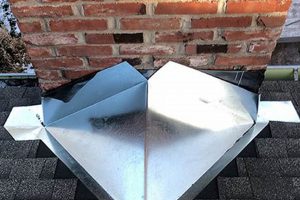

A critical component of a fireplace system, this mechanism regulates airflow within the chimney. It is typically a metal plate or valve that can be opened to allow smoke and exhaust gases to escape during a fire or closed to seal the chimney when the fireplace is not in use. Its position directly affects the efficiency and safety of the fireplace.

The function of this device is multifaceted. It prevents heat loss from the home when the fireplace is not active, thereby increasing energy efficiency and reducing heating costs. Furthermore, it prevents drafts and entry of unwanted elements such as rain, snow, and animals into the house through the chimney. Historically, inefficient designs led to significant energy wastage, prompting the development of more effective and airtight sealing solutions.

The following sections will delve into the various types of these mechanisms, their installation processes, maintenance requirements, and potential troubleshooting scenarios. A comprehensive understanding of these aspects ensures the optimal performance and longevity of the fireplace system.

Essential Usage Tips

Optimizing fireplace performance and ensuring home safety requires adherence to crucial guidelines regarding the operation of this specific component.

Tip 1: Prioritize Regular Inspection: Conduct a visual examination at least annually, ideally before the heating season. Look for signs of rust, corrosion, or damage to the metal plate and its operating mechanism. Functionality should be verified to ensure smooth opening and closing.

Tip 2: Ensure Proper Sealing: When closed, the component must create an airtight seal. A loose or warped component will allow heat to escape and drafts to enter the home. Replacement may be necessary if an adequate seal cannot be achieved.

Tip 3: Operate with Caution: Always open the component completely before starting a fire. Partial opening restricts airflow, increasing the risk of smoke backdraft into the living space and potentially leading to carbon monoxide poisoning.

Tip 4: Understand its Limitations: Realize it does not provide complete protection against all drafts and heat loss. Supplemental insulation strategies, such as chimney balloons or top-sealing components, can further enhance energy efficiency.

Tip 5: Address Sticking Issues Promptly: If the component becomes difficult to open or close, lubricate the hinges and operating mechanism with a high-temperature lubricant designed for fireplace components. Avoid forcing the mechanism, as this could cause damage.

Tip 6: Consider Professional Assistance: For complex repairs or if unsure about the component’s condition or operation, consult a qualified chimney sweep or fireplace technician. Attempting repairs without proper knowledge can lead to safety hazards.

Following these guidelines ensures safe and efficient fireplace operation, minimizes energy loss, and protects the home from potential hazards. Regular attention to this critical component is essential for any homeowner with a fireplace.

The subsequent discussion will focus on troubleshooting common problems encountered with this mechanism and provide insights into preventative maintenance strategies.

1. Airflow Regulation

The primary function of this specific component centers on airflow regulation within the chimney system. Its operation directly influences the draft, which is the movement of air through the fireplace and chimney. When open, the component allows exhaust gases and smoke to escape efficiently, preventing them from entering the living space. Conversely, a closed component restricts airflow, preventing drafts and heat loss when the fireplace is not in use. Improper regulation due to a malfunctioning or improperly positioned component can result in inefficient combustion, smoke backdraft, and potential carbon monoxide exposure.

The design of the component significantly impacts its ability to regulate airflow effectively. A properly sized and positioned plate or valve creates a relatively airtight seal when closed, minimizing heat loss. Modern designs may incorporate features such as adjustable settings to fine-tune airflow based on the fire’s intensity and prevailing weather conditions. For example, during windy conditions, a slightly restricted airflow can prevent excessive draft and rapid burning of fuel. Conversely, a fully open component is crucial during initial fire startup to establish a strong draft and prevent smoke from entering the room.

In summary, the link between airflow regulation and this particular component is integral to fireplace functionality and safety. Correct operation ensures efficient combustion, minimizes heat loss, and prevents hazardous conditions. Regular inspection and maintenance of the component are essential for maintaining optimal airflow regulation and preventing potential issues related to poor draft or smoke backdraft. This understanding contributes to the safe and efficient use of fireplaces and solid fuel-burning appliances.

2. Energy Conservation

The functional device’s contribution to energy conservation is significant. When a fireplace is not in use, an open chimney acts as a conduit for heat to escape the home. The primary mechanism in preventing this is the closure, which effectively seals the chimney flue, minimizing the upward flow of heated air and preventing cold air from entering the living space. Without a properly functioning one, substantial heat loss occurs, particularly during colder months, leading to increased energy consumption and higher heating bills. Older, ill-fitting devices are notably less effective, highlighting the importance of maintaining a tight seal.

Real-world examples demonstrate the impact on energy bills. A homeowner replacing an old, leaky device with a modern, airtight model can experience a noticeable reduction in heating costs over a winter season. Similarly, failing to close the existing component results in a perceptible drop in room temperature near the fireplace, causing the heating system to work harder to maintain a comfortable indoor climate. Additionally, its efficiency prevents drafts, reducing the need for supplementary heating measures in adjacent areas. This contributes to energy conservation and lowers overall energy consumption.

In summary, the effectiveness of this integral part is intrinsically linked to energy conservation. By minimizing heat loss and preventing drafts, it reduces the demand on heating systems, resulting in lower energy consumption and associated cost savings. Regular inspection and maintenance ensure proper functionality and sustained energy efficiency. Failing to address this fundamental consideration can lead to significant energy waste and increased environmental impact.

3. Backdraft Prevention

Backdraft, the reversal of normal airflow in a chimney, presents a significant safety hazard, potentially introducing smoke and carbon monoxide into a living space. This phenomenon often occurs when the pressure inside the chimney is lower than the pressure within the building, creating a pressure imbalance that draws air downwards. A properly functioning component plays a crucial role in backdraft prevention by controlling the airflow within the chimney, and when closed, creating a barrier against downdrafts when the fireplace is not in use. This preventative action minimizes the risk of smoke and dangerous gases entering the home.

The effectiveness of this component as a backdraft deterrent depends on its design and condition. A tightly sealing component effectively isolates the chimney from the interior of the building, preventing negative pressure from drawing air down the flue. Conversely, a damaged or improperly fitted component may fail to provide an adequate seal, allowing backdraft to occur. For example, strong winds creating negative pressure on one side of a home can exacerbate backdraft issues in chimneys with compromised sealing. Regular inspection and maintenance are essential to ensure the component functions as intended, preventing this hazardous situation.

In conclusion, the relationship between backdraft prevention and the mechanical component is critical for maintaining a safe home environment. The device, when in good working order, actively mitigates the risk of backdraft by controlling airflow and providing a barrier against negative pressure. Vigilance in inspecting and maintaining this device is paramount, ensuring the protection of occupants from the dangers of smoke and carbon monoxide intrusion caused by reversed airflow within the chimney system. This understanding provides critical foundation for safe fireplace operation.

4. Material Integrity

The functional reliability and longevity of a fireplace system hinge significantly on the material integrity of its components. Specifically, the ability of a chimney component to withstand the harsh conditions within the fluehigh temperatures, corrosive combustion byproducts, and fluctuating weather patternsdirectly affects its performance and safety. Compromised material integrity in a critical part can lead to operational failures, increased risk of fire, and the potential for carbon monoxide leaks into the dwelling. The selection of appropriate materials during manufacturing, coupled with regular inspection and maintenance, dictates the effective lifespan and safe operation of the entire fireplace apparatus.

Material degradation manifests in several ways. Rust and corrosion, particularly in components constructed from standard steel, weaken the structure, leading to warping, cracking, or complete failure. High-temperature fatigue, caused by repeated thermal cycling, can embrittle metals and compromise their ability to seal the flue effectively. Consider, for example, a warped metal piece in a cold climate: the seal is compromised, leading to an increase in heating bills and a possibility for moisture to damage the chimney structure. Regular inspection for these signs of material degradation is crucial. Replacing a damaged part before it fails entirely prevents more extensive and costly repairs down the line. Upgrading to corrosion-resistant materials, such as stainless steel, significantly extends component lifespan and enhances overall system safety.

In conclusion, the inextricable link between material integrity and the operational effectiveness of the chimney mechanism cannot be overstated. Selecting durable, heat-resistant materials during manufacturing, coupled with a diligent inspection and maintenance regime, are paramount for ensuring safe, efficient, and long-lasting fireplace operation. Prioritizing material integrity minimizes the risk of component failure, prevents hazardous conditions, and ultimately protects the inhabitants of the dwelling.

5. Operational Safety

Operational safety related to fireplace use is inextricably linked to the function and condition of a key component. This mechanism directly impacts the safe removal of combustion byproducts from the dwelling. A properly functioning component ensures smoke, carbon monoxide, and other harmful gases are efficiently vented through the chimney. Conversely, a malfunctioning, obstructed, or improperly operated component can lead to the accumulation of these dangerous substances within the living space, posing significant health risks. Strict adherence to operational guidelines and regular maintenance are paramount for safe fireplace utilization.

Examples illustrate the importance of this element. Before initiating a fire, the component must be fully opened to allow for unrestricted airflow. Attempting to burn fuel with a partially or fully closed valve creates a high risk of smoke and carbon monoxide backdraft into the room. Similarly, a damaged or corroded part that prevents a complete seal, introduces a hazard. Creosote buildup, a flammable byproduct of incomplete combustion, can accumulate on the device, increasing the risk of chimney fires. These examples highlight the critical need for visual inspection prior to each use and for regular professional cleaning to remove creosote and ensure proper operation. Ignoring these precautions can lead to life-threatening consequences.

In summary, maintaining operational safety in fireplace use demands diligent attention to this critical component. Proper operation, regular inspection, and professional maintenance are essential for mitigating the risks associated with incomplete combustion and potential backdraft. Prioritizing safety through responsible fireplace practices safeguards the health and well-being of occupants and protects the dwelling from fire hazards. A proactive approach to fireplace safety, including a thorough understanding of the device’s function and limitations, is indispensable.

6. Maintenance Schedule

A structured maintenance schedule is paramount for preserving the functionality and safety of the chimney component, ensuring its continued effectiveness in regulating airflow and preventing hazards. Adherence to a prescribed timeline for inspection, cleaning, and repair prevents premature degradation and optimizes fireplace performance.

- Annual Inspection and Assessment

A comprehensive visual inspection should be conducted annually, ideally before the onset of the heating season. This inspection entails assessing the component for signs of rust, corrosion, warping, or cracking. An example involves examining the hinge mechanism for smooth operation and ensuring the plate or valve creates a tight seal when closed. Failure to conduct this assessment may result in undetected damage, leading to operational inefficiencies or safety risks.

- Creosote Removal and Cleaning

Regular removal of creosote buildup is essential, as creosote is a highly flammable byproduct of incomplete combustion. The frequency of cleaning depends on the type of fuel burned and the frequency of fireplace use. For instance, fireplaces used frequently with softwood may require cleaning more than once per heating season. Neglecting creosote removal increases the risk of chimney fires and obstructs proper component operation, compromising its ability to regulate airflow.

- Lubrication and Mechanical Maintenance

The moving parts of the mechanism, such as hinges and levers, require periodic lubrication to ensure smooth operation. Use of a high-temperature lubricant specifically designed for fireplace components prevents sticking and binding. For example, applying lubricant to a stiff hinge allows for easier opening and closing, preventing strain on the mechanism. Insufficient lubrication can lead to increased wear and tear, potentially causing premature failure.

- Component Repair or Replacement

Based on the findings of the annual inspection, necessary repairs or replacements should be performed promptly. A warped or corroded plate or valve, for instance, must be repaired or replaced to ensure a proper seal and prevent heat loss or backdraft. Ignoring these issues can compromise the component’s functionality, leading to increased energy costs and potential safety hazards. Timely intervention prevents minor problems from escalating into more significant and costly repairs.

These facets of a maintenance schedule are interconnected and contribute to the sustained optimal performance of the fireplace and its safety. Regular adherence to the schedule ensures the component functions effectively, regulating airflow, preventing backdraft, and contributing to overall energy efficiency. Neglecting this schedule exposes the system to potential hazards and diminishes its long-term value.

7. Proper Sealing

A primary function of a flue component is to create a tight, effective seal when closed. Proper sealing directly impacts energy efficiency and prevents the entry of unwanted elements. An ineffective seal allows heated air to escape the building in cold weather, increasing heating costs. Conversely, it permits cold air, rain, snow, and debris to enter the dwelling, potentially causing damage and discomfort. This highlights its crucial role in maintaining a comfortable and energy-efficient indoor environment.

The effectiveness of the sealing action depends on several factors. The physical condition of the component itself plays a significant role; warping, rust, or damage can compromise its ability to form a tight seal against the chimney flue. The design of the sealing mechanism is also critical. Older designs may rely on a simple metal-on-metal contact, which is prone to leakage over time. Modern designs often incorporate gaskets or other sealing materials to enhance the airtightness. For instance, a home with a poorly sealed mechanism might experience noticeable drafts near the fireplace and higher-than-expected heating bills, while a well-sealed mechanism minimizes these issues.

In summary, proper sealing is an indispensable attribute, contributing directly to energy conservation, comfort, and protection against environmental elements. The effectiveness hinges on the physical condition, design, and material integrity of the device. Regular inspection and maintenance, including cleaning and replacement of worn components, are essential for preserving the sealing functionality and ensuring the benefits it provides.

Frequently Asked Questions

The following questions address common concerns regarding the operation, maintenance, and troubleshooting of the chimney flue mechanism. Clarity on these matters ensures safe and efficient fireplace usage.

Question 1: What is the primary purpose?

The primary purpose is to regulate airflow within the chimney. It is opened to allow exhaust gases to escape during a fire and closed to seal the chimney when the fireplace is not in use, preventing heat loss and drafts.

Question 2: How often should it be inspected?

It should be inspected at least annually, ideally before the heating season. Visual inspection should check for rust, corrosion, damage, and proper functionality.

Question 3: What are the signs that it is not sealing properly?

Signs of improper sealing include noticeable drafts near the fireplace, higher-than-expected heating bills, and visual gaps or damage to the component itself.

Question 4: Can a fire be started with it closed?

No. A fire should never be started with it closed. This can cause smoke and carbon monoxide to back up into the living space, posing a significant health risk.

Question 5: What type of lubricant should be used?

A high-temperature lubricant specifically designed for fireplace components should be used on moving parts. Standard lubricants may not withstand the high temperatures and could potentially create a fire hazard.

Question 6: What are the consequences of neglecting maintenance?

Neglecting maintenance can lead to component failure, increased risk of chimney fires due to creosote buildup, reduced energy efficiency, and potential carbon monoxide exposure. Regular maintenance is crucial for safety and performance.

Understanding these frequently asked questions contributes to informed decision-making regarding fireplace operation and safety. Adherence to recommended practices minimizes risks and ensures optimal performance.

The subsequent segment will delve into advanced troubleshooting techniques and detailed repair procedures.

Chimney Flue Damper

This examination has clarified the multifaceted role of the chimney flue damper. From its primary function of airflow regulation to its impact on energy conservation, backdraft prevention, and overall operational safety, the significance of this seemingly simple component cannot be overstated. Neglecting its maintenance or operation jeopardizes not only the efficiency of the fireplace system but also the well-being of the occupants.

Therefore, a commitment to responsible fireplace practices, encompassing regular inspection, diligent maintenance, and informed operation of the chimney flue damper, remains paramount. A properly functioning system ensures safe and efficient heating, mitigating potential hazards and contributing to a secure home environment. Ongoing vigilance and adherence to established guidelines are essential for preserving the integrity and longevity of this critical component.