A device consisting of a camera attached to a flexible rod or cable, often with its own light source, allows visual assessment of the internal condition of a flue. This equipment enables the identification of blockages, deterioration, or other potential hazards that would otherwise be inaccessible without destructive measures.

Using this tool ensures comprehensive safety checks and preventative maintenance, mitigating fire risks and improving heating system efficiency. Historically, physical dismantling was required for internal examination; current technology offers a less intrusive and more cost-effective method for evaluating flue integrity.

The subsequent discussion will explore the types of equipment available, common findings during assessments, and best practices for utilizing this technology effectively. It will also address the qualifications needed to conduct professional evaluations and the reporting of observations.

Inspection Guidance

This section outlines several recommendations for effective flue assessment using specialized visual equipment.

Tip 1: Acquire Proper Equipment. Ensure that the selected equipment has sufficient cable length to reach the entire flue, adequate lighting for clear image capture, and a high-resolution camera for detailed visual assessment.

Tip 2: Conduct a Pre-Inspection Assessment. Before insertion, visually inspect the exterior of the chimney and interior fireplace or appliance connections for obvious signs of damage or deterioration. Note any pre-existing conditions.

Tip 3: Utilize Appropriate Insertion Techniques. Carefully introduce the camera into the flue, avoiding forceful maneuvers that could damage the equipment or the chimney lining. Use a smooth, controlled motion.

Tip 4: Document All Observations. Maintain a detailed record of the assessment, including still images and video footage of any anomalies, such as cracks, blockages, or signs of deterioration. Note the location and severity of each issue.

Tip 5: Implement a Systematic Inspection Pattern. Follow a consistent pattern, such as a spiral or grid, to ensure that the entire internal surface of the chimney is thoroughly inspected. Overlapping coverage prevents omissions.

Tip 6: Calibrate Equipment Regularly. To maintain accuracy and reliability, adhere to the manufacturer’s guidelines for calibration and maintenance of the assessment equipment.

Tip 7: Understand Potential Findings. Become familiar with common types of chimney deterioration, such as creosote buildup, spalling, and flue liner damage, to accurately identify and assess the severity of observed conditions.

Proper implementation of these recommendations will contribute to a more thorough and accurate assessment of flue integrity, ultimately enhancing safety and preventing potential hazards.

The following sections will address training requirements and documentation protocols for professional inspections.

1. Visual Access

Visual access is the foundational capability enabled by a chimney inspection camera. The technology overcomes the inherent limitations of direct human observation within the confined and often obscured interior of a chimney flue. Prior to the widespread adoption of this technology, assessments relied heavily on external observations, limited internal probes, and, in many cases, destructive methods to gain a comprehensive understanding of the flue’s condition. The device offers real-time visual data where previously there was only inferred information. For example, a homeowner experiencing drafting issues may have suspected a blockage, but without visual access, the precise nature and location of the obstruction (e.g., a bird’s nest, accumulated debris, or a collapsed liner section) remained unknown.

The use of an imaging device equipped with internal lighting and a flexible probe allows for detailed inspection without the need for dismantling chimney components. This reduces the time and expense associated with assessments and minimizes the disruption to the building. For instance, when selling a property, a home inspector can quickly and non-destructively assess the condition of the chimney, providing potential buyers with valuable information about its structural integrity and operational safety. Furthermore, by providing clear visual evidence, the equipment facilitates more informed decision-making regarding repairs or preventative maintenance.

In summary, visual access, facilitated by a assessment tool, transforms assessment from a process of educated guesswork into one of direct observation. It promotes accuracy, reduces costs, and empowers property owners and professionals with the necessary data to ensure chimney systems are both safe and efficient. The challenges lie in ensuring the equipment is properly operated and the visual data is accurately interpreted, highlighting the need for trained and qualified inspection personnel.

2. Flue Integrity

Flue integrity, the unimpaired structural and functional condition of a chimney’s internal lining, is inextricably linked to the application of a chimney inspection camera. Degradation in flue integrity, caused by factors such as thermal stress, chemical corrosion from combustion byproducts, or physical damage, directly compromises the chimney’s ability to safely vent exhaust gases. This compromise creates potential hazards including carbon monoxide intrusion into the living space and increased risk of chimney fires due to creosote accumulation within damaged or improperly sealed liners. The assessment camera provides the crucial capability to visually assess the internal condition of the flue, identifying breaches, cracks, or other defects that would otherwise remain undetected.

The use of a assessment device enables targeted interventions to maintain or restore flue integrity. For example, upon identifying a cracked clay liner during an assessment, a professional can recommend relining the chimney with a stainless-steel liner, thereby restoring its structural integrity and preventing further deterioration. Similarly, the technology can detect mortar joint erosion between flue tiles, allowing for timely repairs that prevent dangerous gas leaks. Furthermore, insurance companies increasingly rely on inspection reports generated using such tools to assess risk and determine coverage for chimney-related incidents.

Therefore, the relationship between flue integrity and the assessment tool is characterized by a cycle of assessment, diagnosis, and remediation. The assessment device provides the means to accurately assess flue integrity; compromised integrity prompts corrective actions; and these actions, informed by the initial assessment data, serve to restore and maintain the chimney’s safe and efficient operation. Challenges remain in ensuring that inspections are conducted by qualified personnel who can accurately interpret the visual data and recommend appropriate remedies. The continued advancement of camera technology further enhances the ability to detect and address subtle but significant threats to flue integrity.

3. Hazard Detection

Hazard detection is a primary function facilitated by chimney inspection cameras. These devices enable the identification of potential dangers within a chimney system that are not readily apparent through external observation. The presence of creosote buildup, a highly flammable byproduct of combustion, represents a significant fire hazard. Cameras allow for the visual assessment of creosote accumulation, determining its extent and composition, which directly informs the appropriate course of action, such as professional cleaning or chemical treatment. Similarly, structural damage, such as cracks or spalling within the flue liner, compromises the chimney’s ability to safely vent exhaust gases, increasing the risk of carbon monoxide intrusion into the building. The tool identifies these structural deficiencies, allowing for timely repairs and preventing potentially life-threatening situations.

The practical application of a inspection system in hazard detection extends beyond identifying immediate threats. Regular assessments enable proactive maintenance, preventing the escalation of minor issues into major hazards. For instance, early detection of water damage can prevent costly structural repairs and mitigate the risk of mold growth within the chimney system. In cases of suspected chimney blockage, such as from animal nests or debris accumulation, the camera provides a clear visual confirmation, allowing for targeted removal efforts. By providing a comprehensive view of the chimney’s interior, these inspection tools empower professionals to make informed decisions regarding safety and maintenance, minimizing risks and ensuring the proper functioning of the system.

Ultimately, the effectiveness of hazard detection relies on the operator’s skill and experience in interpreting the visual data acquired by the camera. While the device provides valuable insight, accurate diagnosis and appropriate action require a thorough understanding of chimney systems and potential hazards. Challenges remain in ensuring that inspections are conducted by qualified professionals and that inspection reports are clear and actionable. The development of more advanced assessment technology, incorporating image analysis software and automated defect recognition, holds the potential to further enhance the accuracy and efficiency of hazard detection, contributing to improved safety and reduced risk.

4. Creosote Buildup

Creosote buildup represents a significant fire hazard in chimney systems. The degree of accumulation and type of creosote directly correlate to the risk of chimney fires. A chimney inspection camera serves as the primary tool for assessing creosote levels, informing subsequent maintenance decisions.

- Visual Identification

Assessment tools enable the visual identification of creosote within a chimney flue. Varying formations from light, flaky deposits to hard, glazed layers are distinguishable via camera imagery. For example, a level one creosote deposit, appearing as a thin, easily removable layer, presents a lower fire risk than a level three glazed deposit, which adheres tightly to the flue walls and requires specialized removal techniques.

- Quantitative Assessment

While visual identification determines the type of creosote, a competent professional also assesses the quantity. The equipment provides a means to estimate the thickness and extent of the creosote accumulation within the flue. A chimney exhibiting creosote buildup exceeding one-quarter inch warrants immediate attention due to the increased risk of a chimney fire.

- Risk Evaluation

Data collected by a chimney inspection system informs risk evaluation. Factors considered include the type and amount of creosote, the chimney’s construction, and the homeowner’s burning habits. For example, a chimney serving a wood stove used frequently during winter months is more susceptible to rapid creosote accumulation. This risk evaluation determines the frequency of future inspections and cleanings.

- Documentation and Reporting

Cameras facilitate the documentation and reporting of creosote findings. Photographic or video evidence provides a clear record of the chimney’s condition before and after cleaning. These records serve as a valuable reference for future assessments and can be used to demonstrate compliance with safety regulations. For example, insurance companies may request inspection reports as part of a homeowner’s insurance policy.

Through visual identification, quantitative assessment, risk evaluation, and detailed reporting, a chimney inspection system serves as an indispensable tool in mitigating the hazards associated with creosote buildup, ensuring the safe and efficient operation of chimney systems. Ongoing advancements in imaging technology promise to further enhance the accuracy and effectiveness of creosote assessment.

5. Structural Damage

Structural damage to a chimney system poses significant risks to both property and occupants. Detection of such damage often requires specialized equipment due to the confined and obscured nature of chimney flues. Assessment tools provide a crucial means of identifying and evaluating structural defects, enabling timely repairs and preventing further deterioration.

- Flue Liner Cracks and Spalling

Cracks and spalling (surface disintegration) of the flue liner compromise its ability to contain combustion byproducts. A camera can visualize these defects, revealing their extent and severity. For instance, a vertical crack extending the length of a flue tile significantly increases the risk of carbon monoxide leakage into the building. Similarly, spalling can reduce the effective diameter of the flue, impeding draft and promoting creosote accumulation.

- Mortar Joint Deterioration

Deterioration of mortar joints between flue tiles or masonry units weakens the structural integrity of the chimney. The equipment enables the assessment of mortar joint condition, identifying erosion, cracking, or complete loss of mortar. Compromised mortar joints allow for air infiltration, reducing draft efficiency, and create pathways for hot gases to escape, potentially igniting adjacent combustible materials.

- Water Damage and Corrosion

Water penetration, whether from rain, snow, or condensation, accelerates the deterioration of chimney components. Cameras can detect signs of water damage, such as efflorescence (salt deposits) on masonry surfaces, rust on metal components, and staining or rotting of adjacent wood structures. Prolonged exposure to moisture weakens the chimney structure and promotes corrosion of metal liners and connectors.

- Chimney Crown Degradation

The chimney crown, a concrete or masonry cap at the top of the chimney, protects the chimney structure from water intrusion. Cracks, crumbling, or complete loss of the crown allows water to penetrate the chimney, leading to internal damage. Cameras facilitate the inspection of the crown, identifying these defects and enabling timely repairs to prevent further deterioration.

Effective assessment of structural damage using imaging tools requires a thorough understanding of chimney construction principles and common failure mechanisms. Accurate diagnosis and appropriate corrective actions are essential to ensure the safety and longevity of chimney systems. Regular assessments, coupled with prompt repairs, mitigate the risks associated with structural damage and preserve the functional integrity of the chimney.

6. Preventative Maintenance

Preventative maintenance, characterized by proactive measures taken to avert potential problems, is intrinsically linked to the utilization of a chimney inspection camera. The technology facilitates early detection of issues, allowing for timely interventions that prevent costly repairs and potential hazards.

- Early Defect Detection

The primary role of this tool in preventative maintenance lies in its ability to detect defects that are not readily visible through external inspection. For instance, minor cracks in a flue liner, if left unaddressed, can propagate over time, leading to significant structural damage and compromising the chimney’s ability to safely vent exhaust gases. A chimney inspection camera allows for the early identification of such cracks, enabling prompt repairs that prevent further deterioration.

- Creosote Management

Regular assessments using a visual aid device enable proactive creosote management. By visually assessing creosote buildup, homeowners or professionals can determine the need for cleaning before dangerous levels are reached. The imaging tool provides a means to assess the type and quantity of creosote, allowing for informed decisions regarding cleaning methods and frequency, minimizing the risk of chimney fires.

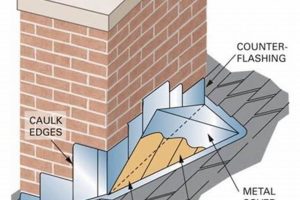

- Water Intrusion Prevention

Water intrusion poses a significant threat to chimney systems, accelerating deterioration and promoting corrosion. The assessment camera can identify sources of water intrusion, such as cracks in the chimney crown or damaged flashing. Addressing these issues proactively prevents water damage, extending the lifespan of the chimney and minimizing costly repairs.

- System Efficiency Optimization

Preventative maintenance, facilitated by the assessment tool, optimizes the efficiency of the entire heating system. By identifying and addressing issues such as flue blockages or damaged dampers, airflow can be improved, leading to more efficient combustion and reduced fuel consumption. The tool enables a comprehensive assessment of the system’s performance, allowing for targeted interventions that maximize efficiency and minimize energy costs.

In summary, the integration of inspection technology into a preventative maintenance program enhances the longevity, safety, and efficiency of chimney systems. Early defect detection, creosote management, water intrusion prevention, and system efficiency optimization collectively contribute to a proactive approach that minimizes risks and maximizes the lifespan of chimney infrastructure. Consistent assessment and prompt remedial action are crucial to ensuring the continued safe operation of these systems.

7. Equipment Calibration

Equipment calibration is a critical process for ensuring the accuracy and reliability of data obtained using a chimney inspection camera. Without proper calibration, the measurements and observations made during an assessment may be skewed, leading to inaccurate diagnoses and potentially unsafe outcomes. Therefore, adherence to calibration protocols is paramount for maintaining the integrity of inspection results.

- Image Clarity and Resolution

Calibration ensures that the camera provides images with sufficient clarity and resolution for accurate identification of defects. For example, a miscalibrated camera may produce blurry or distorted images, making it difficult to discern fine cracks in a flue liner or accurately assess the extent of creosote buildup. Regular calibration maintains the camera’s focus, color balance, and image stabilization, optimizing visual data acquisition.

- Distance Measurement Accuracy

Certain chimney assessment tools are equipped with distance measurement capabilities, allowing inspectors to quantify the size of defects or the distance to obstructions within the flue. Calibration is essential to ensure that these measurements are accurate. For instance, an uncalibrated distance measurement tool may overestimate the width of a crack, leading to unnecessary repairs. Calibration against known standards verifies the accuracy of distance measurements, providing reliable data for decision-making.

- Light Source Intensity and Color Temperature

The intensity and color temperature of the camera’s light source can significantly impact the appearance of the chimney’s interior. Calibration ensures that the light source provides consistent and accurate illumination, preventing misinterpretations of surface features. For instance, a light source with an incorrect color temperature may alter the perceived color of creosote, leading to an inaccurate assessment of its composition. Calibration procedures verify the light source’s output, ensuring consistent and reliable visual data.

- Data Logging and Storage Integrity

Many assessment tools incorporate data logging and storage capabilities, allowing inspectors to record images, videos, and measurements for later analysis and reporting. Calibration ensures that the stored data is accurate and free from corruption. For example, a miscalibrated data logging system may introduce errors into the recorded measurements, compromising the integrity of the inspection report. Calibration procedures verify the accuracy of the data logging system and the integrity of the storage media, ensuring reliable data preservation.

The outlined calibration facets emphasize its role in guaranteeing precise and dependable chimney inspections. Consistent adherence to established calibration protocols is not only a matter of best practice but also a fundamental element in upholding safety standards and ensuring the structural soundness of chimney systems. Ultimately, the validity and trustworthiness of inspections hinge directly on the rigor and regularity of calibration procedures.

Frequently Asked Questions

This section addresses common inquiries regarding the use and benefits of assessment tools for chimney inspections.

Question 1: What constitutes a valid reason for employing a chimney inspection camera?

A visual assessment is warranted whenever there is a suspicion of internal damage, blockage, or deterioration within a chimney flue. Additionally, it is advisable before relining a chimney, after a chimney fire, or when connecting a heating appliance to an existing flue. Periodic inspections are recommended as part of routine maintenance.

Question 2: What types of defects are typically detectable with a chimney inspection camera?

This equipment can identify various issues, including flue liner cracks, spalling, deteriorated mortar joints, creosote buildup, blockages from debris or animal nests, and water damage. The device allows for a comprehensive internal assessment of the flue’s condition.

Question 3: Can a homeowner conduct a chimney inspection using this technology, or is a professional required?

While homeowners can purchase assessment devices, professional expertise is generally recommended. Accurate interpretation of the visual data requires a thorough understanding of chimney construction, potential hazards, and applicable safety codes. Misinterpretation can lead to improper repairs or overlooked safety concerns.

Question 4: How often should a chimney inspection be performed using a camera?

Industry best practices recommend an annual inspection, particularly for chimneys connected to wood-burning appliances. More frequent inspections may be necessary if there are known issues or if the appliance is used heavily.

Question 5: Does a chimney inspection camera replace the need for a physical chimney sweep?

No. The device provides a visual assessment of the chimney’s condition. A chimney sweep physically removes creosote and debris, ensuring proper airflow and reducing fire hazards. Visual assessment often precedes or follows a chimney sweep’s services.

Question 6: Are there specific certifications or qualifications required to operate a chimney inspection camera professionally?

While specific certifications may vary by region, organizations such as the Chimney Safety Institute of America (CSIA) offer certifications for chimney sweeps and inspectors. These certifications demonstrate a commitment to professional standards and expertise in chimney safety and inspection practices.

The assessment tool is a valuable diagnostic instrument, but expertise and experience are necessary for correct interpretation and informed decision-making.

The subsequent section will focus on Technological Advancement.

Conclusion

This exploration has demonstrated the crucial role of “chimney inspection camera” in ensuring the safety and efficiency of chimney systems. The ability to visually assess internal conditions, identify potential hazards, and facilitate preventative maintenance is paramount. Adherence to calibration protocols and competent interpretation of data are crucial for accurate diagnoses.

Continued technological advancements in imaging and assessment capabilities promise to further enhance the effectiveness of “chimney inspection camera” technology. Rigorous application of inspection protocols by qualified professionals remains essential for mitigating risks and safeguarding properties. Proactive assessment is vital for maintaining chimney system integrity.