The expenditure associated with constructing a vertical structure designed to vent smoke and combustion gases from a fireplace, furnace, stove, or incinerator represents a significant home improvement investment. The final figure is influenced by a range of factors, from material selection to local labor rates. For instance, a simple brick installation on a single-story home will differ substantially in price from a complex, multi-story structure using specialized stone.

Such structures are crucial for safe and efficient heating, mitigating the risks of carbon monoxide poisoning and chimney fires. Historically, they have been essential components of dwellings, evolving from rudimentary clay pipes to sophisticated architectural features. Their presence has not only ensured comfortable living environments but also contributed to the aesthetic appeal and resale value of properties.

Understanding the variables impacting the total investment is paramount. The subsequent discussion will delve into these critical factors, encompassing material choices, labor considerations, regional price variations, and potential unforeseen expenses, providing a comprehensive overview of what to expect when undertaking such a project.

Cost-Effective Chimney Construction

Prudent planning and informed decision-making are crucial to managing expenses associated with chimney construction. The following tips offer strategies to optimize value without compromising safety or functionality.

Tip 1: Material Selection: Carefully evaluate material options. Brick and concrete are common choices, but alternatives like prefabricated metal can offer cost savings, particularly if installation labor is a significant portion of the overall expenditure. Compare the long-term durability and maintenance requirements of each material.

Tip 2: Obtain Multiple Quotes: Seek bids from at least three reputable contractors. A detailed, itemized estimate allows for a clear comparison of costs for materials, labor, and any necessary permits. Scrutinize the qualifications and experience of each contractor, verifying licenses and insurance.

Tip 3: Design Simplicity: Complex chimney designs often translate to higher labor costs and specialized materials. Opt for a straightforward design that meets functional needs without unnecessary embellishments or intricate detailing. Consider the architectural style of the property and choose a design that complements it while minimizing construction complexity.

Tip 4: Schedule Strategically: Construction demand fluctuates seasonally. Attempting to schedule during off-peak periods, such as late winter or early spring in some regions, may yield lower labor rates due to decreased contractor workloads. Be mindful of weather-related delays and plan accordingly.

Tip 5: Explore Prefabricated Options: Prefabricated chimney systems can reduce on-site labor time and material waste. These systems are engineered for specific applications and often come with detailed installation instructions. Ensure the chosen system meets all local building codes and safety standards.

Tip 6: Factor in Permit Costs: Obtain all necessary building permits before commencing construction. Failure to do so can result in fines, delays, and potential rework. Permit costs vary depending on location and the scope of the project. Incorporate these fees into the overall budget.

Careful consideration of these factors allows for a more controlled budget and a reduced risk of unexpected expenses. Thorough research and a proactive approach are vital to achieving a successful and affordable chimney construction project.

By implementing these strategies, property owners can navigate the intricacies of chimney construction costs and ensure a well-built, safe, and aesthetically pleasing addition to their home.

1. Material Selection

Material selection represents a critical determinant in the final expenditure associated with chimney construction. The chosen material not only influences the aesthetic appearance but also dictates the structural integrity, longevity, and, crucially, the overall financial investment required.

- Brick Composition and Cost

Brick, a traditional material, offers a range of options, from standard clay bricks to more expensive, specialized varieties. The composition, manufacturing process, and aesthetic qualities of the brick significantly influence its unit cost. Higher-quality bricks, offering improved durability and visual appeal, command a premium, directly affecting the material expenses.

- Stone Acquisition and Installation

Natural stone chimneys impart a distinctive aesthetic; however, stone is often a more expensive material choice. Acquisition costs vary based on the type of stone, its availability, and the distance required for transportation. Installation is generally more labor-intensive and specialized, increasing the labor component of the overall investment relative to simpler materials.

- Prefabricated Metal Chimney Systems

Prefabricated metal chimney systems present a cost-effective alternative. These systems are engineered for ease of installation, reducing on-site labor time. While the initial material cost might be comparable to some brick options, the reduced labor expenses often result in a lower overall expenditure. Furthermore, material selection must consider longevity, frequency of repairs and maintenance, especially in terms of durability.

- Mortar and Accessory Materials

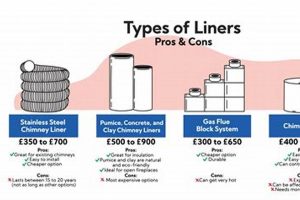

Beyond the primary structural material, the choice of mortar and other accessory components also contributes to the aggregate cost. Specialized mortars, required for certain stone types or to enhance weather resistance, can add to material expenses. Similarly, the selection of flue liners, caps, and other accessories impacts both material costs and long-term performance.

Ultimately, the selection of chimney construction materials represents a balance between aesthetic considerations, structural requirements, and budgetary constraints. A thorough evaluation of material properties, acquisition costs, and installation complexities is essential to optimizing value and mitigating unnecessary expenses in the process.

2. Labor Expenses

Labor expenses constitute a significant and often substantial component of the overall expenditure associated with chimney construction. The complexity of the construction process, skill requirements, and regional market conditions all contribute to the variability in labor costs.

- Skill Level and Specialization

Chimney construction necessitates specialized skills, particularly when working with materials like stone or complex designs. Highly skilled masons and technicians command higher hourly rates, reflecting their expertise and ability to execute intricate tasks. The level of specialization required for a particular project directly influences the overall labor cost.

- Project Duration and Complexity

The time required to complete a chimney project directly correlates with labor expenses. Complex designs, challenging site conditions, or unexpected delays can extend the construction timeline, increasing the total labor hours. The duration of the project, therefore, is a primary factor in determining labor costs.

- Regional Labor Market Conditions

Labor rates vary considerably across different geographic regions. Areas with high demand for skilled tradespeople or a limited supply of qualified workers typically experience higher labor costs. The prevailing economic conditions and local market dynamics play a crucial role in shaping labor expenses for chimney construction.

- Permitting and Inspection Requirements

Adherence to local building codes and regulations often necessitates inspections at various stages of the construction process. These inspections may require additional labor hours for preparation and coordination. Furthermore, any rework required to address inspection findings will further increase labor costs.

The interplay of skill requirements, project scope, regional market forces, and regulatory compliance collectively shapes the labor component of chimney construction expenditure. Careful consideration of these factors is essential for accurate budgeting and effective cost management throughout the project lifecycle. Furthermore, hiring licensed and insured contractors, although potentially more expensive upfront, often mitigates the risk of costly errors or non-compliance issues in the long term.

3. Permit acquisitions

Acquiring the requisite permits represents an integral component of chimney construction and, consequently, a contributing factor to its overall expenditure. Permit fees are imposed by municipal or regional governing bodies to ensure construction projects adhere to established safety standards and building codes. This regulatory oversight seeks to minimize potential hazards associated with improperly constructed or maintained chimneys, such as fire risks and carbon monoxide exposure. The cost of these permits can vary significantly depending on the location, the scope of the project, and the specific regulations in force. For instance, a permit for a simple chimney repair may incur a modest fee, while a permit for a complete chimney installation on a new construction project could be considerably more expensive. This expense is unavoidable and must be factored into the project budget from the outset.

Failure to secure the necessary permits prior to commencing chimney construction can result in significant financial penalties and project delays. Building inspectors have the authority to issue stop-work orders, halting construction until the proper permits are obtained. Moreover, unpermitted construction may be subject to fines and legal action. In some cases, the property owner may be required to dismantle the unpermitted structure, incurring additional costs for demolition and reconstruction. A recent example in a suburban community highlighted a homeowner who faced substantial fines and mandated reconstruction after proceeding with chimney construction without obtaining the required permits, demonstrating the practical implications of neglecting this regulatory requirement.

In conclusion, the cost associated with permit acquisitions is a non-negotiable aspect of chimney construction expenditure. While the fees themselves may represent a relatively small percentage of the total project cost, neglecting to obtain the necessary permits can lead to far more significant financial consequences, including fines, delays, and potential legal repercussions. Diligent adherence to local building codes and regulations, including timely permit acquisition, is essential for ensuring a safe, compliant, and cost-effective chimney construction project. These costs, while sometimes viewed as an inconvenience, are a critical investment in ensuring the safety and longevity of the structure, thus ultimately protecting property and lives.

4. Design Complexity

The intricacy of a chimney’s design directly influences the total expenditure required for its construction. More complex designs necessitate increased labor hours, specialized materials, and advanced construction techniques, all contributing to elevated costs. For instance, a straightforward chimney design involving a simple flue and a basic brick structure will invariably be less expensive than a design incorporating multiple flues, intricate stonework, or custom-fabricated components. The level of detail and the need for specialized craftsmanship are key drivers of cost escalation in these scenarios.

The impact of design complexity extends beyond mere aesthetics. A complex design may require extensive structural reinforcement, specialized flue systems to accommodate different appliances, and enhanced safety features to comply with building codes. Each of these elements adds to the material costs and necessitates the involvement of experienced professionals. For example, a chimney designed to accommodate both a fireplace and a high-efficiency furnace requires a more sophisticated flue system than a chimney serving only a single appliance. This added complexity necessitates precise engineering and installation, further impacting the overall project budget. The practical significance of understanding this connection lies in the ability to make informed design choices that balance aesthetic preferences with budgetary constraints. A homeowner considering an elaborate chimney design must carefully evaluate the cost implications and weigh them against the perceived benefits.

In summary, design complexity serves as a critical cost driver in chimney construction. While intricate designs may enhance the visual appeal and functionality of a home, they inevitably lead to increased expenses. A thorough understanding of this relationship allows homeowners to make informed decisions, balancing aesthetic desires with budgetary limitations and ensuring a successful and cost-effective chimney construction project. Ignoring the cost implications of design complexity can lead to unexpected financial burdens and potentially compromise the feasibility of the project. Therefore, careful planning and consultation with experienced professionals are essential to navigating this critical aspect of chimney construction.

5. Regional variations

Geographic location exerts a substantial influence on the expenditure associated with chimney construction. Regional variations encompass a confluence of factors that collectively shape the overall cost, necessitating careful consideration of local market conditions and regulatory landscapes.

- Material Availability and Transportation Costs

The proximity to material suppliers significantly impacts material costs. Regions with abundant local sources of brick, stone, or prefabricated metal systems typically benefit from lower material prices. Conversely, areas requiring long-distance transportation of materials will experience elevated costs due to shipping expenses. For instance, constructing a stone chimney in a region with limited stone quarries will be significantly more expensive than in an area where stone is readily available.

- Labor Rates and Union Influence

Prevailing labor rates vary considerably across different geographic regions. Areas with strong labor unions or a high demand for skilled tradespeople tend to have higher labor costs. The level of union influence in a particular region can dictate wage standards and project timelines, both of which impact the overall cost of chimney construction. A project in a major metropolitan area with a strong union presence will likely incur higher labor expenses compared to a rural area with a less organized workforce.

- Building Codes and Permitting Requirements

Building codes and permitting requirements are established and enforced at the local level. These regulations vary significantly from one jurisdiction to another, impacting the scope of work required and the associated costs. Regions with stringent building codes may necessitate additional inspections, specialized materials, or enhanced safety features, all of which contribute to higher project expenses. An example is seismic zones where more rigorous reinforcements are required.

- Climate and Weather Conditions

Climatic factors influence both material choices and construction timelines. Regions with harsh weather conditions may require the use of more durable, weather-resistant materials, increasing material costs. Inclement weather can also cause delays, extending the construction timeline and inflating labor expenses. A chimney built in a region prone to severe winters will likely require more robust insulation and weatherproofing measures compared to a chimney built in a milder climate.

In conclusion, regional variations represent a critical consideration in assessing the overall cost of chimney construction. The interplay of material availability, labor rates, building codes, and climate collectively shapes the financial landscape of such projects, necessitating careful analysis of local conditions and regulatory requirements to ensure accurate budgeting and effective cost management. Ignoring these regional factors can lead to significant budget overruns and project delays.

Frequently Asked Questions

This section addresses common inquiries regarding the financial aspects of chimney construction, providing factual answers to aid in informed decision-making.

Question 1: What constitutes the primary cost drivers when building a chimney?

The predominant expenses are materials (brick, stone, metal), labor for skilled masons, permits mandated by local jurisdictions, and design complexity. Unforeseen structural repairs or modifications can also inflate the total.

Question 2: How does material selection impact the overall financial outlay?

Material selection directly affects the budget. Brick, while traditional, varies in price depending on quality and availability. Stone, often considered a premium choice, involves higher material and specialized installation costs. Prefabricated metal systems offer potential savings on labor.

Question 3: Why do labor expenses vary considerably across projects?

Labor costs fluctuate based on the required skill level, project duration, design complexity, and geographic location. Highly skilled masons commanding premium rates, intricate designs extending the timeline, and varying regional wage standards contribute to cost variations.

Question 4: What role do building permits play in the overall project budget?

Permits, mandatory for ensuring code compliance, represent an additional expense. Permit fees vary based on location and project scope. Failure to acquire necessary permits can result in fines, project delays, and potential legal ramifications, significantly impacting the final cost.

Question 5: How does design complexity influence the construction cost?

Intricate designs necessitate specialized materials, advanced construction techniques, and increased labor hours, all contributing to higher expenses. Simpler designs utilizing readily available materials and straightforward construction methods minimize costs.

Question 6: Do geographic location and regional variations affect the total cost?

Geographic location significantly influences the financial aspect due to material availability, labor rates, and regional building codes. Access to local materials reduces transportation costs. Varying labor market conditions and code requirements across regions also affect overall expenses.

In summary, chimney construction necessitates careful consideration of material choices, labor expenses, permitting procedures, design complexities, and regional factors to effectively manage costs and ensure a successful project.

The subsequent section will explore strategies for reducing expenses without compromising safety or structural integrity.

Cost to Build a Chimney

The preceding analysis has explored the multi-faceted nature of the cost to build a chimney. From material selection and labor rates to permit acquisitions and design complexities, numerous factors contribute to the final expenditure. Regional variations further complicate the estimation process, necessitating thorough research and planning.

Ultimately, prudent decision-making and a comprehensive understanding of these variables are essential for successful and cost-effective chimney construction. Careful consideration of the presented information can aid in mitigating unforeseen expenses and ensuring a safe, code-compliant structure that meets both functional and aesthetic requirements.