This service addresses the maintenance and cleaning of residential and commercial flues within the capital city of North Carolina. This specialized trade focuses on the removal of soot, creosote, and other debris from exhaust systems to ensure proper ventilation and reduce the risk of fire hazards. Local residents often seek this service during the fall and winter months, prior to increased fireplace usage.

Regular maintenance of this nature offers several key benefits. It significantly diminishes the potential for chimney fires, promotes efficient heating appliance operation, and can extend the lifespan of the chimney structure itself. Historically, the practice involved manual scrubbing, but contemporary methods often incorporate specialized brushes, vacuums, and inspection cameras for a more thorough and comprehensive clean.

The following sections will delve into the specific aspects of flue inspection protocols, the selection criteria for qualified professionals, and the preventative measures homeowners can undertake to maintain a safe and efficient home heating system.

Maintenance Recommendations

The following recommendations aim to facilitate safe and efficient fireplace operation by addressing key maintenance requirements.

Tip 1: Schedule Annual Inspections. A qualified technician should inspect the system annually to assess its structural integrity and identify potential hazards. Early detection of issues, such as cracks or deterioration, can prevent costly repairs and safety risks.

Tip 2: Prioritize Professional Cleaning. Creosote buildup is a primary fire hazard. Professional cleaning removes this accumulation, mitigating the risk of flue fires. Frequency of cleaning depends on usage, but at least annual cleaning is advisable.

Tip 3: Utilize Seasoned Wood. Burning green or damp wood increases creosote production. Ensure wood has been properly seasoned (dried) for at least six months to minimize this buildup and promote cleaner burning.

Tip 4: Install a Chimney Cap. A flue cap prevents rain, snow, leaves, and animals from entering the flue. This simple addition safeguards the system from moisture damage and obstructions that can impede airflow.

Tip 5: Monitor Smoke Behavior. Observe the direction and volume of smoke exiting the flue. Excessive smoke or improper venting may indicate an obstruction or mechanical issue requiring immediate attention.

Tip 6: Keep Surrounding Area Clear. Maintain a clear space around the hearth and flue. Remove any flammable materials such as drapes, furniture, and papers. Install a fire-resistant hearth rug.

Tip 7: Understand Damper Operation. Learn the proper use of the damper. Only open it before starting a fire and close it completely when the flue is cold. A partially closed damper can lead to carbon monoxide buildup.

Adherence to these recommendations contributes to the safe and efficient utilization of home heating systems, minimizing potential hazards and maximizing operational lifespan.

The concluding section will summarize the benefits of proactive flue maintenance and emphasize the importance of engaging qualified professionals.

1. Inspection frequency

Inspection frequency is a critical determinant in the safe and efficient operation of residential flue systems. Its correlation with comprehensive flue maintenance services directly impacts the mitigation of fire hazards and the optimization of heating appliance performance. Consistent attention to inspection intervals is essential for long-term system integrity.

- Annual Safety Assurance

The National Fire Protection Association (NFPA) recommends annual inspections for all flue systems. This frequency allows for the early detection of potential hazards, such as creosote buildup, flue blockages, or structural damage. Regular evaluation ensures adherence to safety standards and minimizes the risk of flue fires and carbon monoxide intrusion. For example, a homeowner adhering to annual inspection guidelines is more likely to identify and rectify a developing creosote buildup before it ignites, compared to a homeowner neglecting inspections.

- Usage-Based Adjustments

Inspection frequency should be adjusted based on usage patterns. Systems used frequently, particularly with solid fuels, require more frequent inspections. Heavy use accelerates creosote accumulation and increases the likelihood of blockages from debris. A family that uses a fireplace daily throughout the winter should consider inspections more than once per year, while a system used only occasionally may suffice with an annual assessment.

- System Age and Material

Older systems, or those constructed with specific materials, may require more frequent scrutiny. Aging flues can develop cracks, deterioration, or other structural weaknesses that necessitate more frequent inspections to ensure safety. Clay flues, for instance, are more susceptible to cracking than stainless steel liners, warranting closer monitoring in older homes.

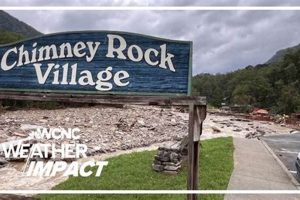

- Post-Event Evaluation

Any event that may impact the integrity of the flue, such as a flue fire, a lightning strike, or a significant weather event, necessitates an immediate inspection. These events can cause unseen damage that compromises the system’s functionality and safety. A post-flue fire inspection is crucial to identify and address any structural damage or creosote buildup resulting from the event, preventing future incidents.

The systematic adherence to a well-defined inspection schedule, tailored to individual system characteristics and usage patterns, forms a cornerstone of proactive flue maintenance. Consistent evaluation and professional service minimizes the potential for hazardous conditions and ensures the continued safety and efficiency of residential heating systems.

2. Creosote Removal

Creosote removal is a primary function associated with professional services for residential flues in the designated North Carolina location. This substance, a byproduct of incomplete combustion, accumulates within the system, presenting a significant fire hazard. Professional services address this accumulation to mitigate risk.

- Formation and Composition

Creosote forms when volatile gases produced during combustion condense within the relatively cool flue. This condensation occurs due to incomplete burning of wood or other solid fuels. The composition varies depending on the type of fuel burned, the temperature of the flue, and the air supply. Regardless of its specific makeup, creosote is highly flammable. For example, burning unseasoned wood increases creosote production due to its higher moisture content, which lowers flue temperatures and promotes condensation.

- Stages of Accumulation

Creosote accumulates in stages, progressing from a flaky, soot-like deposit to a hardened, tar-like glaze. The later stages are considerably more difficult to remove and pose a greater fire risk. Regular services prevent buildup from progressing beyond the initial, easily removable stage. Neglecting the flue allows creosote to harden, potentially requiring specialized tools and techniques for removal.

- Fire Hazard Mitigation

The primary objective of creosote removal is to mitigate the risk of flue fires. Accumulated creosote can ignite from a stray spark or excessive heat, rapidly spreading flames throughout the system and potentially to adjacent structures. Professional removal eliminates this fuel source, significantly reducing the likelihood of a fire. A thorough professional service ensures all accessible creosote deposits are eliminated, minimizing ignition potential.

- Professional Techniques

Professionals employ various techniques for creosote removal, including mechanical brushing, chemical treatments, and rotary power sweeping. The specific method depends on the type and amount of creosote present. Mechanical brushing uses specialized brushes to dislodge deposits, while chemical treatments soften hardened creosote for easier removal. Rotary power sweeping utilizes rotating brushes attached to flexible rods, providing a more aggressive cleaning action for heavily coated flues.

These facets of creosote removal underscore the importance of engaging qualified professionals in the designated area. Consistent maintenance, performed by skilled technicians, minimizes fire risks, enhances system efficiency, and contributes to the overall safety of residential properties.

3. Qualified technician

The selection of a qualified technician is paramount for effective and safe services within the Raleigh, NC area. Competent professionals possess the requisite knowledge, skills, and certifications to perform inspections, cleaning, and repairs according to industry standards and local regulations. This expertise is crucial for mitigating fire hazards and ensuring optimal system performance.

- Certification and Training

A qualified technician typically holds certifications from recognized organizations such as the Chimney Safety Institute of America (CSIA) or the National Fireplace Institute (NFI). These certifications demonstrate a commitment to ongoing education and adherence to best practices. Technicians also undergo specialized training in flue inspection techniques, cleaning procedures, and repair methods. A CSIA-certified technician, for example, has passed rigorous examinations and participates in continuing education to maintain their credentials, ensuring they are up-to-date on the latest safety standards and technologies.

- Licensing and Insurance

In some jurisdictions, services are subject to licensing requirements. Verification of proper licensing ensures that the technician meets minimum competency standards and operates legally within the region. Furthermore, adequate insurance coverage protects homeowners from liability in the event of property damage or personal injury during the service. Engaging an insured technician provides financial security and peace of mind, knowing that potential risks are mitigated through appropriate coverage.

- Experience and Expertise

Years of experience in the field contribute to a technician’s ability to accurately assess system conditions and implement effective solutions. Experienced technicians have encountered a wide range of issues and are better equipped to diagnose problems and perform repairs efficiently. An experienced technician can often identify subtle signs of potential problems that a less experienced professional might overlook, preventing minor issues from escalating into major repairs.

- Adherence to Safety Standards

Qualified technicians prioritize safety throughout the service process. They utilize appropriate safety equipment, follow established protocols for handling hazardous materials, and comply with relevant building codes and regulations. Adherence to safety standards minimizes the risk of accidents and ensures the well-being of both the technician and the homeowner. For example, a qualified technician will use respirators and protective eyewear to avoid exposure to creosote and other harmful substances during cleaning.

The facets detailed above underscore the critical role of a qualified technician in ensuring the safety and efficiency of residential flues. Engaging certified, licensed, and experienced professionals minimizes risks, promotes proper maintenance, and protects homeowners from potential hazards associated with faulty flue systems in the Raleigh, NC area.

4. Fire Prevention

Fire prevention is intrinsically linked to services within Raleigh, NC, acting as a cornerstone for residential safety. Regular maintenance significantly reduces the likelihood of flue fires, protecting homes and occupants from potential hazards. Addressing potential risks through proactive measures is paramount in maintaining a secure living environment. The subsequent discussion examines key facets of fire prevention related to these services.

- Creosote Control and Mitigation

Creosote, a byproduct of incomplete combustion, accumulates within flues and presents a substantial fire hazard. Flue services focus on removing creosote buildup, thereby mitigating the risk of ignition. The accumulation rate depends on factors such as fuel type, flue temperature, and burning practices. For instance, burning unseasoned wood significantly increases creosote production. Regular cleaning by a qualified technician prevents creosote from reaching a critical mass capable of igniting, safeguarding the property.

- Flue Obstruction Removal

Obstructions, such as nests, debris, or fallen masonry, can impede airflow and increase the risk of flue fires. Restricted airflow causes combustion gases to remain in the flue for longer periods, raising temperatures and increasing the likelihood of creosote ignition. Furthermore, obstructions can divert dangerous gases, such as carbon monoxide, into the living space. Flue services include the removal of obstructions to ensure proper ventilation and reduce the risk of both fire and carbon monoxide poisoning.

- Early Defect Detection

Regular inspections by qualified technicians can identify potential defects in the flue structure, such as cracks, deteriorated mortar, or damaged flue liners. These defects compromise the integrity of the system and increase the risk of fire spreading to combustible materials within the building. Early detection allows for timely repairs, preventing minor issues from escalating into major fire hazards. For example, identifying a small crack in the flue liner and repairing it promptly prevents hot gases from escaping and igniting adjacent wooden framing.

- Proper System Usage and Education

Qualified technicians often provide homeowners with valuable information on proper flue system usage and maintenance practices. This education includes guidance on selecting appropriate fuels, maintaining proper airflow, and recognizing signs of potential problems. Informed homeowners are better equipped to prevent fire hazards and ensure the safe operation of their heating appliances. Providing homeowners with information on the benefits of using seasoned firewood, for instance, can directly reduce creosote buildup and minimize the risk of flue fires.

These multifaceted aspects of fire prevention underscore the crucial role of flue maintenance within Raleigh, NC. Proactive measures, including creosote control, obstruction removal, defect detection, and homeowner education, collectively contribute to a safer residential environment by significantly reducing the risk of flue-related fires.

5. System efficiency

The correlation between routine flue maintenance and system efficiency is significant, impacting heating appliance performance and fuel consumption. Regular services provided within Raleigh, NC, directly contribute to optimizing the energy output and cost-effectiveness of residential heating systems. Neglecting maintenance can lead to decreased efficiency and increased operational expenses.

- Optimized Airflow Dynamics

Flues free of obstructions, such as creosote buildup or debris, facilitate optimal airflow. Unrestricted airflow allows for complete combustion, maximizing heat output and minimizing wasted fuel. For instance, a flue blocked by bird nests restricts the flow of combustion gases, leading to incomplete burning of wood and reduced heat production. Services that clear these obstructions restore proper airflow, improving overall system efficiency.

- Reduced Creosote Buildup Impact

Creosote accumulation not only presents a fire hazard but also acts as an insulator, reducing the transfer of heat from the flue to the living space. This insulation effect forces the heating appliance to work harder to maintain the desired temperature, resulting in increased fuel consumption. Removal services eliminate this insulating layer, allowing for more efficient heat transfer and reduced fuel costs. A flue with a thick layer of creosote, for example, will radiate significantly less heat into the home compared to a clean flue.

- Proper Damper Operation

A malfunctioning or improperly sealed damper can lead to significant heat loss when the heating appliance is not in use. Gaps in the damper allow warm air to escape, increasing heating bills and reducing overall system efficiency. Flue services include inspection and repair of dampers, ensuring a tight seal and minimizing heat loss. A damaged damper that remains partially open, for example, can result in a continuous draft, pulling warm air out of the house and increasing the load on the heating system.

- Enhanced Draft Performance

A properly maintained flue generates a strong draft, which draws combustion gases upward and out of the house. This efficient draft prevents backdrafting, which can introduce harmful gases, such as carbon monoxide, into the living space. It also ensures that the heating appliance burns cleanly and efficiently. Services that address flue height, diameter, and internal surface conditions contribute to enhanced draft performance, improving both safety and system efficiency. A flue that is too short or has a rough interior surface, for example, may not generate sufficient draft, leading to smoky fires and reduced heating efficiency.

These considerations highlight the direct link between regular flue maintenance and enhanced system efficiency within Raleigh, NC. Addressing airflow restrictions, creosote buildup, damper functionality, and draft performance through professional services optimizes heating appliance operation, reduces fuel consumption, and lowers overall heating costs.

6. Maintenance cost

The expense associated with professional flue maintenance in Raleigh, NC, represents a critical consideration for homeowners. This cost is directly influenced by several factors, including the frequency of service, the severity of creosote buildup, the complexity of the system, and the geographic location. Routine preventative measures typically result in lower overall expenditure compared to addressing neglected flues that require extensive cleaning or repairs. For example, annual inspections, costing approximately $100 to $300, can identify minor issues before they escalate into major problems, such as flue fires that can result in thousands of dollars in damage and potential safety hazards.

Furthermore, the type of fuel used impacts the frequency and cost of maintenance. Solid fuels, such as wood, produce more creosote than gas or oil, necessitating more frequent professional cleanings. Systems utilizing solid fuels may require cleaning every one to two years, while gas flues may only need inspection and cleaning every three to five years. Neglecting proper maintenance can lead to structural damage, necessitating costly repairs or even complete flue replacement. Instances of deteriorated liners, cracked masonry, or blocked vents resulting from deferred maintenance significantly increase expenses beyond routine cleaning costs.

In summary, understanding the factors influencing maintenance cost enables homeowners to make informed decisions regarding flue upkeep. Proactive maintenance, including regular inspections and cleaning, minimizes long-term expenses by preventing costly repairs and mitigating fire hazards. Engaging qualified professionals and adhering to recommended maintenance schedules are essential for maintaining safe and efficient heating systems in the Raleigh, NC area, ultimately ensuring both financial prudence and homeowner well-being.

Frequently Asked Questions

The following addresses common inquiries regarding flue maintenance, inspection, and related services in the Raleigh, NC area. These questions aim to clarify best practices and dispel misconceptions regarding flue system upkeep.

Question 1: How frequently should a residential flue be inspected?

The National Fire Protection Association (NFPA) recommends annual inspections for all flue systems. More frequent inspections are advisable for systems used regularly, especially with solid fuels, or those exhibiting signs of damage.

Question 2: What are the potential consequences of neglecting flue maintenance?

Neglecting maintenance can lead to creosote buildup, flue obstructions, structural damage, and an increased risk of flue fires. Inefficient heating, carbon monoxide intrusion, and costly repairs are also potential consequences.

Question 3: How does creosote accumulation contribute to fire hazards?

Creosote is a flammable byproduct of incomplete combustion that accumulates within flues. When ignited by a stray spark or excessive heat, accumulated creosote can cause a rapid and intense flue fire, potentially spreading to adjacent structures.

Question 4: What qualifications should a flue technician possess?

A qualified technician should hold certifications from recognized organizations such as the Chimney Safety Institute of America (CSIA) or the National Fireplace Institute (NFI). Proper licensing, insurance coverage, and relevant experience are also essential.

Question 5: What preventative measures can homeowners undertake to maintain the safety of their flue system?

Homeowners can use seasoned wood, install a flue cap, monitor smoke behavior, maintain a clear space around the hearth, and understand proper damper operation. Scheduling annual inspections is also crucial.

Question 6: How does flue maintenance affect system efficiency?

Maintenance promotes optimal airflow, reduces creosote buildup, ensures proper damper operation, and enhances draft performance. These factors contribute to efficient combustion, reduced fuel consumption, and lower heating costs.

Consistent maintenance, adhering to recognized standards, ensures continued operation and minimizes risks related to residential flue systems.

The subsequent section will summarize key takeaways and emphasize the importance of engaging qualified professionals within the Raleigh, NC region.

Conclusion

The preceding discussion has detailed the multifaceted nature of services for the cleaning and maintenance of residential flues within Raleigh, NC. Key areas addressed include the necessity of regular inspections, the risks associated with creosote accumulation, the importance of qualified technicians, and the direct impact of maintenance on system efficiency and fire prevention. Understanding these components enables property owners to make informed decisions regarding the care and upkeep of their heating systems.

Effective flue management requires a proactive approach. Addressing potential issues before they escalate remains paramount to ensuring both property safety and operational cost-effectiveness. Prioritizing comprehensive flue management protocols represents a commitment to the preservation of structural integrity and the minimization of potential hazards.