The component addressed is a crucial element in roof construction, specifically where a chimney penetrates the roof plane. It refers to the material installed to prevent water from entering the building at this vulnerable junction. Common materials used in its construction include aluminum, copper, or steel, often bent and shaped to create a watertight seal. This system interweaves with both the roofing material and the chimney itself, forming a barrier against precipitation. For instance, imagine rain running down a roof; this system redirects the water around the chimney, preventing leaks into the structure below.

This protective element is paramount for preventing water damage, which can lead to structural decay, mold growth, and costly repairs. Properly installed and maintained, it safeguards the building’s integrity and longevity. Historically, less effective methods were used to seal chimney penetrations, resulting in frequent leaks and subsequent problems. The development of modern materials and techniques has significantly improved the effectiveness and durability of these systems, offering increased protection and reducing the need for frequent maintenance.

Further discussion will detail the various types of materials utilized, the correct installation procedures, common problems encountered, and best practices for ensuring its long-term performance and watertight effectiveness. Understanding these aspects is essential for homeowners, contractors, and anyone involved in building maintenance and repair.

Essential Practices for Chimney Sealing Systems

Effective management of chimney sealing systems is crucial for preventing water intrusion and maintaining building integrity. Adherence to best practices during installation and maintenance will minimize the risk of costly repairs and structural damage.

Tip 1: Proper Material Selection: Selecting a compatible material for the chimney sealing system is vital. Consider the existing roofing material and chimney construction. Dissimilar metals can cause galvanic corrosion, leading to premature failure. Copper, aluminum, and galvanized steel are common choices, each with specific advantages and limitations based on environmental conditions and compatibility with other materials.

Tip 2: Precise Installation is Paramount: The installation process demands meticulous attention to detail. The component must be integrated with both the roofing and the chimney structure to create a weathertight seal. Overlapping sections should be properly sealed, and all edges must be securely fastened. Improper installation can lead to immediate or eventual leaks, negating the system’s effectiveness.

Tip 3: Step Sealing for Optimal Protection: Employ step sealing techniques, where individual pieces are interwoven with the roofing material in a staggered fashion. This method provides a superior barrier against water penetration compared to a single, continuous piece. Each section directs water away from the chimney, minimizing the potential for leaks.

Tip 4: Countersealing Above the Step: Incorporate countersealing, which involves installing a second layer of material that extends over the stepped component. This reinforces the seal and provides an additional layer of protection, particularly in areas prone to heavy rainfall or snow accumulation.

Tip 5: Regular Inspection and Maintenance: Conduct routine inspections of the chimney sealing system, ideally twice a year, to identify potential issues early. Check for signs of corrosion, damage, or displacement. Addressing minor problems promptly can prevent them from escalating into major repairs.

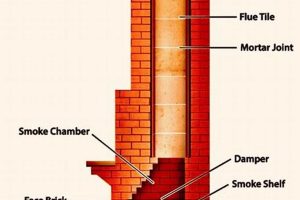

Tip 6: Mortar Joint Integrity: Ensure the mortar joints of the chimney are in good condition. Cracks or deterioration in the mortar can compromise the effectiveness of the sealing system by allowing water to penetrate behind it. Repointing the mortar joints is often necessary to maintain a secure and weathertight seal.

Tip 7: Professional Assessment When Needed: If there are persistent leaks or significant damage to the chimney sealing system, consult a qualified professional. Attempting complex repairs without the necessary expertise can lead to further damage and increased costs. A professional assessment will identify the root cause of the problem and recommend the appropriate solution.

Adhering to these guidelines ensures the chimney sealing system functions effectively, protecting the building from water damage and preserving its structural integrity. Regular maintenance and prompt attention to any signs of deterioration are key to maximizing the lifespan of the system and preventing costly repairs.

The following sections will delve into specific materials, common repair techniques, and advanced methods for ensuring long-term performance and resilience.

1. Material Compatibility

The selection of compatible materials is paramount when addressing chimney sealing systems. Incompatibility can lead to accelerated degradation, compromising the effectiveness of the system and potentially causing significant structural damage. Careful consideration of material properties and their interactions is therefore essential.

- Galvanic Corrosion

When dissimilar metals are in contact in the presence of an electrolyte (such as rainwater), galvanic corrosion can occur. One metal acts as an anode and corrodes more rapidly than it would otherwise, while the other acts as a cathode and corrodes more slowly. For example, direct contact between aluminum and copper flashing can lead to rapid corrosion of the aluminum. This phenomenon undermines the integrity of the flashing system and necessitates premature replacement.

- Thermal Expansion and Contraction

Different materials expand and contract at different rates in response to temperature changes. If the material used for the chimney flashing has a significantly different coefficient of thermal expansion than the surrounding roofing material or the chimney itself, it can lead to stress and fatigue. This stress can cause the flashing to crack, warp, or detach from the structure, creating pathways for water intrusion. Matching the thermal expansion properties of the materials used can mitigate this risk.

- Chemical Reactivity

Some materials may react chemically with each other or with the surrounding environment, leading to degradation. For instance, certain types of flashing may react with acidic rainwater or with chemicals present in treated wood. This chemical reactivity can cause the flashing to corrode, dissolve, or otherwise break down, compromising its protective function. Selecting materials that are resistant to chemical degradation is crucial for long-term performance.

- Aesthetic Considerations and Long-Term Performance

Material selection is not solely about preventing corrosion or physical degradation; aesthetic compatibility is also relevant. Although functional, a flashing system using mismatched materials can detract from a building’s overall appearance. Moreover, considering the long-term aging process of various materials ensures a cohesive and aesthetically pleasing result over time. For example, natural patina development on copper flashing could complement certain roofing styles, while other materials may require periodic painting to maintain their visual appeal.

The long-term effectiveness of chimney sealing systems hinges on the selection of compatible materials that resist corrosion, accommodate thermal expansion, and withstand chemical reactivity. Failure to address these factors can result in premature failure, costly repairs, and potential damage to the building’s structure. Consulting with a qualified professional can help ensure the appropriate materials are selected for a specific application.

2. Precise Installation

The performance and longevity of chimney sealing systems are directly contingent upon the precision of the installation process. Deviations from established best practices during installation can compromise the system’s ability to prevent water intrusion, leading to costly repairs and potential structural damage. Therefore, meticulous attention to detail is paramount during every stage of the installation process.

- Proper Overlap and Sealing

Adequate overlap between individual flashing components and roofing materials is essential for creating a watertight seal. Insufficient overlap allows water to seep beneath the flashing, bypassing the intended barrier. Furthermore, proper sealing of seams and joints, often achieved through the application of specialized sealants, is critical. For example, inadequate sealant application around the chimney’s perimeter can result in water penetrating behind the flashing, leading to rot and decay of the surrounding roof structure. Precise measurements and meticulous sealant application are, therefore, indispensable.

- Correct Fastener Placement

The placement and type of fasteners used to secure the flashing are crucial. Incorrect fastener placement can create stress points in the flashing, leading to cracks or tears. Using the wrong type of fastener can result in corrosion or galvanic reactions, weakening the system over time. For instance, driving nails too close to the edge of the flashing can cause it to buckle, creating gaps for water entry. Similarly, using steel fasteners with aluminum flashing can trigger galvanic corrosion. Correct fastener selection and precise placement are vital for maintaining the flashing’s structural integrity.

- Accurate Cutting and Shaping

Chimneys often have irregular shapes or angles, requiring precise cutting and shaping of the flashing to ensure a proper fit. Inaccurate cuts or bends can create gaps or stress points, compromising the seal. For example, if the flashing is not accurately shaped to conform to the chimney’s profile, water can easily find its way behind the flashing. Skilled craftsmanship and precise measurements are necessary to achieve a snug, watertight fit around the chimney.

- Integration with Roofing Material

The chimney sealing system must be seamlessly integrated with the surrounding roofing material. This often involves weaving the flashing between rows of shingles or tiles to create a continuous, watertight barrier. Failure to properly integrate the flashing with the roofing can result in leaks at the intersection. For instance, simply laying flashing on top of shingles without proper interweaving provides minimal protection against water intrusion. Careful attention to detail and adherence to established roofing practices are essential for successful integration.

These facets highlight the critical role precise installation plays in ensuring the long-term effectiveness of chimney sealing systems. Neglecting any of these aspects can compromise the system’s ability to protect the building from water damage. Therefore, engaging qualified professionals with expertise in chimney flashing installation is paramount for achieving a durable and reliable solution.

3. Weather Resistance

Weather resistance is an indispensable attribute of any effective chimney sealing system. The primary function of such a system is to prevent water intrusion at the junction where a chimney penetrates the roof. Its ability to withstand a range of environmental conditions directly determines its success in fulfilling this function. Exposure to rain, snow, ice, wind, and ultraviolet radiation presents a continuous challenge. If the materials or installation methods are inadequate, the system will fail, leading to leaks, structural damage, and compromised indoor air quality. For instance, a system utilizing low-grade sealant may crack and deteriorate under prolonged exposure to sunlight, creating pathways for water entry. Similarly, improperly installed material may be dislodged by high winds, leaving the building vulnerable. Thus, the selection of robust, weather-resistant materials and the application of precise installation techniques are paramount.

Materials used in chimney sealing systems must exhibit specific properties to ensure weather resistance. These properties include impermeability to water, resistance to degradation from ultraviolet radiation, ability to withstand temperature fluctuations without cracking or warping, and resilience against physical impact from wind-borne debris or ice accumulation. For example, copper is often used due to its inherent corrosion resistance and durability, while certain synthetic rubber sealants offer excellent flexibility and adhesion even under extreme temperature variations. However, material selection alone is insufficient. Proper installation techniques, such as overlapping seams and secure fastening, are equally crucial for preventing water penetration and maintaining structural integrity under adverse weather conditions. Regular inspections and maintenance, including the timely replacement of damaged or deteriorated components, are also essential for preserving the weather resistance of the system over its lifespan.

In summary, weather resistance is not merely a desirable characteristic of chimney sealing systems; it is a fundamental requirement. The selection of appropriate materials, the application of precise installation methods, and the implementation of a consistent maintenance schedule are all necessary to ensure long-term protection against the elements. Failure to prioritize weather resistance will inevitably result in water damage, compromising the structural integrity of the building and necessitating costly repairs. Therefore, thorough consideration of weather resistance is crucial in the design, installation, and maintenance of chimney sealing systems.

4. Mortar Condition

The structural integrity of a chimney and the effectiveness of its sealing system are inextricably linked to the condition of the mortar. Deteriorated mortar joints provide direct pathways for water intrusion, undermining the function of even the most expertly installed sealing components. Cracks, crumbling, or missing mortar allow water to penetrate behind the protective metal, saturating the chimney’s masonry and potentially entering the building’s interior. This infiltration can lead to accelerated deterioration of the brick or stone, freeze-thaw damage, and the growth of mold and mildew. For example, if mortar joints are severely eroded, rainwater can run directly down the chimney’s interior, bypassing the protective flashing altogether and causing significant water damage within the building. The flashing functions as a barrier, but its efficacy is contingent on a solid, intact substrate. Neglecting mortar condition effectively nullifies the benefits of a properly installed sealing system.

The relationship between mortar and sealing components is further complicated by the dynamics of water movement. Water absorbed by deteriorated mortar expands when frozen, exerting pressure on the surrounding masonry and the sealing material. This expansion can exacerbate existing cracks or create new ones, further compromising the system’s integrity. Repeated freeze-thaw cycles gradually weaken the mortar, leading to increased water absorption and accelerated deterioration. Furthermore, the presence of moisture behind the sealing metal can promote corrosion, reducing the lifespan of the flashing itself. Regular inspection of the mortar joints and prompt repair through repointing are, therefore, essential for maintaining the overall effectiveness of the sealing system. Using appropriate mortar mixes that are compatible with the existing masonry is also crucial to avoid further damage.

In summary, the condition of the chimney’s mortar is a critical factor in determining the longevity and effectiveness of its water-sealing system. Deteriorated mortar provides pathways for water intrusion, undermines the function of the flashing, and can lead to significant structural damage. Regular inspection, prompt repair, and the use of appropriate materials are essential for preserving the integrity of both the mortar and the sealing system, ensuring long-term protection against water damage. Prioritizing mortar maintenance is a proactive measure that safeguards the building’s structural health and prevents costly repairs in the future.

5. Regular Inspection

Regular inspection constitutes a critical aspect of maintaining the functionality and longevity of chimney sealing systems. The primary cause-and-effect relationship at play is straightforward: the absence of regular inspection leads to undetected damage, which in turn results in water intrusion and subsequent structural compromise. Sealing systems, while designed to withstand environmental stressors, are not impervious to degradation over time. Thermal expansion and contraction, wind-driven debris, and the natural aging of materials all contribute to potential weaknesses in the system. A routine inspection schedule allows for the early identification of such issues, preventing minor problems from escalating into major repairs. For instance, a homeowner who neglects to inspect their chimney sealing system may be unaware of a small crack in the sealant, which, over time, will expand due to freeze-thaw cycles, ultimately leading to a significant leak and potential damage to interior walls and ceilings.

The importance of regular inspection lies in its proactive nature. By identifying and addressing problems early, homeowners can avoid costly and disruptive repairs down the line. For example, a simple inspection might reveal a displaced section of step sealing that can be easily reattached, preventing water from penetrating the roofing system. Conversely, without regular inspection, this displaced section could remain unnoticed, allowing water to seep into the underlying structure, potentially leading to wood rot and requiring extensive and expensive remediation. Furthermore, regular inspection allows for timely maintenance tasks, such as cleaning debris from around the chimney base, which can prevent water from pooling and potentially compromising the sealing system. These preventative measures are far more cost-effective than addressing significant water damage after it has occurred.

In conclusion, regular inspection is not merely a recommended practice but a necessary component of ensuring the long-term effectiveness of chimney sealing systems. Its absence directly correlates with increased risk of water damage and structural compromise. By adopting a proactive approach to inspection and maintenance, homeowners can safeguard their investment and prevent costly repairs. Challenges may include accessibility to the chimney and a lack of expertise in identifying potential problems, in which case professional inspection services are advisable. This systematic approach connects to the broader theme of preventative home maintenance, emphasizing the importance of diligent care in preserving the integrity and value of the property.

6. Professional Expertise

The specialized nature of chimney sealing installation and maintenance necessitates a level of expertise that often exceeds the capabilities of general contractors or homeowners. The integration of flashing with both roofing materials and chimney masonry requires a nuanced understanding of building science principles and specific trade skills.

- Accurate Diagnosis of Existing Problems

Professional expertise enables the accurate identification of existing issues that may compromise the integrity of a chimney sealing system. This extends beyond simply observing a leak; it includes assessing the condition of the mortar joints, identifying potential galvanic corrosion, and evaluating the effectiveness of existing flashing materials. For instance, a seemingly minor leak may be indicative of a more significant underlying problem, such as structural damage to the chimney crown, which would require a different remediation approach than simply replacing the flashing. Accurate diagnosis is crucial for implementing effective solutions.

- Selection of Appropriate Materials and Techniques

Professionals possess the knowledge to select the most appropriate materials and installation techniques for a given chimney and roofing configuration. This includes understanding the compatibility of different metals, the properties of various sealant types, and the proper methods for integrating flashing with different roofing materials. For example, a professional would be aware that using aluminum flashing in direct contact with a copper chimney can lead to galvanic corrosion, and would therefore recommend alternative materials or installation techniques to mitigate this risk. Informed material selection is essential for ensuring the long-term performance of the chimney sealing system.

- Compliance with Building Codes and Regulations

Chimney sealing installations must adhere to local building codes and regulations, which can vary significantly depending on the jurisdiction. Professionals are familiar with these requirements and ensure that all work is performed in compliance with applicable standards. This includes adhering to specific requirements for flashing dimensions, overlap, and fastening methods. Failure to comply with building codes can result in costly rework and potential liability issues. A qualified professional mitigates these risks by ensuring that all installations meet the necessary regulatory requirements.

- Proper Execution of Installation and Repair Procedures

The successful execution of chimney sealing installations and repairs demands specialized skills and tools. Professionals possess the necessary expertise to properly cut, shape, and install flashing materials, ensuring a watertight seal around the chimney. This includes using appropriate techniques for bending and shaping metal, applying sealants, and integrating the flashing with the roofing materials. For example, a professional will employ specialized tools to create clean, precise bends in the flashing, ensuring a snug fit against the chimney and preventing water penetration. Skillful execution is paramount for achieving a durable and effective chimney sealing system.

The various facets of professional expertise underscore its importance in ensuring the long-term performance and reliability of chimney sealing systems. The nuances of material compatibility, installation techniques, and regulatory compliance demand a level of knowledge and skill that is often beyond the scope of non-professionals. Engaging qualified professionals is, therefore, a prudent investment in the structural integrity and longevity of any building with a chimney.

Frequently Asked Questions Regarding Chimney Sealing Systems

This section addresses common inquiries and misconceptions regarding chimney sealing systems, providing concise and informative answers based on established best practices and industry standards.

Question 1: What constitutes the primary function of chimney sealing components?

The core purpose is to prevent water from entering the building at the intersection where a chimney structure penetrates the roofline. This protection mitigates water damage to roofing structures, chimney masonry, and interior spaces.

Question 2: What are the typical materials employed in chimney sealing construction?

Common materials include aluminum, copper, galvanized steel, and occasionally lead. The selection depends on factors such as cost, compatibility with existing roofing and chimney materials, and desired lifespan.

Question 3: How often should a chimney sealing system be inspected?

A minimum of twice per year is recommended, ideally in the spring and fall. Inspections should focus on identifying signs of damage, corrosion, or displacement of the sealing components.

Question 4: What are the indications of a failing chimney sealing system?

Indicators may include water stains on interior ceilings or walls adjacent to the chimney, visible corrosion or rust on the material, displaced or missing sections of flashing, and crumbling or damaged mortar joints on the chimney itself.

Question 5: Is it possible to perform chimney sealing repairs as a do-it-yourself project?

While minor repairs, such as applying sealant to small cracks, may be within the capabilities of some homeowners, more extensive repairs are best left to qualified professionals. Improper repairs can exacerbate existing problems and potentially lead to significant structural damage.

Question 6: What is the expected lifespan of a properly installed and maintained chimney sealing system?

The lifespan varies depending on the materials used and the environmental conditions to which it is exposed. However, a well-maintained system constructed from durable materials, such as copper, can last for several decades.

These answers provide a general overview of common questions related to chimney sealing systems. Consultation with a qualified professional is recommended for specific applications and concerns.

The subsequent section will explore advanced techniques and emerging technologies in chimney sealing to enhance performance and durability.

Conclusion

This article has thoroughly explored the critical role of the flashing chimney in safeguarding building structures. Key points addressed include material selection, installation precision, weather resistance, mortar condition, regular inspection, and the importance of professional expertise. The absence of adherence to these factors directly correlates with increased vulnerability to water damage and subsequent structural compromise.

Maintaining an effective flashing chimney system is not merely an aesthetic concern but a fundamental aspect of building preservation. Continued research and adherence to best practices remain essential for ensuring long-term structural integrity and mitigating the costly consequences of water intrusion. Prudent property owners and building professionals should prioritize the proper design, installation, and maintenance of these vital systems.