The act of mitigating the risk of combustion within a flue or stack attached to a heating appliance is a critical aspect of home safety. This process includes regular inspection and maintenance to remove creosote and other combustible deposits. An example is the scheduled cleaning of a chimney to prevent the buildup of flammable materials.

Maintaining a safe heating system through preventative measures provides significant benefits, primarily safeguarding property and lives. Historically, uncontrolled burning within chimneys has been a major cause of house fires, leading to widespread damage and, unfortunately, loss of life. Proactive attention to heating appliance systems minimizes these hazards.

The following sections detail the key elements involved in ensuring the operational safety of flues and stacks, including inspection procedures, appropriate cleaning techniques, and the importance of professional services in maintaining optimal system performance.

Key Measures for Flue and Stack Safety

The following recommendations outline essential actions to minimize the potential for uncontrolled combustion within heating appliance exhaust systems.

Tip 1: Schedule Annual Inspections. A qualified professional should conduct a thorough assessment of the flue and stack to identify potential hazards such as cracks, blockages, or excessive creosote buildup. Early detection allows for timely remediation.

Tip 2: Burn Seasoned Wood. Using dry, well-seasoned wood reduces creosote formation compared to burning green or damp wood. Seasoned wood burns hotter and more completely, minimizing unburnt residue.

Tip 3: Maintain Proper Airflow. Ensure adequate airflow to the heating appliance. Restricted airflow can lead to incomplete combustion and increased creosote production. Follow manufacturer guidelines for ventilation.

Tip 4: Conduct Regular Cleaning. Clean the flue and stack as needed, or at least annually. Removing accumulated creosote reduces the fuel load available for a potential fire. The frequency of cleaning depends on usage and fuel type.

Tip 5: Install a Flue Thermometer. Monitor flue gas temperatures to ensure efficient combustion. Consistently low temperatures can indicate incomplete combustion and increased creosote accumulation.

Tip 6: Use Caution with Artificial Logs. If using artificial logs, adhere strictly to manufacturer instructions. Some artificial logs can produce higher flue gas temperatures or leave behind residues that increase the risk of combustion.

Tip 7: Understand Warning Signs. Be alert for warning signs such as a smoky odor when the appliance is not in use, thick black smoke from the flue, or unusual sounds (e.g., rumbling or roaring) coming from the flue.

Adhering to these recommendations significantly reduces the likelihood of uncontrolled combustion incidents, protecting both property and inhabitants.

The subsequent sections will explore the specific techniques and tools involved in cleaning and maintaining flues and stacks to ensure their continued safe operation.

1. Regular inspections

Regular inspections are a cornerstone of effective flue and stack safety. These assessments provide a critical opportunity to identify potential hazards before they escalate into dangerous situations. The absence of routine evaluation significantly increases the risk of uncontrolled combustion events.

- Creosote Accumulation Detection

Inspections allow for the visual assessment of creosote buildup within the flue. Creosote, a highly flammable byproduct of incomplete combustion, accumulates over time and poses a significant fire hazard. Early detection enables timely removal, mitigating the risk of ignition.

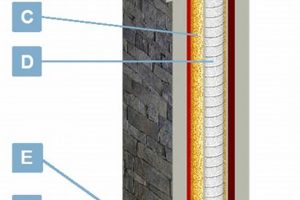

- Structural Integrity Assessment

Inspections reveal any structural damage, such as cracks or deterioration in the flue liner. Damaged flues can allow heat and sparks to escape, potentially igniting surrounding combustible materials within the building structure. Prompt repairs prevent fire spread.

- Blockage Identification

Inspections can identify obstructions, such as bird nests or debris, that impede airflow within the flue. Blockages restrict the proper venting of combustion gases, leading to increased creosote production and the potential for carbon monoxide buildup within the dwelling. Removal of obstructions is crucial for safe operation.

- Appliance Connection Verification

Inspections verify the proper connection of the heating appliance to the flue. Improper connections can result in the leakage of combustion gases into the living space, posing a carbon monoxide poisoning risk. Ensuring a secure and properly sealed connection is vital for occupant safety.

The benefits of systematic assessments are multifaceted. By proactively addressing potential hazards identified during inspections, homeowners significantly reduce the likelihood of uncontrolled combustion incidents, safeguarding property and lives. The cost of inspections is minimal compared to the potential consequences of a destructive fire originating in a poorly maintained or damaged system.

2. Creosote Removal

The elimination of creosote from flues and stacks is a paramount component of maintaining operational safety and mitigating the risk of uncontrolled combustion. Creosote, a byproduct of incomplete combustion, accumulates within these systems and serves as a readily ignitable fuel source.

- Reduction of Fuel Load

Creosote removal directly reduces the amount of combustible material present within the flue. This decreases the likelihood of a fire ignition, limiting the potential intensity of any fire that may occur. A reduced fuel load translates to a diminished hazard profile.

- Prevention of Chimney Fires

The primary purpose of creosote removal is to prevent flue fires. By eliminating or significantly reducing the creosote layer, the probability of ignition from sparks or embers is minimized. Regular maintenance is essential for ongoing fire safety.

- Improved Appliance Efficiency

Creosote buildup can insulate the flue, hindering proper draft and reducing the efficiency of the heating appliance. Removal of this buildup restores optimal airflow, improving combustion efficiency and reducing the production of additional creosote.

- Prolonged Flue Lifespan

The acidic nature of creosote can corrode flue liners and other components over time. Regular removal helps to prevent this corrosion, extending the lifespan of the entire system and averting potentially costly repairs or replacements.

The integration of consistent creosote removal practices into a comprehensive maintenance regimen is integral to maintaining the integrity of flues and stacks. Consistent attention to this process reduces the risk of fire. It contributes to efficient operation, and enhances the longevity of the entire system, ensuring its continued safety and reliability.

3. Proper Airflow

Optimal airflow within a flue or stack is critical for the safe and efficient operation of heating appliances. Its direct impact on combustion completeness and the venting of exhaust gases makes it a fundamental aspect of fire safety protocols.

- Complete Combustion Enhancement

Adequate oxygen supply to the combustion chamber promotes complete combustion of fuel. This process minimizes the production of unburnt hydrocarbons and particulate matter, primary components of creosote. The reduction of creosote formation inherently lessens the risk of ignition within the system.

- Efficient Exhaust Gas Venting

Proper airflow facilitates the efficient removal of combustion gases, including carbon monoxide, from the dwelling. Obstructions or inadequate draft can lead to the accumulation of these gases, posing a significant health hazard to occupants. Furthermore, restricted venting can result in backdrafting, increasing the risk of flue fires.

- Temperature Regulation Within the Flue

Appropriate airflow helps regulate the temperature within the flue. Excessive heat can damage the flue liner and surrounding combustible materials, increasing the risk of fire spread. Insufficient airflow, conversely, can lead to lower flue temperatures, promoting creosote condensation and buildup.

- Minimization of Creosote Deposition

Sufficient draft velocity within the flue reduces the likelihood of creosote particles adhering to the flue walls. The faster the exhaust gases move through the system, the less opportunity there is for creosote to condense and accumulate, effectively minimizing the fuel load available for a potential flue fire.

The relationship between airflow and safety is direct and quantifiable. Optimizing air movement through the system, either through design modifications, regular maintenance, or operational adjustments, provides a tangible reduction in the risk of uncontrolled combustion events. A commitment to maintaining proper ventilation, is a safeguard against potential hazards within the structure.

4. Seasoned Wood

The utilization of seasoned wood directly impacts the mitigation of risks associated with uncontrolled combustion events in flues. Seasoned wood, defined as wood that has been dried to a moisture content of 20% or less, undergoes a significant transformation in its combustion properties compared to green or wet wood. The presence of excess moisture in unseasoned wood impedes efficient burning, leading to the incomplete combustion of volatile compounds. This incomplete combustion results in the formation of creosote, a highly flammable byproduct that accumulates on flue surfaces. The direct consequence of burning unseasoned wood is an accelerated rate of creosote deposition, increasing the probability of a flue fire.

Real-world examples consistently demonstrate the correlation between seasoned wood use and reduced flue fire incidence. Households that consistently burn seasoned wood experience significantly lower creosote buildup rates, thereby minimizing the risk of ignition. Conversely, instances of severe flue fires are often traced back to the prevalent use of green or wet wood. Some common effects include; excessive smoke when the heating appliance is in use, or a delayed response in the heating appliance.

In summary, the choice of wood fuel directly influences the safety profile of flues. The utilization of seasoned wood represents a proactive measure. It reduces the formation of creosote and thereby mitigates the potential for uncontrolled combustion within the appliance. This understanding is crucial for homeowners. It empowers them to actively manage the risks associated with solid fuel heating, safeguarding property and life. The challenges are consistent and the need is for safety and fuel efficiency.

5. Flue Temperature Monitoring

Flue temperature monitoring serves as a critical proactive measure in fire prevention. The temperature of exhaust gases within a flue provides a direct indication of combustion efficiency and creosote accumulation rates. Elevated temperatures can signal excessive fuel consumption or improper appliance operation, while consistently low temperatures often indicate incomplete combustion and accelerated creosote deposition. Accurate monitoring, therefore, enables timely intervention to address these underlying issues before they escalate into dangerous conditions.

The practical application of flue temperature monitoring involves the installation of a thermometer on the flue pipe, typically at a point recommended by the appliance manufacturer. Regular observation of flue temperatures allows homeowners to identify deviations from normal operating ranges. For example, a sudden and sustained increase in flue temperature might indicate a buildup of creosote that has ignited, signaling an immediate and serious fire hazard. Conversely, consistently low temperatures could necessitate adjustments to airflow or fuel type to improve combustion efficiency and reduce creosote formation. Real-world scenarios often demonstrate the effectiveness of this monitoring. Homeowners who diligently track flue temperatures are often able to detect and address potential problems before a fire ignites.

Flue temperature monitoring is not a standalone solution but an integral component of a comprehensive fire prevention strategy. While it provides valuable insights into system performance, it should be combined with regular inspections, creosote removal, and proper appliance maintenance. The challenge lies in ensuring consistent monitoring and understanding the significance of temperature fluctuations. When effectively integrated into a holistic approach, flue temperature monitoring significantly enhances the safety and longevity of heating systems, contributing directly to the mitigation of fire risks.

6. Professional cleaning

The employment of certified professionals for the cleaning of flues represents a critical intervention in the mitigation of fire risks. Creosote, a highly combustible byproduct of incomplete combustion, accumulates within flues over time. The properties of creosote make it prone to ignition from stray sparks or embers. Professional cleaning ensures complete removal of accumulated deposits. This eliminates a primary fuel source for chimney fires.

Professionals utilize specialized tools and techniques to access and clean areas of the flue that are often inaccessible to homeowners. These may include rotary brushes, vacuums with HEPA filters designed for creosote removal, and inspection cameras. For example, a certified professional may use a camera to inspect the flue for structural defects or hidden creosote buildup, thereby informing the cleaning process. Lack of professional intervention can result in inadequate cleaning, leaving residual creosote that continues to pose a fire hazard. In contrast, professional services ensure the flue is thoroughly cleaned, minimizing the risk of ignition and subsequent fire.

Professional cleaning offers the added benefit of expert inspection. Certified technicians are trained to identify potential safety hazards, such as cracks in the flue liner or improper appliance connections. Early detection and correction of these issues prevent further degradation of the system and diminish the risk of fire spread. The combination of thorough cleaning and expert inspection underscores the essential role of professional services in the implementation of comprehensive fire safety protocols. This action enhances the safety of homes with fuel-burning appliances. It also extends the lifespan of the heating system.

7. Safe appliance operation

Safe appliance operation is intrinsically linked to the overarching goal of flue fire prevention. The manner in which heating appliances are used and maintained directly influences the accumulation of creosote and other flammable deposits within the system. Proper operation minimizes the production of these byproducts and reduces the likelihood of combustion events.

- Proper Fuel Selection

The use of approved and appropriate fuels is paramount for safe operation. Deviation from manufacturer recommendations, such as burning treated lumber or inappropriate fuel types, results in incomplete combustion and increased creosote production. Adhering to fuel specifications minimizes the creation of flammable deposits. This prevents the escalation of flue fire risks.

- Adherence to Manufacturer Guidelines

Operating heating appliances in accordance with manufacturer instructions ensures optimal combustion efficiency and reduces the potential for malfunction. Overfiring, underfiring, or improper use of dampers can lead to excessive smoke, increased creosote buildup, and potential system damage. Strict adherence to guidelines promotes safe and efficient operation.

- Regular Maintenance and Cleaning

Consistent maintenance, including the cleaning of internal components and the removal of ash and debris, is critical for optimal performance. Neglecting maintenance can impede airflow, reduce combustion efficiency, and increase the risk of component failure. Regular cleaning ensures efficient operation. It prevents the accumulation of flammable materials.

- Proper Ventilation

Ensuring adequate ventilation within the space where the heating appliance is located supports complete combustion and prevents the buildup of carbon monoxide. Restricted airflow can lead to incomplete combustion, resulting in increased creosote production and a potentially hazardous environment. Proper ventilation is a cornerstone of safe appliance operation.

These facets of safe appliance operation are not isolated practices but rather interconnected elements of a comprehensive strategy for mitigating flue fire risks. By prioritizing fuel selection, adherence to guidelines, regular maintenance, and proper ventilation, individuals directly contribute to the safety and longevity of their heating systems and the well-being of occupants. The diligence given to operational aspects ultimately translates into tangible reductions in the incidence of uncontrolled combustion events and related property damage.

Frequently Asked Questions About Chimney Fire Prevention

This section addresses prevalent inquiries concerning the proactive measures required to minimize the risk of uncontrolled combustion events originating in flues.

Question 1: What constitutes a chimney fire, and what are its primary causes?

A chimney fire involves the uncontrolled burning of accumulated deposits, primarily creosote, within the flue. The primary causes include infrequent cleaning, the use of unseasoned wood, and restricted airflow. The resulting rapid combustion can generate intense heat and flames that extend beyond the confines of the flue.

Question 2: How frequently should chimneys undergo professional inspection and cleaning?

Flues should be professionally inspected at least annually. The frequency of cleaning depends on usage and fuel type. A flue servicing a wood-burning appliance used regularly throughout the heating season requires more frequent cleaning than one serving a gas appliance used sparingly.

Question 3: What are the discernible indicators of a potential or ongoing flue fire?

Indicators may include a smoky odor when the appliance is not in use, thick black smoke emanating from the flue, loud rumbling or roaring sounds originating from the flue, and the presence of visible flames extending from the flue opening.

Question 4: What role does the type of fuel burned play in minimizing fire risk?

Burning seasoned wood with a low moisture content minimizes creosote formation. Unseasoned wood produces significantly more smoke and unburnt particles, leading to accelerated creosote accumulation. Gas and oil fuels, while cleaner-burning, still require regular inspection and maintenance to ensure proper venting and prevent obstructions.

Question 5: How does one select a qualified professional for chimney inspection and cleaning?

Seek individuals or companies holding certifications from reputable organizations. Request proof of insurance and inquire about their experience and adherence to industry standards. Obtain references from previous clients to assess their reputation and reliability.

Question 6: What immediate actions should be taken in the event of a suspected or confirmed chimney fire?

Immediately evacuate the premises and contact emergency services (fire department). Do not attempt to extinguish the fire yourself unless properly trained and equipped. After the fire is extinguished, a thorough inspection by a qualified professional is essential to assess the extent of the damage and ensure the flue’s structural integrity.

Proactive engagement with these FAQs, paired with consistent maintenance protocols, represents a tangible commitment to fire prevention.

The subsequent section addresses emergency procedures.

Conclusion

This discourse has thoroughly examined the critical aspects of “chimney fire prevention”, emphasizing the multifaceted nature of this responsibility. Regular inspections, the elimination of creosote, ensuring optimal airflow, utilizing seasoned wood, monitoring flue temperatures, and enlisting professional cleaning services are vital components of a comprehensive approach. Safe appliance operation further reinforces the effectiveness of these preventative measures.

The consistent application of these principles represents an investment in the safety and security of property and life. A proactive stance towards flue maintenance mitigates the risk of destructive fires, safeguarding homes and communities. Vigilance and adherence to best practices are essential to maintain the integrity of heating systems and prevent the devastating consequences of uncontrolled combustion.

![Why Chimney Birds Matter: [Chimney Bird] Care Tips Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Why Chimney Birds Matter: [Chimney Bird] Care Tips | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/03/th-25-300x200.jpg)