The internal structure of a flue, the vertical channel within a structure designed to vent combustion gases away from a building, plays a vital role in heating system performance and safety. This component, often constructed of materials like brick, clay tile, or metal, provides a contained pathway for smoke and other byproducts of fire to exit a building. For example, creosote, a flammable byproduct of wood burning, can accumulate on these interior surfaces, posing a fire hazard if not properly maintained.

The integrity of this internal venting passage is paramount for efficient operation and occupant safety. Historical construction methods frequently employed brick and mortar, which, over time, can deteriorate and allow harmful gases like carbon monoxide to leak into living spaces. Modern construction often utilizes insulated metal flues to improve draft and reduce condensation, leading to enhanced heating efficiency and minimizing potential hazards. Regular inspections and cleaning of this critical component are essential for preventing chimney fires and maintaining a safe living environment.

Therefore, an understanding of the various components and the maintenance needs are vital for responsible homeowners. The following sections will detail the importance of regular inspections, proper cleaning techniques, and common issues that can arise within a flue system.

Inside Chimney Tips

Maintaining the integrity of the internal flue system is crucial for safe and efficient heating appliance operation. The following tips provide guidance on preserving its function and preventing potential hazards.

Tip 1: Schedule Annual Professional Inspections: A certified chimney sweep can identify structural weaknesses, creosote buildup, or obstructions that impede proper venting and pose a fire risk.

Tip 2: Utilize Appropriate Fuel: Burning only seasoned, dry wood in wood-burning appliances minimizes creosote formation. Avoid burning treated wood or trash, as these release harmful chemicals and contribute to accelerated degradation of the internal structure.

Tip 3: Ensure Proper Appliance Installation: Incorrectly installed appliances can generate excessive smoke and heat, damaging the internal lining and increasing the risk of carbon monoxide poisoning. Follow manufacturer’s guidelines meticulously.

Tip 4: Address Moisture Intrusion Promptly: Water damage weakens the structure, leading to cracks and spalling. Repair leaks and ensure proper flashing to prevent water from entering the system.

Tip 5: Install a Chimney Cap: A chimney cap prevents rain, snow, and debris from entering the flue, thereby protecting against moisture damage and blockages caused by nesting animals.

Tip 6: Maintain Proper Draft: A strong draft ensures efficient venting of combustion gases. Address any issues affecting draft, such as oversized flues or obstructions, to prevent backdrafting and carbon monoxide exposure.

Tip 7: Regularly Clean the System: Frequent cleaning removes creosote and other debris, reducing the risk of chimney fires and improving appliance efficiency. The frequency of cleaning depends on fuel type and appliance usage.

Adhering to these tips significantly reduces the risk of chimney fires, carbon monoxide poisoning, and structural damage, thereby extending the lifespan of the venting system and ensuring a safe and efficient heating experience.

The following sections will provide further details on specific maintenance procedures and troubleshooting common issues.

1. Flue liner integrity

Flue liner integrity is fundamentally linked to the safety and operational effectiveness of the internal structure of a chimney. The flue liner, typically constructed of clay tile, metal, or concrete, forms the internal pathway for combustion gases to exit a building. Its primary function is to contain these gases, which include carbon monoxide and other harmful byproducts, preventing them from seeping into the building’s living spaces. A compromised liner, characterized by cracks, gaps, or deterioration, negates this containment, creating a significant health and safety risk. For instance, carbon monoxide leaks, resulting from damaged liners, can lead to carbon monoxide poisoning, a potentially fatal condition. Furthermore, damaged liners can expose combustible building materials to high temperatures, increasing the risk of chimney fires.

The condition of the flue liner directly impacts the efficiency of the heating appliance. A well-maintained, intact liner promotes proper draft, facilitating the complete removal of combustion gases. Conversely, a damaged liner can impede draft, leading to incomplete combustion, reduced heating efficiency, and increased creosote buildup. Creosote, a flammable byproduct of incomplete combustion, accumulates on the interior surfaces and increases the risk of chimney fires. Regular inspections by qualified professionals are essential to assess the liner’s condition and detect any signs of damage or deterioration. These inspections can reveal issues such as cracked tiles, spalling, or mortar joint erosion, allowing for timely repairs or liner replacements.

In summary, flue liner integrity is paramount for ensuring the safe and efficient operation of any chimney system. Neglecting its maintenance can result in severe consequences, including carbon monoxide poisoning and chimney fires. Regular inspections, prompt repairs, and the use of appropriate liner materials are crucial for maintaining a safe and functional chimney. The overall integrity of this internal component directly influences the safety and well-being of building occupants, highlighting the practical significance of understanding and addressing liner-related issues.

2. Creosote Accumulation

Creosote accumulation within the internal structure of a chimney represents a significant fire hazard and a key determinant of the system’s operational safety and efficiency. This accumulation, a direct byproduct of incomplete combustion in wood-burning appliances, necessitates diligent management to mitigate its inherent risks.

- Formation Process and Composition

Creosote forms when unburned wood particles and volatile gases cool and condense within the flue. Its composition varies depending on the fuel type, combustion efficiency, and chimney temperature, ranging from a flaky soot to a hardened, tar-like substance. Each form poses a distinct fire risk; however, the hardened form is particularly dangerous due to its high flammability and difficulty in removal.

- Factors Influencing Accumulation Rate

Several factors influence the rate at which creosote accumulates. Burning unseasoned wood, operating with a low draft, and using appliances with restricted airflow promote incomplete combustion, leading to increased creosote production. Additionally, cooler flue temperatures accelerate condensation and deposition. These factors collectively contribute to the buildup of hazardous deposits on the internal surfaces.

- Fire Hazards and Prevention

Creosote is highly combustible, and its accumulation significantly elevates the risk of chimney fires. Even a thin layer can ignite under the right conditions, generating intense heat and potentially spreading to the surrounding structure. Preventing creosote accumulation involves burning seasoned wood, ensuring adequate draft, and maintaining optimal appliance airflow. Regular inspections and cleaning are critical for removing existing deposits and preventing future buildup.

- Inspection and Removal Techniques

Professional chimney sweeps employ various techniques to inspect and remove creosote. Inspections involve visual assessments using specialized cameras to examine the internal flue surfaces. Removal methods range from manual scraping with specialized tools to chemical treatments that break down the deposits. The chosen technique depends on the type and thickness of the creosote accumulation, as well as the material of the flue liner. Regular professional cleaning is essential for maintaining a safe and efficient chimney system.

The multifaceted nature of creosote accumulation necessitates a proactive approach to chimney maintenance. From understanding its formation process to implementing effective prevention and removal strategies, responsible homeowners must prioritize diligent management to safeguard against the inherent fire risks associated with this byproduct of wood burning. Regular attention to these details ensures the longevity and safe operation of the chimney system.

3. Draft effectiveness

Draft effectiveness, in the context of a chimney, refers to the ability of the internal structure to facilitate the upward flow of combustion gases from a heating appliance. This effectiveness is intrinsically linked to the design, maintenance, and environmental conditions affecting the internal passage. A properly functioning draft ensures the efficient removal of byproducts such as carbon monoxide, smoke, and particulate matter, directly influencing the safety and air quality within a building. Conversely, inadequate draft can lead to backdrafting, where combustion gases enter the living space, posing a serious health hazard and potentially triggering carbon monoxide poisoning. For instance, a chimney obstructed by debris or poorly designed may exhibit insufficient draft, resulting in smoke spillage into the room during fireplace use.

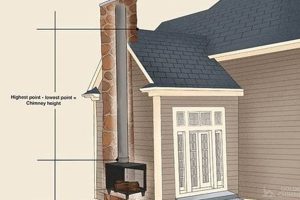

Several factors contribute to the effectiveness of a chimney’s draft. The height and diameter of the internal flue influence the natural buoyancy of hot gases. A taller flue typically generates a stronger draft due to the greater temperature differential between the flue gases and the ambient air. The internal surface smoothness also plays a role; rough or deteriorated surfaces increase friction and impede airflow. Furthermore, external factors, such as wind conditions and the presence of nearby structures, can significantly impact draft. Wind blowing across the chimney outlet can either enhance or diminish draft, depending on the direction and intensity. Buildings or trees that obstruct airflow around the chimney can also create negative pressure zones that reduce draft effectiveness. Proper insulation of the internal structure minimizes heat loss, maintaining the temperature of the flue gases and promoting a stronger draft.

In conclusion, draft effectiveness is a critical performance parameter of a chimney, directly affecting both safety and efficiency. Maintaining a clear, unobstructed, and properly insulated flue is essential for ensuring adequate draft. Regular inspections and cleaning, coupled with addressing any structural deficiencies, contribute to a system that effectively removes combustion gases, minimizing the risk of indoor air pollution and maximizing the performance of the heating appliance. Understanding the factors that influence draft enables informed decision-making regarding chimney design, maintenance, and operation, ultimately promoting a safer and more comfortable living environment.

4. Structural soundness

Structural soundness, in the context of the internal components of a chimney, refers to the ability of the materials and construction to withstand environmental stressors, thermal fluctuations, and the corrosive effects of combustion byproducts over an extended period. This integrity is paramount to prevent the escape of harmful gases and to ensure the chimney’s continued safe operation.

- Material Degradation and Load-Bearing Capacity

The materials used in chimney construction, such as brick, mortar, and flue liners, are subject to degradation from moisture, freeze-thaw cycles, and acidic condensation. Over time, this degradation weakens the materials, reducing the chimney’s load-bearing capacity. For example, cracked or spalling brickwork can compromise the chimney’s structural stability, potentially leading to collapse. Maintaining the integrity of these materials is crucial for preventing structural failure.

- Flue Liner Integrity and Gas Containment

The flue liner, the internal lining of the chimney, is responsible for containing combustion gases and preventing them from seeping into the building’s structure. Cracks or gaps in the flue liner compromise its gas containment function, allowing harmful gases like carbon monoxide to enter living spaces. Regular inspections are necessary to identify and repair any damage to the flue liner, ensuring its continued effectiveness in preventing gas leakage.

- Water Damage and Foundation Stability

Water intrusion into the chimney structure can cause significant damage over time. Water can weaken the mortar joints, leading to structural instability, and can also damage the chimney’s foundation. A compromised foundation can cause the chimney to lean or even collapse. Proper flashing and a functional chimney cap are essential for preventing water damage and maintaining the foundation’s stability.

- Chimney Height and Wind Load Resistance

The height of a chimney influences its susceptibility to wind loads. Taller chimneys are more vulnerable to wind forces, which can exert significant stress on the structure. Proper design and construction techniques are necessary to ensure that the chimney can withstand anticipated wind loads without experiencing structural damage. This includes reinforcing the chimney with steel rods or other structural elements, as well as ensuring that the foundation is adequately sized to support the chimney’s weight and resist overturning forces.

These aspects of structural soundness are interconnected and collectively contribute to the overall safety and longevity. Regular inspections, proper maintenance, and timely repairs are essential for preserving the structural integrity of an internal venting structure and preventing potentially hazardous conditions. A structurally sound system ensures the safe and efficient removal of combustion gases, safeguarding the well-being of building occupants and protecting the building from fire hazards.

5. Obstruction removal

Obstruction removal within the internal venting structure is a critical aspect of chimney maintenance, directly influencing its safety and operational efficiency. The accumulation of debris, nesting animals, and other foreign materials within the flue can impede airflow, creating hazardous conditions and diminishing heating appliance performance.

- Debris Accumulation and Airflow Restriction

Debris, such as leaves, twigs, and deteriorated masonry, can accumulate within the system over time. This accumulation restricts airflow, hindering the proper venting of combustion gases. Reduced airflow can lead to incomplete combustion, increasing creosote buildup and the risk of carbon monoxide poisoning. Regular inspections and cleaning are essential to remove accumulated debris and maintain adequate airflow.

- Nesting Animals and Flue Blockage

Animals, including birds, squirrels, and raccoons, frequently nest within the internal passage, seeking shelter and protection. Nests can completely block the flue, preventing the venting of combustion gases and creating a fire hazard. In addition to the blockage, nesting materials can be highly flammable, further increasing the risk of chimney fires. Chimney caps and screens are effective in preventing animals from entering and nesting within the system.

- Creosote Buildup and Venting Impairment

Creosote, a byproduct of wood burning, accumulates on the inner walls of the system. Excessive creosote buildup can significantly restrict airflow, impairing the venting of combustion gases. This restriction increases the risk of chimney fires, as creosote is highly flammable. Regular cleaning is essential to remove creosote buildup and maintain adequate venting capacity.

- Foreign Object Intrusion and Functionality Disruption

Foreign objects, such as construction materials or dislodged components, can inadvertently enter the chimney and obstruct the flue. These objects can impede airflow and disrupt the proper functioning of the system. Inspection and removal of foreign objects are necessary to restore proper venting and prevent potential hazards. The presence of a chimney cap can mitigate the risk of foreign object intrusion.

The prompt removal of obstructions is crucial for maintaining the safety and efficiency. These obstructions can lead to serious consequences, including chimney fires, carbon monoxide poisoning, and reduced heating appliance performance. Regular inspections, preventive measures, and timely removal are essential for ensuring the safe and reliable operation of the system.

6. Insulation efficiency

Insulation efficiency, within the context of a chimneys internal structure, directly influences the system’s ability to maintain optimal flue gas temperatures, thereby enhancing draft and reducing condensation-related issues. When a chimney is inadequately insulated, the hot flue gases rapidly cool as they ascend the flue. This cooling process diminishes the buoyant force that drives the draft, potentially leading to incomplete combustion and the deposition of creosote, a highly flammable substance. An example of this is seen in older homes with unlined brick chimneys, where the lack of insulation allows for significant heat loss, resulting in poor draft and accelerated creosote accumulation. Properly insulated flues, on the other hand, maintain higher flue gas temperatures, promoting a stronger draft and more complete combustion, thus minimizing creosote formation and reducing the risk of chimney fires. The practical significance of this understanding lies in its ability to mitigate fire hazards, improve heating appliance efficiency, and extend the lifespan of the chimney system.

Further analysis reveals that insulation efficiency directly impacts the longevity of the flue liner. Condensation within the chimney, a consequence of inadequate insulation, results in the formation of corrosive acids that can degrade the flue liner material. For instance, in regions with cold climates, significant temperature differentials between the hot flue gases and the cold external environment exacerbate condensation issues, leading to rapid deterioration of clay tile liners. Insulated metal liners offer a solution to this problem, as they not only retain heat more effectively but also resist corrosion from acidic condensate. The practical application of this understanding is evident in the increasing adoption of insulated metal liners in both new construction and chimney restoration projects, aimed at preventing liner degradation and ensuring long-term system integrity.

In conclusion, insulation efficiency is an indispensable component of a well-functioning chimney system. It mitigates fire hazards by promoting proper draft and reducing creosote accumulation, extends the lifespan of the flue liner by minimizing condensation and corrosion, and enhances the overall efficiency of the heating appliance. While achieving optimal insulation presents challenges in existing structures, the benefits of improved safety, efficiency, and longevity outweigh the costs associated with upgrading the chimney’s insulation. Prioritizing insulation efficiency is, therefore, a prudent investment in the long-term performance and safety of the internal structure.

Frequently Asked Questions

The following questions address common concerns and misunderstandings regarding the internal workings of a chimney system. The responses aim to provide clarity and promote a better understanding of proper maintenance and safety practices.

Question 1: What constitutes an acceptable material for lining the interior of a chimney?

Acceptable materials for lining a chimney include clay tile, cast-in-place concrete, and stainless steel. The selection of material depends on the type of fuel burned and the specific requirements of the heating appliance. Each material offers varying degrees of resistance to heat, corrosion, and thermal stress.

Question 2: How frequently should a chimney’s interior be professionally inspected?

A chimney’s interior should be professionally inspected at least annually. More frequent inspections are recommended if the appliance is used heavily or if there are known issues with the system’s performance. Regular inspections allow for the early detection of potential hazards and structural problems.

Question 3: What are the primary indicators of creosote buildup within the internal structure?

Primary indicators of creosote buildup include a restricted flue opening, the presence of black, flaky or tar-like deposits on the interior surfaces, and a strong, pungent odor emanating from the chimney. These indicators suggest a need for immediate cleaning to prevent chimney fires.

Question 4: What measures can be taken to prevent animals from nesting within the system?

Preventive measures include installing a chimney cap with a mesh screen, regularly inspecting the top of the chimney for signs of animal activity, and trimming any overhanging branches that could provide access. These measures deter animals from entering and nesting within the flue.

Question 5: How does moisture intrusion affect the structural integrity of the interior?

Moisture intrusion can lead to the deterioration of mortar joints, spalling of brickwork, and corrosion of metal components within the system. These effects weaken the chimney’s structural integrity and can compromise its ability to safely vent combustion gases.

Question 6: What are the potential consequences of neglecting interior maintenance?

Neglecting interior maintenance can result in chimney fires, carbon monoxide poisoning, structural collapse, and reduced heating appliance efficiency. These consequences pose significant risks to property and occupant safety, underscoring the importance of regular inspections and timely repairs.

In summary, diligent maintenance and a thorough understanding of the internal structure are essential for ensuring the safe and efficient operation of a chimney system. Neglecting these aspects can lead to serious consequences, emphasizing the need for proactive care.

The following sections will provide practical guidance on specific maintenance procedures and troubleshooting common issues encountered within the interior venting structure.

Conclusion

The foregoing analysis has elucidated the critical role of the internal structure in the safe and efficient operation of a venting system. Key considerations, including flue liner integrity, creosote management, draft effectiveness, structural soundness, obstruction removal, and insulation efficiency, collectively determine the system’s performance and longevity. Failure to address any of these factors can result in significant hazards and diminished functionality. Consistent adherence to recommended inspection and maintenance practices is essential for mitigating risks.

The complex interplay of factors within “inside chimney” necessitates ongoing vigilance and proactive intervention. Responsible homeowners and building managers must prioritize regular assessments and necessary repairs to safeguard property and occupant well-being. The future of safe and efficient combustion relies on a continued commitment to understanding and addressing the challenges presented by these intricate systems.