A component designed to prevent the spread of fire through the opening around a chimney as it passes through floors, ceilings, or roofs. These devices are typically constructed of non-combustible materials and are installed to close any gaps between the chimney and the surrounding structure. For example, when a chimney is installed in a home, a specialized collar, made of steel or other fire-resistant material, is placed where the chimney penetrates the ceiling, effectively sealing the space and halting potential flame propagation.

This protective measure plays a crucial role in fire safety, limiting the potential for a house fire to rapidly spread beyond the immediate area of origin. Historically, inadequate protection around chimneys has been a significant factor in structural fires, emphasizing the importance of proper installation and maintenance of these safety features. By containing a fire within the chimney structure and preventing it from reaching combustible materials in the building’s framework, this measure enhances the overall safety and integrity of the dwelling.

The following sections will delve into specific types, installation procedures, inspection protocols, and the relevant building codes associated with these crucial fire safety components. Understanding these aspects is essential for homeowners, builders, and inspectors to ensure effective fire protection within residential and commercial buildings.

Essential Considerations for Chimney Fire Safety

The following points outline critical considerations for ensuring adequate protection against chimney fires, focusing on preventative measures and responsible maintenance.

Tip 1: Professional Installation is Paramount: Ensure that any fire-stopping materials are installed by a qualified professional familiar with local building codes and best practices. Improper installation can render the system ineffective.

Tip 2: Regular Inspection of Fire-Stopping Materials: Conduct routine visual inspections of the chimney and surrounding areas, particularly at points where the chimney passes through ceilings, floors, or the roof. Look for signs of damage, deterioration, or gaps in the fire-stopping material.

Tip 3: Utilize Approved Materials: Only use fire-resistant materials explicitly approved for use in chimney fire-stopping applications. Consult with a building inspector or fire safety expert to verify material suitability.

Tip 4: Address Gaps and Cracks Immediately: Any cracks or gaps identified in the fire-stopping material should be addressed immediately. Use appropriate fire-resistant sealant or patching compounds to restore the integrity of the barrier.

Tip 5: Maintain Adequate Clearance: Ensure that combustible materials are kept at a safe distance from the chimney. Refer to manufacturer specifications and local building codes for minimum clearance requirements.

Tip 6: Schedule Professional Chimney Sweeping: Regular chimney sweeping removes creosote buildup, a highly flammable byproduct of wood burning. This reduces the risk of a chimney fire and subsequent damage to the fire-stopping components.

Tip 7: Verify Compliance with Building Codes: Prior to using a fireplace or wood-burning stove, confirm that the installation adheres to all relevant local building codes and regulations pertaining to chimney fire safety.

Adhering to these recommendations minimizes the risk of fire propagation through the chimney structure and protects the buildings structural integrity. The investment in proper fire-stopping methods is a critical element of comprehensive fire safety planning.

The subsequent sections will explore the impact of these preventative measures on overall home safety and property value.

1. Material Selection

The selection of appropriate materials is fundamental to the effectiveness of any system designed to prevent fire spread around a chimney. The inherent fire resistance and durability of chosen components directly impact the system’s ability to contain flames and protect surrounding combustible materials. Failure to specify and utilize appropriate materials can render the entire protective measure ineffective.

- Non-Combustible Insulation Performance

The insulation component must be composed of materials classified as non-combustible, such as mineral wool or ceramic fiber blankets. These materials exhibit superior resistance to heat transfer and flame penetration compared to standard insulation, providing a crucial barrier against fire propagation. Examples include high-temperature mineral wool wraps specifically designed for chimney applications, capable of withstanding sustained exposure to extreme heat without degrading or igniting. The implications of using combustible insulation materials in chimney fire-stopping applications include rapid fire spread and structural damage.

- Fire-Rated Sealants and Mortars

Any sealants or mortars used to fill gaps or joints must possess specific fire-resistance ratings, indicating their ability to withstand prolonged exposure to flames without compromising their integrity. These materials often incorporate intumescent properties, expanding upon exposure to heat to create a tighter seal and further prevent flame penetration. For instance, specialized fire-rated caulk used around chimney penetrations forms a char barrier when heated, effectively sealing off potential pathways for fire spread. The failure to use fire-rated sealants and mortars can allow flames and hot gases to bypass the primary fire-stopping materials.

- Chimney Liner Materials and their impact

Chimney liners impact the overall safety. Damaged or deteriorated liners increase the risk of fire spreading to combustible materials surrounding the chimney chase. Stainless steel and ceramic liners are common, each with different heat resistance. For example, if a clay liner cracks, it can expose combustible materials to high heat, and start a fire. Materials must be chosen based on the chimney type and appliance connected.

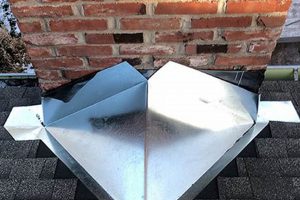

- Metal Flashing Composition

Metal flashing serves as a critical element in preventing water intrusion around the chimney, but its composition also influences its fire resistance. Materials like steel and aluminum with specific gauges provide superior protection against flame penetration and structural deformation compared to thinner, less durable metals. For example, thick-gauge steel flashing offers a robust barrier against fire, minimizing the risk of flames spreading through gaps in the roof or wall assembly. Use of improper flashing will degrade the chimney assembly over time.

The consistent theme underpinning each of these considerations is that material selection is not merely a compliance issue, but a fundamental factor in determining the long-term fire safety performance of a chimney system. The use of fire-resistant and durable materials directly influences the system’s ability to contain fires, protect structural elements, and ultimately, safeguard lives and property.

2. Proper Installation

Proper installation constitutes a non-negotiable element of an effective fire-stopping system around a chimney. The correct installation directly determines the efficacy of the system in preventing fire spread, irrespective of the quality of materials used. Improperly installed fire-stopping measures offer a false sense of security, failing to perform as intended during a chimney fire.

Consider the instance of a chimney passing through a wooden framed structure. If the fire-stopping material, such as mineral wool, is not tightly packed around the chimney and flush with the surrounding combustible materials, gaps form potential pathways for flames and hot gases. These gaps bypass the intended barrier, allowing the fire to propagate through the floor or ceiling assembly. Similarly, if fire-rated caulk is applied inadequately, leaving air pockets or incomplete seals, the protection is compromised. Correct installation procedures, as outlined in manufacturer specifications and relevant building codes, dictate precise methods for packing, sealing, and securing materials. Deviation from these prescribed methods introduces vulnerabilities that can lead to catastrophic consequences. For example, a homeowner attempting a do-it-yourself installation without the requisite knowledge and experience may unknowingly create hazardous conditions. Incorrectly applying a fire-rated sealant or using the wrong type for the temperature, or not using enough of the sealant, can lead to rapid fire propagation and significant property damage. In this case, proper professional installation can save lives and property.

In summary, the correlation between proper installation and effective chimney fire protection is direct and unequivocal. Proper installation of chimney fire stop components involves strictly adhering to the manufacturer’s guidelines. It involves selecting the correct materials, creating a fire barrier between the combustible parts of the house and the chimney to provide a means of protection against the chimney assembly. The challenges in achieving consistent installation quality underscore the need for trained professionals who can ensure compliance with building codes and best practices. Investing in professional installation is a proactive measure that significantly reduces the risk of chimney-related fires and enhances overall structural safety. The lack of attention to detail in execution can render even the most advanced fire-stopping systems virtually useless. Firestopping installation needs to be planned and executed to ensure a safe and long-lasting chimney assembly.

3. Code Compliance

Code compliance is a cornerstone of effective fire safety relating to chimney construction and operation. Building codes mandate specific requirements for chimney design, materials, and installation to mitigate the risk of fire spread. These codes establish a minimum standard of safety, reflecting lessons learned from historical fire incidents and advancements in fire protection technology. Failure to adhere to code requirements directly compromises the fire resistance of a structure, increasing the likelihood of a chimney fire escalating into a larger, more destructive event. For instance, the International Residential Code (IRC) specifies minimum clearances between a chimney and combustible materials, dictating the type and thickness of fire-stopping materials required at chimney penetrations. A real-world example illustrates this point: a house constructed without proper code compliance had reduced clearances around the chimney, leading to a smoldering fire within the wall cavity. The fire was detected late, resulting in extensive damage and highlighting the practical significance of adhering to code-mandated safety measures.

Compliance with these regulations ensures that chimneys are constructed and maintained in a manner that minimizes fire hazards. Many codes require that the chimney fire stops must be constructed of approved noncombustible material. Codes establish the height requirements above the roofline and nearby obstructions. Fire codes and standards typically specify regular inspections and maintenance schedules for chimneys, including flue cleaning to remove creosote buildup, a highly flammable byproduct of wood burning. The National Fire Protection Association (NFPA) publishes standards like NFPA 211, which provides detailed guidance on chimney construction, installation, and maintenance, often referenced in local building codes. Strict adherence to inspection protocols is vital. For example, a poorly maintained chimney with excessive creosote buildup and deteriorated fire-stopping could cause a fire to jump to nearby combustible materials if not properly mitigated.

In summary, code compliance represents a critical component of chimney fire safety. Challenges to achieving consistent compliance often stem from outdated building codes, lack of enforcement, or insufficient awareness among homeowners and contractors. Addressing these challenges requires ongoing education, rigorous enforcement of building codes, and proactive engagement from all stakeholders to promote a culture of fire safety. The benefits of adherence to code go beyond mere regulatory compliance; they directly translate into safer homes, reduced property damage, and ultimately, the preservation of lives.

4. Clearance Maintenance

Effective chimney fire protection relies heavily on maintaining adequate clearance between the chimney structure and any combustible materials within the building. This separation is a critical component of a comprehensive fire-stopping strategy. The presence of combustible materials in close proximity to a chimney increases the risk of ignition and fire spread, negating the protective benefits of a properly installed fire stop. For example, if wood framing, insulation, or other flammable materials are allowed to contact the chimney, the prolonged exposure to heat during normal chimney operation or a chimney fire can lead to pyrolysis, a process where the materials decompose and release flammable gases, eventually igniting and bypassing the fire stop entirely.

Real-world incidents frequently underscore the significance of clearance maintenance. Consider cases where homeowners store firewood too close to the chimney base, or where insulation is improperly installed, leaving insufficient airspace around the chimney chase. During a chimney fire, the intense heat radiating from the chimney can ignite these nearby combustibles, initiating a structural fire that quickly spreads beyond the chimney area, regardless of the presence of fire-stopping materials. The practical implication is clear: proper clearance must be consistently maintained as an ongoing fire safety measure, not merely a one-time installation consideration. Regular inspections are essential to ensure that no combustible materials are inadvertently introduced into the vicinity of the chimney.

In conclusion, the efficacy of any chimney fire stop is directly linked to maintaining adequate clearance from combustible materials. Ignoring this aspect undermines the entire fire-stopping system. Consistent vigilance and adherence to recommended clearance distances, as specified in building codes and manufacturer guidelines, are essential to prevent fires and protect buildings and their occupants. Effective fire safety is an ongoing duty.

5. Regular Inspection

Regular inspection serves as a critical proactive measure in ensuring the continued effectiveness of chimney fire-stopping systems. These inspections identify potential degradation, damage, or breaches in the fire stop, preventing a localized chimney fire from escalating into a full-blown structural conflagration. Frequent and thorough inspections are essential for maintaining the integrity of fire safety measures.

- Identifying Degradation of Materials

Chimney fire stops are subject to degradation over time due to exposure to heat, moisture, and corrosive byproducts of combustion. Regular inspections can reveal signs of material deterioration, such as cracking, crumbling, or displacement of fire-resistant materials. For instance, mineral wool insulation can settle or become dislodged, creating gaps that compromise its fire-stopping capabilities. Early detection of such degradation allows for timely repairs or replacements, preserving the intended level of protection. Failure to identify degradation can result in failure of the fire stop.

- Detecting Improper Installation or Alterations

Inspections can uncover instances of improper initial installation or subsequent alterations that may have compromised the fire stop. This includes inadequate filling of gaps, use of non-approved materials, or modifications made during renovations that violate code requirements. For example, a contractor might inadvertently remove or damage the fire stop while performing unrelated work, leaving a concealed fire hazard. Identifying these issues enables corrective actions to restore the integrity of the fire-stopping system, ensuring code compliance.

- Assessing Clearance to Combustible Materials

Periodic inspections are crucial for verifying that adequate clearance is maintained between the chimney and any nearby combustible materials. Over time, homeowners may unknowingly introduce flammable items in proximity to the chimney, increasing the risk of ignition. For example, storing firewood too close to the chimney base or allowing insulation to come into contact with the chimney chase can create a fire hazard. Inspections identify and address these clearance violations, mitigating the risk of fire spread and maintaining the effectiveness of the fire stop.

- Evaluating the Chimney Liner and Flue Condition

While not directly part of the fire stop itself, the condition of the chimney liner and flue significantly impacts the overall fire safety of the system. Inspections assess the liner for cracks, deterioration, or blockages that can increase the risk of chimney fires and compromise the effectiveness of the fire stop. For example, a cracked chimney liner can allow hot gases and embers to escape, potentially igniting nearby combustible materials and bypassing the fire stop. Addressing liner issues promptly prevents these hazards and maintains the integrity of the entire fire protection system.

In essence, the regular inspections are a primary strategy for maintaining the chimney fire stop. Neglecting these inspections can have serious consequences. Inspections ensures materials haven’t shifted and are still able to block heat and potential flames, verifying all the chimney components are in proper working order. Each inspection adds another layer of protection, adding safety and minimizing hazards.

6. Creosote Removal

Creosote accumulation within a chimney flue represents a significant fire hazard, directly impacting the effectiveness of a chimney fire stop. Creosote is a combustible byproduct of incomplete combustion from burning wood or other fuels. As hot flue gases cool, creosote condenses and deposits on the inner surfaces of the chimney. This buildup restricts airflow, increases the risk of chimney fires, and can compromise the integrity of any fire-stopping measures in place. The presence of substantial creosote renders a chimney fire stop less effective by providing a ready source of fuel within the chimney itself. In cases where a chimney fire occurs, the intensity and duration of the fire are significantly increased due to the presence of creosote. The increased heat load can overwhelm the fire stop, leading to a breach and potential ignition of surrounding combustible materials.

Regular creosote removal, typically achieved through professional chimney sweeping, is therefore an essential component of an effective chimney fire protection strategy. By reducing the amount of combustible material within the flue, creosote removal lessens the severity of potential chimney fires and minimizes the stress placed on the fire stop. For example, consider a scenario where a homeowner neglects to have their chimney cleaned for several years, resulting in a thick layer of creosote buildup. If a chimney fire ignites, the intense heat could cause the creosote to expand and crack the chimney liner, creating pathways for flames to bypass the fire stop and ignite surrounding structural members. Conversely, a chimney that is regularly swept and maintained will have minimal creosote accumulation, reducing the risk of a high-intensity fire and improving the likelihood that the fire stop will function as intended.

In summary, creosote removal and the implementation of a chimney fire stop are not mutually exclusive but rather interdependent components of a comprehensive fire safety plan. Creosote removal plays a direct role in minimizing the risk of chimney fires and reducing the thermal stress placed on fire-stopping materials. Regular cleaning ensures that the fire stop is more likely to perform as designed, protecting the building from fire damage. Prioritizing both creosote removal and maintaining an effective fire stop is essential for the protection of the structure and its occupants.

7. Sealing Integrity

Sealing integrity forms a critical and often overlooked aspect of an effective chimney fire stop system. This refers to the completeness and durability of the seal between the chimney structure and the surrounding building materials at points of penetration, such as floors, ceilings, and roofs. The effectiveness of a fire stop relies heavily on its ability to prevent the passage of flames, hot gases, and embers through any gaps or openings. Compromised sealing integrity renders the fire stop significantly less effective, potentially allowing a chimney fire to spread rapidly into the building’s structure. For example, even if a chimney fire stop utilizes fire-resistant materials, any unsealed cracks or gaps between the chimney and the surrounding wood framing provide a direct pathway for flames to bypass the fire-resistant barrier. Similarly, deteriorated or improperly applied sealant can lose its effectiveness over time, creating openings that undermine the entire fire protection system. This illustrates a direct cause-and-effect relationship, where poor sealing directly results in reduced fire protection capability.

The importance of sealing integrity is further underscored by real-life examples of chimney fires. In numerous instances, fires have spread rapidly through buildings due to inadequate sealing around chimneys, even when fire-stopping materials were present. These cases often involve older structures where sealant has deteriorated, or instances where improper installation left gaps unsealed. Building codes specify the types of sealants and installation methods required to ensure adequate sealing integrity. These codes often mandate the use of fire-rated sealants designed to withstand high temperatures without melting or losing their adhesive properties. Proper application techniques, such as completely filling gaps and ensuring adequate coverage, are also crucial for achieving a reliable and durable seal. Practical applications of this understanding include rigorous inspection of chimney seals during routine chimney maintenance and prompt repair or replacement of any damaged or deteriorated sealant.

In conclusion, sealing integrity is an indispensable component of a functional chimney fire stop. Compromised sealing can negate the benefits of even the most advanced fire-resistant materials. Challenges in maintaining sealing integrity stem from material degradation over time, improper installation techniques, and a lack of awareness among homeowners regarding the importance of this aspect of fire safety. Consistent vigilance and adherence to building codes, coupled with regular inspections and timely repairs, are essential for ensuring that chimney fire stops effectively protect buildings from fire hazards. Maintaining the integrity of chimney seals represents a proactive and cost-effective measure for mitigating the risk of catastrophic fire damage and safeguarding lives.

Frequently Asked Questions about Chimney Fire Stops

The following addresses common inquiries concerning chimney fire stops, their function, and their importance in maintaining fire safety.

Question 1: What constitutes a chimney fire stop?

A chimney fire stop is a non-combustible barrier installed around a chimney where it passes through floors, ceilings, or roofs. Its primary function is to prevent the spread of fire from the chimney to the surrounding structure.

Question 2: What materials are typically used for chimney fire stops?

Common materials include mineral wool, fire-rated caulk, steel, and other non-combustible or fire-resistant materials approved for high-temperature applications. Material selection is dictated by building codes and manufacturer specifications.

Question 3: Why is a chimney fire stop considered important for fire safety?

Chimney fires can rapidly spread to adjacent combustible materials in a building. A properly installed fire stop acts as a critical barrier, containing the fire within the chimney structure and preventing its propagation.

Question 4: How often should chimney fire stops be inspected?

Chimney fire stops should be inspected at least annually as part of a comprehensive chimney inspection. Inspections should also occur after any chimney fire or significant event that may have compromised the fire stop’s integrity.

Question 5: Who should install a chimney fire stop?

Installation should be performed by a qualified professional familiar with local building codes and best practices for chimney fire safety. Improper installation can render the fire stop ineffective.

Question 6: What are the potential consequences of neglecting a damaged or missing chimney fire stop?

Neglecting a damaged or missing chimney fire stop significantly increases the risk of a structural fire. This can lead to extensive property damage, injury, or loss of life. Remediation is a critical element of fire safety and prevention.

Effective fire stopping minimizes the risks to life and property.

The subsequent section will provide resources and references for further study.

In Conclusion

This exploration has underscored the critical role of a “chimney fire stop” in safeguarding structures from the devastating consequences of chimney fires. From material selection and installation to code compliance and ongoing maintenance, each element contributes to the overall effectiveness of this vital fire safety measure. Neglecting any aspect of the fire stop system can significantly increase the risk of fire propagation and structural damage.

The implementation of a robust “chimney fire stop” system is not merely a regulatory obligation but a fundamental responsibility for homeowners, builders, and inspectors. A proactive approach to chimney fire safety, characterized by diligent inspection, timely repairs, and adherence to best practices, is essential for protecting lives and preserving property. The investment in a properly functioning “chimney fire stop” is an investment in security and peace of mind, mitigating the potential for catastrophic loss and ensuring a safer environment for all.