A vertical structure, often cylindrical, designed to exhaust combustion byproducts from a heating appliance to the outside atmosphere is a critical component of residential and commercial heating systems. This structure facilitates the safe and efficient removal of smoke, fumes, and other gases produced during the burning of fuel, such as natural gas, oil, or wood. Proper drafting through this structure ensures optimal combustion and prevents the buildup of hazardous substances within the building.

The effective operation of such a system contributes significantly to indoor air quality and the safety of occupants. Historically, these structures have evolved from simple brick flues to more complex, engineered systems designed to withstand high temperatures and corrosive gases. Modern designs incorporate materials that resist deterioration and promote efficient draft, reducing energy consumption and minimizing environmental impact. Regular inspection and maintenance are essential to ensure continued safe and reliable performance, mitigating potential hazards such as carbon monoxide poisoning and chimney fires.

Understanding the principles of draft, material selection for these venting systems, and the importance of regular inspections forms the basis for a safe and efficient heating system. The following sections will delve into the specific components, common problems, and best practices related to their installation, maintenance, and repair.

Essential Guidance for Optimal Performance

Maintaining the integrity and functionality of the combustion venting system is crucial for safety and efficiency. Adherence to the following guidelines ensures optimal operation and mitigates potential hazards.

Tip 1: Schedule Regular Inspections: Annual inspections by qualified professionals are essential. These inspections identify potential problems such as cracks, blockages, or deterioration that could compromise performance and safety.

Tip 2: Ensure Proper Sizing: The dimensions of the venting system must be appropriately sized to the heating appliance. An improperly sized system can lead to inadequate draft, incomplete combustion, and the buildup of hazardous gases.

Tip 3: Maintain Clear Airflow: Remove any obstructions, such as bird nests or debris, that may impede airflow. Blockages can significantly reduce draft and increase the risk of carbon monoxide poisoning.

Tip 4: Seal Air Leaks: Inspect and seal any air leaks in the structure. Air leaks can disrupt the draft and reduce heating efficiency.

Tip 5: Use Approved Materials: Only use materials that are approved for the specific type of heating appliance and fuel being used. Using incompatible materials can lead to premature deterioration and safety hazards.

Tip 6: Address Corrosion Promptly: Corrosion can weaken the venting system and create pathways for dangerous gases to escape. Address any signs of corrosion immediately through repair or replacement.

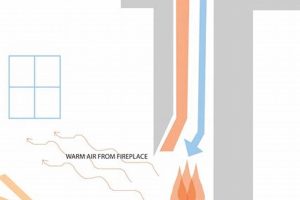

Tip 7: Understand Backdrafting: Be aware of the potential for backdrafting, a condition where combustion gases are drawn back into the building. Install carbon monoxide detectors and address any factors that may contribute to backdrafting, such as negative pressure within the building.

Consistent adherence to these guidelines fosters a safer and more efficient heating environment, minimizing risks associated with combustion byproducts and ensuring optimal performance of the heating appliance.

The subsequent sections will elaborate on specific troubleshooting techniques and preventative maintenance procedures to further enhance the longevity and reliability of the overall heating system.

1. Draft

Effective draft within a venting system is paramount for the safe and efficient removal of combustion gases from a heating appliance. It represents the pressure differential between the appliance and the outside environment, causing combustion byproducts to rise and exit the building. Insufficient draft leads to incomplete combustion, resulting in carbon monoxide production and potential backdrafting, where dangerous gases enter the living space. Conversely, excessive draft can cool combustion gases prematurely, leading to condensation within the venting system, corrosion, and reduced heating efficiency. A properly designed and maintained system optimizes draft, ensuring complete combustion and safe venting.

The design of the venting structure significantly impacts draft. Height, diameter, and material all influence the airflow. A taller structure generally produces a stronger draft, while the diameter must be appropriately sized to the heating appliance’s output. Smooth interior surfaces reduce friction and improve airflow. Furthermore, external factors such as wind and temperature variations affect draft. For example, a cold outside temperature increases the density of air, enhancing draft. However, strong winds can create downdrafts, hindering the upward flow of gases. Barometric dampers and draft regulators are often incorporated to stabilize draft and compensate for these external influences.

In summary, the relationship between draft and a residential or commercial heating appliance system is critical for safe and effective operation. Optimizing draft necessitates careful design considerations, regular maintenance, and awareness of environmental factors. Failure to maintain adequate draft can result in severe safety hazards and reduced heating efficiency. Professional inspection and adjustments are crucial to ensure that the system operates within the appropriate draft range, maximizing safety and minimizing energy consumption.

2. Materials

The selection of appropriate materials in the construction of a venting structure is paramount to ensuring its long-term functionality, safety, and resistance to degradation. Combustion byproducts often contain corrosive elements, such as sulfurous and nitrous oxides, which can rapidly degrade unsuitable materials, leading to structural failure and the escape of harmful gases. Improper material selection can also result in inefficient venting and an increased risk of fire. Therefore, understanding the properties of various materials and their suitability for specific heating appliance types is essential. For instance, single-wall metal pipes are typically inadequate for modern high-efficiency furnaces due to their tendency to condense acidic moisture, leading to rapid corrosion.

Common materials employed include stainless steel, galvanized steel, and specialized refractory linings. Stainless steel offers excellent corrosion resistance and high-temperature tolerance, making it suitable for a wide range of heating appliances. Galvanized steel, while more affordable, has a limited lifespan in corrosive environments and is generally restricted to certain applications. Refractory linings are used in high-temperature applications, such as wood-burning stoves and fireplaces, to protect the surrounding structure from extreme heat. The choice of material must also consider the type of fuel used by the heating appliance, as different fuels produce different types of combustion byproducts. Natural gas, for example, produces relatively clean combustion gases, while oil and wood can generate more corrosive and particulate-laden emissions. Regulatory codes and manufacturer specifications dictate the acceptable materials for each specific heating appliance and venting system configuration.

In conclusion, the selection of materials is a critical aspect of the overall design and safety of a heating appliance venting structure. Careful consideration of corrosion resistance, temperature tolerance, fuel type, and regulatory requirements is necessary to ensure long-term performance and prevent potentially hazardous situations. Regular inspections are vital to detect any signs of material degradation and to implement timely repairs or replacements, upholding both safety standards and operational efficiency within the heating system.

3. Clearance

The concept of clearance in relation to venting structures is of paramount importance in mitigating fire hazards and ensuring the safe operation of heating appliances. Maintaining adequate clearance involves adhering to specified distances between the venting system and combustible materials, preventing the transfer of heat and potential ignition.

- Wall and Ceiling Clearance

This refers to the minimum distance a venting structure must be from walls, ceilings, and other structural components made of combustible materials like wood or drywall. This clearance is critical because these surfaces can ignite if exposed to prolonged high temperatures. National and local building codes stipulate specific clearance requirements, often varying depending on the type of venting structure and heating appliance. Failing to meet these requirements can lead to structural fires.

- Appliance Connector Clearance

The connection between the heating appliance and the venting structure is a particularly vulnerable area. Connectors, typically metal pipes, can reach extremely high temperatures. Adequate clearance in this zone prevents direct contact with combustible materials in the vicinity of the appliance. Heat shields or insulated connectors are often used to further reduce the risk of heat transfer.

- Attic and Concealed Space Clearance

Venting structures passing through attics or other concealed spaces necessitate greater clearance considerations. These areas are often filled with insulation, dust, and other readily combustible materials. Furthermore, fires in concealed spaces can be difficult to detect and extinguish. Consequently, code requirements for clearance in these areas are typically more stringent.

- Exterior Clearance to Overhangs and Projections

The termination point of the venting structure requires specific clearance from roof overhangs, adjacent buildings, and other external projections. This clearance prevents the re-entry of combustion gases into the building and minimizes the risk of igniting nearby structures or vegetation. Downdrafts created by nearby objects can also impede proper venting, necessitating careful placement of the termination point.

Adherence to these clearance guidelines, along with regular inspection and maintenance, is crucial for preventing fires and ensuring the safe and efficient operation of any system associated with combustion byproduct venting. These clearances are designed to mitigate the risk of heat transfer and ignition, safeguarding both the building structure and its occupants. Violations can result in serious consequences, including property damage, injury, and even loss of life. Therefore, professional installation and inspection are highly recommended to ensure code compliance and optimal safety.

4. Termination

The termination, as it relates to a furnace exhaust structure, represents the critical point where combustion gases are expelled into the external environment. Its design and placement directly impact the dispersion of these gases and, consequently, influence both the efficiency of the furnace and the potential for re-entry of harmful pollutants into the building. Improper termination can result in inadequate draft, leading to incomplete combustion and the buildup of dangerous carbon monoxide within the structure. The location of the termination relative to windows, doors, and air intakes is crucial to prevent re-entrainment of exhaust gases, thereby safeguarding indoor air quality. For example, a termination positioned directly beneath a window can allow combustion byproducts to enter the building, posing a significant health hazard. Therefore, adherence to established building codes and manufacturer specifications regarding termination height and location is essential.

Furthermore, the physical design of the termination affects the system’s performance. Certain termination caps are designed to prevent the entry of rain, snow, and debris, which can obstruct the venting system and reduce draft. Others are engineered to mitigate downdrafts caused by wind, ensuring consistent and efficient gas expulsion. In coastal environments, materials resistant to corrosion from salt air are essential to prevent premature deterioration of the termination. Consider, for instance, a stainless-steel termination with a bird screen, which prevents animal intrusion while resisting corrosion. The absence of such protective measures can lead to blockages and eventual system failure.

In summary, the furnace exhaust structure termination is a key component, influencing both safety and efficiency. Its proper design, location, and material composition are vital for preventing the re-entry of combustion gases, maintaining adequate draft, and ensuring long-term system performance. Regular inspection and maintenance of the termination, including clearing debris and addressing corrosion, are essential practices that contribute to the overall safety and efficiency of the heating system. Failure to properly manage the termination can undermine the integrity of the entire system, posing serious risks to occupants and reducing heating efficiency.

5. Inspections

Regular evaluations of venting structures are essential to ensure the safety, efficiency, and longevity of heating systems. These assessments identify potential hazards and performance issues that may compromise the structure’s integrity. Systematic examinations facilitate proactive maintenance, preventing costly repairs and safeguarding occupants from risks associated with combustion byproducts.

- Structural Integrity Assessment

Visual examination of the system components reveals cracks, corrosion, or other forms of deterioration that can compromise structural integrity. For instance, a cracked flue liner allows combustion gases to escape into the building, posing a carbon monoxide poisoning risk. Detection of such flaws during an inspection allows for timely repairs or replacement, preventing further degradation and potential hazards.

- Draft Measurement and Analysis

Measuring draft ensures proper venting of combustion gases. Insufficient draft leads to incomplete combustion and the potential for backdrafting. Conversely, excessive draft wastes energy by drawing too much heat up the structure. Inspection includes measuring draft under various operating conditions to identify imbalances and recommend adjustments. Example: Measuring draft with a manometer ensures it is within the appliance manufacturer’s specifications.

- Obstruction Detection and Removal

Inspections identify and remove obstructions, such as bird nests or debris, that impede airflow. Blockages reduce draft, leading to inefficient combustion and the buildup of hazardous gases. Routine clearing of obstructions maintains optimal airflow and prevents potential safety hazards. For example: Removal of a bird nest blocking the flue ensures proper draft and prevents carbon monoxide buildup.

- Code Compliance Verification

Inspections confirm compliance with local and national building codes, ensuring that the venting structure meets safety standards. Code violations can lead to fines and potential safety hazards. Verification of proper clearances, materials, and installation techniques during inspection ensures compliance and mitigates risks. An example is confirming the venting structure has the required clearance from combustible materials.

These facets demonstrate the vital role inspections play in maintaining the safety and efficiency of structures associated with venting. By identifying potential problems early, proactive measures can be taken to prevent costly repairs and safeguard occupants from risks associated with combustion byproducts. Regular, professional assessments are essential for ensuring the continued safe operation of heating systems.

6. Maintenance

Consistent upkeep of combustion venting systems is indispensable for ensuring safe, efficient, and reliable operation of heating appliances. Scheduled maintenance mitigates risks associated with the accumulation of combustion byproducts, deterioration of materials, and potential system failures. Neglecting routine maintenance can compromise system performance, increase energy consumption, and create hazardous conditions for occupants.

- Creosote Removal and Soot Cleaning

Accumulation of creosote, a byproduct of wood combustion, within venting systems poses a significant fire hazard. Regular removal prevents chimney fires by eliminating flammable deposits. Similarly, soot buildup in oil and gas systems reduces draft and efficiency. Professional cleaning involves specialized tools and techniques to safely remove these deposits, restoring proper airflow and minimizing the risk of ignition.

- Obstruction Clearing and Debris Removal

Venting systems are susceptible to obstructions from various sources, including bird nests, leaves, and other debris. These blockages impede airflow, leading to incomplete combustion and the buildup of hazardous gases. Regular inspection and clearing of obstructions maintain proper draft and prevent carbon monoxide poisoning. Example: A professional technician removing a bird nest from the flue to ensure adequate venting.

- Structural Inspection and Repair

Routine examination of the venting system reveals cracks, corrosion, or other structural defects that compromise its integrity. Prompt repair or replacement of damaged components prevents the escape of combustion gases into the building. Addressing minor issues early averts more extensive and costly repairs in the future. For example, repairing a cracked flue liner prevents carbon monoxide leakage.

- Draft Optimization and System Tuning

Maintaining optimal draft ensures efficient combustion and safe venting of exhaust gases. Draft regulators and barometric dampers are adjusted to compensate for variations in weather conditions and appliance performance. System tuning involves calibrating the heating appliance to achieve maximum efficiency and minimize emissions. Proper draft optimization minimizes fuel consumption and reduces environmental impact.

The multifaceted nature of maintenance underscores its importance in ensuring the long-term safety and performance of venting systems. By adhering to a regular maintenance schedule, potential problems are identified and addressed proactively, minimizing risks and maximizing the efficiency of the heating appliance. Neglecting maintenance can lead to significant safety hazards and costly repairs, emphasizing the value of consistent and thorough upkeep.

Frequently Asked Questions About Furnace Chimneys

The following addresses common inquiries and misconceptions regarding structures associated with furnace venting. Understanding these aspects is crucial for ensuring safe and efficient heating system operation.

Question 1: What constitutes a suitable material for a furnace chimney?

Selection hinges on the fuel type and appliance efficiency. High-efficiency appliances necessitate materials resistant to acidic condensation, such as stainless steel. Older, less efficient systems may utilize alternative materials, but adherence to local codes is paramount.

Question 2: How often should a furnace chimney undergo professional inspection?

Annual inspections are recommended. These assessments identify potential structural issues, blockages, and draft deficiencies that can compromise safety and efficiency. Early detection facilitates timely repairs and prevents escalating problems.

Question 3: What are the potential consequences of neglecting furnace chimney maintenance?

Neglect can lead to creosote buildup (in wood-burning systems), carbon monoxide leaks, reduced heating efficiency, and increased risk of chimney fires. Regular maintenance is crucial for preventing these hazardous situations.

Question 4: What constitutes a proper termination height for a furnace chimney?

Building codes dictate minimum termination heights above the roofline and adjacent structures. These regulations aim to prevent down drafts and re-entry of combustion gases into the building. Consult local codes for specific requirements.

Question 5: What measures can prevent blockages in a furnace chimney?

Installation of a chimney cap with a mesh screen prevents entry of animals, debris, and precipitation. Regular inspection and removal of accumulated debris further minimizes the risk of blockages.

Question 6: How does chimney draft impact furnace performance?

Adequate draft ensures proper venting of combustion gases. Insufficient draft results in incomplete combustion and potential carbon monoxide buildup. Conversely, excessive draft wastes energy. Professional assessment ensures optimal draft levels.

Properly maintained and inspected venting systems are essential for safe and efficient heating. Addressing these FAQs helps mitigate potential issues and ensures a reliable heating system.

The subsequent section will explore troubleshooting techniques for common furnace chimney problems.

Conclusion

This exploration has underscored the critical role of the furnace chimney in maintaining both the safety and efficiency of heating systems. Key aspects include material selection, proper draft, adherence to clearance requirements, appropriate termination design, and the necessity of routine inspections and maintenance. Neglecting any of these factors compromises the overall performance of the heating system and elevates the risk of hazardous conditions.

The continued and diligent oversight of these venting structures is paramount. Prioritizing professional inspections, addressing any identified deficiencies promptly, and adhering to established safety guidelines contribute to a safer, more energy-efficient, and environmentally responsible approach to residential and commercial heating. The long-term benefits of a properly functioning system far outweigh the costs associated with its maintenance and upkeep.