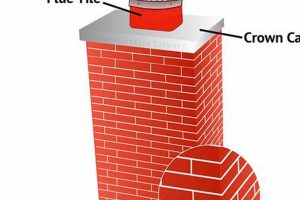

A protective covering, typically constructed from fired earth material, is positioned atop a flue to prevent the entry of rain, snow, debris, and animals. This component serves as a barrier against the elements, thereby safeguarding the internal structure of the chimney and connected systems. Examples include those crafted from terra cotta, offering both functionality and aesthetic appeal.

The implementation of such a safeguard offers significant advantages. It extends the lifespan of the chimney by preventing water damage, which can lead to deterioration of the masonry. Furthermore, it enhances the efficiency of the flue by preventing downdrafts and ensuring proper ventilation. Historically, these components were essential for maintaining the integrity of hearths and heating systems, contributing to the safety and comfort of dwellings.

The subsequent sections will delve into the selection criteria, installation procedures, maintenance requirements, and various design options for this important architectural element. Further discussion will include considerations for code compliance and regional variations in design and materials.

Clay Chimney Cap

Proper installation and maintenance are critical to ensuring the longevity and functionality of a clay chimney cap. The following tips offer guidance on selecting, installing, and maintaining this essential component.

Tip 1: Material Selection: When choosing a covering, prioritize high-fired clay. This material exhibits superior resistance to freeze-thaw cycles, minimizing the risk of cracking and degradation over time. Consider local climate conditions when making a final material determination.

Tip 2: Accurate Sizing: Precise measurements of the flue opening are essential. The covering must adequately cover the flue, preventing precipitation ingress while allowing for unimpeded exhaust flow. Consult manufacturer specifications for recommended sizing guidelines.

Tip 3: Secure Installation: Utilize appropriate mortar or adhesive compounds designed for chimney applications. A secure bond between the covering and the flue is paramount to prevent displacement due to wind or seismic activity. Ensure the chosen material is compatible with both the clay component and the existing chimney structure.

Tip 4: Regular Inspections: Conduct routine inspections, at least annually, to identify any signs of damage or deterioration. Cracks, loose mortar, or shifting of the covering should be addressed promptly to prevent further degradation.

Tip 5: Professional Cleaning: Schedule professional chimney cleaning services to remove creosote buildup, which can accelerate the deterioration of both the flue and the covering. Creosote can also trap moisture, exacerbating freeze-thaw damage.

Tip 6: Consider Spark Arrestors: In areas prone to wildfires, integrate a spark arrestor into the covering design. This feature prevents embers from escaping the flue, reducing the risk of igniting surrounding vegetation.

Tip 7: Address Vegetation: Trim any overhanging trees or vegetation that may come into contact with the chimney. Branches can damage the covering during storms and contribute to moisture retention, promoting deterioration.

Adherence to these guidelines will ensure optimal performance, minimize maintenance requirements, and extend the lifespan of your clay chimney cap, protecting the integrity of the chimney system.

The subsequent sections will provide more detailed information on specialized applications and advanced maintenance techniques.

1. Material Durability

The longevity and functionality of a clay chimney cap are intrinsically linked to the durability of the clay material from which it is constructed. Substandard material choices invariably lead to premature failure, necessitating costly repairs or replacements. The constant exposure to environmental elements, including rain, snow, ice, and extreme temperature fluctuations, subjects the cap to considerable stress. Clay that lacks sufficient firing or possesses inherent structural weaknesses will crack, crumble, and ultimately disintegrate over time, compromising its ability to protect the chimney from water intrusion and other forms of damage. A compromised covering exposes the chimney structure to accelerated deterioration, potentially affecting structural stability and requiring extensive and costly repairs. Consider instances where improperly fired clay resulted in widespread cracking after a single winter season, highlighting the crucial link between material integrity and product lifespan.

The selection of appropriate clay materials and firing processes is therefore paramount. High-fired clay, which undergoes a vitrification process, exhibits superior resistance to water absorption and freeze-thaw cycles. This inherent resilience significantly extends the lifespan of the covering, minimizing the need for frequent maintenance and replacement. Furthermore, the presence of certain impurities or inconsistencies within the clay matrix can create weak points that are susceptible to cracking or spalling. The absence of rigorous quality control measures during the manufacturing process can result in the production of defective components that fail to meet minimum durability standards. A damaged or ineffective covering then exposes the chimney to the elements.

In summary, material durability serves as a foundational element of the overall performance and longevity of a clay chimney cap. Prioritizing high-quality clay materials and employing stringent manufacturing processes are essential for ensuring that the covering can withstand the rigors of prolonged exposure to the elements. Investing in a durable component represents a cost-effective strategy in the long term, mitigating the risk of premature failure and safeguarding the integrity of the chimney structure. Ignoring this consideration inevitably leads to increased maintenance costs and potentially significant structural damage.

2. Weather Protection

Weather protection is a primary function of a clay chimney cap, directly influencing the lifespan and operational efficiency of a chimney system. The component’s capacity to shield the chimney from the detrimental effects of precipitation, temperature fluctuations, and wind-driven debris determines its overall value.

- Prevention of Water Intrusion

Water penetration into the chimney structure accelerates the deterioration of mortar joints, flue liners, and surrounding masonry. The covering acts as a barrier, diverting rainwater and snowmelt away from the flue opening. Unprotected flues are susceptible to significant water damage, leading to structural weaknesses and costly repairs. Examples of the absence of weather protection includes deteriorated brickwork and spalling due to freeze-thaw cycles.

- Mitigation of Freeze-Thaw Damage

Water that infiltrates the chimney system expands upon freezing, exerting pressure on the surrounding materials. This cycle of freezing and thawing causes cracks and fissures to develop, weakening the structure over time. The protective barrier provided by a clay unit minimizes the absorption of moisture, thereby reducing the risk of freeze-thaw damage. Instances of chimney collapse due to unmanaged freeze-thaw expansion exemplify the component’s importance.

- Defense Against Wind-Driven Debris

Wind can carry leaves, twigs, and other debris into the flue, obstructing airflow and creating a fire hazard. A correctly designed and installed component prevents the entry of foreign materials, maintaining proper ventilation and reducing the risk of chimney fires. Blocked flues impede exhaust flow, potentially leading to dangerous carbon monoxide buildup within the dwelling.

- Stabilizing internal temperatures and preventing wind downdrafts.

The clay chimney cap has some insulative properties that help stabilize the internal temperature within the chimney stack, preventing extreme fluctuations. Wind can cause a chimney to have downdrafts which means to force air down the stack, pushing smoke or fumes back into the home. A well designed chimney cap can create a shield to keep winds out of the chimney stack.

The interconnectedness of these weather-related challenges underscores the significance of a robust and appropriately designed clay chimney cap. Its capacity to provide effective weather protection is paramount to ensuring the long-term structural integrity and operational safety of the chimney system, serving as a critical element in safeguarding the building and its occupants from the detrimental effects of the environment. A damaged or missing cap can negate the overall performance of a chimney.

3. Flue Size Matching

Flue size matching represents a critical factor in the effective performance of a clay chimney cap. The internal dimensions of the flue dictate the necessary dimensions of the covering to ensure proper ventilation and prevent the ingress of external elements. A covering that is too small will restrict airflow, potentially leading to incomplete combustion and the accumulation of dangerous gases within the dwelling. Conversely, a covering that is too large may not adequately protect the flue from rain, snow, and debris, negating its primary protective function. The precise correlation between flue size and cap dimensions ensures the chimney functions as intended, efficiently expelling combustion byproducts while preventing the entry of environmental contaminants. Improper matching compromises the overall efficiency and safety of the heating system. Examples of the effects of incorrect sizing include: reduced heating efficiency which causes higher fuel costs, smoke backdrafts, and increased carbon monoxide levels.

Accurate measurement of the flue opening is therefore essential prior to selecting and installing a clay chimney cap. Manufacturers typically provide specifications that detail the appropriate cap dimensions for various flue sizes. These specifications must be adhered to in order to ensure optimal performance. Additionally, local building codes often stipulate specific requirements regarding the sizing and installation of chimney components. Compliance with these codes is mandatory to ensure the safety and integrity of the chimney system. In practice, a certified chimney sweep or contractor should conduct the measurement and installation to guarantee adherence to best practices and regulatory standards. This ensures an appropriate cap is selected and installed. This also ensures the cap does not interfere with airflow dynamics.

In summary, flue size matching is an indispensable consideration in the selection and installation of a clay chimney cap. Proper matching ensures optimal ventilation, protects against environmental elements, and complies with relevant building codes. Failure to address this critical factor can result in compromised performance, increased safety risks, and potential code violations. Therefore, a thorough understanding of flue size and its corresponding impact on the cap selection is paramount for any chimney installation or maintenance project. The effects of flue size matching have been the subject of numerous studies.

4. Proper Installation

The structural integrity and protective function of a clay chimney cap are inextricably linked to the execution of proper installation techniques. Deviations from established installation protocols can negate the inherent benefits of the cap, rendering it ineffective and potentially hazardous. Correct installation ensures a secure and weatherproof seal between the cap and the chimney flue, preventing water intrusion, mitigating freeze-thaw damage, and ensuring proper ventilation. The cause-and-effect relationship is clear: improper installation leads to compromised performance, while meticulous adherence to established procedures ensures optimal functionality.

The significance of proper installation extends beyond mere protection from the elements. A securely installed cap prevents displacement due to wind or seismic activity, safeguarding against potential property damage and personal injury. Furthermore, a properly fitted cap prevents the entry of birds, animals, and debris, maintaining the integrity of the flue and reducing the risk of chimney fires. Real-life examples abound of caps dislodged by high winds or failing due to substandard mortar, resulting in costly repairs and potential safety hazards. Adherence to manufacturer specifications, proper mortar application, and secure anchoring techniques are all critical components of proper installation.

In conclusion, the benefits of a clay chimney cap are contingent upon the execution of proper installation practices. Addressing the installation process with due diligence and adhering to established guidelines is essential for maximizing the cap’s protective capabilities and ensuring the long-term safety and efficiency of the chimney system. Neglecting this critical step can lead to a cascade of problems, undermining the investment and potentially jeopardizing the structural integrity of the building. Engaging qualified professionals and adhering to best practices during installation is thus paramount.

5. Creosote Prevention

Creosote prevention is a paramount safety and maintenance consideration inextricably linked to the functionality and longevity of a clay chimney cap. The cap’s design and condition significantly influence creosote accumulation within the chimney flue, thereby impacting fire safety and operational efficiency.

- Proper Ventilation and Airflow

A clay covering designed for correct flue size matching ensures optimal ventilation. Restricted airflow, resulting from an undersized or damaged component, can lead to lower flue temperatures. Lower temperatures promote creosote condensation on flue walls. For example, a severely cracked covering obstructing airflow will exacerbate creosote buildup compared to a properly sized and maintained unit.

- Moisture Control and Creosote Formation

The primary function of the unit, preventing water intrusion, directly impacts creosote formation. Water accelerates the deterioration of creosote deposits, creating acidic compounds that corrode the flue liner. A cap that effectively shields the flue from rain and snow mitigates this corrosive process, reducing the risk of chimney degradation and fire hazards. A missing or damaged clay top facilitates water entry, increasing creosote-related issues.

- Cap Design and Soot Accumulation

The design of the component can influence soot accumulation. Intricate designs or those with narrow openings may trap soot particles, contributing to creosote buildup over time. A simple, open design facilitates the natural expulsion of soot, minimizing creosote formation. Examples of cap designs hindering soot removal include those with excessive decorative elements or inadequate clearance.

- Regular Inspection and Maintenance

Regular inspection of the chimney covering for damage or blockage is crucial for creosote prevention. Cracks, dislodged sections, or debris accumulation can impede airflow and promote creosote buildup. Prompt repair or replacement of damaged units ensures continued protection and minimizes creosote-related risks. Neglecting maintenance will inevitably lead to increased creosote accumulation and associated hazards.

The interplay between a clay chimney cap and creosote prevention underscores the importance of selecting a properly sized and maintained unit. Failure to address these considerations increases the risk of chimney fires, structural damage, and carbon monoxide exposure. Therefore, integrating creosote prevention strategies into routine chimney maintenance practices is essential for ensuring the safety and efficiency of wood-burning appliances.

Frequently Asked Questions

The following questions address common inquiries and misconceptions surrounding clay chimney caps, providing concise and informative answers based on established industry practices.

Question 1: What is the expected lifespan of a component constructed from fired earth material?

The longevity of such a component is contingent upon material quality, installation precision, and environmental exposure. Typically, a high-fired clay unit, properly installed and maintained, can endure for several decades. However, severe weather conditions or substandard materials can significantly reduce its lifespan.

Question 2: How does this covering prevent water damage?

This covering acts as a barrier, diverting rainwater and snowmelt away from the flue opening. This prevents water from penetrating the chimney structure, which can lead to the deterioration of mortar joints, flue liners, and surrounding masonry.

Question 3: What are the risks associated with an improperly sized one of these components?

An undersized covering can restrict airflow, leading to incomplete combustion and the accumulation of dangerous gases. Conversely, an oversized unit may not adequately protect the flue from rain and debris. Accurate sizing is essential for optimal performance and safety.

Question 4: How frequently should the unit be inspected?

Routine inspections, preferably on an annual basis, are recommended to identify any signs of damage or deterioration. Cracks, loose mortar, or shifting of the covering should be addressed promptly to prevent further degradation.

Question 5: Can this material be used with any type of chimney flue?

While clay is a versatile material, compatibility depends on specific flue construction and local building codes. Consult with a qualified chimney professional to determine suitability for a given chimney system. Code compliance is paramount.

Question 6: What maintenance is required to ensure the unit remains effective?

Maintenance includes regular inspections for damage, removal of debris, and professional cleaning to prevent creosote buildup. Prompt repairs are crucial to address any cracks or loose mortar. Preventative maintenance extends the lifespan and ensures optimal functionality.

In summary, the effective utilization of this component necessitates a thorough understanding of its properties, installation requirements, and maintenance protocols. Diligence in these areas ensures the long-term performance and safety of the chimney system.

The subsequent section will provide detailed information on the selection criteria and installation procedures for these components.

Clay Chimney Cap

This exploration of the clay chimney cap underscores its pivotal role in chimney system integrity. From material durability and weather protection to precise flue size matching, proper installation, and creosote prevention, each aspect contributes significantly to the functionality and longevity of the chimney. Neglecting any of these factors can compromise performance and increase safety risks.

The information presented herein serves as a foundation for informed decision-making. Prioritizing proper selection, installation, and maintenance of the clay chimney cap is crucial for safeguarding property and ensuring the safe operation of heating systems. Continued diligence in these areas will contribute to a safer and more efficient built environment.