A structure combining the visual appeal of a traditional hearth with the convenience of gas fuel, designed with a specific venting system, is the subject of this exploration. This assembly typically features a firebox where natural gas or propane is combusted to produce flames, and a dedicated passageway for safely expelling combustion byproducts. This venting pathway is crucial for directing exhaust gases away from the living space. An example would be a pre-fabricated metal firebox installed within a brick surround, connected to a metal flue that extends through the roof.

Such heating systems offer several advantages including ease of use, consistent heat output, and reduced maintenance compared to solid fuel-burning alternatives. Historically, these configurations represent an evolution in residential heating technology, offering a cleaner and more controllable source of warmth. Their contribution to indoor environmental quality and user convenience has made them a popular choice in modern home design.

The following discussion will delve into the different types of venting systems available, explore considerations for safe and efficient operation, and examine relevant building codes and inspection procedures. Topics such as installation best practices and troubleshooting common issues will also be addressed, providing a thorough understanding of this heating appliance.

Essential Guidance for Optimal Performance

The following recommendations are intended to ensure the safe and efficient operation of systems combining the allure of a traditional hearth with the practicality of gas fuel. Adherence to these guidelines is paramount for user safety and longevity of the appliance.

Tip 1: Schedule Annual Inspections. A certified professional should conduct a thorough examination annually. This includes inspection of the burner, gas connections, venting system, and overall structural integrity. Neglecting this can lead to carbon monoxide leaks or fire hazards.

Tip 2: Maintain Adequate Ventilation. Ensure proper airflow within the room where the unit is installed. Obstruction of vents or sealing off the room can impede combustion and increase the risk of carbon monoxide poisoning.

Tip 3: Regularly Clean the Glass. The glass front can accumulate soot and residue, diminishing the flame’s visibility and potentially affecting heat radiation. Use a cleaner specifically designed for fireplace glass, following the manufacturer’s instructions.

Tip 4: Monitor Flame Appearance. A healthy flame should be blue with slight yellow tips. An orange or sooty flame indicates incomplete combustion, suggesting a need for professional servicing or adjustment of the gas-air mixture.

Tip 5: Replace the Pilot Light Thermocouple. The thermocouple, responsible for keeping the pilot light lit, has a limited lifespan. If the pilot light frequently goes out, replacing the thermocouple is often the solution.

Tip 6: Understand the Venting System. Be aware of the type of venting system utilized (direct vent, B-vent, or vent-free). Modifications or obstructions to the venting system are strictly prohibited and pose significant safety risks.

Tip 7: Keep Combustible Materials Clear. Maintain a safe distance between the unit and any combustible materials, such as furniture, curtains, or decorations. Consult the manufacturer’s specifications for recommended clearances.

By adhering to these recommendations, the lifespan and safety of the equipment can be significantly extended. Prioritizing safety and routine maintenance ensures sustained enjoyment and peace of mind.

The subsequent sections will provide further detail on troubleshooting common issues and interpreting relevant safety codes, ensuring a comprehensive understanding of this type of heating appliance.

1. Venting System Integrity

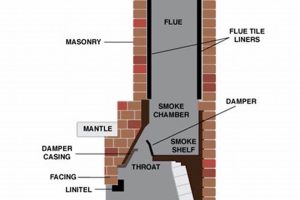

The performance and safety of a chimney gas fireplace are inextricably linked to the integrity of its venting system. This system is specifically designed to expel combustion byproducts, including carbon monoxide, water vapor, and other potentially harmful gases, from the living space. A compromised venting system can lead to a dangerous accumulation of these byproducts within the dwelling, posing a significant health risk to occupants.

Consider a scenario where corrosion weakens a section of the chimney flue. This weakening can create breaches, allowing exhaust gases to seep into adjacent rooms. Similarly, obstructions within the chimney, such as bird nests or accumulated debris, can impede the flow of exhaust, leading to backdrafting and the introduction of combustion byproducts into the home. Regular inspections and maintenance are crucial to identify and address these issues promptly. For example, a homeowner who neglects annual chimney inspections might be unaware of a developing crack in the flue liner, resulting in gradual carbon monoxide exposure over time. The proper installation and selection of vent materials are also important, as using incorrect materials can lead to accelerated corrosion and failure.

Therefore, ensuring the ongoing integrity of the venting system is not merely a matter of appliance maintenance, but a critical safety measure for protecting the well-being of occupants. Regular professional inspections, prompt repairs, and adherence to building codes are essential for maintaining a safe and efficiently functioning chimney gas fireplace system. Failing to prioritize venting system integrity can have severe, even life-threatening, consequences.

2. Gas Line Connections

The integrity of gas line connections is fundamentally linked to the safe operation of a chimney gas fireplace. These connections, typically employing threaded fittings or specialized connectors, facilitate the delivery of natural gas or propane from the supply line to the appliance’s burner. A compromised connection, such as a loose fitting or corroded pipe, can lead to a gas leak, creating a significant risk of fire or explosion. The absence of properly tightened unions can disrupt the flow and create an environment prone to disastrous events. A faulty connection introduces raw fuel into the surrounding air, potentially reaching explosive concentrations and igniting in the presence of a spark or open flame. Therefore, rigorous installation practices, regular inspections, and the use of appropriate sealing compounds are paramount.

Beyond the immediate safety concerns, gas line connections influence the efficiency of the unit. A minor leak may not pose an immediate hazard but can result in wasted fuel and increased utility costs. Inadequate gas pressure, caused by undersized pipes or partially obstructed connections, can result in improper combustion and reduced heat output. An installer might mistakenly employ the wrong diameter for the gas line, thus not allowing the burner to operate at its design capacity, producing insufficient heat or causing the appliance to malfunction over time. Consequently, adherence to manufacturer specifications and local building codes is essential for ensuring both safety and optimal performance.

In summary, gas line connections represent a critical interface in the operation of a chimney gas fireplace. Their proper installation and maintenance are not merely procedural steps, but crucial safeguards against potential hazards and contributors to efficient performance. Recognizing the potential consequences of compromised connections, regular inspections and prompt repairs, performed by qualified professionals, are essential for responsible ownership of this type of appliance.

3. Combustion Air Supply

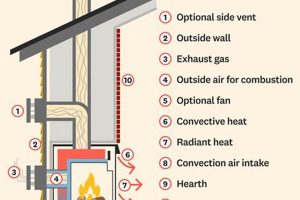

An adequate supply of combustion air is essential for the safe and efficient operation of a chimney gas fireplace. This air provides the necessary oxygen for the complete combustion of natural gas or propane within the firebox. Without sufficient oxygen, the combustion process becomes incomplete, leading to the production of carbon monoxide, a colorless and odorless gas that poses a serious health risk. Furthermore, inadequate combustion air can result in reduced heating efficiency and the accumulation of soot within the chimney.

- The Role of Oxygen in Combustion

Oxygen serves as a crucial reactant in the chemical process of combustion. During combustion, hydrocarbons in the fuel (natural gas or propane) react with oxygen to produce heat, water vapor, and carbon dioxide. If the oxygen supply is limited, incomplete combustion occurs, resulting in the formation of carbon monoxide and unburned hydrocarbons. For example, a sealed room with insufficient ventilation will lead to incomplete combustion in a fireplace, resulting in a hazardous buildup of carbon monoxide.

- Sources of Combustion Air

Combustion air can be sourced from various locations, including the surrounding room, dedicated outdoor air ducts, or a combination of both. The specific source depends on the fireplace design and local building codes. For example, a direct-vent fireplace draws combustion air directly from outside through a coaxial vent system, while a traditional natural-vent fireplace relies on air from within the room. Blocked air vents or improperly sealed rooms can drastically reduce the availability of combustion air.

- Impact on Fireplace Efficiency

An insufficient supply of combustion air reduces the overall efficiency of the fireplace. Incomplete combustion wastes fuel and generates less heat. A fireplace operating with inadequate air will exhibit a yellow or orange flame, indicating incomplete combustion, as opposed to the desired blue flame indicative of efficient burning. This inefficiency translates to higher fuel consumption and potentially increased heating costs.

- Safety Implications

The most critical implication of inadequate combustion air is the potential for carbon monoxide poisoning. Carbon monoxide is a toxic gas that can cause illness or death. Symptoms of carbon monoxide poisoning include headache, dizziness, nausea, and confusion. Properly installed and maintained carbon monoxide detectors are essential for early detection of leaks. A fireplace deprived of combustion air is a significant source of carbon monoxide, highlighting the importance of proper ventilation.

These facets underscore the critical importance of a proper combustion air supply for a chimney gas fireplace. Ensuring an adequate and consistent supply of oxygen is essential for safe, efficient, and reliable operation. Understanding these relationships allows for informed decisions regarding installation, maintenance, and operation, ultimately promoting occupant safety and maximizing the benefits of this heating appliance. Regular inspections by qualified professionals are critical for verifying adequate ventilation and preventing potential hazards.

4. Pilot Light Function

The pilot light within a chimney gas fireplace serves as a constant ignition source, essential for initiating the main burner operation. Its function is to maintain a small, continuous flame that, upon demand for heat, ignites the primary gas flow, generating the larger, visible flames within the firebox. A properly functioning pilot light ensures reliable and immediate ignition, facilitating efficient heating and eliminating the potential for gas accumulation before ignition, which could lead to a hazardous explosion. The absence of a consistent pilot flame renders the fireplace inoperable, necessitating troubleshooting and potential repair. For example, if the thermocouple fails, the pilot light will extinguish repeatedly, preventing the main burner from activating, thus hindering the fireplace’s heating capability.

The design and operation of the pilot light are integrated with safety mechanisms to prevent gas leaks. Typically, a thermocouple or thermopile is positioned within the pilot flame. This device generates a small electrical current when heated by the flame. This current, in turn, holds open the main gas valve, allowing gas to flow to the main burner. If the pilot light is extinguished, the thermocouple cools, the electrical current ceases, and the gas valve automatically closes, preventing the release of unburned gas into the home. This system illustrates a crucial safety interlock. A common example of its real-world application is when a gust of wind extinguishes the pilot light; the system shuts off the gas supply preventing potential hazards. A malfunctioning thermocouple, therefore, poses a safety risk and requires immediate attention.

In summary, the pilot light function represents a critical component of a chimney gas fireplace, both for operational reliability and safety. Its consistent flame enables immediate heat generation while its integrated safety mechanisms mitigate the risk of gas leaks. Challenges to pilot light function, such as thermocouple failure or blocked gas lines, necessitate prompt diagnosis and repair to ensure continued safe and efficient operation. Addressing these issues is fundamental to maintaining the integrity and safety of the entire heating system.

5. Flame Arrestor Condition

The flame arrestor, a safety component within a chimney gas fireplace system, mitigates the risk of flashback, a potentially hazardous event where flames propagate back through the gas supply lines. Its condition directly impacts the overall safety of the appliance. Deterioration or damage to the flame arrestor can compromise its ability to prevent flashbacks, leading to potential explosions or fires within the gas lines. For example, corrosion or physical damage to the arrestor mesh can create gaps through which flames can pass, negating its intended protective function. The material the arrestor is made of and its mechanical integrity must remain intact. Consequently, maintaining the flame arrestor in optimal condition is paramount for preventing catastrophic failures within the heating system.

The practical significance of understanding the flame arrestor’s condition extends beyond mere safety concerns. A properly functioning flame arrestor contributes to efficient and consistent gas combustion. When damaged, it may impede gas flow, leading to incomplete combustion and reduced heat output. Imagine a scenario where a partially obstructed flame arrestor restricts the gas supply to the burner; the resulting flame might be uneven and inefficient, leading to higher fuel consumption and increased levels of unburned hydrocarbons. The implication is that a poorly maintained flame arrestor not only presents a safety risk but also undermines the fireplace’s operational effectiveness. This is the reason for scheduled and regular inspections and replacements to keep the system safely operational.

In summary, the condition of the flame arrestor is a crucial aspect of chimney gas fireplace safety and performance. Its role in preventing flashback, combined with its influence on combustion efficiency, underscores the importance of regular inspections and maintenance. Addressing any signs of damage or deterioration promptly ensures the safe and efficient operation of the fireplace, protecting both the occupants and the integrity of the appliance itself. Furthermore, the design of these safety elements continues to adapt ensuring the prevention of flashbacks and the reduction of potential explosions.

6. Carbon Monoxide Detection

Effective carbon monoxide (CO) detection is intrinsically linked to the safe operation of any combustion appliance, including chimney gas fireplaces. These systems, while convenient and aesthetically pleasing, pose a potential risk of CO emission due to incomplete combustion. Therefore, reliable CO detection is not merely a recommended precaution, but a necessary safeguard against a silent and potentially lethal hazard.

- The Silent Threat: Carbon Monoxide Characteristics

Carbon monoxide is an odorless, colorless, and tasteless gas produced by the incomplete burning of carbon-based fuels. Its insidious nature makes it undetectable to human senses, allowing it to accumulate to dangerous levels without warning. In the context of a chimney gas fireplace, a malfunctioning burner, a blocked flue, or inadequate ventilation can lead to CO buildup. Without detection, occupants may experience symptoms mimicking the flu, progressing to unconsciousness and death at higher concentrations. A common scenario involves gradual CO poisoning over days or weeks due to a partially blocked chimney, with occupants attributing their symptoms to other causes.

- CO Detector Functionality and Placement

CO detectors utilize various sensing technologies, such as biomimetic sensors or electrochemical sensors, to detect the presence of CO in the air. These devices trigger an alarm when CO levels exceed a predetermined threshold, providing an audible warning to occupants. Proper placement is crucial for effective detection. Detectors should be installed on each level of the home, particularly near sleeping areas, as CO is slightly lighter than air and tends to accumulate near the ceiling. Placing a detector directly adjacent to a fireplace is not advisable, as transient, localized CO spikes during ignition could cause nuisance alarms. Regular testing and battery replacement are essential for maintaining detector functionality. A detector placed in a hallway near bedrooms offers optimal protection against CO infiltration from a faulty fireplace.

- Integration with Smart Home Systems

Modern CO detectors can be integrated with smart home systems, providing enhanced monitoring and notification capabilities. These systems can send alerts to mobile devices, allowing occupants to be notified of CO events even when they are away from home. Some advanced systems can also shut off the gas supply to the fireplace automatically upon detecting elevated CO levels, mitigating the hazard. Such integration represents a proactive approach to CO safety, offering a valuable layer of protection beyond the standard audible alarm. For example, a smart CO detector could alert homeowners to a CO leak while they are on vacation, enabling them to contact emergency services to investigate and prevent further CO buildup.

- Regulatory Compliance and Standards

Building codes and safety standards often mandate the installation of CO detectors in homes with fuel-burning appliances, including chimney gas fireplaces. These regulations aim to ensure a minimum level of CO safety. Compliance with these standards is not only a legal requirement but also a responsible practice for protecting occupants. Regular inspections of CO detectors are often included in routine home inspections, ensuring that the devices are functional and properly located. Failure to comply with these regulations can result in fines or legal liabilities in the event of a CO-related incident.

The preceding facets illustrate the vital role of carbon monoxide detection in ensuring the safe utilization of chimney gas fireplaces. Beyond the convenience and aesthetic appeal of these appliances lies an inherent risk that demands diligent monitoring and proactive safety measures. Understanding the characteristics of CO, the functionality of detectors, integration with smart home systems, and regulatory compliance is crucial for minimizing this risk and safeguarding the well-being of occupants.

Frequently Asked Questions

The following addresses prevalent inquiries regarding systems combining a firebox fueled by gas with a dedicated venting structure. The answers provided aim to clarify common misconceptions and offer guidance on safe and efficient operation.

Question 1: What are the primary advantages of a chimney gas fireplace compared to traditional wood-burning models?

Chief advantages include ease of use, consistent heat output, reduced maintenance requirements, and cleaner emissions. Gas units eliminate the need for wood storage and hauling, offer precise temperature control, and produce fewer particulate pollutants than solid-fuel alternatives.

Question 2: How often should a chimney gas fireplace be inspected by a qualified technician?

Annual inspections are recommended. A certified professional can assess the venting system, burner assembly, gas line connections, and overall safety of the unit, ensuring proper function and preventing potential hazards.

Question 3: What are the telltale signs of a carbon monoxide leak from a chimney gas fireplace?

While carbon monoxide is odorless and colorless, certain indicators suggest a potential leak. These include soot accumulation around the firebox, a persistent pilot light malfunction, and unexplained symptoms such as headaches, dizziness, or nausea among occupants.

Question 4: Are all chimney gas fireplaces vent-free?

No. The majority of chimney gas fireplaces require venting to expel combustion byproducts safely. Vent-free models exist, but their use may be restricted by local building codes, and they require careful consideration due to potential indoor air quality concerns.

Question 5: Can a chimney gas fireplace be converted to burn wood?

Generally, no. Gas fireplaces are specifically designed and constructed for gas fuel. Attempting to burn wood in a gas unit can damage the firebox, compromise the venting system, and create a significant fire hazard.

Question 6: What maintenance steps can be performed by the homeowner?

Homeowners can clean the glass front with a specialized cleaner, ensure clear ventilation around the unit, and regularly test carbon monoxide detectors. However, tasks involving gas line connections or burner adjustments should be performed by a qualified technician.

The safety and efficacy of such heating systems rely on both professional maintenance and informed user practices. Neglecting routine inspection or attempting unauthorized repairs can have serious repercussions.

The next segment will delve into the relevant safety codes and regulatory standards governing the installation and operation of such heating appliances, ensuring a comprehensive understanding of their safe and responsible use.

In Closing

The preceding discussion has explored various facets of the chimney gas fireplace, encompassing its operational principles, safety considerations, and maintenance requirements. Key points addressed include the significance of venting system integrity, the criticality of secure gas line connections, the necessity of adequate combustion air supply, and the importance of functioning safety components such as flame arrestors and carbon monoxide detectors. Regular inspections by qualified professionals were consistently emphasized as a cornerstone of safe and efficient operation.

The responsible utilization of a chimney gas fireplace demands a comprehensive understanding of its potential hazards and a commitment to adhering to safety protocols. Prudent homeowners will prioritize regular maintenance, heed warning signs of malfunction, and remain vigilant in their pursuit of a safe and comfortable home environment. The integration of knowledge and diligence remains paramount in mitigating risk and maximizing the benefits of this heating appliance.