Ceramic or terracotta structures designed to extend a chimney above the roofline and enhance its function, frequently available through retail channels, serve as both practical components of a venting system and architectural embellishments. These items, offered in a variety of designs and materials, provide a means to improve draft and prevent downdrafts within a chimney, thereby ensuring efficient combustion and minimizing the risk of smoke entering the building.

The utilization of these rooftop fixtures provides several advantages. Improved draft leads to more effective removal of combustion byproducts, reducing the potential for carbon monoxide buildup. The extended height can also minimize the impact of wind conditions on chimney performance. Furthermore, these architectural elements contribute to the aesthetic appeal of a building, often reflecting historical or regional design preferences. Their enduring presence on structures throughout history underscores their continued relevance and functional value.

The subsequent sections will delve into the materials commonly used in their construction, the diverse range of styles available, and the critical factors to consider when selecting the appropriate size and design for a specific application. These considerations are paramount to ensuring both optimal performance and compatibility with the existing architectural style of the building.

Guidance on Selection and Procurement

The following guidance assists in the selection and proper procurement of chimney extensions. Careful consideration of these factors is crucial for ensuring optimal performance and integration with existing structures.

Tip 1: Material Suitability. Evaluate the material composition relative to the climate. Terracotta offers aesthetic appeal but may be susceptible to freeze-thaw damage in colder regions. Metal alloys provide durability and weather resistance, requiring careful assessment of corrosion potential based on fuel type.

Tip 2: Dimensional Accuracy. Precise measurements of the chimney flue are imperative prior to purchase. Internal diameter must align precisely to ensure secure mounting and prevent exhaust leakage. Discrepancies can compromise draft efficiency and create hazardous conditions.

Tip 3: Design Compatibility. Select a design that complements the architectural style of the building. Period-specific designs, such as Victorian or Georgian styles, should be carefully matched to maintain historical authenticity. Modern designs may be more suitable for contemporary structures.

Tip 4: Draft Optimization. Consider the impact of design on draft performance. Taller structures and specific cap designs can enhance draft, especially in areas prone to downdrafts. Research the aerodynamic properties of different designs to select the most appropriate option.

Tip 5: Regulatory Compliance. Confirm adherence to local building codes and regulations pertaining to chimney height, design, and installation. Failure to comply can result in fines and necessitate costly modifications.

Tip 6: Professional Installation. Engage a qualified professional for installation. Improper installation can compromise structural integrity, impede draft, and create fire hazards. Verify installer credentials and insurance coverage prior to engaging their services.

Tip 7: Inspection and Maintenance. Conduct regular inspections to identify any signs of damage or deterioration. Cracks, chips, or loose components should be addressed promptly to prevent further degradation and ensure continued safe operation. Schedule professional chimney sweeps to maintain optimal draft and reduce creosote buildup.

Adherence to these guidelines will facilitate informed decision-making, ensuring the acquisition of an appropriate and effectively functioning chimney extension. This proactive approach minimizes risks and maximizes the longevity and performance of the venting system.

These preparatory measures are vital for a successful outcome, leading to the final considerations for long-term maintenance and safety protocols discussed later in this discourse.

1. Material Composition

The selection of materials for chimney pots significantly influences their longevity, performance, and aesthetic integration with the building. The composition dictates resistance to weathering, thermal stress, and the corrosive byproducts of combustion.

- Terracotta Durability and Aesthetic Appeal

Terracotta, a clay-based ceramic, offers a traditional aesthetic and moderate resistance to heat. However, its porous nature can lead to cracking in freeze-thaw climates due to water absorption. Specific formulations and firing processes can improve its durability, making it suitable for regions with milder winters. Its availability in various shapes and glazes contributes to its popularity for historically accurate restorations and decorative installations.

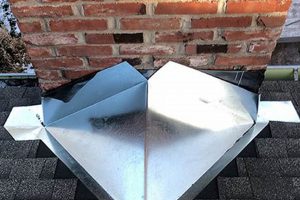

- Metal Alloys: Corrosion Resistance and Thermal Stability

Metal alloys, such as stainless steel or copper, offer superior resistance to thermal stress and corrosion from flue gases. Stainless steel provides excellent durability and is suitable for various fuel types, including those that produce acidic condensates. Copper exhibits exceptional corrosion resistance but is more expensive and can develop a patina over time. The thermal stability of metal alloys ensures structural integrity under high-temperature conditions, crucial for efficient venting.

- Concrete: Cost-Effectiveness and Structural Strength

Concrete chimney pots offer a cost-effective alternative for applications where aesthetic concerns are secondary. Reinforced concrete provides substantial structural strength and resistance to weathering. However, concrete is susceptible to cracking due to thermal expansion and contraction, requiring careful design and installation to minimize stress. Its weight can also pose challenges during installation, necessitating specialized equipment and structural support.

- Hybrid Materials: Balancing Properties and Costs

The combination of different materials aims to balance performance characteristics and costs. For example, a terracotta pot with a stainless steel liner can provide the aesthetic appeal of terracotta with the corrosion resistance of stainless steel. Similarly, a concrete base with a metal flue offers structural support and weather resistance at a lower cost than a fully metal option. These hybrid designs represent a practical compromise for specific applications and budgets.

The choice of material for chimney pots involves a careful evaluation of environmental conditions, fuel type, budget, and aesthetic preferences. Understanding the properties of each material is essential for selecting a product that delivers optimal performance, longevity, and visual appeal. The material directly impacts the lifespan and maintenance requirements of the installation.

2. Design Variety

The diversity in design of chimney pots significantly influences the aesthetics of a building and, consequently, the value proposition associated with chimney pots available for purchase. Design considerations extend beyond mere ornamentation, impacting functionality and historical accuracy.

- Historical Styles

Chimney pot designs often reflect specific historical periods, such as Victorian, Georgian, or Tudor styles. These designs are characterized by distinct shapes, embellishments, and materials. For example, Victorian-era chimney pots frequently feature intricate detailing and complex geometries, while Georgian designs tend to be simpler and more symmetrical. The selection of a historically accurate design is crucial for maintaining the architectural integrity of period buildings, influencing market demand and pricing.

- Functional Designs

Beyond aesthetics, design influences the performance of a chimney pot. Conical shapes and wind-deflecting cowls are incorporated to improve draft and prevent downdrafts, enhancing combustion efficiency and minimizing smoke intrusion. The effectiveness of these functional designs impacts their desirability, especially in regions with challenging weather conditions. Such models often command a premium due to their enhanced utility.

- Material-Specific Designs

The design options available are constrained by the material used in construction. Terracotta allows for intricate molding and glazing, while metal alloys are better suited for simpler, more geometric forms. The material dictates the design possibilities, affecting the aesthetic outcome and influencing the selection process for consumers. The aesthetic limitations and advantages of differing materials contribute to the overall design variety in the market.

- Customization Options

Increasingly, manufacturers offer customization options, allowing customers to specify dimensions, materials, and decorative elements. This trend caters to niche markets and specific architectural requirements, expanding the range of available designs. Customization drives innovation and provides consumers with greater control over the final product, impacting purchase decisions and overall satisfaction.

The wide array of designs available underscores the multifaceted role of these components, extending from purely functional considerations to significant aesthetic contributions. This design variety caters to diverse architectural styles and performance requirements, shaping the market landscape for chimney pots and influencing purchasing decisions.

3. Flue Diameter

Flue diameter constitutes a critical parameter in the context of chimney pots, influencing both the functional efficiency and the safe operation of venting systems. The selection of chimney pots necessitates precise matching of the flue diameter to ensure optimal performance and prevent potential hazards. Discrepancies in these dimensions can compromise draft, increase the risk of backdrafting, and lead to inefficient combustion.

- Matching for Optimal Draft

The internal diameter of the chimney pot must align with the flue’s diameter to facilitate efficient evacuation of combustion gases. A mismatch can create turbulence, impeding the natural draft and causing incomplete combustion. Consider a scenario where a pot with a smaller diameter is installed on a larger flue; this constriction reduces airflow, potentially leading to smoke spillage into the dwelling.

- Preventing Condensation Issues

Inadequate flue diameter can exacerbate condensation problems, particularly in high-efficiency heating systems. If the flue is too large for the appliance, exhaust gases cool excessively, leading to condensation of water vapor and corrosive acids. This condensate can damage the chimney structure and reduce its lifespan. Chimney pot selection, therefore, must account for the appliance’s BTU output and the flue’s venting capacity to minimize condensation.

- Enhancing Safety and Compliance

Building codes and safety standards often dictate minimum flue diameters based on the type of appliance being vented. Proper sizing ensures compliance with these regulations, reducing the risk of carbon monoxide poisoning and chimney fires. Ignoring flue diameter specifications during chimney pot selection can result in code violations, fines, and potential safety hazards.

- Impact on Cost and Installation

The flue diameter influences the cost and complexity of chimney pot installation. Non-standard flue sizes may require custom-made pots or adapters, increasing the overall expense. Furthermore, improper installation due to mismatched diameters can necessitate costly repairs and modifications. Accurate measurement and specification of flue diameter are essential for cost-effective and safe installations.

The interconnection between flue diameter and chimney pot selection emphasizes the importance of precise measurements and informed decision-making. Overlooking this critical parameter can lead to performance issues, safety risks, and financial burdens. A comprehensive understanding of flue diameter’s impact is paramount for ensuring the efficient and safe operation of any venting system utilizing a chimney pot.

4. Height Specifications

Height specifications for chimney pots represent a crucial determinant in both their functionality and regulatory compliance. The appropriate height, when considering chimney pots available for purchase, directly impacts draft efficiency, smoke dispersion, and overall safety. Adherence to established guidelines is paramount for ensuring optimal performance and mitigating potential hazards.

- Minimum Height Above Roofline

Building codes typically stipulate minimum height requirements for chimneys above the roofline. This regulation aims to ensure adequate draft and prevent downdrafts caused by wind turbulence. For instance, a chimney must extend at least two feet above any portion of the roof within ten feet horizontally. The availability of chimney pots of varying heights allows compliance with these regulations, ensuring proper venting and minimizing the risk of smoke re-entering the building.

- Impact on Draft Efficiency

The height of a chimney pot influences the natural draft, which is the upward movement of air within the chimney. Taller chimney pots generally promote a stronger draft, facilitating more efficient removal of combustion gases. This is particularly relevant in areas with frequent wind or obstructions that can impede airflow. When considering chimney pots for purchase, specifiers should evaluate the draft requirements of the appliance and select a height that optimizes venting performance.

- Influence of Nearby Obstructions

Nearby structures, trees, or topographical features can affect the airflow around a chimney. Building codes often mandate increased chimney height to mitigate the effects of these obstructions. For example, a chimney located near a taller building may need to extend above that building’s roofline to ensure adequate draft. The availability of extended-height chimney pots addresses this need, providing solutions for installations where surrounding obstructions pose a challenge.

- Material and Structural Considerations

The height of a chimney pot influences its structural stability and the required material strength. Taller pots are subject to greater wind loads and require robust construction to withstand these forces. The choice of material, such as terracotta or metal, must account for the height specifications and the expected environmental conditions. Therefore, height considerations directly impact material selection and the overall durability of chimney pots offered for purchase.

In summary, height specifications play a pivotal role in the selection and installation of chimney pots. These specifications directly affect draft efficiency, regulatory compliance, and structural integrity, emphasizing the need for careful consideration during the procurement process. Understanding the interplay between height requirements and the available options ensures the selection of a chimney pot that effectively meets both functional and safety standards.

5. Regulatory Compliance

Regulatory compliance constitutes a critical aspect of chimney pot procurement and installation. Adherence to relevant codes and standards ensures both safety and operational efficiency, impacting the range of chimney pots legally available for purchase and their permitted applications.

- Building Codes and Chimney Height

Local building codes often specify minimum chimney height requirements to ensure adequate smoke dispersion and prevent downdrafts. These codes influence the permissible height of chimney pots offered for sale and necessitate that installations comply with established standards. For instance, a specific jurisdiction may require a chimney to extend at least two feet above any portion of a roof within ten feet horizontally, directly affecting the selection of chimney pots based on their height.

- Material Standards and Fire Safety

Regulations frequently mandate the use of specific materials that meet fire safety standards. Chimney pots must be constructed from materials that can withstand high temperatures and resist degradation from flue gases. Compliance with standards such as ASTM C315 (Standard Specification for Clay Flue Linings) ensures that the materials used in chimney pots meet minimum performance requirements, influencing the types of chimney pots that manufacturers can legally market and sell.

- Emissions Regulations and Draft Efficiency

Emissions regulations may indirectly impact chimney pot design by influencing draft efficiency requirements. Chimney pots that enhance draft can improve combustion efficiency, reducing emissions of pollutants. Regulatory bodies may establish performance criteria that chimney pots must meet to contribute to overall emissions reduction, thereby shaping the market for high-performance chimney pots designed to optimize venting.

- Historic Preservation Guidelines

In historic districts, regulations often dictate the allowable designs and materials for chimney pots to preserve architectural authenticity. These guidelines restrict the types of chimney pots that can be used in historical buildings, influencing the availability of historically accurate reproductions and limiting the use of modern designs. Compliance with historic preservation guidelines ensures that chimney pot installations are consistent with the architectural character of the area.

The interplay between regulatory compliance and chimney pot selection underscores the importance of understanding applicable codes and standards before making a purchase. Adherence to these regulations ensures safety, optimizes performance, and preserves architectural integrity, shaping the market dynamics and availability of chimney pots for various applications.

6. Installation Costs

Installation costs represent a significant component of the overall expense associated with procuring chimney pots. These costs are influenced by several factors, including the complexity of the installation process, the accessibility of the chimney, and regional labor rates. For instance, replacing a standard chimney pot on a readily accessible roof might involve minimal labor charges. Conversely, installing a custom-designed pot on a chimney requiring specialized scaffolding or rigging can substantially elevate the total expenditure. Therefore, when evaluating chimney pots offered for sale, the upfront purchase price represents only a fraction of the ultimate investment. Ignoring these associated installation costs can lead to budgetary miscalculations and project delays.

The structural integrity of the existing chimney significantly impacts installation costs. If the chimney requires repairs or reinforcement before a new pot can be installed, these additional services will increase the overall project budget. Older chimneys, in particular, may exhibit deterioration requiring extensive masonry work. Geographic location also plays a role, as labor rates and material costs can vary considerably between regions. Securing multiple quotes from qualified contractors is essential to accurately assess installation costs, enabling informed decisions based on comprehensive financial projections. Failure to account for these variables can result in unexpected expenses and project overruns.

In conclusion, installation costs are inextricably linked to the economic considerations surrounding chimney pots. They are not merely ancillary charges but rather integral components of the total investment. A thorough understanding of the factors influencing these costs, coupled with diligent planning and professional consultation, is crucial for ensuring cost-effective and successful project outcomes. The comprehensive evaluation of chimney pots for sale must, therefore, encompass a detailed assessment of anticipated installation expenses to avoid unforeseen financial burdens.

7. Longevity Expectations

Longevity expectations represent a critical purchase determinant when evaluating chimney pots. The anticipated lifespan of these components directly impacts long-term cost-effectiveness and maintenance schedules. Customers selecting from “chimney pots for sale” implicitly consider the relationship between initial investment and the period over which the pot will reliably function. A longer lifespan reduces replacement frequency and associated labor costs, while shorter lifespans necessitate more frequent interventions, increasing overall expense. Material selection is the primary driver of longevity, with terracotta, for example, exhibiting varying degrees of resistance to freeze-thaw cycles and flue gas corrosion compared to stainless steel. A customer purchasing a terracotta pot in a region with severe winters should have different longevity expectations than one purchasing a stainless-steel variant in a mild climate. The failure to align expectations with material properties can result in premature degradation and the need for costly replacements.

The operational environment significantly influences longevity. Chimneys venting high-efficiency appliances producing acidic condensate may experience accelerated deterioration compared to those serving traditional wood-burning fireplaces. Furthermore, proper installation and regular maintenance, including chimney sweeps and inspections, contribute substantially to extending the lifespan of chimney pots. Neglecting maintenance can exacerbate material degradation and shorten the functional period, regardless of initial material quality. For instance, creosote buildup in chimneys venting wood-burning stoves can accelerate corrosion of the pot, particularly those constructed from less durable materials. Conversely, proactive maintenance, such as applying protective coatings, can prolong the lifespan of even more susceptible materials. The correlation between maintenance practices and longevity expectations is, therefore, undeniable.

In conclusion, longevity expectations are inseparable from the economic and practical considerations surrounding chimney pots. Material selection, operational environment, and maintenance practices jointly determine the actual lifespan of these components. Aligning expectations with these factors is crucial for maximizing value, minimizing long-term costs, and ensuring the safe and efficient operation of venting systems. Manufacturers and retailers have a responsibility to provide transparent information regarding material properties and expected lifespans under varying operating conditions to enable informed purchasing decisions. The long-term performance and reliability of chimney pots directly impact customer satisfaction and the overall cost of home ownership.

Frequently Asked Questions Regarding Chimney Pots

The following questions and answers address common inquiries and concerns regarding chimney pots, their selection, installation, and maintenance. This information aims to provide clarity and facilitate informed decision-making.

Question 1: What factors determine the appropriate chimney pot size?

The internal flue diameter dictates the appropriate chimney pot size. The pot’s diameter must precisely match the flue’s to ensure optimal draft and prevent backdrafting. Furthermore, local building codes may specify minimum chimney height requirements based on roof pitch and nearby obstructions, influencing the pot’s overall height.

Question 2: Which materials offer the greatest longevity in harsh climates?

Stainless steel and certain high-fired terracotta formulations provide superior resistance to freeze-thaw cycles and corrosive flue gases. Stainless steel offers exceptional durability and is suitable for various fuel types. Properly treated terracotta can withstand moderate temperature fluctuations but may require periodic sealing to prevent water absorption.

Question 3: How can chimney pot installation costs be minimized?

Obtain multiple quotes from qualified contractors. Ensure the existing chimney structure is sound to avoid costly repairs. Select a standard-size chimney pot to avoid custom fabrication charges. Proper planning and accurate measurements can prevent installation errors and subsequent rework.

Question 4: Are permits required for chimney pot installation?

Local building codes dictate permit requirements. Inquire with the municipal building department to determine if a permit is necessary for chimney pot replacement or new installation. Failure to obtain required permits can result in fines and necessitate removal of the non-compliant installation.

Question 5: How often should a chimney pot be inspected?

Chimney pots should be visually inspected annually for cracks, spalling, or deterioration. Professional chimney sweeps can assess the condition of the pot and the overall chimney structure during routine cleanings. Early detection of damage can prevent costly repairs and maintain safe operation.

Question 6: What maintenance practices extend chimney pot lifespan?

Regular chimney sweeps remove creosote and debris that can corrode chimney pot materials. Applying protective coatings can seal terracotta pots against water absorption. Promptly repairing any cracks or damage prevents further degradation. Addressing moisture issues within the chimney system minimizes the risk of freeze-thaw damage.

This information provides a foundation for understanding key considerations related to chimney pots. Proper selection, installation, and maintenance are crucial for ensuring safe and efficient venting systems.

The subsequent discussion explores strategies for effectively comparing prices across different vendors, assisting in securing the most cost-effective solution.

Chimney Pots for Sale

The preceding discussion has elucidated critical aspects surrounding “chimney pots for sale”, ranging from material properties and design considerations to regulatory compliance and cost factors. A thorough understanding of these elements empowers stakeholders to make informed procurement decisions, aligning product selection with specific performance requirements and budgetary constraints. Rigorous evaluation of flue diameter, height specifications, and installation complexities is paramount for ensuring safe and efficient venting systems.

The proper selection and maintenance of these components constitutes a vital investment in both structural integrity and occupant safety. It is incumbent upon property owners and construction professionals to prioritize informed decision-making, thereby mitigating risks associated with substandard materials or improper installation practices. Further research and consultation with qualified professionals are encouraged to optimize chimney performance and ensure long-term durability. Prioritize safety and compliance with local regulations and don’t forget to measure correctly.