A vertical structure extending above a roofline, typically constructed of brick, stone, or metal, designed to vent gases and fumes from a building’s interior, can exist independently of a traditional hearth. This venting system provides a dedicated pathway for exhausting byproducts of combustion or other internal processes, even without an open fireplace. For instance, it can serve as an outlet for a furnace, water heater, or other appliance requiring exhaust ventilation.

Such a structure facilitates the safe and efficient removal of potentially harmful substances, contributing to improved indoor air quality and preventing the buildup of dangerous gases like carbon monoxide. Historically, these structures predate widespread central heating systems, initially serving individual stoves or ovens. Their ongoing utility lies in their adaptability to various venting needs beyond traditional wood-burning fireplaces, offering a reliable and code-compliant solution for diverse residential and commercial applications.

The subsequent sections will delve into the specifics of design considerations, materials selection, maintenance requirements, and relevant building codes pertaining to such installations. Further discussion will address the different types of appliances typically connected, troubleshooting common issues, and exploring alternative venting strategies where applicable.

Essential Considerations

This section provides crucial insights into the planning, construction, and maintenance associated with a venting system absent a traditional fireplace. These guidelines are designed to ensure safety, efficiency, and regulatory compliance.

Tip 1: Code Compliance is Paramount: Always consult local building codes and regulations prior to installation. These codes specify acceptable materials, required clearances, and proper venting techniques to guarantee safe operation.

Tip 2: Proper Sizing is Critical: The dimensions of the flue must be appropriately sized for the connected appliance. Undersized flues can lead to incomplete combustion and carbon monoxide buildup; oversized flues can result in draft issues and condensation.

Tip 3: Material Selection Matters: Choose materials rated for the specific application. Stainless steel is often preferred for its corrosion resistance, particularly with high-efficiency appliances that produce acidic condensate. Consider the temperature rating and chemical compatibility of the materials with the exhaust gases.

Tip 4: Regular Inspections are Essential: Conduct annual inspections to identify potential problems such as cracks, blockages, or deterioration. Address any issues promptly to prevent hazards and maintain optimal performance.

Tip 5: Cap it Properly: Install a suitable chimney cap to prevent rain, snow, and debris from entering the flue. A cap also helps to prevent downdrafts and nesting animals from obstructing the vent.

Tip 6: Professional Installation Recommended: Unless possessing extensive experience, engage a qualified professional for installation and significant repairs. Improperly installed venting systems can pose serious safety risks.

Tip 7: Maintain Clearances: Adhere to recommended clearances from combustible materials. Proper insulation and firestopping techniques are vital to prevent fire hazards.

By adhering to these essential considerations, individuals can ensure the safe, efficient, and compliant operation of venting systems within structures.

The following section will cover common issues and their possible solutions, to ensure longetivity and optimal performance.

1. Venting Appliance Exhaust

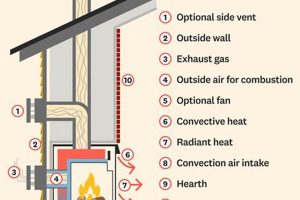

The practice of venting appliance exhaust via a dedicated structure, absent a traditional fireplace, represents a fundamental aspect of building safety and functionality. Such a configuration is common in modern construction, providing a designated channel for the safe removal of combustion byproducts and other potentially hazardous fumes generated by various appliances.

- Combustion Byproduct Removal

The primary role is the safe and efficient removal of combustion byproducts, such as carbon monoxide, nitrogen oxides, and particulate matter, produced by fuel-burning appliances. Furnaces, water heaters, and generators frequently rely on these systems. Failure to properly vent these gases can lead to dangerous indoor air quality and potential health risks, including carbon monoxide poisoning.

- Appliance-Specific Venting Requirements

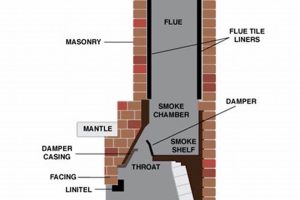

Different appliances necessitate different venting specifications. High-efficiency furnaces, for example, produce acidic condensate that requires corrosion-resistant venting materials like stainless steel or specialized plastics. Gas-fired appliances require properly sized flues to ensure adequate draft and prevent backdrafting, which can force exhaust gases back into the living space. Proper venting design considers the BTU input of the appliance, vent height, and local climate conditions.

- Draft Control and Backdraft Prevention

Maintaining adequate draft is crucial for the proper function of the exhaust system. Insufficient draft can result in incomplete combustion and the accumulation of dangerous gases. Backdrafting, where exhaust gases flow back into the building, poses a significant health hazard. Design elements such as chimney height, flue size, and the presence of a chimney cap contribute to effective draft control and backdraft prevention. Barometric dampers can also be used to regulate draft and prevent excessive pressure variations.

- Code Compliance and Safety Standards

The design and installation of appliance venting systems are governed by strict building codes and safety standards. These codes specify acceptable materials, installation practices, and inspection requirements to ensure safe operation. Adherence to these codes is essential to prevent fire hazards, carbon monoxide poisoning, and other potential dangers. Regular inspections by qualified professionals are recommended to verify code compliance and identify any potential issues.

These considerations highlight the criticality of understanding appliance venting requirements in structures where a traditional fireplace is absent. The proper selection, installation, and maintenance of venting systems are paramount for ensuring occupant safety, preserving indoor air quality, and complying with relevant regulations. The system serves as a critical safety component of the building’s infrastructure.

2. Structural Integrity Paramount

The longevity and safe operation of a structure designed solely for venting exhaust, absent a traditional fireplace, hinge critically on its structural integrity. As this construction lacks the reinforcement often provided by a hearth and fireplace assembly, the materials and methods used in its construction must withstand environmental stressors and operational demands independently. Deterioration of the structure compromises its capacity to contain and direct exhaust gases effectively, potentially leading to hazardous leaks, structural collapse, and impaired venting performance. A compromised structure can expose building occupants to dangerous fumes and necessitates costly repairs or complete reconstruction.

For example, consider a metal venting structure exposed to prolonged freeze-thaw cycles. Without adequate weatherproofing and robust material composition, the metal can corrode and develop cracks, creating pathways for exhaust leakage. Similarly, brick or masonry structures, if not properly reinforced and maintained, can suffer from mortar erosion, leading to instability and potential collapse. The absence of a fireplace, typically a significant structural element, shifts the entire burden of stability onto the independent chimney structure. Consequently, foundational stability, resistance to wind loads, and the integrity of the flue lining become even more critical.

Therefore, ensuring paramount structural integrity in a “chimney no fireplace” scenario requires meticulous attention to material selection, construction practices, and ongoing maintenance. Regular inspections for cracks, corrosion, or other signs of deterioration are essential. Addressing these issues proactively prevents more significant structural problems and maintains the critical function of safely venting exhaust gases. The inherent vulnerability of such systems underscores the importance of prioritizing structural robustness from initial design through the entire lifespan of the structure.

3. Material Compatibility Crucial

In structures employing a venting system without a fireplace, material compatibility assumes heightened significance. The absence of the buffering and moderating effects of a traditional hearth exposes the venting structure to more direct and potentially corrosive exhaust conditions. Therefore, the interaction between the exhaust gases and the chimney’s constituent materials directly dictates the system’s longevity, safety, and performance. Incompatibility leads to accelerated degradation, increasing the risk of leaks, structural failure, and hazardous emissions. For instance, using standard mortar with high-efficiency appliances can result in rapid deterioration due to the acidic condensate produced, a consequence avoided in a fireplace system where the flue gases are hotter and drier. The lack of a fireplace shifts the onus entirely to the materials to resist chemical attack.

Selecting appropriate materials requires a comprehensive understanding of the specific appliances being vented and the composition of their exhaust. Natural gas furnaces, oil-burning systems, and wood stoves each produce different byproducts necessitating unique material considerations. Stainless steel is often favored for its resistance to corrosion from acidic condensates, while refractory materials are crucial for high-temperature applications involving solid fuels. Improper material selection results in premature failure, necessitating costly repairs and potentially posing significant safety hazards. A real-world example involves the use of single-wall vent pipes with condensing furnaces; the corrosive condensate quickly eats through the metal, leading to leaks and potentially carbon monoxide intrusion. Proper installation entails using double-walled, corrosion-resistant venting specifically designed for condensing appliances.

Ultimately, material compatibility in a venting structure lacking a fireplace serves as a critical safeguard against system failure and ensures the safe and efficient removal of exhaust gases. The understanding of exhaust composition, appliance-specific requirements, and material properties is paramount. Prioritizing material compatibility not only extends the lifespan of the venting system but also protects building occupants from potential health hazards, solidifying its role as a fundamental consideration in design and installation practices. The selection process requires a proactive assessment of potential chemical interactions to prevent long-term degradation.

4. Draft Requirements Critical

The absence of a traditional fireplace fundamentally alters the dynamics of airflow within a chimney, rendering adherence to stringent draft requirements unequivocally critical. In systems where a hearth is present, the fire itself contributes significantly to establishing and maintaining an adequate draft. Without this thermal assist, the chimney relies solely on the design and external environmental factors to ensure proper venting of exhaust gases. Insufficient draft results in incomplete combustion, carbon monoxide accumulation, and potential backdrafting, posing severe health risks to building occupants. The chimney’s effectiveness in removing harmful byproducts is directly proportional to the adequacy of the draft it provides. For instance, a furnace connected to an improperly sized structure experiences reduced efficiency and increased wear, shortening its lifespan and escalating energy costs. Conversely, an optimally designed and maintained structure ensures safe and efficient appliance operation.

The design considerations influencing draft in a “chimney no fireplace” scenario are multifaceted. Chimney height, flue diameter, geographical location, and prevailing wind conditions all play a significant role. Taller chimneys generally generate stronger drafts due to increased buoyancy of the hot exhaust gases. Flue diameter must be appropriately sized for the connected appliance; undersized flues restrict airflow, while oversized flues can lead to cooling of the gases and subsequent draft reduction. Furthermore, factors such as proximity to tall buildings or trees can negatively impact draft by creating downdrafts. The selection of a suitable chimney cap becomes particularly crucial to prevent wind-induced downdrafts and precipitation from entering the flue. Building codes mandate specific draft requirements for various appliances to ensure safe and efficient operation, necessitating careful calculations and adherence to established guidelines during the design and installation phases. These codes often specify minimum chimney heights and flue diameters based on appliance BTU input and local climate conditions.

In summary, the absence of a fireplace elevates the importance of precise draft management within a chimney system. Insufficient draft jeopardizes safety and efficiency, while proper draft control ensures reliable and effective venting. Addressing this challenge requires a comprehensive understanding of airflow dynamics, meticulous design practices, and adherence to stringent building codes. Prioritizing draft requirements mitigates risks associated with incomplete combustion, carbon monoxide exposure, and structural damage, ultimately safeguarding the well-being of building occupants and preserving the integrity of the building’s ventilation system. Achieving optimal draft necessitates a holistic approach, considering all relevant factors from chimney design to appliance selection and routine maintenance.

5. Code Compliance Mandated

The configuration of a venting system independent of a fireplace is directly and inextricably linked to mandated code compliance. The absence of a traditional hearth, which provides inherent structural and venting characteristics, necessitates rigorous adherence to building codes to ensure safety and performance. Codes dictate material specifications, installation methods, and inspection protocols, all of which are essential in mitigating risks associated with improper venting. The absence of a fireplace requires a more exacting approach to ensuring the system functions safely and efficiently, making code compliance not merely a suggestion but a legal and ethical imperative.

Real-life instances highlight the consequences of neglecting code compliance. Improperly sized flues, for example, can lead to incomplete combustion and carbon monoxide buildup, a potentially fatal outcome. The use of non-approved materials may result in premature degradation and structural failure, necessitating costly repairs and posing fire hazards. Furthermore, inadequate clearance from combustible materials can initiate fires, endangering both property and lives. The practical significance lies in proactively preventing these adverse outcomes through meticulous adherence to code requirements. Compliance often involves obtaining permits, undergoing inspections, and employing qualified professionals who are knowledgeable about local regulations. This ensures that the venting system meets or exceeds minimum safety standards, safeguarding occupants from potential hazards.

In summary, mandated code compliance serves as the bedrock upon which safe and effective “chimney no fireplace” installations are built. The absence of a traditional hearth amplifies the need for rigorous adherence to regulations governing materials, installation, and maintenance. Neglecting code compliance invites significant risks, whereas prioritizing it ensures occupant safety, structural integrity, and long-term system performance. This underscores the critical role of building codes in establishing a baseline for safe and reliable venting systems in the absence of a conventional fireplace.

6. Maintenance Minimizes Hazards

A direct correlation exists between diligent maintenance practices and hazard mitigation in venting systems lacking a traditional fireplace. The absence of a hearth amplifies the criticality of routine inspections and upkeep. Without the inherent heat dissipation and structural support of a fireplace, these dedicated venting structures are more susceptible to degradation, blockages, and subsequent hazards. Debris accumulation, such as leaves, nests, or creosote buildup, can obstruct the flue, leading to incomplete combustion and carbon monoxide intrusion into the building. Structural issues, like cracks or mortar deterioration, compromise the system’s integrity, potentially resulting in gas leaks and structural instability. Regular maintenance, therefore, serves as a proactive measure to identify and address these potential problems before they escalate into dangerous situations. This preventive approach minimizes the risk of fire, carbon monoxide poisoning, and costly repairs.

Examples of maintenance practices illustrating this connection include annual inspections by qualified professionals. These inspections involve assessing the structural integrity of the chimney, checking for blockages, and evaluating the condition of the flue lining. Cleaning the flue removes accumulated debris, ensuring proper airflow and reducing the risk of chimney fires. Repairing cracks and deteriorating mortar prevents gas leaks and structural collapse. Installing a chimney cap prevents the entry of rain, snow, and animals, further reducing the likelihood of blockages. These proactive steps directly translate to a safer and more efficient venting system. Conversely, neglecting maintenance leads to a gradual accumulation of problems, increasing the potential for catastrophic failure and associated hazards. A lack of upkeep on a chimney connected to a gas furnace, for example, can result in carbon monoxide backdrafting due to a blocked flue, posing a serious health risk to the occupants. The practical significance lies in the ability of consistent maintenance to avert these potentially life-threatening scenarios.

In summation, the “chimney no fireplace” configuration necessitates a heightened awareness of the direct link between maintenance and hazard minimization. The absence of a hearth’s mitigating factors places greater emphasis on proactive upkeep to ensure safe and efficient operation. Routine inspections, cleaning, and repairs are essential components of a comprehensive maintenance strategy. By prioritizing these practices, building owners and occupants can significantly reduce the risk of fire, carbon monoxide poisoning, and structural failures, thereby safeguarding their well-being and protecting their property. This proactive approach underscores the importance of viewing maintenance not as a reactive measure but as a critical investment in safety and long-term system performance.

Frequently Asked Questions

The following addresses common inquiries regarding venting systems operating independently of a traditional fireplace. These questions aim to clarify misconceptions and provide concise, factual information about their function and maintenance.

Question 1: Is a structure designed for venting, absent a fireplace, inherently less stable than one incorporating a hearth?

Not necessarily. Stability depends on design, materials, and adherence to building codes. Structures lacking a hearth necessitate a more robust independent design to compensate for the absence of integrated support.

Question 2: What appliances typically utilize a chimney structure when a fireplace is not present?

Common appliances include furnaces (gas, oil, or propane), water heaters, boilers, and sometimes generators. The specific appliance dictates venting requirements and compatible materials.

Question 3: How often should a venting system without a fireplace undergo professional inspection?

Annual inspections are recommended. More frequent inspections may be warranted in cases of suspected malfunctions or identified issues.

Question 4: What are the most common signs of a malfunctioning venting system independent of a fireplace?

Common signs include unusual odors, soot accumulation around appliances, increased condensation, and appliance malfunction. The presence of a carbon monoxide detector is crucial as many malfunctions are undetectable without specialized equipment.

Question 5: Can any type of material be used for constructing a structure intended solely for venting?

No. Material selection is dictated by building codes and the specific exhaust gases being vented. Stainless steel, refractory materials, and certain plastics are common choices, depending on the application.

Question 6: Does the absence of a fireplace affect home insurance premiums related to venting structures?

Potentially. Insurance providers may consider the type and condition of the venting system when determining premiums. Maintaining a well-maintained and code-compliant system can positively influence insurance rates.

In summary, understanding the unique requirements of structures dedicated to venting, without the presence of a fireplace, is crucial for ensuring safety and efficiency. Regular maintenance, code compliance, and appropriate material selection are paramount.

The next section will explore troubleshooting common issues encountered in these specialized venting configurations.

Chimney No Fireplace

The preceding discussion has explored the intricacies of venting systems designed independently of a traditional fireplace. Key considerations have been highlighted, encompassing structural integrity, material compatibility, draft requirements, code compliance, and the paramount importance of consistent maintenance. These elements coalesce to ensure the safe and efficient removal of combustion byproducts, safeguarding building occupants from potential hazards. The functional demands placed upon a “chimney no fireplace” structure are unique, necessitating a heightened awareness of design specifications and operational best practices. A departure from these guidelines can result in compromised performance and increased risks.

The continued reliance on these specialized venting systems underscores their critical role in modern building infrastructure. Proper installation and adherence to established safety protocols are non-negotiable. Further research and technological advancements will undoubtedly refine venting system designs, enhancing their efficiency and safety. Building professionals and homeowners alike must remain informed and committed to upholding the highest standards in the design, installation, and maintenance of these essential components of a building’s mechanical systems, therefore ensuring a sustainable and safe environment for all.