The provision of maintenance, inspection, and repair work for residential and commercial flues and venting systems is a specialized trade. This service focuses on ensuring the safe and efficient operation of these systems, which are critical for removing combustion byproducts from heating appliances and fireplaces. An example includes scheduled cleaning to remove creosote buildup, thereby reducing the risk of chimney fires.

The importance of professional flue maintenance lies in preventing hazards such as carbon monoxide poisoning and structural damage from chimney fires. Regular inspections can identify potential problems, such as cracks or blockages, early on, preventing costly repairs and ensuring the system functions correctly. Historically, reliance on open fires necessitated regular flue maintenance, and this need persists today with modern heating systems.

The subsequent sections will delve into specific aspects of professional chimney care, encompassing inspection procedures, cleaning methodologies, repair techniques, and safety considerations to ensure optimal system performance and homeowner well-being.

Professional Chimney Maintenance Guidelines

Adherence to these guidelines ensures the safety and longevity of residential and commercial flue systems.

Tip 1: Schedule Annual Inspections: Implement a yearly inspection protocol by a qualified professional. Early detection of cracks, blockages, or deterioration prevents costly repairs and potential hazards.

Tip 2: Prioritize Creosote Removal: Creosote buildup is a significant fire hazard. Schedule regular cleaning to remove accumulated creosote, particularly with frequent fireplace use.

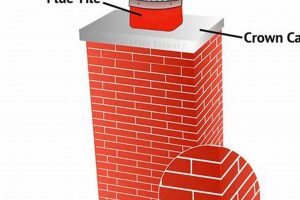

Tip 3: Address Water Intrusion Promptly: Water damage accelerates chimney deterioration. Repair damaged flashing, install a chimney cap, and address any leaks immediately to prevent structural weakening.

Tip 4: Ensure Proper Ventilation: Adequate ventilation is crucial for efficient combustion and the safe removal of exhaust gases. Verify that flues are unobstructed and properly sized for the appliance.

Tip 5: Monitor for Spalling Bricks: Spalling indicates water damage and freeze-thaw cycles. Damaged bricks should be replaced promptly to maintain the structural integrity of the chimney.

Tip 6: Professional repair when needed: A chimney professional can diagnose and propose the best solutions to help avoid fire hazards. Ensure a working chimney before use to protect you and your family from fire.

These measures are essential for maintaining a safe and efficient flue system, mitigating potential risks associated with combustion appliances and fireplaces.

The concluding section will provide a summary of key considerations for chimney maintenance and safety.

1. Inspection Thoroughness

Inspection thoroughness, as a core tenet of professional flue maintenance, directly influences safety and operational efficiency. The quality and depth of a chimney inspection determine the identification of potential hazards, system inefficiencies, and structural weaknesses. Inadequate inspections can lead to overlooked issues such as minor cracks that, over time, compromise the integrity of the entire structure, or the presence of early-stage creosote buildup that elevates fire risk. The thoroughness of the inspection is not merely a procedural formality but a critical safeguard against potential hazards.

A comprehensive inspection includes, but is not limited to, a visual assessment of the chimney’s exterior and interior, evaluation of flue lining integrity using specialized cameras, checking the condition of the chimney crown, and assessing the functionality of dampers and venting systems. For instance, failing to identify a compromised flue liner could result in carbon monoxide leakage into a residence, posing a significant health risk to occupants. Effective inspection methods, therefore, represent a substantial investment in the longevity and safe operation of chimney systems. A thorough chimney sweep will be able to identify any repairs that need to be done to a chimney before use.

In summary, inspection thoroughness stands as a primary factor in effective chimney maintenance. Insufficient or superficial inspections render the entire maintenance process ineffective, potentially exposing homeowners to hazards that could have been prevented. Prioritizing meticulous inspections is therefore an indispensable element in ensuring system safety and optimal performance, as well as providing homeowners with the knowledge and support that they need before using their chimneys.

2. Cleaning Frequency

The regularity with which a flue system is cleaned directly impacts its safety and operational effectiveness. A consistent cleaning schedule, tailored to usage patterns and fuel type, is a cornerstone of preventative maintenance.

- Creosote Accumulation Mitigation

Creosote, a byproduct of incomplete combustion, accumulates within the flue. Its accumulation rate is influenced by factors such as wood type, burning practices, and appliance efficiency. Frequent cleaning removes creosote, thus minimizing the risk of chimney fires. For instance, heavy users of wood-burning stoves may require cleaning multiple times per season, while infrequent fireplace users may require only annual servicing.

- Optimal Draft Maintenance

Soot and debris buildup impede airflow within the flue. This obstruction reduces draft efficiency, potentially leading to backdrafting of harmful gases into the living space. Regular cleaning ensures unobstructed airflow, maintaining optimal draft and preventing the introduction of dangerous combustion byproducts into the home.

- Inspection Access Enhancement

A clean flue facilitates thorough inspections. The absence of excessive soot and debris allows for a more comprehensive visual assessment of the flue liner, chimney crown, and other critical components. This enhanced visibility enables early detection of cracks, spalling, or other structural issues that might otherwise be obscured.

- Prevention of Carbon Monoxide Poisoning

Buildup within the chimney flue can cause blockages, which in turn, lead to carbon monoxide build-up within a home. A clean chimney supports effective venting, which reduces potential Carbon Monoxide Poisoning within the home.

The considerations highlighted reinforce the integral role of cleaning frequency in maintaining safe and efficient flue systems. Proper and consistent maintenance decreases the risk of chimney fires. Additionally, the regular process prevents carbon monoxide poisoning through improving ventilation and drafting.

3. Repair Quality

The caliber of repairs performed on a flue system directly impacts its long-term functionality and safety. Competent repair work extends the lifespan of the structure, prevents hazardous conditions, and ensures efficient operation. Deficient or substandard repairs, conversely, can lead to recurring problems, escalating costs, and potential safety risks.

- Material Selection and Durability

The choice of materials used in repair work significantly influences the chimney’s longevity. Utilizing materials that are incompatible with the existing structure or of inferior quality can lead to premature deterioration, requiring further repairs. For example, using non-refractory mortar in the firebox can result in rapid cracking and spalling due to high temperatures, necessitating frequent replacements and compromising the structural integrity.

- Adherence to Building Codes and Regulations

Proper repair work must comply with local building codes and regulations. These codes are in place to ensure safety and prevent hazards. Failure to adhere to these codes can result in fines, legal liabilities, and, more importantly, compromised safety. For instance, improperly installed flue liners can lead to carbon monoxide leaks, posing a serious health risk to occupants. Professional adherence and knowledge of regulations are vital for proper and legal repairs.

- Diagnostic Accuracy and Problem Resolution

Effective repair work begins with accurate diagnosis of the underlying problem. Misdiagnosis can lead to ineffective repairs that address symptoms rather than the root cause. For example, water leaks may be caused by damaged flashing, a cracked chimney crown, or porous brick. Correctly identifying the source of the leak is crucial to implementing the appropriate repair solution.

- Workmanship and Installation Techniques

The skill and expertise of the repair technician play a vital role in the quality of the finished work. Improper installation techniques can compromise the effectiveness of the repair. For instance, poorly applied chimney crown sealant can fail to prevent water intrusion, leading to further damage. Attention to detail and proper workmanship are essential for ensuring lasting repairs.

In summary, the quality of repair work is paramount to maintaining safe and efficient flue systems. The correct choice of materials, adherence to building codes, accurate problem diagnoses, and skillful workmanship combine to ensure durable and reliable repairs. Investing in quality repairs safeguards against potential hazards, extends the lifespan of the structure, and provides peace of mind.

4. Safety Compliance

Adherence to established safety protocols and regulatory standards forms an indispensable element within the context of professional flue services. Such compliance is not merely a procedural formality but a fundamental requirement to mitigate risks associated with flue systems, which inherently involve combustion processes and potential hazards such as carbon monoxide leaks or chimney fires. Neglecting safety compliance can have dire consequences, including property damage, health risks, and legal liabilities. A service provider’s commitment to safety compliance directly reflects its operational integrity and the value it places on client well-being. An example is adhering to NFPA 211 standards, which outlines guidelines for chimney, fireplace, and vent maintenance.

Safety compliance manifests in various operational aspects, including the utilization of certified technicians, proper equipment usage, adherence to inspection checklists, and the implementation of safety protocols during cleaning and repair procedures. For instance, ensuring technicians are certified by organizations such as the Chimney Safety Institute of America (CSIA) demonstrates a commitment to professional standards and expertise. Moreover, employing appropriate safety gear, such as respirators and protective eyewear, during creosote removal minimizes the risk of occupational hazards. Documented adherence to safety protocols during each service call provides a record of compliance and accountability. This approach not only meets regulatory requirements but also fosters a culture of safety within the organization.

In conclusion, safety compliance constitutes an essential and non-negotiable aspect of professional flue services. It safeguards against potential hazards, ensures operational integrity, and fosters trust between the service provider and the client. Challenges remain in consistently enforcing safety standards across the industry, and ongoing education and training are crucial for maintaining a high level of safety awareness and compliance. The link between rigorous safety practices and the overall quality of flue services is undeniable, underscoring the importance of prioritizing safety in all aspects of chimney maintenance and repair.

5. Ventilation Efficiency

Ventilation efficiency represents a critical performance metric for flue systems, directly affecting combustion appliance operation and indoor air quality. In the context of professional chimney services, optimizing ventilation efficiency becomes paramount for safety and system longevity.

- Draft Optimization

Efficient ventilation relies on consistent and adequate draft within the flue. Blockages, improper sizing, or atmospheric conditions can impede draft, leading to incomplete combustion and backdrafting of harmful gases. Services, such as chimney sweeping and flue liner inspection, directly address draft-related issues by removing obstructions and ensuring proper airflow. A well-maintained chimney system ensures that combustion byproducts are effectively expelled, minimizing risks to occupants.

- Flue Liner Integrity

The condition of the flue liner is integral to ventilation efficiency. A damaged or deteriorated liner can restrict airflow and compromise the flue’s ability to effectively vent combustion gases. Chimney services routinely include flue liner inspections to identify cracks, spalling, or other damage that may impede ventilation. Timely repairs or relining can restore ventilation efficiency and prevent hazardous gas leakage into the living space.

- Appliance Compatibility

Ventilation efficiency is inextricably linked to the compatibility between the chimney and the connected appliance. An undersized or improperly designed flue can restrict airflow and impair appliance performance. Chimney service professionals evaluate appliance compatibility to ensure that the flue system is appropriately sized and configured for the connected heating appliance. This assessment prevents problems related to backdrafting, incomplete combustion, and reduced heating efficiency.

- Cap and Termination Design

The chimney cap and termination design influence ventilation efficiency by protecting the flue from weather elements and preventing downdrafts. A properly designed cap minimizes wind-induced turbulence and maintains consistent airflow, while preventing rainwater or debris from entering the flue. Chimney services offer cap installation and maintenance to optimize ventilation efficiency and safeguard the system from external factors.

These multifaceted aspects of ventilation efficiency underscore the essential role of chimney services in maintaining safe and effective flue systems. By addressing draft-related issues, ensuring flue liner integrity, verifying appliance compatibility, and optimizing cap design, these services contribute directly to improved ventilation and overall system performance, ensuring household safety.

6. Creosote Management

Creosote management constitutes a critical function within professional flue services. The buildup of creosote, a byproduct of incomplete combustion, within chimney systems presents a significant fire hazard. Professional chimney services directly address this risk through routine cleaning and inspection procedures designed to mitigate creosote accumulation. The effectiveness of these services in preventing chimney fires depends significantly on the thoroughness of creosote removal and the frequency with which it is performed. For example, a homeowner who uses a wood-burning stove as a primary heating source may require more frequent creosote removal compared to a household that uses a fireplace only occasionally. Improper creosote management increases the risk of chimney fires, emphasizing the practical significance of professional intervention.

Real-world instances of chimney fires frequently underscore the consequences of inadequate creosote management. Cases of property damage and even injuries resulting from chimney fires highlight the importance of regular cleaning schedules and professional inspections. Furthermore, understanding the different stages of creosote formation from easily removable soot to hardened, glazed deposits informs the appropriate cleaning methods employed by professional services. This tailored approach ensures that creosote is effectively removed, regardless of its stage, thereby minimizing the potential for ignition.

Creosote management, therefore, is not merely a supplementary task but an integral aspect of professional flue maintenance. Challenges remain in educating homeowners about the importance of routine cleaning and selecting qualified service providers. However, consistent creosote management is essential for maintaining safe chimney operation and preventing the devastating consequences of chimney fires. In essence, creosote management reinforces the importance of preventative maintenance as a core function of chimney care, contributing directly to homeowner safety and well-being.

Frequently Asked Questions

The following section addresses common inquiries concerning chimney maintenance and safety.

Question 1: How frequently should a chimney be professionally inspected?

Industry best practices recommend annual chimney inspections to identify potential hazards, such as creosote buildup or structural damage.

Question 2: What are the potential consequences of neglecting chimney cleaning?

Failure to clean a chimney regularly can lead to chimney fires, carbon monoxide poisoning, and reduced heating efficiency.

Question 3: What are the indicators that a chimney requires repair?

Visible signs of damage, such as spalling bricks, cracks in the crown, or water leaks, indicate the need for immediate repair.

Question 4: What certifications should a qualified chimney technician possess?

Technicians certified by the Chimney Safety Institute of America (CSIA) have demonstrated competency in chimney inspection and maintenance.

Question 5: What safety precautions should be observed during fireplace use?

Maintain a clear area around the fireplace, use a fire screen, and never leave a fire unattended to prevent accidents.

Question 6: How does water intrusion affect a chimney’s structural integrity?

Water penetration can lead to freeze-thaw damage, corroded components, and eventual structural collapse of the chimney.

Regular maintenance, thorough inspections, and prompt repairs are critical for ensuring safe and efficient chimney operation.

The subsequent section will summarize the key considerations for maintaining a safe and efficient chimney.

Conclusion

This exploration of flue maintenance highlights the critical nature of regular inspection, cleaning, and repair in ensuring system safety and operational efficiency. Adherence to established safety protocols, proper ventilation management, and timely creosote removal are essential for mitigating risks associated with residential and commercial flue systems. Comprehensive understanding of these factors provides a foundation for informed decision-making related to chimney care.

Prioritizing professional maintenance and addressing potential issues proactively ensures the longevity and safe functioning of these systems. The importance of flue maintenance extends beyond mere compliance; it is fundamental to safeguarding property and ensuring the well-being of occupants.