This device is a specialized valve used to control the flow of gas to a fireplace or other gas-fueled appliance that vents through a chimney. It typically consists of a small, removable, keyed mechanism that, when inserted and turned, opens or closes the gas supply line. An example is a recessed valve located near the fireplace with a corresponding tool that must be inserted to enable gas flow.

The valve’s primary importance lies in its safety function. It allows for complete shut-off of the gas supply when the appliance is not in use, mitigating the risk of leaks and potential hazards. Historically, these valves provided a more secure method of gas control compared to earlier systems, offering a tangible means of preventing accidental gas release and improving overall safety of gas-fueled appliances.

The following sections will elaborate on the specific types of these valves, installation procedures, maintenance requirements, and potential troubleshooting scenarios. Furthermore, code compliance considerations and safety best practices will be addressed to ensure the safe and effective operation of gas-fueled appliances utilizing this type of valve.

Essential Usage Considerations

The proper and safe operation of a fireplace or other gas appliance necessitates understanding and adhering to several crucial guidelines. These guidelines ensure both user safety and the longevity of the equipment.

Tip 1: Locate and Identify: Prior to any attempt to ignite the fireplace, the location of the shut-off valve must be known. Ensure all household members are familiar with its placement and operation.

Tip 2: Leak Testing: After opening the valve, a soap-and-water solution should be applied to all connections. The formation of bubbles indicates a leak, requiring immediate attention from a qualified technician.

Tip 3: Full Open or Full Close: The valve should always be fully opened or fully closed. Partially open valves can lead to incomplete combustion and the buildup of dangerous gases.

Tip 4: Proper Key Storage: The key itself should be stored in a readily accessible but secure location, away from children. This ensures quick access in emergencies but prevents unauthorized use.

Tip 5: Regular Professional Inspection: Schedule annual inspections by a qualified gas appliance technician. These inspections can identify potential problems before they become hazardous.

Tip 6: Carbon Monoxide Detectors: Functioning carbon monoxide detectors are critical. Ensure detectors are properly installed and maintained in accordance with manufacturer’s instructions.

Tip 7: Chimney Inspection: Prior to each heating season, the chimney should be inspected for blockages or damage. A clear flue is essential for the safe venting of combustion byproducts.

Adhering to these guidelines maximizes safety and ensures the efficient operation of gas-fueled fireplaces. Regular maintenance and a thorough understanding of the system are paramount.

The subsequent sections will address specific troubleshooting steps and delve into more advanced topics related to gas fireplace systems.

1. Valve Operation

The operation of a gas valve is intrinsically linked to the function and safety profile of a gas chimney key system. The valve, controlled by the key, governs the initiation and cessation of gas flow to the appliance. Malfunction or improper operation of the valve directly impacts the entire system’s performance. For example, a corroded or stiff valve may not fully seal, resulting in a slow gas leak even when the system is ostensibly “off.” This presents a significant fire and carbon monoxide hazard.

Effective valve operation relies on several factors, including regular inspection, proper lubrication (where applicable and recommended by the manufacturer), and the use of a correctly sized and functioning key. The key acts as the physical interface between the user and the valve mechanism. A bent or damaged key may fail to fully engage the valve, leading to incomplete opening or closing. This can result in inefficient combustion, pilot light outages, or, in severe cases, a dangerous buildup of uncombusted gas within the appliance or chimney system. Routine testing of the valves shut-off capability, by observing the immediate extinguishing of the pilot light when the valve is closed, is critical to confirm its proper function.

In summary, the reliable operation of the gas valve is paramount to the safe and effective functioning of a gas chimney key system. Regular maintenance, proper key usage, and vigilance for signs of valve malfunction are essential. Ignoring these factors increases the risk of gas leaks, fires, and carbon monoxide poisoning. Understanding this connection is a foundational element of safe gas appliance operation and homeowner responsibility.

2. Gas Shut-off

The ability to rapidly and completely cease the flow of gas to a fireplace or appliance is critical to safety, and the gas chimney key system is designed to provide this functionality. An effective gas shut-off mechanism minimizes risks associated with leaks, malfunctions, and emergencies. Understanding the components and procedures involved is essential for responsible operation and maintenance.

- Primary Valve Function

The primary function is the complete cessation of gas supply. This is achieved by the physical blocking of the gas line via the valve mechanism, which is activated by the key. In a normal operational scenario, the key is turned to the ‘off’ position, engaging the valve to seal the gas line. Should the valve fail to completely seal, a hazardous gas leak could occur. Therefore, the integrity of the valve is paramount.

- Emergency Shut-off Protocol

In emergency situations, such as a detected gas leak or appliance malfunction, immediate shut-off is essential. The location of the gas chimney key and its valve must be known by all occupants. A readily accessible key facilitates swift intervention. Delays in shut-off can exacerbate the risk of fire or explosion.

- Redundancy and Backup Systems

While the valve controlled by the gas chimney key serves as the primary shut-off, modern installations often incorporate secondary or redundant shut-off systems. These may include an electronically controlled gas valve triggered by a carbon monoxide detector or a main gas line shut-off valve located outside the building. Such redundancy provides added protection against gas-related hazards.

- Regular Testing and Maintenance

The effectiveness of the gas shut-off mechanism should be regularly tested. This involves confirming the complete cessation of gas flow when the key is turned to the ‘off’ position. Soap and water solutions applied to gas line connections can reveal even minute leaks. Regular maintenance, including lubrication (where applicable) and visual inspection of the valve and key, ensures optimal performance and longevity.

The discussed components and procedures surrounding gas shut-off highlight the crucial role of the gas chimney key system in preventing gas-related incidents. The ability to quickly and reliably cut off the gas supply is a fundamental safety measure. Therefore, familiarity with the system, adherence to proper operation protocols, and regular maintenance are of utmost importance.

3. Safety Mechanism

The gas chimney key system incorporates several features specifically designed to enhance safety during the operation of gas fireplaces and appliances. These mechanisms aim to mitigate the risks of gas leaks, accidental ignition, and carbon monoxide poisoning, forming a critical component of the overall system design.

- Keyed Valve Control

The keyed valve represents the primary safety feature. It requires a specific key for operation, preventing unauthorized access and accidental turning of the gas supply. Without the key, the gas flow remains securely shut off, thereby reducing the risk of unintentional gas release. This is particularly relevant in environments with children or where the valve might be inadvertently bumped or tampered with.

- Positive Shut-Off Design

The valve is engineered to provide a positive shut-off, meaning it completely blocks the gas flow when closed. This design minimizes the possibility of even minor gas leaks, which can accumulate over time and pose a significant hazard. Regular inspection and maintenance are essential to ensure the valve maintains its sealing integrity. A faulty valve should be replaced promptly by a qualified technician.

- Pilot Light Monitoring (Where Applicable)

In some older systems, the pilot light serves as a safety feature. If the pilot light is extinguished due to a draft or other issue, a thermocouple shuts off the gas supply to the main burner. This prevents the buildup of uncombusted gas within the appliance and chimney. Modern systems may use electronic ignition and flame sensors to achieve a similar safety function.

- Pressure Regulation

Gas chimney key systems are typically integrated with a pressure regulator. This regulator ensures a consistent gas pressure to the appliance, preventing over-pressurization that could damage components or lead to unsafe combustion. A stable gas pressure contributes to efficient and safe operation of the appliance.

These safety mechanisms, when functioning correctly and regularly maintained, provide significant protection against gas-related hazards. It is imperative that users understand the operation of these features and adhere to recommended maintenance schedules. Neglecting these safety aspects can compromise the integrity of the system and increase the risk of accidents.

4. Key Control

The essence of the gas chimney key system revolves around the concept of key control, which directly dictates its functionality and inherent safety characteristics. The purpose of a physical key is to restrict access to the gas supply, acting as a primary safeguard against unauthorized use or accidental gas release. The physical key acts as an enabling device, without which the gas supply remains securely shut off. The absence of the key prevents manipulation of the valve, mitigating potential risks associated with unintentional gas flow. Consider, for example, a scenario where children are present. Without the key control feature, the temptation or inadvertent action of a child could lead to a dangerous gas leak. Similarly, in rental properties or public spaces, unrestricted access to a gas valve significantly elevates the risk of tampering or vandalism.

Effective key control demands responsible management of the key itself. Its storage location should be both accessible to authorized users and secure from unauthorized individuals. A readily accessible key allows for swift action in emergencies, while secure storage prevents misuse. Loss of the key presents a practical challenge, necessitating replacement and potentially valve modification to maintain security. Furthermore, the physical design of the key contributes to its control effectiveness. Uniquely shaped keys or those requiring specific insertion depths reduce the likelihood of successful manipulation with generic tools. Periodic inspection of the key and valve mechanism ensures proper engagement and prevents wear or damage that could compromise functionality. The key also serves as a visual reminder that the gas supply is connected and potentially active. This visual cue encourages caution and reinforces the need for responsible handling.

In conclusion, key control is not merely an accessory feature of a gas chimney key system; it is a fundamental element of its operational design and safety performance. Responsible key management, coupled with a robust valve mechanism, significantly minimizes the risks associated with gas leaks and unauthorized use. Challenges related to key loss or damage necessitate proactive measures to maintain the integrity of the system and ensure continued safety. A comprehensive understanding of key control and its implications is, therefore, paramount for all users of gas-fueled appliances employing this type of system.

5. Leak Prevention

Effective leak prevention is a critical safety component of any gas-fueled appliance system, and the proper functioning of a gas chimney key is central to maintaining this safety. Leaks, even small ones, can lead to significant hazards including fire, explosion, and carbon monoxide poisoning. The design and operation of the valve controlled by the device are specifically intended to minimize these risks.

- Positive Valve Seal

The gas chimney key system incorporates a valve designed to create a positive seal when in the closed position. This seal physically obstructs the flow of gas, preventing its escape into the surrounding environment. The effectiveness of this seal is contingent upon the quality of the valve components, proper installation, and regular maintenance. A worn or damaged valve may fail to achieve a complete seal, resulting in a slow, persistent leak. Such leaks may be difficult to detect initially but can accumulate over time, posing a significant danger.

- Key-Controlled Access

Restricting access to the gas supply through a key-controlled mechanism serves as a leak prevention measure. It prevents unauthorized or accidental opening of the valve, which could lead to unintended gas release. This is particularly important in environments where children or individuals unfamiliar with the system have access. The key should be stored in a secure location, accessible only to authorized users, to maintain this control.

- Regular Inspection Procedures

To ensure ongoing leak prevention, regular inspection of the entire gas system, including the valve controlled by the key, is essential. This involves visually inspecting the valve for signs of corrosion or damage, as well as using a soap-and-water solution to check for leaks around connections. Any evidence of leaks should be addressed immediately by a qualified technician. Regular inspections help to identify and rectify potential problems before they escalate into serious hazards.

- Material Compatibility

Gas valves must be constructed of materials resistant to corrosion or degradation by natural gas. Valve seats, seals, and body material must be properly rated and selected for gas line use. Using the wrong materials can cause premature component failure and gas leakage.

The facets discussed underscore the vital connection between leak prevention and the functionality of a gas chimney key. Its design and application are critical for the safe operation of gas-fueled appliances. The importance of proper installation, regular maintenance, and diligent monitoring cannot be overstated, as they are essential for mitigating the risks associated with gas leaks.

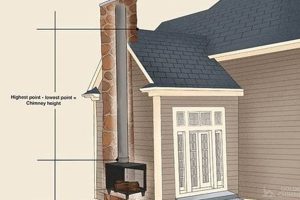

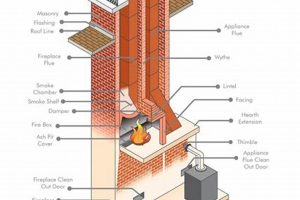

6. Chimney Connection

The chimney connection represents a critical interface in any gas-fueled appliance system employing a gas chimney key. The proper evacuation of combustion byproducts is paramount for both safe and efficient operation. The chimney, as the conduit for these gases, directly impacts the performance and safety profile of the entire system. A malfunctioning or improperly connected chimney can negate the safety features of the gas chimney key and related components. For example, a blocked chimney can cause backdrafting, forcing carbon monoxide into the living space, regardless of the functionality of the shut-off valve.

The gas chimney key controls the flow of gas to the appliance, and the chimney connection dictates the path for the resulting exhaust. A properly sized and installed chimney ensures adequate draft, which facilitates the removal of combustion gases and prevents their accumulation. This is particularly important in older systems where a natural draft chimney is relied upon. In these cases, factors such as chimney height, diameter, and insulation play a significant role. Conversely, a chimney that is too large can result in insufficient draft, leading to incomplete combustion and increased levels of carbon monoxide. Furthermore, the material of the chimney liner must be compatible with the combustion byproducts to prevent corrosion and deterioration, which can compromise the structural integrity of the chimney and create pathways for leaks. Real-world examples include instances where improperly installed gas fireplace inserts have led to carbon monoxide poisoning due to incompatible flue liners.

Therefore, the connection between the gas chimney key and the chimney is not merely a physical one; it is a functional interdependence that directly impacts safety and efficiency. Ensuring the chimney is properly sized, installed, and maintained is as crucial as ensuring the gas chimney key and associated valve are functioning correctly. Neglecting the chimney connection can undermine the entire safety design of the system, leading to potentially hazardous consequences. Regular inspection and cleaning of the chimney are essential to maintain its functionality and prevent the buildup of soot, creosote, or other obstructions that can impede proper venting.

7. Appliance Compatibility

The compatibility between a gas appliance and the gas chimney key system governing its gas supply is a non-negotiable prerequisite for safe and efficient operation. This compatibility encompasses several interconnected aspects, each playing a pivotal role in ensuring the reliable and hazard-free use of the appliance.

- Pressure Regulation Matching

The gas pressure requirements of the appliance must align precisely with the pressure delivered by the gas line and regulated by any components within the gas chimney key system. An imbalance can lead to either insufficient gas flow, resulting in incomplete combustion and carbon monoxide production, or excessive gas flow, creating a fire hazard. For example, connecting an appliance designed for low-pressure gas to a high-pressure line without proper regulation could overwhelm the appliance’s internal components and cause a gas leak. The gas chimney key valve and associated pressure regulator must be selected to match the appliance’s specifications.

- Valve Capacity and Flow Rate

The gas chimney key’s valve must possess sufficient capacity to deliver the required gas flow rate to the appliance, particularly during peak demand. A valve with inadequate capacity will starve the appliance of gas, leading to poor performance and potential safety issues. Conversely, an oversized valve may introduce unnecessary complexity and expense without providing any functional benefit. A real-world scenario involves attempting to operate a large gas furnace with a valve designed for a small fireplace; the furnace will struggle to reach its set temperature, and incomplete combustion may occur. Proper sizing ensures both adequate performance and optimal safety.

- Connection Fittings and Standards

The connection fittings between the gas line, the gas chimney key components, and the appliance itself must adhere to established safety standards and be compatible in terms of size and thread type. Mismatched fittings can create weak points in the system, prone to leaks or catastrophic failure. For instance, attempting to connect a flared gas line to a compression fitting without an adapter will likely result in a gas leak due to the incompatible sealing surfaces. Adherence to ANSI standards and local building codes is paramount in ensuring proper connections and minimizing the risk of gas leaks.

- Ignition System Synchronization

In appliances with electronic ignition systems, the gas chimney key system should not interfere with the ignition sequence or flame sensing mechanisms. Any disruption to these systems can result in delayed ignition, flame instability, or complete failure of the appliance to operate safely. For instance, a poorly installed gas chimney key system could introduce electrical interference that prevents the electronic ignition from properly detecting the presence of a flame, causing the gas supply to shut off prematurely or, worse, allowing gas to accumulate without igniting. Compatibility between the gas control system and the appliance’s ignition system is crucial for reliable and safe operation.

The interplay between these facets highlights the significance of thorough assessment and verification during the installation or replacement of a gas chimney key system. Failure to ensure appliance compatibility can compromise safety, efficiency, and the lifespan of the gas appliance. Consulting with a qualified gas appliance technician is strongly recommended to ensure proper system design and avoid potentially hazardous situations.

Frequently Asked Questions Regarding Gas Chimney Keys

The following questions address common concerns and misconceptions surrounding the installation, operation, and maintenance of gas chimney key systems.

Question 1: What constitutes a properly functioning gas chimney key?

A properly functioning gas chimney key allows for complete shutoff of the gas supply to the appliance when in the “off” position, and allows for a consistent and controlled flow of gas when in the “on” position. There must be no detectable gas leaks when the valve is closed, and the key should turn smoothly and without excessive force.

Question 2: How frequently should a gas chimney key system be inspected?

A gas chimney key system requires inspection by a qualified professional at least annually, preferably before the start of each heating season. More frequent inspections may be warranted if the appliance is used heavily or if any irregularities are observed.

Question 3: What are the potential hazards associated with a malfunctioning gas chimney key?

A malfunctioning gas chimney key can lead to gas leaks, explosions, fires, and carbon monoxide poisoning. Even small leaks can accumulate over time and pose a significant risk. A valve that does not fully shut off the gas supply is particularly dangerous.

Question 4: Can a gas chimney key be replaced by a homeowner?

Replacement of a gas chimney key should only be performed by a qualified gas appliance technician. Improper installation can lead to gas leaks and other hazards. The technician will ensure that the replacement valve is compatible with the appliance and complies with all relevant safety codes.

Question 5: What is the recommended method for detecting gas leaks in a gas chimney key system?

The recommended method involves applying a soap and water solution to all gas line connections, including the valve controlled by the key. If bubbles form, this indicates a gas leak. The gas supply should be immediately shut off, and a qualified technician should be contacted.

Question 6: What should be done if the gas chimney key is lost or damaged?

If the gas chimney key is lost or damaged, a replacement key should be obtained from a qualified supplier. In some cases, it may be necessary to replace the entire valve mechanism to ensure proper key engagement and prevent unauthorized access. Do not attempt to operate the valve with an improvised tool.

These FAQs are not exhaustive but cover the most common issues. Refer to a qualified technician for specific concerns.

The following section will delve into troubleshooting procedures for common problems encountered with the appliance.

Conclusion

This discussion has extensively examined the purpose, operation, and safety implications of the gas chimney key. Its function as a control mechanism for gas flow, leak prevention, and overall system safety has been highlighted. The critical interplay between key control, valve integrity, and chimney connection has been emphasized.

Given the potential hazards associated with gas-fueled appliances, rigorous adherence to safety protocols and regular professional maintenance are essential. Neglecting these aspects can compromise the system’s integrity and endanger life and property. A comprehensive understanding and responsible application of these guidelines remain paramount.