Professional remediation of chimney systems signifies comprehensive service performed to the highest standards. This includes thorough inspection, meticulous cleaning, expert masonry work, and proper flue maintenance, all executed with demonstrable excellence. For example, a project might involve addressing damaged brickwork, resolving drafting issues, and ensuring compliance with current safety codes, culminating in a structurally sound and efficiently operating chimney.

Proper chimney maintenance is crucial for home safety and operational efficiency. Regular upkeep prevents hazardous situations like chimney fires and carbon monoxide leaks, contributing to the well-being of building occupants. Historically, diligent maintenance has been essential for preserving these structures, reflecting an understanding of the fundamental role chimneys play in a building’s heating and ventilation systems.

The following sections will explore common chimney issues, preventative measures, and the selection of qualified professionals for ensuring optimal performance and longevity of these essential components of residential and commercial buildings.

Essential Chimney Maintenance Guidelines

Adhering to a consistent maintenance schedule is paramount for ensuring chimney safety, optimal performance, and extended lifespan. The following guidelines provide actionable strategies for homeowners and building managers.

Tip 1: Schedule Annual Inspections. Professional chimney sweeps conduct thorough examinations to identify potential structural damage, creosote buildup, and blockages. Early detection minimizes the risk of costly repairs and hazardous conditions.

Tip 2: Prioritize Regular Cleaning. Creosote accumulation is a primary fire hazard. Annual cleaning removes flammable deposits, maintaining a clear flue passage and reducing the potential for chimney fires.

Tip 3: Address Water Damage Promptly. Water penetration can cause significant damage to chimney masonry, leading to structural instability. Repairing cracks and applying waterproofing treatments prevents further deterioration.

Tip 4: Maintain a Functional Chimney Cap. A chimney cap prevents rain, snow, and debris from entering the chimney, reducing the risk of blockages and water damage. Ensure the cap is properly installed and free of damage.

Tip 5: Monitor for Signs of Deterioration. Regularly observe the chimney exterior for spalling brick, crumbling mortar, and loose flashing. Addressing these issues promptly prevents extensive damage and costly repairs.

Tip 6: Ensure Proper Ventilation. Verify that the flue is appropriately sized for the connected appliance. Inadequate ventilation can lead to inefficient combustion and increased creosote buildup.

Tip 7: Use Seasoned Wood. Burning dry, seasoned wood reduces creosote production compared to burning unseasoned wood. Seasoned wood burns cleaner and more efficiently, minimizing the risk of chimney fires.

Implementing these maintenance strategies protects property and ensures the safe and efficient operation of chimney systems. Regular maintenance contributes significantly to the longevity and overall performance of these structures.

The next section will provide information regarding selecting appropriate repair services when addressing significant chimney issues.

1. Meticulous Inspection

Meticulous inspection forms the bedrock of effective chimney repair. The connection between thorough evaluation and successful remediation is causal: the accuracy and completeness of the initial inspection directly influence the appropriateness and effectiveness of subsequent repair strategies. Without a detailed assessment, underlying structural issues, flue obstructions, or compromised components can remain undetected, leading to incomplete or misdirected repairs. For instance, a superficial inspection might overlook hairline cracks in the flue lining, which, if left unaddressed, can escalate into significant structural damage requiring extensive and costly reconstruction.

The importance of meticulous inspection as a core component of quality repair service stems from its ability to identify hidden problems. Consider a scenario where water infiltration is suspected. A detailed inspection would not only identify the presence of moisture but also pinpoint the source, whether it is a damaged chimney crown, deteriorated flashing, or compromised brickwork. By accurately diagnosing the cause, the repair solution can be tailored to address the specific problem, preventing recurrence and ensuring long-term stability. Furthermore, a comprehensive inspection includes a review of the chimney’s compliance with local building codes and safety standards, ensuring that all repairs are performed in accordance with regulatory requirements.

In conclusion, meticulous inspection is not merely a preliminary step; it is an integral part of quality repair. This critical assessment provides the foundation for accurate diagnoses, targeted repairs, and long-term solutions. Overlooking the significance of thorough inspection can lead to incomplete repairs, recurring problems, and compromised safety. Therefore, prioritizing comprehensive assessment is essential for achieving durable and effective chimney restorations.

2. Expert Masonry

Expert masonry is inextricably linked to chimney integrity and, by extension, defines the quality of chimney service. The causal relationship is direct: deficient masonry work results in compromised structural stability and increased vulnerability to environmental factors, leading to premature deterioration. In contrast, skillful masonry contributes to a robust and long-lasting chimney structure, effectively resisting water infiltration, weathering, and structural stress. For example, improper mortar joints can allow water to penetrate the brickwork, leading to freeze-thaw damage, spalling, and eventual collapse. The availability of chimney service that can provide and utilize the expertise of a proper masonry construction team makes such service desirable and highly valued.

The importance of expert masonry within comprehensive service lies in its role in preserving and restoring the chimney’s core structural components. Services encompass tuckpointing, brick replacement, crown reconstruction, and chimney rebuilding. Consider a scenario where a chimney exhibits extensive cracking and mortar degradation. A high-caliber masonry team would meticulously remove deteriorated mortar, replace damaged bricks with matching materials, and repoint the joints, ensuring a seamless and structurally sound repair. This process not only restores the chimney’s aesthetic appeal but also reinforces its ability to withstand harsh weather conditions. Further, such high level masonry can ensure that all the dimensions are correct and built to last with proper care and attention.

In summary, expert masonry is a non-negotiable aspect of service. It directly influences chimney’s safety, longevity, and performance. Neglecting the importance of skillful masonry work can lead to short-term fixes and recurring problems, ultimately jeopardizing the structural integrity. Therefore, selecting service that emphasizes proficient masonry practices is essential for achieving effective and durable chimney remediations.

3. Flue Integrity

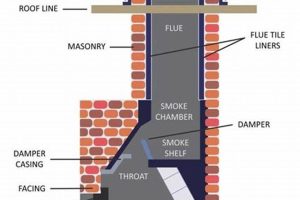

Flue integrity is a paramount factor within comprehensive chimney service, directly influencing safety and operational efficiency. A compromised flue liner poses significant risks, including carbon monoxide leaks and chimney fires. This discussion highlights critical facets of flue integrity within the context of chimney remediation.

- Liner Inspection and Assessment

Thorough inspection of the flue liner is the initial step in evaluating its condition. This involves visual inspection for cracks, spalling, and displacement, often utilizing specialized cameras. For instance, a level III inspection may reveal hidden damage caused by creosote buildup or thermal stress, requiring immediate attention to prevent hazardous conditions.

- Liner Repair and Relining Techniques

When flue liners are damaged, repair or relining becomes necessary. Techniques include the application of heat-resistant coatings, the installation of stainless steel liners, or the use of cast-in-place liners. The selection of the appropriate method depends on the extent and nature of the damage, as well as the specific requirements of the appliance being vented.

- Flue Sizing and Appliance Compatibility

Proper flue sizing is crucial for efficient venting and preventing backdrafting. The flue diameter must be appropriately matched to the connected appliance to ensure adequate draft and combustion. For example, installing an oversized flue can lead to insufficient draft, resulting in incomplete combustion and increased creosote accumulation.

- Material Selection and Durability

The materials used for flue liners must be durable and resistant to high temperatures, corrosive gases, and moisture. Stainless steel liners are often preferred for their longevity and resistance to degradation, while clay tile liners may be suitable for certain applications. The choice of material significantly impacts the lifespan and performance of the flue system.

The discussed facets are critical to ensuring long-term operational safety. Addressing each aspect meticulously contributes to a chimney system that operates safely and efficiently. Neglecting any of these aspects can undermine the overall efficacy of efforts to maintain chimney functionality.

4. Code Compliance

Adherence to building codes and safety standards constitutes a foundational element of quality chimney service. Code compliance ensures that all repairs and installations meet minimum safety requirements, protecting property and occupants from potential hazards. The intersection of code adherence and comprehensive service underscores the commitment to responsible and reliable remediation.

- Permitting and Inspections

Local building codes often require permits for chimney repairs and installations. Obtaining the necessary permits ensures that the work is subject to inspection by qualified building officials, verifying compliance with applicable regulations. For example, a municipality might require a permit for relining a flue or rebuilding a chimney crown. Failure to obtain permits can result in fines and the need to redo non-compliant work.

- Material Standards

Building codes specify the types of materials that are acceptable for use in chimney construction and repair. These standards ensure that the materials are durable, fire-resistant, and suitable for the intended application. For instance, codes may dictate the type of mortar used for brickwork, the gauge of stainless steel used for flue liners, and the fire rating of insulation materials.

- Clearance Requirements

Building codes establish minimum clearance requirements between chimneys and combustible materials. These clearances are designed to prevent the spread of fire from the chimney to surrounding structures. For example, codes may require a minimum distance between the chimney and wooden framing members or roofing materials.

- Safety Regulations

Safety regulations govern various aspects of chimney construction and maintenance, including flue sizing, draft requirements, and chimney cap installation. These regulations are designed to prevent carbon monoxide poisoning, chimney fires, and other hazards. For instance, codes may require the installation of a carbon monoxide detector in homes with fuel-burning appliances.

Compliance with building codes and safety standards is not merely a formality; it is an integral part of quality. It safeguards property and occupants from potential hazards, while ensuring work aligns with regulatory demands. Engaging service that prioritizes code compliance is essential for achieving safe and reliable chimney restorations.

5. Waterproofing

Waterproofing represents a critical component of comprehensive chimney maintenance and repair. Its application prevents water intrusion, mitigating structural damage and preserving the chimney’s functionality. Prioritizing effective waterproofing measures is integral to upholding the integrity of chimney systems.

- Material Selection for Water Resistance

Choosing appropriate water-resistant materials is foundational to successful waterproofing. This involves selecting sealants, coatings, and membranes that can withstand harsh weather conditions and prevent moisture penetration. For example, using a high-quality silicone-based sealant to seal cracks in the chimney crown prevents water from entering the chimney structure, reducing the risk of freeze-thaw damage.

- Application Techniques for Effective Sealing

Proper application techniques are essential for ensuring effective sealing. This includes surface preparation, uniform coating application, and meticulous attention to detail around joints and flashing. As an example, applying a waterproofing membrane to the chimney’s exterior requires thorough cleaning of the surface, followed by even application of the membrane, ensuring complete coverage and adhesion to prevent water intrusion.

- Flashing Installation and Maintenance

Flashing, the metal material installed at the intersection of the chimney and roof, is a critical component of waterproofing. Proper installation and regular maintenance of flashing prevent water from seeping into the structure. A real-world example includes ensuring that the flashing is correctly integrated with both the chimney masonry and the roofing materials to create a watertight seal, thereby preventing leaks into the attic or interior of the building.

- Inspection and Maintenance of Waterproofing Systems

Regular inspection and maintenance of waterproofing systems are vital for identifying and addressing potential issues before they escalate. This involves checking for cracks, deterioration, and signs of water damage. For instance, a homeowner can periodically inspect the chimney’s exterior for any signs of water staining, efflorescence, or damaged sealants, and promptly address any issues to maintain the effectiveness of the waterproofing system.

The facets discussed contribute significantly to the durability and longevity of chimney systems. The proper selection of water-resistant materials, meticulous application techniques, correct installation and upkeep of flashing, and periodic inspections culminate in effective chimney safeguarding. Overlooking any of these aspects compromises the overall protection, which can then impact the overall structural integrity of the system.

6. Creosote Removal

Creosote removal constitutes a critical aspect of comprehensive chimney service, directly impacting safety and operational efficiency. Creosote, a byproduct of incomplete combustion, accumulates within the chimney flue, posing a significant fire hazard. Its presence necessitates professional intervention to mitigate risks and ensure the chimney operates safely. The correlation between thorough creosote removal and the quality of chimney remediation is evident: deficient removal leaves flammable deposits intact, increasing the likelihood of chimney fires, while effective removal minimizes risks and enhances system performance. A real-world example is a case where a homeowner neglects annual cleaning; creosote buildup ignites, leading to a chimney fire that could have been prevented through routine maintenance. Such instances underscore the practical significance of understanding creosote formation and its associated dangers.

The methods employed for creosote removal vary depending on the extent and type of accumulation. Chemical treatments, mechanical scrubbing, and specialized tools are utilized to dislodge and extract creosote deposits from the flue lining. For instance, a chimney sweep may employ a rotary power brush to remove hardened creosote from a stainless steel liner, ensuring a thorough cleaning without damaging the liner itself. Further, service includes inspection of the flue after cleaning to verify complete removal and identify any underlying structural issues that may contribute to creosote buildup. This holistic approach not only addresses the immediate hazard but also aims to prevent future accumulation through proper maintenance and system optimization.

Creosote removal is integral to sustaining chimney safety and performance. The failure to prioritize thorough cleaning can compromise the integrity of the chimney system and increase the risk of fire. Effective service integrates creosote removal with other essential maintenance tasks, such as inspection, repairs, and code compliance. By emphasizing the importance of creosote removal, comprehensive service safeguards properties and contributes to the overall well-being of building occupants.

7. Safe Operation

Safe operation is the ultimate measure of effective chimney remediation, encompassing all facets of inspection, repair, and maintenance to ensure the chimney functions without posing risks to property or occupants. High-quality service prioritizes safety through adherence to codes, proper material selection, and meticulous execution, directly influencing the operational integrity of the system.

- Combustion Efficiency and Ventilation

Optimal combustion requires adequate ventilation to ensure complete burning of fuel and proper expulsion of exhaust gases. Inefficient combustion leads to increased creosote buildup, raising the risk of chimney fires and carbon monoxide leaks. For example, if a chimney lacks sufficient draft due to undersized flue or obstructions, incomplete combustion occurs, resulting in the accumulation of flammable deposits. Such instances emphasize the importance of assessing and correcting ventilation issues to ensure safe operation.

- Carbon Monoxide Prevention

Carbon monoxide (CO) poisoning poses a serious threat to occupants. A properly functioning chimney system effectively vents CO away from living spaces, preventing hazardous exposure. Cracks, leaks, or blockages in the flue can allow CO to enter the building, creating a life-threatening situation. Regular inspections, proper sealing of joints, and the installation of CO detectors are crucial steps in preventing CO-related incidents.

- Chimney Fire Prevention

Chimney fires, often caused by creosote accumulation, can result in significant property damage and pose a risk to life. Regular cleaning, proper fuel selection (e.g., seasoned wood), and adherence to burning guidelines are essential for preventing chimney fires. A poorly maintained chimney with excessive creosote buildup is a prime candidate for a chimney fire, underscoring the importance of proactive maintenance measures.

- Structural Stability and Integrity

A structurally sound chimney is critical for safe operation. Deteriorated masonry, damaged flue liners, or compromised foundations can lead to instability and potential collapse. Regular inspections, timely repairs, and the use of durable materials are essential for maintaining structural integrity. A leaning or visibly damaged chimney presents an imminent safety hazard, necessitating immediate professional intervention to prevent catastrophic failure.

Each discussed facet underscores the interconnectedness between comprehensive service and operational safety. By addressing issues related to combustion, CO prevention, fire risk, and structural stability, high-quality repairs contribute to a chimney system that operates safely and reliably. Neglecting any of these facets compromises overall safety and increases the potential for hazardous incidents, emphasizing the necessity of comprehensive approach to chimney remediations.

Frequently Asked Questions About Chimney Maintenance

This section addresses common inquiries regarding chimney maintenance, aiming to clarify best practices and dispel potential misconceptions about comprehensive chimney care.

Question 1: What constitutes “five star chimney repair?”

It denotes a superior standard of service characterized by meticulous inspection, expert masonry, flue integrity assurance, code compliance, waterproofing measures, thorough creosote removal, and a commitment to ensuring safe operation.

Question 2: Why is annual chimney inspection necessary?

Annual inspection allows for early detection of structural damage, creosote buildup, and potential hazards. Early identification minimizes the risk of costly repairs and ensures the chimney system operates safely and efficiently.

Question 3: What are the primary risks associated with creosote accumulation?

Creosote is a highly flammable byproduct of combustion that accumulates in the chimney flue. Excessive creosote buildup significantly increases the risk of chimney fires, potentially leading to property damage and personal injury.

Question 4: How does water damage affect chimney integrity?

Water penetration can cause significant damage to chimney masonry, leading to spalling, cracking, and structural instability. Freeze-thaw cycles exacerbate water damage, accelerating the deterioration of the chimney system.

Question 5: What role does the chimney cap play in overall chimney maintenance?

A properly installed chimney cap prevents rain, snow, debris, and animals from entering the chimney flue. This reduces the risk of blockages, water damage, and potential hazards within the chimney system.

Question 6: How does code compliance factor into quality chimney restoration?

Adherence to building codes and safety standards ensures that all repairs and installations meet minimum safety requirements. Code compliance protects property and occupants from potential hazards, verifying all work aligns with regulatory demands.

Maintaining chimney safety and integrity requires ongoing attention and expert service. Diligent inspection, timely repairs, and adherence to best practices contribute to a chimney system that operates efficiently and safely.

The next section will cover how to select the right professional to provide chimney care.

Concluding Remarks on Chimney Remediation Standards

The preceding analysis has illuminated the essential components defining high-caliber chimney maintenance and repair. Meticulous inspection, expert masonry, flue integrity, code compliance, waterproofing, creosote removal, and safe operation stand as pillars of responsible and effective service. These elements, when diligently applied, ensure the longevity, safety, and optimal performance of critical venting systems.

Recognizing the gravity of chimney system integrity is paramount for property owners. A commitment to preventative maintenance and the engagement of qualified professionals are imperative for safeguarding structures and occupants. The consequences of neglecting chimney care can range from costly repairs to life-threatening hazards. Therefore, a proactive approach, guided by the principles, represents a prudent investment in long-term safety and structural well-being.