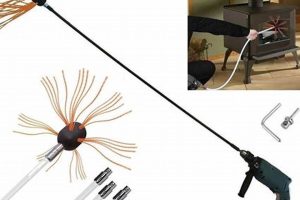

A rotary cleaning system utilizes a power tool to spin specialized brushes or whips within a flue. This method dislodges creosote and debris more effectively than traditional manual techniques. The powered rotation allows the cleaning implement to reach all surfaces of the chimney, regardless of shape or obstructions.

Employing such systems offers enhanced cleaning capabilities, leading to improved efficiency and safety of the heating appliance. Thorough removal of deposits minimizes the risk of chimney fires and ensures proper ventilation, contributing to a safer living environment. Historically, manual methods were the standard, but technological advancements have introduced more efficient and effective options.

The following sections will delve into the specific components of rotary chimney cleaning systems, examine their application in various chimney types, and discuss safety protocols for their operation.

Rotary Flue Cleaning System Usage

Optimal employment of powered flue cleaning equipment requires adherence to specific guidelines to ensure both safety and efficacy. Neglecting these recommendations may result in damage to the chimney structure or inadequate removal of hazardous deposits.

Tip 1: Select Appropriate Brush Heads. The brush or whip head must match the dimensions and material of the flue. Employing an incorrectly sized or overly aggressive head risks damaging the liner, particularly in older or more fragile chimney systems.

Tip 2: Maintain Controlled Rotational Speed. Excessive speed generates friction and heat, potentially damaging the flue and creating a fire hazard. Adhere to the manufacturers recommended speed settings for optimal cleaning and safety.

Tip 3: Ensure Proper Ventilation. The cleaning process releases significant amounts of particulate matter into the air. Adequate ventilation, preferably through negative pressure systems like HEPA vacuums specifically designed for chimney cleaning, is crucial for respiratory health and minimizing dust dispersal.

Tip 4: Conduct Pre-Cleaning Inspection. Prior to initiating the cleaning process, thoroughly inspect the flue for structural defects or obstructions. Addressing these issues before using powered equipment prevents further damage and ensures a more effective cleaning operation.

Tip 5: Wear Appropriate Protective Gear. Respiratory protection, eye protection, and gloves are essential to mitigate exposure to creosote, soot, and other potentially harmful substances dislodged during the cleaning process.

Tip 6: Regularly Inspect and Maintain Equipment. Periodically examine brushes, rods, and the power drill itself for wear or damage. Replacing worn components and ensuring proper lubrication extends the equipment’s lifespan and maintains cleaning effectiveness.

Tip 7: Follow Manufacturer’s Instructions. Adherence to the equipment manufacturer’s guidelines regarding operation, maintenance, and safety precautions is paramount. This ensures both the longevity of the equipment and the safety of the operator.

By diligently following these guidelines, users can maximize the effectiveness and safety of power-assisted flue cleaning, contributing to a safer and more efficient heating system. Proper technique and preparedness minimize risks and enhance the overall value of this advanced cleaning method.

The next section will cover advanced techniques and troubleshooting common issues encountered during rotary flue cleaning operations.

1. Brush Head Selection

The selection of an appropriate brush head is paramount for the effective and safe utilization of power-driven flue cleaning systems. An incorrect choice can compromise cleaning efficacy, damage the flue lining, or pose a significant safety risk. Therefore, a comprehensive understanding of brush head characteristics and their suitability for various chimney types is essential.

- Material Compatibility

Brush head materials must be compatible with the flue liner. Steel brushes, while durable and effective on masonry chimneys, can damage or scratch stainless steel liners. Poly or nylon brushes are generally recommended for metal liners to prevent such damage. The selection must consider both the cleaning power required and the integrity of the flue material.

- Diameter and Shape

The diameter of the brush head should closely match the internal diameter of the flue. An undersized brush will not effectively clean the flue walls, while an oversized brush can become lodged or exert excessive pressure, potentially causing damage. The shape of the brush (round, square, rectangular) must also correspond to the flue’s geometry to ensure complete contact with all surfaces.

- Bristle Stiffness and Density

Bristle stiffness dictates the brush’s ability to remove stubborn creosote deposits. Aggressive, stiff bristles are effective for heavy buildup but can damage delicate liners. Softer, more flexible bristles are suitable for lighter deposits and more fragile flue materials. Bristle density influences the contact area and cleaning efficiency. A denser brush provides more consistent cleaning action.

- Connection Type and Durability

The brush head’s connection to the extension rods must be secure and robust to withstand the rotational forces generated by the power tool. Weak or poorly designed connections can fail, leading to brush head detachment within the flue. The overall durability of the brush head, including the bristles and the core, determines its lifespan and resistance to wear and tear from repeated use.

These considerations highlight the critical role of proper brush head selection in optimizing the performance and safety of power-assisted flue cleaning. A deliberate and informed choice, based on flue material, geometry, and deposit characteristics, ensures thorough cleaning without compromising the integrity of the chimney system. Failure to adequately address these factors can negate the benefits of powered cleaning and potentially exacerbate existing problems.

2. Rotational Speed Control

Effective power-assisted flue cleaning hinges upon precise management of the rotational speed of the cleaning apparatus. Excessive or insufficient speed compromises both cleaning efficacy and the structural integrity of the chimney system, rendering speed regulation a critical operational parameter.

- Material Compatibility and Abrasion

Flue liners constructed from materials such as stainless steel or terracotta are susceptible to abrasion damage from rapidly rotating cleaning heads. Excessive speed amplifies the abrasive forces, potentially leading to scratches, gouges, or even structural weakening of the liner. Slower speeds, coupled with appropriate brush head materials, minimize the risk of such damage while still enabling effective deposit removal.

- Creosote Removal Efficiency

The composition and adhesion of creosote deposits vary considerably. Hard, glazed creosote often necessitates higher rotational speeds to fracture and dislodge. Conversely, softer, sooty deposits can be effectively removed at lower speeds, preventing excessive dust generation and minimizing the risk of airborne particulate contamination. Selection of the appropriate speed based on deposit characteristics is crucial for optimal cleaning.

- Equipment Longevity and Maintenance

Continuous operation at high rotational speeds places increased stress on the cleaning equipment, including the power drill, extension rods, and brush head connections. This stress accelerates wear and tear, potentially leading to premature equipment failure. Reduced speeds, when appropriate for the cleaning task, extend the lifespan of the equipment and reduce maintenance requirements.

- Safety Considerations and Control

Uncontrolled or excessively high rotational speeds pose a safety hazard. The cleaning head can become unstable, whipping violently within the flue and potentially damaging the chimney structure or injuring the operator. Controlled speeds allow for greater precision and stability, reducing the risk of accidents and ensuring a more predictable cleaning process.

These interconnected elements underscore the importance of rotational speed control within the context of power-assisted flue cleaning. Skillful modulation of speed, taking into account flue material, deposit characteristics, equipment limitations, and safety protocols, is essential for achieving optimal cleaning results while safeguarding the chimney system and the operator.

3. Ventilation Implementation

Effective chimney maintenance utilizing powered rotary tools mandates a comprehensive ventilation strategy. The aggressive action of these tools dislodges significant quantities of particulate matter, necessitating measures to control airborne contaminants and ensure operator safety.

- Negative Pressure Containment

The establishment of negative pressure within the combustion appliance and flue is paramount. This is typically achieved through the use of a high-efficiency particulate air (HEPA) filtered vacuum system specifically designed for chimney cleaning. The vacuum draws air and dislodged debris away from the operator, preventing widespread dissemination of soot, creosote, and other irritants. The use of a sealed connection between the vacuum hose and the appliance access point further minimizes escape of particulates.

- Respiratory Protection

Regardless of the effectiveness of negative pressure systems, respiratory protection remains an essential safeguard. A properly fitted respirator, rated for protection against fine particulate matter, should be worn by all personnel involved in the cleaning process. This precaution mitigates the risk of respiratory irritation, allergic reactions, and long-term health consequences associated with exposure to chimney deposits.

- Airflow Management and Containment

Careful attention must be paid to airflow patterns within the work area. Sealing off doorways and windows, when feasible, limits the spread of contaminants to other areas of the building. The strategic placement of air purifiers with HEPA filters can further reduce airborne particulate levels. These measures contribute to a cleaner and healthier working environment.

- Post-Cleaning Air Purification

Following the cleaning process, it is advisable to run an air purifier within the work area for an extended period to capture any remaining airborne particulates. Surface cleaning with a HEPA-filtered vacuum is also recommended to remove settled dust and debris. This final step ensures thorough removal of contaminants and minimizes the risk of subsequent exposure.

The implementation of a robust ventilation strategy is inextricably linked to the safe and effective employment of powered rotary chimney cleaning tools. These precautions collectively minimize the risk of exposure to hazardous materials, protecting both the operator and the building occupants. Neglecting this critical aspect undermines the benefits of rotary cleaning and potentially creates a more hazardous environment than traditional cleaning methods.

4. Flue Structure Integrity

The assessment of a chimney flue’s structural integrity is paramount before employing any cleaning method, particularly power-driven rotary systems. The robust action of these systems can exacerbate existing weaknesses, leading to further damage or even system failure. A pre-cleaning inspection is thus an indispensable step.

- Material Condition Assessment

Flue liners are constructed from a variety of materials, including clay tile, metal, and cast-in-place concrete. Each material degrades differently over time. Clay tiles can crack or spall, metal liners corrode, and concrete deteriorate due to freeze-thaw cycles or acid attack. The rotary cleaning process applies mechanical stress; compromised materials are susceptible to further fracturing or dislodgement, potentially leading to flue blockage or hazardous gas leakage.

- Joint and Connection Stability

Flue liners are assembled from multiple sections joined together. The integrity of these joints is critical for maintaining a continuous, gas-tight pathway. Mortar joints in clay tile liners can erode, and connections in metal liners can loosen or corrode. The vibration induced by rotary cleaning can further weaken these joints, creating gaps that allow for flue gas leakage into the building or structural collapse within the chimney.

- Obstruction Identification

Flue obstructions, such as bird nests, debris accumulation, or creosote blockages, impede proper ventilation and increase the risk of chimney fires. Attempting to force a rotary cleaning tool through a significant obstruction can damage the tool, the flue liner, or both. A pre-cleaning inspection should identify and remove any substantial obstructions before initiating rotary cleaning.

- Flue Geometry and Alignment

Deviations from the intended flue geometry, such as offsets, bends, or misalignments, can create points of stress during rotary cleaning. The flexible rods and cleaning heads may become lodged or exert excessive force on the flue walls, leading to damage. Identifying these geometric irregularities allows for the adjustment of cleaning techniques to minimize stress and prevent damage.

These facets of flue structure integrity demonstrate the inherent risks associated with employing rotary cleaning systems on compromised chimneys. While powered cleaning offers enhanced efficiency, its application necessitates a thorough assessment of the flue’s condition to prevent unintended consequences and ensure the continued safe operation of the heating appliance.

5. Protective Gear Usage

The operation of power-driven flue cleaning systems inherently generates significant occupational hazards. Therefore, the consistent and proper employment of appropriate protective gear is not merely advisable but an absolute necessity for mitigating risks associated with exposure to hazardous materials and physical injury during the cleaning process.

- Respiratory Protection

Power-driven cleaning releases substantial quantities of fine particulate matter, including soot, creosote, and other combustion byproducts. Inhalation of these substances poses significant health risks, ranging from acute respiratory irritation to long-term chronic lung disease. Properly fitted respirators with appropriate filtration (e.g., N95 or P100 rating) are essential for preventing inhalation of these hazardous particles. Real-world examples include cases of chimney sweeps developing respiratory ailments after prolonged exposure without adequate protection. The implications extend to potential legal liabilities and ethical considerations for employers failing to provide sufficient respiratory safeguards.

- Eye Protection

Debris dislodged during power-driven flue cleaning can become airborne with considerable force, posing a direct threat to eye injury. Impact-resistant safety glasses or goggles are crucial for preventing particulate matter from entering the eyes. Field reports frequently document instances of eye irritation, abrasions, or more severe injuries resulting from inadequate eye protection. The consequences can range from temporary discomfort and lost work time to permanent vision impairment.

- Hand Protection

Direct contact with creosote and other chimney deposits can cause skin irritation, allergic reactions, and potential absorption of hazardous chemicals. Durable, chemical-resistant gloves are necessary for protecting the hands during all phases of the cleaning process, including equipment handling, brush head changes, and debris removal. Real-world examples illustrate cases of chimney sweeps developing dermatitis or chemical burns from unprotected hand contact. The implications include potential medical expenses, lost productivity, and long-term skin sensitivity.

- Hearing Protection

The operation of power drills and the impact of cleaning heads against flue walls can generate significant noise levels, potentially leading to hearing damage over time. Earplugs or earmuffs with appropriate noise reduction ratings are recommended for mitigating noise exposure. Studies on occupational noise hazards demonstrate the cumulative effect of prolonged exposure to loud noises, leading to gradual hearing loss. In the context of power-driven flue cleaning, consistent use of hearing protection is essential for preserving auditory health.

The integration of these protective measures constitutes a comprehensive safety protocol for power-driven flue cleaning operations. Neglecting any element of this protocol increases the risk of occupational injury and long-term health consequences. The consistent and diligent application of these safeguards is not merely a recommended practice but a fundamental requirement for responsible and ethical chimney maintenance.

6. Equipment Maintenance

Proper maintenance is vital for ensuring the safe and effective operation of powered chimney cleaning systems. Neglecting maintenance protocols compromises cleaning efficacy, accelerates equipment degradation, and elevates the risk of operational hazards. The relationship between equipment upkeep and optimal system function is inextricable.

- Brush Head Integrity

Regular inspection and replacement of worn or damaged brush heads is essential. Worn bristles reduce cleaning effectiveness, while damaged brush heads can detach within the flue, creating obstructions or damaging the chimney liner. Real-world scenarios include instances where detached brush heads necessitated costly and time-consuming retrieval efforts. Consistent monitoring and timely replacement mitigate these risks.

- Rod and Connection Security

Extension rods and their connecting mechanisms are subject to significant stress during rotary cleaning. Regular inspection for bending, cracking, or thread wear is crucial. Loose or damaged connections can fail under load, leading to rod separation within the flue. Field reports frequently document instances of rod separation, requiring specialized tools and techniques for retrieval. Preventative maintenance, including thread lubrication and prompt replacement of compromised components, minimizes the likelihood of such incidents.

- Power Drill Functionality

The power drill serves as the prime mover for the cleaning system. Regular inspection of the drill’s motor, chuck, and power cord is necessary. Overheating, erratic speed control, or frayed power cords present significant safety hazards. Routine maintenance, including motor brush replacement and chuck lubrication, ensures consistent performance and extends the drill’s lifespan. Neglecting these aspects can lead to drill failure during operation, interrupting the cleaning process and potentially creating hazardous conditions.

- Vacuum System Performance

For systems incorporating vacuum-assisted dust control, proper maintenance of the vacuum unit is critical. Filter replacement, hose inspection, and motor maintenance are essential for maintaining effective negative pressure and minimizing airborne particulate contamination. Clogged filters reduce suction, compromising dust control effectiveness. Damaged hoses can leak, releasing hazardous particles into the work area. Routine maintenance ensures optimal vacuum performance and protects the operator from exposure to harmful substances.

These interconnected maintenance aspects underscore the importance of a proactive approach to equipment upkeep. Consistent attention to detail, coupled with adherence to manufacturer’s recommendations, ensures the reliability, safety, and longevity of powered chimney cleaning systems. Conversely, neglecting these maintenance protocols jeopardizes both the equipment and the operator, undermining the intended benefits of this advanced cleaning method.

Frequently Asked Questions

The following addresses common inquiries regarding the use of power-driven systems for chimney maintenance, clarifying operational aspects and safety considerations.

Question 1: Is powered chimney cleaning suitable for all chimney types?

Powered cleaning systems are versatile but not universally applicable. Chimneys with severe structural damage or those lined with fragile materials may not be suitable candidates. Pre-cleaning inspection is mandatory to assess flue integrity and determine the appropriateness of this cleaning method.

Question 2: Does powered cleaning pose a greater risk of chimney damage compared to manual methods?

The risk of damage is dependent on operator skill and equipment selection. Inexperienced operators or the use of inappropriate brush heads can increase the risk of liner damage. Proper training, careful brush selection, and adherence to recommended speed settings mitigate this risk. Skilled manual cleaning also has the potential to cause damage.

Question 3: How often should a chimney be cleaned using power-driven methods?

Cleaning frequency depends on fuel type, appliance usage, and chimney design. Annual inspections are recommended, with cleaning performed as needed based on creosote accumulation. Excessive cleaning, regardless of method, can accelerate liner wear. A professional assessment is recommended to determine the appropriate cleaning schedule.

Question 4: What safety precautions are essential during powered chimney cleaning?

Essential safety precautions include respiratory protection, eye protection, hand protection, and hearing protection. Furthermore, proper ventilation with HEPA-filtered vacuum systems is necessary to minimize airborne particulate exposure. Adherence to equipment manufacturer’s safety guidelines is also crucial.

Question 5: Can powered cleaning remove all types of creosote deposits?

Powered cleaning is effective for removing most types of creosote, including glazed creosote, which is difficult to remove with manual methods. However, extremely thick or hardened deposits may require specialized techniques or chemical treatments in conjunction with powered cleaning.

Question 6: Is professional training required to operate power-driven chimney cleaning equipment?

While not always legally mandated, professional training is strongly recommended. Proper training ensures safe and effective operation, minimizes the risk of damage, and enhances the overall quality of the cleaning service. Untrained operators may inadvertently damage the chimney or create hazardous conditions.

In summary, powered flue cleaning offers enhanced efficiency and effectiveness when performed correctly, but requires careful consideration of chimney condition, equipment selection, safety precautions, and operator training.

The following section will provide a conclusion summarizing the key aspects of power-assisted flue cleaning and its role in maintaining chimney safety.

Conclusion

The preceding discussion elucidated the various facets of utilizing power-driven rotary systems for chimney maintenance. Key aspects included brush head selection, rotational speed control, ventilation implementation, assessment of flue structure integrity, protective gear usage, and equipment maintenance. Each element contributes to the overall effectiveness and safety of the process, emphasizing the interconnectedness of these considerations.

Employing a drill chimney sweep system demands adherence to established protocols and a thorough understanding of the equipment’s capabilities and limitations. Prudent application of these techniques, coupled with ongoing professional development, will contribute to enhanced chimney safety and prolonged system lifespan. Neglecting these considerations carries the potential for both property damage and personal injury; therefore, diligence and expertise remain paramount.