Addressing deterioration in masonry structures that vent combustion byproducts is crucial for maintaining safety and structural integrity within residential and commercial properties in New Jersey. Such services encompass a range of procedures, including patching cracks, replacing damaged bricks, and resolving issues with flue liners and caps. These measures are essential to prevent hazards associated with carbon monoxide exposure, chimney fires, and water damage to the building’s structure.

The upkeep of these vital building components is not merely cosmetic; it directly impacts the health and safety of occupants. Properly functioning ventilation systems prevent the buildup of hazardous gases and ensure efficient removal of combustion byproducts. Neglecting necessary maintenance can lead to costly repairs down the line, and potentially compromise the entire structure. Historically, the maintenance of these structures has been a preventative measure against fire and structural collapse, a tradition that continues to this day.

Given the critical role of a properly maintained ventilation system, this article will delve into common issues necessitating professional intervention, discuss key considerations when selecting qualified contractors in the region, and explore preventative measures to extend the lifespan and ensure optimal performance of these essential structures.

Essential Considerations for Addressing Deteriorated Chimneys

Maintaining the structural integrity of vertical structures used for exhausting combustion gases requires diligent attention to detail. Ignoring potential issues can lead to significant safety risks and costly repairs. The following are vital considerations for property owners when addressing concerns regarding deteriorated chimneys in New Jersey.

Tip 1: Conduct Regular Inspections: Schedule annual inspections by qualified professionals. Early detection of cracks, spalling brick, or mortar deterioration is crucial for preventing escalation of damage. A certified chimney sweep can assess the interior flue and identify potential hazards unseen from ground level.

Tip 2: Address Water Intrusion Promptly: Water is a primary cause of chimney decay. Ensure the chimney cap is intact and functioning properly to prevent rain and snow from entering the flue. Investigate and repair any leaks around the chimney flashing to protect the roof and surrounding structure.

Tip 3: Repair Damaged Mortar Joints: Deteriorated mortar joints allow water penetration and weaken the chimney’s structural integrity. Repointing, the process of removing and replacing damaged mortar, should be performed by experienced masons using appropriate materials compatible with the existing brick or stone.

Tip 4: Replace Damaged Bricks: Spalling or cracked bricks compromise the chimney’s stability and aesthetic appeal. Matching the existing brick type and color is essential for a seamless repair. Improper brick replacement can lead to further deterioration due to differential expansion and contraction.

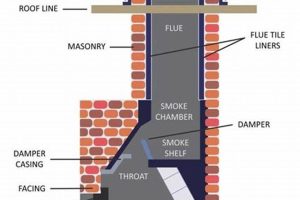

Tip 5: Ensure Proper Flue Liner Integrity: The flue liner protects the chimney structure from corrosive combustion byproducts. Damaged or cracked flue liners must be repaired or replaced to prevent hazardous gas leakage into the home. A professional inspection can determine the extent of the damage and recommend the appropriate liner system.

Tip 6: Consider Chimney Crown Repair or Replacement: The chimney crown, the concrete slab at the top of the chimney, prevents water from entering the chimney chase. Cracks or deterioration in the crown necessitate prompt repair or replacement to safeguard the chimney structure.

Tip 7: Prioritize Professional Expertise: Engage qualified and licensed contractors experienced in this kind of chimney restoration. Verify their credentials, insurance coverage, and references before commencing any work. Proper execution is paramount to ensuring long-term structural stability and safety.

Adhering to these guidelines is vital for safeguarding the structural integrity and operational safety of chimneys. Proactive maintenance and timely repairs mitigate risks associated with water damage, gas leaks, and structural failure, thereby protecting property and occupants.

The following section will provide a detailed examination of the cost factors associated with various types of chimney repairs in New Jersey, providing valuable insights for budgeting and planning necessary maintenance.

1. Inspection Thoroughness

Inspection thoroughness constitutes a foundational element within the spectrum of chimney remediation services offered throughout New Jersey. The efficacy of any subsequent effort to rectify deterioration is directly proportional to the initial assessment. A cursory examination may overlook subtle, yet consequential, structural deficiencies, ultimately leading to premature failure of completed repairs and the persistence of safety hazards. For example, hairline cracks in the flue liner, if undetected, can permit the insidious infiltration of carbon monoxide into living spaces, creating a silent threat to occupants. Similarly, seemingly minor mortar erosion may, in actuality, signify extensive subsurface damage compromising the chimney’s overall stability.

Comprehensive inspection protocols typically incorporate visual assessments, often supplemented by specialized tools such as chimney cameras, to scrutinize the entire flue length for obstructions, cracks, and displacement. Furthermore, a qualified inspector will evaluate the condition of the chimney crown, flashing, and surrounding masonry for signs of water damage, a prevalent cause of deterioration in the regions climate. A precise diagnosis, derived from a meticulous inspection, allows for the formulation of a targeted repair strategy, ensuring the appropriate allocation of resources and the implementation of effective solutions. Consider a scenario where creosote buildup contributes to a chimney fire. Only a detailed inspection can reveal the extent of the deposit, prompting a thorough cleaning alongside structural repairs, preventing future occurrences.

The connection between inspection rigor and successful chimney remediation is therefore undeniable. Neglecting this initial phase invariably compromises the longevity, safety, and efficacy of any subsequent undertaking. Consequently, property owners should prioritize engaging certified professionals who adhere to stringent inspection standards, ensuring the delivery of informed and effective chimney maintenance and restoration solutions. The investment in a thorough inspection is, in effect, an investment in the long-term structural integrity of the property and the safety of its inhabitants.

2. Mortar Joint Integrity

The structural integrity of a chimney is inextricably linked to the condition of its mortar joints. These joints, composed of a mixture of cement, lime, sand, and water, serve as the binding agent between individual bricks or stones, collectively forming a stable and weather-resistant structure. Deterioration of mortar joints, a prevalent issue necessitating masonry restoration, directly impacts the overall stability and safety of chimneys in New Jersey, rendering maintenance and repair essential. The degradation process, often accelerated by freeze-thaw cycles and water penetration, leads to cracking, crumbling, and eventual loss of mortar, compromising the chimney’s ability to withstand environmental stressors.

Compromised mortar joints permit water infiltration, which can exacerbate deterioration through freeze-thaw action and cause internal structural damage. This moisture can also combine with flue gases to form corrosive acids, further weakening the masonry. Moreover, failing mortar joints create pathways for dangerous carbon monoxide to leak into the building, posing a significant health hazard. Ignoring the signs of mortar joint degradation can lead to more extensive and costly repairs, potentially requiring complete chimney rebuilds. Consider a scenario where seemingly minor cracks in the mortar are left unattended. Over time, water seeps into these cracks, freezes, and expands, gradually widening the fissures and weakening the bond between the bricks. This process, repeated annually, results in significant structural damage, necessitating extensive repointing or even complete chimney reconstruction.

Addressing mortar joint integrity is therefore a critical component of chimney maintenance. Repointing, the process of removing deteriorated mortar and replacing it with new mortar, is a common remedial measure. Selecting the correct mortar mix, compatible with the existing masonry, is essential to ensure a durable and lasting repair. In conclusion, maintaining the soundness of mortar joints is paramount for preventing structural failure, mitigating safety risks, and preserving the longevity of chimneys. Regular inspections and prompt repairs are vital for upholding the safety and integrity of these essential building components.

3. Flue Liner Condition

The condition of the flue liner is a critical factor dictating the necessity for chimney maintenance in New Jersey. The flue liner, typically constructed of clay tile, metal, or concrete, serves as a protective barrier within the chimney, safeguarding the surrounding masonry from the corrosive byproducts of combustion. Deterioration of this liner directly impacts structural integrity and poses potential safety hazards, frequently prompting the need for professional intervention.

- Protection Against Combustion Byproducts

The primary function of a flue liner is to contain and vent harmful gases, such as carbon monoxide, and corrosive compounds produced during the burning of wood, oil, or gas. A compromised liner allows these substances to permeate the chimney’s masonry, leading to its degradation and potential leakage of hazardous gases into the living space. Cracks, spalling, or complete disintegration of the liner necessitate repair or replacement to maintain a safe and functional venting system. For instance, a cracked clay tile liner can allow acidic condensation to saturate the brickwork, accelerating its deterioration and potentially leading to chimney collapse.

- Prevention of Chimney Fires

Flue liners also play a crucial role in preventing chimney fires. Creosote, a highly flammable byproduct of wood combustion, can accumulate on the inner surface of the liner. A damaged liner provides crevices and rough surfaces that promote creosote buildup, increasing the risk of a fire that can spread to the surrounding structure. Additionally, a liner with gaps or cracks can allow hot embers to escape and ignite combustible materials near the chimney. Regular inspections to identify and address liner damage are essential for minimizing fire hazards. For example, a stainless steel liner installed after a chimney fire can provide a smoother, more heat-resistant surface that reduces creosote accumulation and fire risk.

- Maintenance of Draft Efficiency

A properly functioning flue liner contributes significantly to the draft efficiency of the chimney. A continuous, airtight liner ensures that combustion gases are effectively vented upwards and out of the building. Cracks or gaps in the liner disrupt the draft, leading to inefficient combustion, back-drafting of smoke and fumes, and potential carbon monoxide poisoning. Inefficient draft can also result in increased fuel consumption and reduced heating system performance. Corrective measures, such as flue liner repair or replacement, are essential for optimizing draft and ensuring safe and efficient operation of the heating appliance. A properly sized and installed liner can significantly improve draft and reduce the risk of back-drafting.

- Compliance with Building Codes and Regulations

Adherence to local building codes and regulations often mandates the presence and proper maintenance of a flue liner. Many jurisdictions in New Jersey require that chimneys serving fuel-burning appliances have a code-compliant liner in good condition. Failure to comply with these regulations can result in fines or the requirement to perform costly upgrades. Routine inspections and timely repairs ensure that the flue liner meets all applicable standards, preventing legal complications and ensuring the safety of the building and its occupants. For example, a home inspection may reveal a non-compliant or damaged liner, requiring immediate remediation before a property sale can be completed.

The multifaceted role of the flue liner in protecting structural integrity, preventing fires, maintaining draft efficiency, and ensuring code compliance underscores its significance in the context of chimney maintenance. Routine inspections and timely remediation of any liner damage are paramount for ensuring the safe and efficient operation of chimneys throughout New Jersey. Addressing flue liner issues promptly mitigates the risks associated with combustion byproducts, fire hazards, and structural deterioration, safeguarding both property and occupants.

4. Water Damage Prevention

The infiltration of water stands as a primary catalyst for deterioration within chimney structures, thereby necessitating proactive water damage prevention measures as a critical component of chimney maintenance in New Jersey. The porous nature of brick and mortar allows for water absorption, which, through cycles of freezing and thawing, expands and contracts, leading to cracking, spalling, and eventual structural compromise. Addressing sources of water entry is therefore not merely cosmetic but fundamental to extending the lifespan and ensuring the safe operation of a chimney system. Improperly sealed chimney caps, damaged flashing around the chimney base, and deteriorating chimney crowns all serve as potential entry points for water, accelerating the degradation process and increasing the need for structural rehabilitation. For example, a chimney lacking a functional cap is directly exposed to precipitation, leading to water saturation of the interior flue and masonry, which can cause significant damage over time.

Effective water damage prevention strategies integrated into chimney repair protocols encompass several key elements. Installing a properly sized and durable chimney cap prevents direct precipitation entry while allowing for adequate ventilation. Replacing or repairing damaged flashing creates a watertight seal between the chimney and the roof, preventing water from seeping into the surrounding structure and causing rot. Applying a water repellent sealant to the exterior masonry can further mitigate water absorption, although it is crucial to select a breathable sealant that allows moisture vapor to escape, preventing internal damage. Regular inspections to identify and address potential sources of water intrusion are also essential. Consider a scenario where damaged flashing allows water to penetrate the roof sheathing around the chimney. Left unchecked, this can lead to extensive rot and structural damage, requiring costly repairs to both the chimney and the roof itself.

In conclusion, water damage prevention constitutes an indispensable element of responsible chimney maintenance, directly impacting structural integrity, safety, and longevity. Implementing proactive measures to mitigate water infiltration, such as installing chimney caps, repairing flashing, and applying water repellent sealants, significantly reduces the need for extensive repairs and protects against potentially hazardous conditions. Recognizing the profound impact of water on chimney structures and prioritizing preventative measures is paramount for property owners seeking to ensure the long-term health and safe operation of their chimney systems throughout New Jersey.

5. Crown Structure Stability

The crown, the uppermost portion of a chimney, serves as a protective barrier, preventing water intrusion into the chimney structure. Deterioration of the crown compromises this protective function, leading to accelerated decay of the underlying masonry and necessitating chimney repair. Crown structure stability is therefore intrinsically linked to the overall health and longevity of the chimney, making its inspection and maintenance a critical component of comprehensive chimney repair services. Failure to address cracks, crumbling, or complete disintegration of the crown can result in significant water damage, which in turn weakens the mortar joints and brickwork, potentially leading to structural collapse. A real-life example is a chimney with a severely cracked crown allowing rainwater to saturate the flue lining and masonry. Over time, this saturation causes the mortar to erode, leading to instability and requiring extensive brick replacement alongside crown reconstruction.

The practical significance of understanding the relationship between crown stability and necessary repairs lies in preventing costly and extensive remediation. Regular inspections, ideally performed annually, allow for the early detection of crown damage, enabling timely and cost-effective repairs. Small cracks can be sealed with appropriate patching compounds, while more extensive damage may require resurfacing or complete crown replacement. Ignoring these early signs of deterioration invariably leads to more significant problems, potentially requiring a complete chimney rebuild. The selection of appropriate materials for crown repair is also crucial, with concrete mixes designed for exterior use and resistance to freeze-thaw cycles being essential for long-term performance. The dimensions and slope of the crown must also be carefully considered to ensure proper water runoff and prevent ponding, which can further exacerbate deterioration.

In summary, crown structure stability is a foundational element of chimney health, directly impacting its resistance to water damage and overall structural integrity. Addressing crown damage through timely and appropriate repairs is essential for preventing more extensive and costly remediation. The proactive inspection and maintenance of the crown, utilizing suitable materials and construction techniques, is a critical component of ensuring the long-term safety and functionality of chimneys in New Jersey. Challenges in maintaining crown stability often stem from exposure to harsh weather conditions and the gradual degradation of materials over time, highlighting the importance of ongoing monitoring and preventative measures.

Frequently Asked Questions

The following addresses common inquiries regarding the upkeep of masonry structures used for venting combustion byproducts. Understanding these points facilitates informed decisions concerning maintenance and remediation.

Question 1: What are the primary indicators that a chimney requires professional repair?

Observable signs include spalling or crumbling brick, cracked or missing mortar joints, water leaks within the firebox or around the chimney base, visible creosote buildup within the flue, and the presence of damaged or missing chimney caps. A professional inspection is recommended to definitively assess the chimney’s condition.

Question 2: How often should a chimney be inspected, even if no apparent damage is present?

Industry best practices dictate that chimneys undergo annual inspections by qualified professionals. This proactive approach enables early detection of minor issues, preventing their escalation into more significant and costly repairs.

Question 3: What potential hazards arise from neglecting necessary chimney repairs?

Deferred maintenance can lead to a range of serious consequences, including carbon monoxide leaks into the living space, increased risk of chimney fires, structural damage to the chimney and surrounding building elements, and compromised efficiency of heating appliances.

Question 4: What factors influence the cost of chimney repair services?

Several variables impact the total expense, including the extent of the damage, the type of repair required (e.g., repointing, flue liner replacement, crown repair), the accessibility of the chimney, and the prevailing labor rates within the region.

Question 5: Are all chimney repair contractors equally qualified?

No. It is crucial to verify that any prospective contractor possesses the necessary certifications, licenses, and insurance coverage to perform chimney repair work in compliance with local building codes and industry standards. Requesting references and reviewing past project portfolios is also advisable.

Question 6: What preventative measures can be taken to extend the lifespan of a chimney?

Implementing preventative measures includes scheduling regular inspections and cleanings, ensuring proper chimney cap installation, addressing water leaks promptly, utilizing appropriate fuel types in fireplaces or stoves, and avoiding the burning of treated or painted wood.

Prioritizing preventative maintenance and addressing repair needs promptly are essential for ensuring the safety and longevity of these structures.

The following section will outline the procedure to select appropriate contractors with “chimney repair nj” keyword.

The Imperative of Diligent Chimney Maintenance in New Jersey

The foregoing exploration underscores the critical importance of proactive and comprehensive chimney maintenance within the state. Structural integrity, operational safety, and regulatory compliance are inextricably linked to the diligent assessment and remediation of deterioration. Neglecting these aspects invites potential hazards, escalates repair costs, and compromises property value.

Given the inherent risks associated with compromised ventilation systems, property owners should prioritize regular inspections and engage qualified professionals to address any identified deficiencies. Consistent vigilance and timely intervention remain the most effective strategies for safeguarding property and ensuring the well-being of occupants.