This pigment, a fine black powder, is produced through the incomplete combustion of organic materials. A common instance of its formation occurs within flues and exhaust systems where carbon-based fuels are burned. The resultant substance, primarily composed of elemental carbon, is characterized by its high tinting strength and lightfastness.

Historically, this material has served as a crucial component in various applications, ranging from artistic endeavors like ink and paint production to industrial processes such as rubber manufacturing and plastics coloring. Its value stems from its ability to impart deep, consistent color and enhance the durability of composite materials. Furthermore, its relative ease of production made it an accessible resource across different eras and cultures.

Considering its unique properties and historical significance, further exploration into its production methods, chemical composition, and contemporary uses will provide a more complete understanding of its impact across diverse fields.

Practical Guidance Regarding Soot Management

Effective management of byproduct accumulation is crucial for maintaining the operational efficiency and safety of combustion-based systems. The following guidance offers practical steps for mitigating its negative effects.

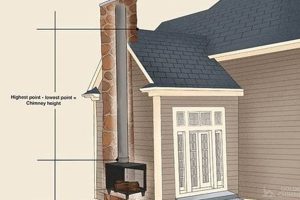

Tip 1: Implement Regular Inspections: Consistent visual examinations of flues and exhaust systems are essential. Early detection of buildup allows for proactive intervention, preventing potential blockages and associated hazards.

Tip 2: Schedule Professional Cleanings: Periodic cleaning by qualified technicians removes accumulated deposits. This service ensures optimal system performance and reduces the risk of chimney fires.

Tip 3: Optimize Combustion Efficiency: Adjusting fuel-to-air ratios can minimize the production of particulate matter. Proper combustion reduces the quantity of residue deposited within the system.

Tip 4: Utilize Appropriate Fuel Types: Employing fuels with lower ash content can significantly decrease byproduct formation. Selecting cleaner-burning fuels is a proactive step in preventative maintenance.

Tip 5: Ensure Proper Ventilation: Maintaining adequate airflow within the system promotes complete combustion and reduces the likelihood of particle deposition. Ventilation assessment is a critical aspect of system maintenance.

Tip 6: Monitor System Performance: Tracking metrics such as draft pressure and exhaust temperature can indicate potential accumulation issues. Deviations from normal operating parameters warrant further investigation.

Adhering to these guidelines will minimize the challenges associated with residue management, ensuring the safe and efficient operation of combustion-based equipment. Proactive measures are vital for preventing system degradation and potential hazards.

By implementing these strategies, stakeholders can mitigate the operational and safety risks associated with byproduct accumulation, fostering a safer and more efficient operating environment.

1. Incomplete Combustion

Incomplete combustion, a chemical process characterized by insufficient oxygen supply during the burning of fuels, is the primary genesis of residue within exhaust systems. The implications of this phenomenon extend beyond mere inefficiency; it directly correlates with the formation of problematic carbonaceous deposits.

- Reduced Oxygen Availability

When oxygen is limited during combustion, fuel molecules fail to fully oxidize. This leads to the production of intermediate compounds, such as carbon monoxide (CO) and unburned hydrocarbons, rather than complete oxidation into carbon dioxide (CO2) and water (H2O). This oxygen deficiency is a fundamental driver of byproduct formation.

- Formation of Carbon Monoxide

Carbon monoxide is a toxic gas, but its presence is also indicative of incomplete combustion. The energy that would have been released by fully oxidizing carbon to carbon dioxide is not realized, and the unreacted carbon atoms often combine to form solid particulate matter. In heating systems, elevated CO levels signal a need for adjustment to air-fuel ratios.

- Production of Soot and Particulate Matter

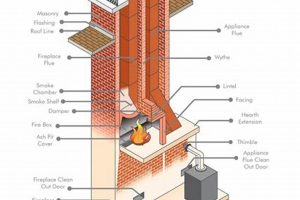

Unburned carbon and hydrocarbon fragments coalesce into soot particles, which deposit on the interior surfaces of flues. These particles, commonly observed as black, powdery residue, accumulate over time, reducing draft efficiency and increasing the risk of chimney fires. The composition of these deposits varies depending on the fuel source and combustion conditions, but they are primarily composed of elemental carbon.

- Creosote Formation

In wood-burning appliances, incomplete combustion leads to the condensation of volatile organic compounds and water vapor within the flue. This condensate mixes with soot and forms creosote, a highly flammable substance that poses a significant fire hazard. Creosote buildup necessitates regular professional cleaning to prevent catastrophic incidents.

The facets of incomplete combustion converge to illustrate its pivotal role in residue formation. The deposition of soot and creosote, directly resulting from this inefficient process, necessitates consistent monitoring and maintenance to ensure safe and efficient operation of any combustion-based system.

2. Carbonaceous Byproduct

Carbonaceous byproduct represents a direct outcome of incomplete combustion processes, forming the essential substance identified as chimney residue. Its presence signals inefficient fuel utilization and poses significant risks within combustion systems.

- Compositional Overview

This byproduct is predominantly composed of elemental carbon, alongside various organic compounds and ash. The specific makeup varies contingent upon the fuel type and combustion efficiency. For instance, wood combustion yields substantial creosote deposits, whereas fossil fuel combustion may result in higher sulfurous compound concentrations within the residue. These variations in composition dictate the residue’s physical properties and reactivity.

- Formation Mechanisms

The formation of carbonaceous byproduct occurs when fuel molecules are not completely oxidized during combustion. Insufficient oxygen supply or inadequate mixing leads to the creation of intermediate carbon-rich compounds that condense and solidify as soot and other particulate matter. These particles are then carried by exhaust gases and deposited onto flue surfaces.

- Accumulation and Impact

The progressive accumulation of this material within flues and exhaust systems reduces draft efficiency, impeding the flow of combustion gases. This restriction can lead to dangerous conditions, such as carbon monoxide backdrafts and increased fire risk. Moreover, the insulating properties of the accumulated residue can cause elevated flue temperatures, further escalating the potential for structural damage.

- Management and Mitigation

Effective management involves optimizing combustion processes to minimize the formation of carbonaceous byproducts and implementing regular cleaning schedules to remove accumulated deposits. Fuel selection also plays a critical role; cleaner-burning fuels produce less residue and reduce the associated risks. Employing technologies such as catalytic converters can further reduce the emission of particulate matter from combustion systems.

The multifaceted nature of carbonaceous byproduct, from its compositional variability to its detrimental impacts on system performance and safety, underscores the importance of proactive management. Addressing the formation and accumulation of this material is essential for ensuring the safe and efficient operation of combustion-based technologies.

3. System Degradation

The accumulation of carbonaceous deposits directly accelerates the degradation of venting systems. This degradation manifests in various forms, impacting both the functional efficiency and structural integrity of the affected components.

- Corrosion of Metal Components

Chimney residue often contains acidic compounds, particularly sulfurous oxides from the combustion of fuels containing sulfur. These compounds react with moisture to form corrosive acids that attack metal components of the venting system, leading to rust, pitting, and eventual structural weakening. The corrosion process compromises the integrity of the flue liner, connectors, and other metal parts, diminishing their capacity to contain combustion gases safely. Examples include the rapid deterioration of unlined chimney flues exposed to condensates from high-efficiency furnaces.

- Erosion of Masonry Structures

In masonry chimneys, the freeze-thaw cycle exacerbates the damaging effects of accumulated residue. Moisture trapped within the porous brick or mortar reacts with the acidic compounds from the residue, causing the masonry to crumble and spall. This erosion weakens the chimney structure, potentially leading to collapse. The degradation of mortar joints allows flue gases to leak into the surrounding building structure, posing a carbon monoxide hazard and accelerating structural damage.

- Reduced Draft Efficiency

The buildup of carbonaceous deposits reduces the effective cross-sectional area of the flue, impeding the flow of combustion gases. This restricted airflow diminishes draft efficiency, leading to incomplete combustion, increased carbon monoxide production, and potential backdrafting. Reduced draft efficiency compromises the performance of the heating appliance, increasing fuel consumption and potentially leading to unsafe operating conditions.

- Increased Risk of Chimney Fires

The flammable nature of accumulated residue, especially creosote from wood-burning appliances, poses a significant fire hazard. Elevated temperatures within the flue can ignite the residue, leading to a rapid and uncontrolled fire that can spread to the surrounding building structure. Chimney fires cause extensive property damage and pose a direct threat to life safety. Regular inspection and cleaning are essential to mitigate this risk.

These degradation pathways highlight the long-term consequences of neglecting residue management. The cumulative effect of corrosion, erosion, reduced draft, and fire risk underscores the necessity of proactive maintenance to preserve the structural integrity and operational safety of venting systems.

4. Fire Hazard

The presence of significant fire risk is intrinsically linked to accumulated residue within flues. This risk stems from the combustible nature of the deposits, primarily composed of carbon and volatile organic compounds. These compounds, when exposed to sufficient heat, readily ignite, initiating a chimney fire. The intensity and propagation speed of such fires are often exacerbated by the restricted airflow within the flue, creating a rapid and potentially catastrophic event. A prime example is the ignition of creosote buildup in wood-burning stoves, where accumulated layers can reach temperatures conducive to combustion, leading to uncontrolled fires that extend into the building structure.

The composition of the residue directly influences the severity of the associated fire hazard. Residue from oil or gas combustion, while often less voluminous than that from wood, can still contain flammable hydrocarbons that contribute to the risk. Furthermore, the physical structure of the deposit plays a role; loose, porous accumulations ignite more readily than tightly packed, denser layers. Regular professional inspections and cleaning are therefore critical, enabling identification and removal of potential ignition sources before they reach critical mass. Preventing the conditions that favor buildup, such as ensuring complete combustion and proper ventilation, also minimizes fire risk.

The understanding of this connection is paramount for homeowners and professionals alike. Recognizing the combustible potential of flue deposits allows for informed decisions regarding maintenance and operation. Ignoring this relationship, on the other hand, leads to increased vulnerability to chimney fires, with potentially devastating consequences. Prioritizing regular inspection and cleaning schedules mitigates this specific fire risk, safeguarding both property and lives.

5. Maintenance Imperative

Sustained operational safety and efficiency of combustion systems necessitate regular and thorough maintenance. The accumulation of “chimney black” directly impacts the performance and safety, making scheduled maintenance an unavoidable requirement.

- Safety Enhancement

Regular maintenance removes combustible deposits, mitigating the risk of chimney fires. The presence of creosote, a byproduct of wood combustion, significantly elevates fire hazards. Scheduled cleanings eliminate this buildup, preventing catastrophic events and safeguarding building occupants. For instance, annual professional inspection and cleaning of wood-burning stoves drastically reduces the incidence of chimney fires.

- Efficiency Optimization

Accumulated deposits impede airflow and reduce the efficiency of combustion systems. This leads to increased fuel consumption and higher energy costs. Regular maintenance removes these obstructions, restoring optimal draft and combustion efficiency. For example, cleaning residue from a furnace flue improves heat transfer, lowering energy bills and reducing greenhouse gas emissions.

- Structural Integrity Preservation

Acidic compounds within “chimney black” corrode metal components and erode masonry structures. Regular maintenance prevents this degradation, extending the lifespan of the venting system and preventing costly repairs. Routine inspections identify early signs of corrosion or structural damage, allowing for timely intervention. Applying protective coatings to flue liners, for instance, can prevent corrosion and prolong their service life.

- Regulatory Compliance

Many jurisdictions mandate regular inspection and maintenance of combustion systems to ensure safety and environmental compliance. Failure to adhere to these regulations can result in fines or legal liabilities. Scheduled maintenance ensures compliance with applicable codes and standards. Maintaining records of inspections and cleanings demonstrates due diligence and protects against potential legal action.

These interconnected facets underscore the critical importance of maintenance in mitigating the risks associated with “chimney black”. Consistent adherence to a maintenance schedule is not merely a suggestion but a fundamental requirement for ensuring the safe, efficient, and compliant operation of any combustion-based system.

Frequently Asked Questions

The following addresses common inquiries regarding “chimney black”, providing clarity on its formation, risks, and management. These answers are designed to offer comprehensive information for system operators and homeowners.

Question 1: What exactly constitutes “chimney black?”

The term refers to the carbonaceous residue resulting from incomplete combustion within flues and exhaust systems. It is primarily composed of elemental carbon, along with various organic compounds and ash.

Question 2: What are the primary dangers associated with buildup?

Accumulation can lead to reduced draft efficiency, increased risk of chimney fires, carbon monoxide backdraft, and accelerated corrosion of system components.

Question 3: How frequently should chimneys be professionally cleaned?

The recommended cleaning frequency varies based on fuel type and usage. Wood-burning systems generally require annual inspection and cleaning, while gas or oil systems may need less frequent attention. Consulting a qualified professional is advised.

Question 4: Can the formation be entirely prevented?

Complete elimination is not always feasible. Optimizing combustion efficiency through proper ventilation, fuel selection, and equipment maintenance can minimize its formation.

Question 5: What are the signs of excessive accumulation?

Indicators include reduced draft, visible soot buildup around appliance connections, unusual odors, and the presence of creosote (in wood-burning systems).

Question 6: What steps can be taken to mitigate the fire risk?

Regular professional inspection and cleaning are paramount. Additionally, ensuring proper ventilation, using seasoned wood (for wood-burning appliances), and maintaining the system’s mechanical integrity are crucial.

Understanding these key points is essential for maintaining safe and efficient operation of combustion-based systems. Proactive management and routine inspection are the cornerstones of effective mitigation.

The subsequent section will explore specific techniques employed for effective removal of this material from various system types.

Conclusion

This exploration has elucidated the formation, dangers, and essential management strategies surrounding “chimney black.” A clear understanding of its carbonaceous composition, coupled with an appreciation for its contribution to system degradation and fire hazards, provides a foundation for informed action. The imperative of regular maintenance, encompassing both inspection and removal, stands as a central tenet for ensuring the safe and efficient operation of combustion-based systems.

The ongoing presence of “chimney black” represents a persistent challenge demanding vigilance and proactive intervention. Ignoring its accumulation carries significant risks, impacting both property and human safety. Therefore, a commitment to regular maintenance schedules and adherence to best practices is not merely advisable, but a necessary component of responsible system ownership and operation. Continued awareness and diligent application of these principles will mitigate the inherent dangers and promote a safer environment.