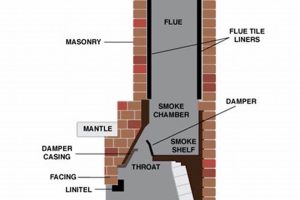

The components forming a hearth and its associated vertical structure are essential for safe and efficient operation. These elements, working in concert, facilitate combustion and the controlled expulsion of smoke and gases from a building. Understanding the function of each individual piece is critical for proper maintenance and ensuring optimal performance.

A well-constructed and maintained system provides warmth, enhances aesthetic appeal, and, historically, served as a central point for cooking and social gathering. The efficient venting of byproducts contributes significantly to indoor air quality and minimizes the risk of dangerous carbon monoxide buildup. Furthermore, preserving structural integrity safeguards against fire hazards and potential property damage.

A closer examination reveals the specific roles of elements such as the firebox, damper, flue, and chimney crown, among others. Each plays a distinct yet interconnected role in the overall functionality and safety of the system. The following sections will detail these components and their respective contributions.

Maintenance and Operational Guidance

Optimal function and longevity are achieved through diligent care and adherence to best practices. The following recommendations promote safety and efficiency.

Tip 1: Regular Inspection: Conduct a thorough visual examination at least annually. Assess for cracks, spalling, or deterioration in brickwork and mortar joints. Address any deficiencies promptly to prevent further degradation.

Tip 2: Professional Cleaning: Schedule professional sweeping to remove creosote buildup. Creosote accumulation is a significant fire hazard and reduces venting efficiency. Frequency depends on usage, but annual cleaning is generally recommended.

Tip 3: Damper Operation: Ensure the damper is fully operational and seals tightly when closed. A malfunctioning or improperly sealed damper allows heat to escape, reducing efficiency and potentially introducing drafts.

Tip 4: Fuel Selection: Utilize seasoned hardwoods for optimal combustion and reduced creosote production. Avoid burning softwoods, treated wood, or trash, as these materials produce excessive smoke and potentially harmful emissions.

Tip 5: Chimney Cap Installation: Install a chimney cap to prevent water, debris, and animals from entering the flue. This protects the structural integrity and prevents obstructions that can impede venting.

Tip 6: Smoke Detector Maintenance: Ensure smoke detectors are properly installed and functioning on every level of the dwelling. Test detectors monthly and replace batteries annually, or as needed.

Tip 7: Carbon Monoxide Detection: Install carbon monoxide detectors near sleeping areas. Carbon monoxide is a colorless, odorless, and potentially lethal gas produced by incomplete combustion. Regular detector maintenance is crucial.

Adhering to these guidelines minimizes safety risks and ensures peak performance. Consistent attention to detail preserves the structural integrity and maximizes the efficiency of the system.

The next section will address troubleshooting common issues and understanding potential hazards.

1. Firebox

The firebox is a foundational element of a hearth, directly interfacing with the combustion process and significantly impacting the functionality of the overall structure. Its design and materials are critical to safety and efficiency within the assembly.

- Material Composition and Heat Resistance

The firebox is typically constructed from fire-resistant materials such as firebrick or cast iron. These materials withstand extreme temperatures generated during combustion, preventing structural damage and ensuring containment of the fire. Selection of appropriate materials directly impacts the lifespan and safety profile of the entire system. For instance, using standard brick can lead to cracking and failure under sustained high heat.

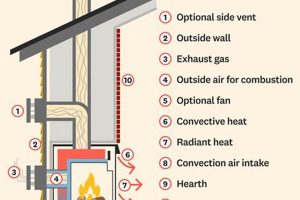

- Dimensions and Combustion Efficiency

The size and shape of the firebox influence airflow and combustion efficiency. An appropriately sized chamber allows for sufficient oxygen supply, promoting complete combustion and minimizing the production of harmful emissions. An undersized firebox may result in incomplete combustion, while an oversized firebox may lead to heat loss and reduced efficiency. The dimensions are calculated based on the expected fuel load and venting capabilities of the installation.

- Air Supply and Control

The firebox design often incorporates vents or openings to regulate airflow. Controlled air supply is crucial for maintaining a stable and efficient fire. Mechanisms such as dampers or air inlets allow the operator to adjust the amount of air entering the firebox, optimizing combustion and controlling the burn rate. Uncontrolled airflow can lead to excessive fuel consumption or dangerous backdraft conditions.

- Interface with the Smoke Chamber

The firebox serves as the lower boundary of the smoke chamber, a transitional area between the firebox and the flue. The smooth and gradual transition from the firebox opening into the smoke chamber is essential for efficient smoke and gas evacuation. An improperly designed transition can create turbulence, reducing draft and potentially causing smoke to enter the living space. The geometry of this interface directly affects the overall performance.

These facets highlight the integral relationship between the firebox and the operational integrity of the entire structure. Proper design, material selection, and maintenance of the firebox are paramount for safe and efficient performance. Deficiencies in any of these areas can compromise the system’s function and potentially introduce significant safety hazards.

2. Damper

The damper, an integral component within a hearth and its associated vertical conduit, regulates airflow through the system. Located typically above the firebox and below the flue, its primary function is to control the draft, thereby influencing combustion efficiency and heat retention within a structure. A properly functioning damper, therefore, directly contributes to the overall operational effectiveness and safety of the complete installation.

When open, the damper facilitates the upward movement of smoke and combustion gases through the flue, preventing their escape into the living space. Conversely, when closed, it minimizes heat loss up the chimney when the unit is not in use. A damaged or malfunctioning damper can lead to several adverse effects. For instance, a damper that does not seal properly allows heated air to escape, increasing energy consumption and heating costs. Alternatively, a damper stuck in the closed position can cause dangerous backdrafts, forcing smoke and carbon monoxide into the dwelling. Furthermore, corrosion or physical damage can compromise the damper’s structural integrity, requiring repair or replacement to ensure continued safe and efficient operation.

In summary, the damper serves a critical role in maintaining the equilibrium of a fireplace and chimney system. Its ability to control airflow directly impacts combustion efficiency, heat retention, and safety. Regular inspection and maintenance of the damper are essential to prevent malfunctions and ensure optimal performance. Neglecting this key component can lead to increased energy costs, compromised indoor air quality, and potentially hazardous conditions.

3. Flue

The flue represents a critical conduit within a fireplace and chimney system, functioning as the primary exhaust channel for combustion byproducts. Its integrity and design directly influence the safety and efficiency of the entire assembly. The flue’s connection to other components, such as the firebox and chimney crown, is inseparable; its malfunction can compromise the entire system, leading to hazardous conditions within a dwelling.

One common example illustrating this connection is the case of creosote buildup within the flue. Incomplete combustion, often caused by burning unseasoned wood, results in the accumulation of creosote on the flue’s interior walls. This highly flammable substance significantly increases the risk of chimney fires, a dangerous scenario that can spread rapidly to the structure of the building. Furthermore, blockages within the flue, whether caused by creosote or external debris such as animal nests, impede the proper venting of carbon monoxide, a colorless and odorless gas that poses a severe health hazard. Therefore, the physical condition and unobstructed passage of the flue directly determine the safe removal of dangerous combustion byproducts.

In summary, the flue’s proper function is paramount to the safe operation of a hearth. Its role as the exhaust pathway for combustion gases underscores its importance within the overall system. Regular inspections and maintenance, including professional cleaning to remove creosote and address any structural damage, are essential. Neglecting the flue’s upkeep can lead to significant safety risks, including chimney fires and carbon monoxide poisoning, highlighting the practical necessity of understanding its function and maintaining its integrity within the broader framework of a fireplace and chimney system.

4. Chimney Crown

The chimney crown serves as a critical protective element atop a chimney, integrated directly within the structural assembly. Its design and maintenance are essential to the system’s longevity and functionality.

- Water Diversion and Structural Integrity

The primary function of the chimney crown is to deflect rainwater, snow, and ice away from the chimney’s flue and masonry. Water penetration accelerates the deterioration of brick and mortar through freeze-thaw cycles, leading to cracking and spalling. A properly constructed crown with an overhanging drip edge significantly reduces water infiltration, thus preserving the chimney’s structural stability. Failure to maintain the crown allows water to permeate the structure, shortening its lifespan and requiring costly repairs.

- Flue Protection and Debris Prevention

The crown acts as a barrier against debris such as leaves, branches, and animal nests from entering the flue. Obstructions in the flue impede proper venting of combustion gases, potentially leading to dangerous backdrafts of carbon monoxide into the living space. Additionally, a well-maintained crown prevents animals from nesting within the chimney, avoiding blockages and the associated risks. A compromised crown allows unrestricted access to the flue, increasing the probability of ventilation problems.

- Material Composition and Longevity

Chimney crowns are typically constructed from concrete, stone, or metal. Concrete crowns, while cost-effective, are susceptible to cracking over time due to thermal expansion and contraction. Stone crowns offer superior durability but are more expensive. Metal crowns provide a lightweight and relatively maintenance-free alternative. The choice of material directly impacts the crown’s resistance to weathering and its overall lifespan. Substandard materials degrade quickly, necessitating frequent repairs or replacements.

- Interface with the Flue Liner and Chimney Structure

The crown must be properly integrated with the flue liner and the chimney’s masonry structure. A secure and watertight seal prevents water from seeping between the crown and the flue, protecting the underlying chimney materials. Poorly sealed or cracked crowns create pathways for water intrusion, accelerating the deterioration of the entire chimney system. Proper installation and periodic inspection of this interface are crucial for maintaining the chimney’s structural integrity.

These facets illustrate the essential role of the chimney crown in safeguarding the entire system from environmental damage and ensuring safe operation. Its condition directly impacts the longevity and functionality of the chimney, underscoring the importance of regular inspection and timely repairs to maintain its protective function.

5. Smoke Chamber

The smoke chamber represents a critical transition zone within a fireplace and chimney system, mediating the flow of combustion byproducts from the firebox to the flue. Its design and functionality significantly impact the draft efficiency and overall safety of the installation, necessitating a thorough understanding of its role among the constituent elements.

- Geometry and Draft Enhancement

The smoke chamber’s tapered shape is engineered to compress and accelerate the rising column of smoke and hot gases. This geometry promotes a stronger draft, facilitating efficient evacuation of combustion byproducts. An improperly shaped or sized chamber can impede airflow, leading to a weak draft and potential backdrafting of smoke into the living space. The angle of the taper, the surface smoothness, and the overall volume of the chamber are all critical parameters that directly influence the draft’s effectiveness. Smooth, parged surfaces are ideal for maximizing the draw, while rough surfaces or obstructions will impede airflow.

- Insulation and Heat Retention

The smoke chamber’s walls often incorporate insulation to minimize heat loss. Retaining heat within the chamber contributes to a stronger, more consistent draft. Insulating materials, such as refractory mortar or ceramic blankets, prevent heat from dissipating into the surrounding masonry, maintaining a higher temperature differential between the chamber and the outside air. This differential is a primary driving force behind the upward movement of gases. In colder climates, adequate insulation becomes even more crucial to prevent downdrafts and condensation within the chimney.

- Transition from Firebox to Flue

The smoke chamber serves as the crucial interface between the firebox and the flue. Its design must ensure a smooth and unobstructed transition to minimize turbulence and resistance to airflow. Abrupt changes in direction or constrictions within the chamber can disrupt the flow of gases, reducing draft efficiency and increasing the risk of smoke spillage. The connection between the smoke shelf (a horizontal projection within the chamber) and the flue’s entrance is particularly important; a properly designed smoke shelf prevents downdrafts and directs rainwater away from the firebox. The height and width of the smoke chamber opening must be properly proportioned for the dimensions of the firebox and flue.

- Maintenance and Inspection

The smoke chamber is prone to creosote accumulation, similar to the flue. Regular inspection and cleaning are essential to prevent blockages and reduce the risk of chimney fires. Creosote buildup restricts airflow and provides a fuel source for potentially dangerous fires. Access to the smoke chamber for inspection and cleaning can be challenging, often requiring specialized tools and techniques. Neglecting this aspect of maintenance can significantly compromise the system’s safety and efficiency.

These facets underscore the smoke chamber’s integral role within a fully functioning fireplace and chimney system. Its design, insulation, and maintenance directly influence draft efficiency, heat retention, and overall safety. Neglecting any aspect of the smoke chamber can compromise the systems performance, making careful attention to its construction and upkeep essential for optimal operation and homeowner safety.

Frequently Asked Questions

This section addresses common inquiries concerning the components of a fireplace and chimney, focusing on their function and maintenance requirements.

Question 1: What constitutes the firebox, and why is its construction critical?

The firebox is the chamber where combustion occurs. Its construction, typically of firebrick or cast iron, is critical due to its need to withstand intense heat and direct flame exposure. Proper firebox construction ensures containment of the fire and prevents structural damage to the surrounding masonry.

Question 2: How does the damper function, and what are the consequences of a malfunctioning unit?

The damper regulates airflow through the chimney. A malfunctioning unit can lead to heat loss when closed or dangerous backdrafts if stuck in the closed position. Ensuring a properly functioning damper is essential for energy efficiency and safety.

Question 3: What is the role of the flue, and why is creosote buildup a concern?

The flue serves as the exhaust channel for combustion byproducts. Creosote buildup, a result of incomplete combustion, is a significant fire hazard. Regular flue cleaning is necessary to prevent chimney fires and ensure proper venting.

Question 4: What purpose does the chimney crown serve, and what materials are typically used in its construction?

The chimney crown protects the chimney from water damage and prevents debris from entering the flue. It is typically constructed from concrete, stone, or metal, with each material offering varying levels of durability and weather resistance. Maintenance of the crown is essential to prevent water infiltration and structural deterioration.

Question 5: How does the smoke chamber contribute to the efficiency of the system?

The smoke chamber’s tapered shape facilitates a smooth transition of combustion gases from the firebox to the flue, enhancing draft efficiency. Its design minimizes turbulence and promotes a stronger, more consistent upward flow of exhaust.

Question 6: What are the implications of neglecting regular inspection and maintenance of the described parts?

Neglecting regular inspection and maintenance can lead to structural damage, reduced efficiency, and increased safety risks, including chimney fires and carbon monoxide poisoning. Consistent upkeep is crucial for ensuring the safe and optimal performance.

Understanding these aspects of fireplace and chimney elements promotes responsible operation and ensures the system’s longevity.

The following section will delve into troubleshooting common issues and identifying potential hazards.

Conclusion

This exploration of the components forming a hearth and its associated vertical structure underscores the interconnectedness of design, function, and safety. Each part, from the firebox to the chimney crown, plays a distinct yet vital role in facilitating safe combustion and efficient venting. Recognizing the individual contributions of these integrated elements informs responsible operation and maintenance practices.

A comprehensive understanding of these components promotes proactive risk mitigation and preserves the structural integrity of the system. Sustained vigilance and adherence to established best practices are paramount in maintaining a safe and efficiently operating system, safeguarding against potential hazards and maximizing the lifespan of the installation. Diligent adherence to these principles contributes directly to occupant safety and the long-term preservation of property.