Evaluations of high-end chimney systems offer crucial insights into their performance, durability, and overall value. These assessments often delve into factors such as material quality, construction techniques, installation complexities, and long-term maintenance requirements. For example, a review might compare the heat resistance and corrosion protection of a stainless steel chimney liner against a ceramic alternative, highlighting the lifespan and cost-effectiveness of each option.

The significance of thorough assessments lies in facilitating informed purchasing decisions. Individuals investing in superior chimney solutions seek assurance that the product aligns with their expectations for safety, efficiency, and longevity. Historical contexts reveal evolving industry standards and technological advancements in chimney design, underscoring the need for current and comprehensive analyses to reflect contemporary offerings and regulations. Well-documented product analyses can save consumers time and money by guiding them toward the most suitable solution for their specific needs.

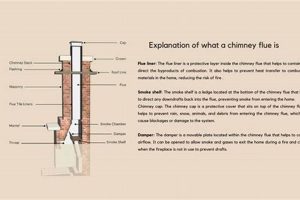

Subsequent sections will explore specific components commonly addressed in product evaluations, including flue liners, chimney caps, and draft enhancement systems. Additionally, this discussion will address how to effectively interpret evaluation data and choose a chimney system that meets unique requirements and local building codes.

Essential Considerations for Chimney System Selection

The following guidelines aim to inform the discerning purchaser during the evaluation and selection of premium chimney systems. Adherence to these points will facilitate a more informed decision-making process.

Tip 1: Material Composition Analysis: Scrutinize the materials employed in the chimney’s construction. Stainless steel alloys, ceramic liners, and refractory cements possess varying degrees of heat resistance and corrosion protection. Verify the specific alloy grade and compliance with relevant industry standards (e.g., UL 1777) to ensure optimal performance and longevity.

Tip 2: Flue Dimensions and Appliance Compatibility: Precise matching of the flue diameter to the connected heating appliance is crucial for proper draft and efficient combustion. Consult appliance manufacturer specifications and local building codes to determine the appropriate flue size. Undersized flues can lead to dangerous backdrafting, while oversized flues can hinder efficient draft.

Tip 3: Insulation Quality and Thermal Performance: Adequate insulation minimizes heat loss and prevents condensation within the chimney. Evaluate the R-value of the insulation materials to assess their thermal resistance. Chimneys installed in colder climates require higher levels of insulation to maintain optimal draft and prevent creosote formation.

Tip 4: Installation Methods and Professional Expertise: Proper installation is paramount to chimney system safety and performance. Engage certified chimney professionals with demonstrable experience in the installation of premium systems. Insist on adherence to manufacturer’s instructions and local building codes throughout the installation process.

Tip 5: Weather Resistance and Chimney Cap Functionality: A durable and appropriately sized chimney cap protects the chimney from precipitation, debris, and animal intrusion. Assess the cap’s material composition and design to ensure resistance to corrosion and blockage. Select a cap with sufficient mesh size to prevent bird nesting while maintaining adequate airflow.

Tip 6: Draft Enhancement Systems: In situations where natural draft is insufficient (e.g., due to tall trees or wind patterns), consider the integration of a draft inducer or fan-assisted system. Evaluate the system’s energy efficiency, noise levels, and control mechanisms to ensure compatibility with the existing heating appliance and chimney configuration.

Tip 7: Warranty Coverage and Manufacturer Reputation: Thoroughly review the warranty terms and conditions offered by the chimney system manufacturer. A comprehensive warranty reflects the manufacturer’s confidence in the product’s quality and provides recourse in the event of defects or premature failure. Research the manufacturer’s reputation and track record in the industry.

Diligent attention to these critical factors will promote a safe, efficient, and durable chimney installation, minimizing potential hazards and maximizing long-term cost savings.

The next step involves consolidating the acquired information to make a selection that aligns with both budgetary constraints and performance expectations.

1. Material Durability

Material durability represents a cornerstone in evaluations of high-end chimney systems, directly impacting longevity, performance consistency, and overall safety. Chimney assessments frequently prioritize material integrity, as the composition dictates a system’s ability to withstand extreme temperatures, corrosive byproducts of combustion, and environmental stressors.

- Stainless Steel Alloy Composition

The grade and composition of stainless steel alloys used in flue liners and chimney components significantly influence resistance to corrosion from acidic condensates. For instance, 316L stainless steel exhibits superior corrosion resistance compared to 304, particularly in systems burning fuels with higher sulfur content. Assessments often detail the specific alloy used and its compliance with industry standards to ensure adequate protection against degradation.

- Mortar Joint Integrity

In masonry chimneys, the mortar joints are a critical point of vulnerability. Reviews may assess the type of mortar used (e.g., Type N, Type S) and its resistance to freeze-thaw cycles and chemical attack. Deteriorated mortar joints compromise structural integrity and create pathways for flue gas leakage, potentially leading to carbon monoxide poisoning or chimney fires. Evaluations should reference documented testing results regarding mortar durability.

- Ceramic Liner Resilience

Ceramic flue liners, while offering excellent heat resistance, are susceptible to cracking and spalling under thermal stress. Reviews may analyze the thermal shock resistance of the ceramic material, evaluating its ability to withstand rapid temperature fluctuations without fracturing. The presence of cracks in a ceramic liner compromises its ability to contain combustion gases and necessitates costly repairs.

- Weatherproofing Component Effectiveness

Chimney caps and crowns protect the system from precipitation, debris, and animal intrusion. Evaluations should consider the materials used in these components (e.g., stainless steel, copper, concrete) and their resistance to weathering and corrosion. A compromised chimney cap allows water to enter the system, accelerating deterioration of the flue liner and masonry structure. Reviews might detail the performance of various weatherproofing materials in different climate conditions.

The cumulative effect of these material considerations directly influences the overall evaluation score of a premium chimney system. Substantiated data on material properties, coupled with documented performance under simulated operating conditions, enables informed comparisons and facilitates the selection of a system engineered for long-term durability and reliable performance.

2. Installation Complexity

The intricacy associated with the installation of high-end chimney systems is a significant factor in product evaluations. The ease or difficulty of installation directly affects labor costs, potential for errors, and the long-term performance of the system. Reviews often scrutinize installation processes and requirements to provide potential buyers with a realistic understanding of the commitment involved.

- Modular System Design

Many premium chimney systems feature modular designs intended to simplify installation. Reviews assess the clarity and completeness of installation manuals, the ease of connecting individual components, and the availability of necessary hardware. A well-designed modular system can significantly reduce installation time and the likelihood of improper assembly, while a poorly designed system can lead to frustration and potential safety hazards. For instance, a review might compare the installation time for a modular stainless-steel chimney system versus a traditional masonry chimney, highlighting the potential cost savings associated with the former.

- Specialized Tools and Expertise

Certain premium chimney systems necessitate the use of specialized tools or techniques for proper installation. Evaluations often address the accessibility and cost of these tools, as well as the level of expertise required. Systems that demand specialized knowledge may limit the pool of qualified installers, potentially increasing labor costs. For example, a system requiring precise laser alignment for optimal draft performance may necessitate the services of a certified technician with specialized equipment. Reviews might include warnings about attempting DIY installation without the necessary tools and skills.

- Code Compliance and Permitting

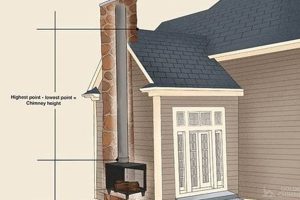

Compliance with local building codes and permitting requirements is an integral aspect of chimney system installation. Reviews may address the system’s compatibility with common code provisions and highlight any potential challenges in obtaining necessary permits. Systems that require extensive modifications to existing structures or necessitate variances from code may incur additional costs and delays. Reviews might cite specific code requirements relevant to chimney height, clearances to combustible materials, and flue liner specifications.

- Accessibility and Site Conditions

The accessibility of the installation site and prevailing site conditions can significantly impact the complexity and cost of chimney installation. Reviews may consider factors such as roof pitch, proximity to trees or power lines, and the presence of obstructions that hinder access. Challenging site conditions may necessitate the use of specialized equipment (e.g., cranes, scaffolding) and increase labor hours. Reviews might include recommendations for addressing common site-related challenges and provide guidance on preparing the site for installation.

Ultimately, installation complexity is a key determinant of the overall value proposition of a premium chimney system. Evaluations that provide detailed insights into the installation process empower consumers to make informed decisions, anticipate potential challenges, and ensure that the system is installed safely and effectively. Careful consideration of installation complexity helps to mitigate risks and optimize the long-term performance and reliability of the chimney system.

3. Performance Under Load

The assessment of chimney system performance under load constitutes a pivotal component of high-end product reviews. This evaluation considers the chimney’s ability to function effectively and safely during periods of peak demand or under adverse operational conditions. It delves beyond nominal specifications, probing the real-world capabilities of the system when subjected to realistic stressors. Deficiencies in performance under load can manifest as reduced draft, increased creosote accumulation, elevated surface temperatures, or even structural compromise. Product evaluations that omit rigorous load testing provide an incomplete and potentially misleading representation of the system’s true capabilities. For example, a chimney system might exhibit acceptable performance during moderate usage but fail to maintain adequate draft when the connected appliance is operating at its maximum output. Such a deficiency would increase the risk of backdrafting and carbon monoxide exposure.

Performance under load is often evaluated through a combination of laboratory testing and field observations. Laboratory tests may involve subjecting the chimney system to prolonged periods of high-temperature flue gas exposure, simulating sustained operation of a wood-burning stove or furnace. Field observations might entail monitoring draft pressure, flue gas temperature, and surface temperatures during typical usage scenarios. The data collected from these tests provides a quantitative basis for assessing the system’s ability to handle demanding operating conditions. Consider a scenario where a chimney system is evaluated for its ability to maintain adequate draft during windy conditions. A review that incorporates data from wind tunnel testing or real-world observations under high-wind conditions would provide valuable insights into the system’s performance in challenging environments.

In summary, the evaluation of performance under load is a critical element of comprehensive chimney system reviews. By considering the system’s ability to function effectively and safely under realistic operating conditions, these assessments provide consumers with the information needed to make informed purchasing decisions and mitigate potential risks. Neglecting this aspect of product evaluation undermines the overall value and reliability of the review process.

4. Long-Term Maintenance

Long-term maintenance is a pivotal aspect frequently examined in high-quality chimney system reviews. These assessments evaluate the ongoing care requirements and associated costs of ownership, providing crucial insight beyond initial purchase price. The scope of maintenance needs, accessibility of components, and frequency of inspections collectively determine the sustained viability of a chimney system.

- Inspection Frequency and Accessibility

Chimney inspections are critical for identifying potential hazards, such as creosote buildup, flue blockages, and structural damage. Evaluations scrutinize recommended inspection intervals and the ease with which various chimney components can be accessed for examination. Systems requiring specialized tools or techniques for inspection may incur higher maintenance costs. For instance, a chimney with a complex liner design may necessitate professional video scanning to thoroughly assess its condition. Reviews often highlight the system’s design features that either facilitate or impede inspection access, influencing overall maintenance convenience.

- Cleaning Requirements and Creosote Management

Creosote accumulation poses a significant fire risk in wood-burning chimney systems. Reviews analyze the system’s design features that minimize creosote deposition and the effectiveness of various cleaning methods. Systems with smooth, non-porous flue liners tend to accumulate less creosote than those with rough or porous surfaces. Evaluations may also address the availability of specialized cleaning tools and the ease with which homeowners can perform routine cleaning tasks. Neglecting creosote management can lead to chimney fires and costly repairs, underscoring the importance of this maintenance aspect.

- Component Replacement and Lifespan

Even with diligent maintenance, chimney components eventually require replacement due to wear and tear. Evaluations often assess the expected lifespan of critical components, such as flue liners, chimney caps, and dampers, as well as the availability and cost of replacement parts. Systems with readily available and competitively priced replacement parts offer a distinct advantage in terms of long-term affordability. Reviews may also compare the replacement costs of different flue liner materials, such as stainless steel versus ceramic, highlighting the potential cost savings associated with more durable materials.

- Weatherproofing Maintenance and Repair

Chimney systems are exposed to harsh weather conditions, which can lead to deterioration of mortar joints, brickwork, and weatherproofing components. Evaluations may address the system’s resistance to water penetration, freeze-thaw cycles, and UV degradation. Regular maintenance of weatherproofing elements, such as applying sealant to mortar joints and replacing damaged chimney caps, is crucial for preventing water damage and prolonging the system’s lifespan. Reviews might also consider the ease with which homeowners can perform routine weatherproofing maintenance tasks, influencing overall maintenance burden.

Comprehensive assessment of long-term maintenance demands is paramount in chimney system evaluations. The frequency of inspections, cleaning requirements, component lifespan, and weatherproofing considerations collectively determine the true cost of ownership and the overall sustainability of the investment. Systems with low maintenance requirements and readily available replacement parts offer a more attractive value proposition for discerning consumers.

5. Safety Compliance

Safety compliance represents a fundamental pillar in the evaluation of high-end chimney systems. Assessments rigorously examine adherence to industry standards and regulatory requirements, ensuring the product meets stringent safety benchmarks. This analysis directly influences consumer confidence and mitigates potential hazards associated with faulty or non-compliant chimney systems.

- UL 103 and UL 1777 Standards

Underwriters Laboratories (UL) establishes safety standards for factory-built chimneys (UL 103) and chimney liners (UL 1777). Product evaluations meticulously verify compliance with these standards, ensuring the system has undergone rigorous testing for fire resistance, structural integrity, and corrosion resistance. For instance, a chimney liner failing UL 1777 standards might exhibit premature degradation, leading to flue gas leakage and potentially hazardous conditions. Reviews must cite specific UL certifications and test results to validate safety claims.

- National Fire Protection Association (NFPA) Codes

NFPA codes, particularly NFPA 211 (Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances), provide comprehensive guidelines for the safe installation and maintenance of chimney systems. Assessments evaluate the system’s design and installation instructions against NFPA requirements, ensuring adherence to minimum clearances, chimney height regulations, and proper connection methods. A system neglecting NFPA 211 guidelines could present increased fire risk or carbon monoxide hazards. Reviews often highlight potential code violations and recommend corrective actions.

- Local Building Codes and Permitting

Local building codes often incorporate or adapt national standards to address specific regional concerns. Evaluations should consider the system’s compatibility with local code provisions and the requirements for obtaining necessary permits. A system that does not meet local code requirements may necessitate costly modifications or even rejection, increasing the overall cost and delaying installation. Reviews might cite specific code requirements regarding seismic bracing, wind load resistance, or snow load capacity.

- Material Safety and Emissions Testing

Premium chimney systems are increasingly subject to scrutiny regarding the safety of their constituent materials and the emissions they produce. Evaluations may analyze the presence of hazardous substances, such as asbestos or lead, and assess the system’s compliance with emissions regulations. Systems utilizing materials that release harmful toxins during combustion or degradation pose a significant health risk. Reviews might reference independent laboratory testing results regarding material composition and emissions levels.

The intersection of safety compliance and chimney reviews ensures products meet rigorous safety standards and regulations. Thorough assessments of UL certifications, NFPA codes, local building regulations, and material safety provide consumers with essential information for making informed decisions and mitigating potential hazards. The absence of robust safety compliance verification undermines the credibility of product reviews and jeopardizes consumer well-being.

6. Cost-Benefit Analysis

A systematic evaluation of advantages and disadvantages is paramount when considering the acquisition of high-caliber chimney systems. This process, termed Cost-Benefit Analysis, provides a structured framework for assessing the economic viability and long-term value associated with premium offerings, especially in the context of discerning evaluations.

- Initial Investment vs. Lifecycle Costs

The analysis must consider not only the initial purchase price but also the projected lifecycle costs, encompassing installation, maintenance, repairs, and potential replacement. While a premium chimney system may present a higher upfront investment, its superior durability and efficiency could yield substantial savings over its operational lifespan, thereby offsetting the initial expense. Conversely, a lower-priced alternative may necessitate frequent repairs and premature replacement, ultimately proving more costly in the long run. Therefore, the calculation of total ownership cost is essential.

- Energy Efficiency and Fuel Savings

Premium chimney systems frequently incorporate design features and materials that enhance energy efficiency. Improved draft control, reduced heat loss, and optimized combustion efficiency can translate into tangible fuel savings, particularly in systems utilizing solid fuels. A comprehensive analysis quantifies these potential savings, comparing the annual fuel consumption of a premium system against that of a standard or lower-grade alternative. This comparison provides a monetary value for the energy-saving benefits, contributing to the overall assessment.

- Safety and Risk Mitigation

The inherent safety features of premium chimney systems, such as superior fire resistance and corrosion protection, contribute significantly to risk mitigation. The analysis assigns a value to these safety enhancements by considering the potential costs associated with chimney fires, carbon monoxide exposure, and structural damage. A robust system reduces the probability of such incidents, thereby minimizing potential financial liabilities and ensuring occupant safety. This assessment extends to compliance with relevant safety standards and building codes, further reducing legal and insurance-related risks.

- Durability and Longevity

The extended lifespan of premium chimney systems, attributable to higher-quality materials and construction, represents a significant economic advantage. The analysis projects the system’s expected lifespan and calculates the cost per year of service. A system with a longer lifespan reduces the frequency of replacement, minimizing disruption and avoiding the associated expenses. Furthermore, the analysis considers the residual value of the system at the end of its service life, accounting for potential salvage or resale opportunities. This long-term perspective is critical for accurately assessing the overall economic value.

In summary, a rigorous cost-benefit analysis is instrumental in guiding informed decisions regarding high-caliber chimney systems. By quantifying the economic advantages associated with enhanced efficiency, safety, and durability, this approach empowers consumers to make prudent investments that yield long-term value and peace of mind. The analysis facilitates a comparative assessment, enabling the selection of a system that aligns with budgetary constraints while optimizing performance and safety.

Frequently Asked Questions

The following questions address common inquiries pertaining to the evaluation of high-end chimney systems. The responses aim to provide clarity and facilitate informed decision-making.

Question 1: What criteria distinguish a “premium” chimney system from standard offerings?

Premium chimney systems typically exhibit superior material quality, advanced design features, enhanced safety mechanisms, and extended warranties. These systems often incorporate stainless steel alloys, ceramic liners, or other high-performance materials that provide enhanced resistance to corrosion, heat, and structural degradation.

Question 2: How often should a premium chimney system be professionally inspected, irrespective of fuel type?

While specific inspection intervals may vary depending on fuel type and usage patterns, a professional chimney inspection is generally recommended at least annually. This proactive measure allows for the early detection of potential problems, such as creosote buildup, flue blockages, or structural damage, thereby minimizing the risk of chimney fires and carbon monoxide exposure.

Question 3: Are DIY installations of premium chimney systems advisable for homeowners seeking cost savings?

DIY installations of complex mechanical systems, including premium chimneys, are generally discouraged unless the homeowner possesses demonstrable expertise and thorough knowledge of applicable building codes. Improper installation can compromise system safety and performance, potentially voiding warranties and increasing the risk of hazardous conditions. Engaging certified professionals ensures code compliance and proper system functionality.

Question 4: What are the key indicators of a compromised chimney system that necessitate immediate professional attention?

Key indicators include visible cracks in the chimney structure, spalling or deterioration of brickwork, excessive creosote buildup, unusual odors emanating from the fireplace or chimney, and evidence of water leakage. Any of these signs warrants immediate professional inspection to assess the extent of the damage and implement appropriate repairs.

Question 5: How can homeowners effectively evaluate the performance claims made by premium chimney system manufacturers?

Homeowners should critically examine performance claims, seeking independent verification from reputable testing agencies, such as Underwriters Laboratories (UL). Scrutinize product specifications, material certifications, and documented test results to ensure claims are substantiated by verifiable data. Consult professional chimney sweeps and building inspectors for expert opinions and real-world performance assessments.

Question 6: What are the long-term cost considerations associated with premium versus standard chimney systems, beyond the initial purchase price?

Long-term cost considerations encompass maintenance expenses, repair costs, potential replacement costs, and energy savings. Premium systems, while initially more expensive, may offer lower long-term costs due to enhanced durability, reduced maintenance requirements, and improved energy efficiency. Conduct a comprehensive lifecycle cost analysis to compare the total cost of ownership for different systems over their expected lifespan.

These FAQs offer a fundamental understanding of critical aspects related to evaluating and selecting premium chimney systems. Consulting with certified professionals remains crucial for specific applications and unique circumstances.

Further sections will delve into specific case studies showcasing the application of these evaluation principles in real-world scenarios.

Premium Chimneys Reviews

The preceding analysis underscores the critical importance of comprehensive evaluations for high-end chimney systems. From material durability and installation complexity to performance under load, safety compliance, and cost-benefit considerations, a meticulous approach is essential for informed decision-making. Neglecting any of these key factors can result in compromised system performance, increased safety risks, and diminished long-term value.

Therefore, prospective purchasers are urged to prioritize thorough research and seek expert guidance when selecting a premium chimney system. Adherence to established evaluation criteria and consultation with certified professionals will ensure a safe, efficient, and durable installation. The future of chimney technology will likely bring further advancements in material science, design, and automation, underscoring the ongoing need for critical assessments that prioritize safety, performance, and sustainability.