venting system is exposed to the elements, including rain, snow, ice, and UV radiation. Materials must resist degradation from these environmental factors to prevent premature aging and failure. UV-resistant coatings and durable outer layers protect the underlying materials from weathering, extending the service life of the system. A compromised outer layer can expose the venting to moisture and accelerated corrosion.

- Joint Integrity

The durability of the exhaust system relies not only on the materials used for the vent pipes themselves but also on the materials and methods used to join them. High-temperature sealants and secure connection mechanisms, such as locking bands or crimped joints, are essential for maintaining a gas-tight seal over the long term. Failure of joint integrity can result in exhaust leaks and reduced venting efficiency.

The interconnectedness of these facets underscores the critical role material durability plays in the performance and longevity of a gas fireplace exhaust system. The selection of appropriate materials, coupled with proper installation and maintenance practices, is essential for ensuring safe and reliable operation throughout the fireplace’s lifespan.

2. Proper Sizing

The dimensions of a gas fireplace exhaust system are fundamentally linked to its safe and effective operation. The exhaust system’s diameter and height must be precisely calculated to accommodate the specific gas fireplace’s British Thermal Unit (BTU) input rating. Undersized systems restrict airflow, leading to incomplete combustion and the accumulation of dangerous carbon monoxide within the dwelling. Oversized systems, conversely, can cause the exhaust gases to cool too rapidly, resulting in condensation and the formation of corrosive acids that degrade the system’s components.

For instance, a high-BTU fireplace installed with an exhaust system intended for a smaller unit might experience backdrafting, where combustion gases are forced back into the living space due to insufficient venting capacity. Conversely, a small fireplace connected to an excessively large exhaust system could experience a weak draft, leading to similar problems with condensation and corrosion. Building codes and manufacturer specifications provide guidelines for proper sizing, typically presented in charts or tables that correlate BTU input with vent diameter and height. These guidelines are derived from empirical data and engineering calculations to ensure optimal performance and safety.

Proper sizing is not merely a matter of compliance with regulations; it directly impacts the fireplace’s efficiency, longevity, and, most importantly, the safety of the occupants. Accurate sizing ensures that the exhaust system effectively removes harmful gases while minimizing the risk of condensation and corrosion. Failure to adhere to these guidelines can result in costly repairs, reduced fireplace lifespan, and potentially life-threatening carbon monoxide poisoning. Therefore, professional assessment and installation are crucial to guarantee that the exhaust system is appropriately sized for the specific gas fireplace being used.

3. Verticality Requirements

Verticality requirements for a gas fireplace exhaust system are not arbitrary specifications; they are integral to ensuring proper draft, efficient venting of combustion byproducts, and overall system safety. Deviation from these requirements can compromise the system’s ability to function as intended, leading to hazardous conditions and operational inefficiencies.

- Natural Convection Enhancement

A predominantly vertical configuration promotes natural convection, where hot exhaust gases rise due to buoyancy. The greater the vertical rise, the stronger the draft created. This natural draft assists in drawing combustion byproducts away from the fireplace and out of the dwelling. Insufficient verticality diminishes the effectiveness of this process, potentially leading to backdrafting.

- Condensation Mitigation

Vertical rise aids in maintaining exhaust gas temperature, preventing premature condensation of water vapor and acidic compounds within the venting system. Condensation can accelerate corrosion and reduce the system’s lifespan. A steep vertical incline allows the gases to remain hotter for a longer duration, minimizing condensation buildup and promoting efficient expulsion of moisture.

- Draft Stability

Consistent verticality reduces turbulence and promotes a more stable and predictable draft. Horizontal runs or excessive bends introduce resistance to airflow, disrupting the natural flow of exhaust gases. Stable draft is essential for ensuring that the fireplace operates efficiently and safely, preventing intermittent backdrafting or incomplete combustion.

- Code Compliance and Safety Standards

Building codes and safety standards mandate minimum vertical rise requirements to ensure that exhaust systems meet established safety criteria. These requirements are based on extensive research and field experience, designed to minimize the risk of carbon monoxide poisoning and other hazards associated with improper venting. Compliance with these codes is not optional; it is a legal and ethical obligation.

The correlation between verticality and the performance of a gas fireplace exhaust system is evident. Proper vertical installation is not merely a cosmetic consideration but a critical element in ensuring safe, efficient, and reliable operation. Adherence to verticality requirements, as specified by manufacturers and building codes, is essential for protecting occupants from the dangers of carbon monoxide and maintaining the long-term integrity of the fireplace system.

4. Draft Optimization

Effective draft optimization is critical to the safe and efficient operation of a gas fireplace exhaust system. The system relies on a pressure differential to draw combustion byproducts out of the fireplace and expel them to the atmosphere. Inadequate draft results in incomplete combustion, leading to carbon monoxide production and potential backdrafting into the living space. Conversely, excessive draft can cause rapid heat loss and inefficient fuel consumption. A properly designed and maintained exhaust system balances these factors to achieve optimal performance.

Several factors influence draft, including the height and diameter of the venting, the presence of bends or obstructions, and external environmental conditions like wind and temperature. For instance, a tall, unobstructed vent typically generates a stronger draft than a short, convoluted one. Barometric dampers and draft regulators are sometimes incorporated into the system to modulate airflow and compensate for variations in external conditions, ensuring a consistent and safe draft. Routine inspection and cleaning of the exhaust system are essential for maintaining optimal draft. Soot buildup or debris can impede airflow, diminishing draft effectiveness and potentially leading to hazardous conditions.

Ultimately, draft optimization is not merely a technical consideration but a fundamental safety requirement. A well-optimized exhaust system protects occupants from carbon monoxide poisoning, minimizes fuel consumption, and ensures the long-term reliability of the gas fireplace. Professional assessment and regular maintenance are vital for achieving and sustaining optimal draft performance, ensuring the safe and efficient operation of the appliance.

5. Seal Integrity

Seal integrity within a gas fireplace venting system is paramount to prevent the escape of harmful combustion byproducts into the dwelling. Compromised seals, typically occurring at joints or seams along the flue, provide pathways for carbon monoxide, water vapor, and other noxious gases to enter the living space. This directly undermines the primary function of the system, which is to safely and efficiently remove these byproducts from the fireplace to the outside environment.

The cause of seal failure varies. Thermal cycling, where repeated heating and cooling expands and contracts materials, can degrade sealants over time. Physical damage, such as impacts or settling of the structure, can also compromise seals. Corrosion due to acidic condensation within the flue can erode sealing materials. Regular inspection and maintenance are essential to identify and rectify breaches in seal integrity before they result in hazardous conditions. For instance, a homeowner might notice a persistent odor near the fireplace, indicating a potential leak in the venting system. Addressing such issues promptly prevents the buildup of dangerous gases.

Maintaining the integrity of the exhaust system is not merely a matter of preventing unpleasant odors; it is a critical safety measure. Regular professional inspections and prompt repairs are crucial components of responsible gas fireplace ownership. Neglecting seal integrity can have severe consequences, leading to health problems, structural damage, and even fatal carbon monoxide poisoning. Therefore, understanding and prioritizing the seal integrity of a gas fireplace venting system is essential for ensuring a safe and comfortable home environment.

6. Termination Location

The placement of a gas fireplace’s exhaust termination point is a critical determinant of system safety and performance. The termination location dictates how effectively combustion byproducts are dispersed into the atmosphere and prevents their re-entry into the building. Improperly positioned terminations can lead to health hazards and operational inefficiencies.

- Clearance from Structures and Openings

Building codes specify minimum distances between the exhaust termination and building components such as windows, doors, and ventilation intakes. These clearances prevent exhaust gases from being drawn back into the structure, minimizing the risk of carbon monoxide poisoning and other respiratory irritants. For example, a termination located directly below a window would violate these clearances and pose a significant health risk to occupants. Adherence to these regulations is crucial for maintaining indoor air quality.

- Height Above Grade

The height of the termination point above ground level affects the dispersion of exhaust gases. Terminations that are too low can be obstructed by snowdrifts or vegetation, hindering proper ventilation. Moreover, low-lying terminations increase the likelihood of exhaust gases pooling near ground level, posing a risk to nearby pedestrians or pets. Elevating the termination to a code-specified height ensures adequate air circulation and minimizes potential exposure to combustion byproducts.

- Proximity to Overhanging Obstructions

Overhanging structures, such as eaves or balconies, can impede the upward flow of exhaust gases, causing them to linger near the building and potentially re-enter through openings. The termination location must be free from such obstructions to ensure unrestricted airflow and effective dispersion. Failure to account for overhanging obstructions can compromise the system’s ability to vent gases effectively, leading to indoor air quality problems.

- Wind Direction and Exposure

Prevailing wind patterns influence the dispersion of exhaust gases. Terminations should be positioned to take advantage of prevailing winds, directing gases away from the building and minimizing the risk of re-entrainment. Consideration of wind direction is particularly important in areas prone to strong winds or complex microclimates. Proper siting can significantly improve the system’s overall performance and reduce the potential for indoor air quality issues.

The interplay between these elements demonstrates that careful selection of the exhaust termination point is vital to proper “gas fireplace chimney vent” functionality. Compliance with building codes, consideration of site-specific conditions, and adherence to manufacturer’s guidelines are all essential for ensuring safe and efficient operation.

Frequently Asked Questions

This section addresses common inquiries and concerns regarding the exhaust system of a gas fireplace. Understanding these aspects promotes safer and more efficient appliance operation.

Question 1: What constitutes an acceptable material for a gas fireplace chimney vent?

An acceptable material typically consists of stainless steel or another corrosion-resistant alloy specifically rated for high-temperature exhaust applications. Galvanized steel and aluminum are generally unsuitable due to their susceptibility to corrosion from acidic combustion byproducts.

Question 2: How frequently should a gas fireplace chimney vent be inspected?

A visual inspection should be conducted at least annually, preferably before the heating season commences. A professional inspection, including a pressure test and internal examination, is recommended every two to three years, or as specified by local codes.

Question 3: What are the potential consequences of an improperly sized gas fireplace chimney vent?

An improperly sized system can lead to incomplete combustion, carbon monoxide buildup, backdrafting of exhaust gases, and condensation-related corrosion, all posing significant safety and health risks.

Question 4: Is it permissible to vent a gas fireplace into an existing masonry chimney previously used for a wood-burning fireplace?

This practice is generally discouraged and often prohibited by code unless the masonry chimney is properly lined with a listed and labeled venting system specifically designed for gas appliances. Unlined masonry chimneys can suffer from deterioration and improper draft.

Question 5: What are the key indicators of a failing or compromised gas fireplace chimney vent?

Indicators include a persistent odor of gas or combustion byproducts, visible corrosion or damage to the vent pipe, soot accumulation around the fireplace or vent connections, and activation of carbon monoxide detectors.

Question 6: What clearance requirements apply to a gas fireplace chimney vent passing through combustible materials?

Clearance requirements vary based on the specific venting system and local codes, but typically range from one to six inches. Manufacturer’s specifications provide precise clearance requirements that must be strictly adhered to.

These FAQs provide a foundational understanding of critical aspects related to venting systems. Compliance with regulations and adherence to best practices are essential for safe and effective operation.

The next section will address troubleshooting techniques for common issues.

Gas Fireplace Chimney Vent

This exploration has underscored the critical role of the gas fireplace chimney vent in ensuring safe and efficient operation of gas fireplaces. From material selection and proper sizing to verticality requirements, draft optimization, seal integrity, and termination location, each aspect contributes to the overall performance and safety of the system. Neglecting any of these elements can lead to severe consequences, including carbon monoxide poisoning and property damage.

Therefore, consistent monitoring, routine maintenance, and strict adherence to building codes and manufacturer’s instructions are paramount. The responsible use of gas fireplaces requires a comprehensive understanding of these exhaust systems and a commitment to maintaining their integrity. Prioritizing safety will ensure a long-lasting and reliable heat source for many years to come.