A system designed to vent exhaust gases from a heating appliance, such as a stove or furnace, horizontally through a building’s exterior wall. This apparatus typically includes components like a thimble, stove pipe adapter, and termination cap, ensuring safe and efficient expulsion of combustion byproducts. For instance, a wood-burning stove installation in a cabin might necessitate this configuration due to space constraints or structural considerations.

Its application offers several advantages, including simplified installation in certain scenarios where a traditional vertical chimney is impractical or costly. Historically, these solutions have evolved to meet stringent safety standards, addressing concerns about heat transfer and potential fire hazards. The development of insulated pipes and improved sealing methods has significantly enhanced the reliability and safety of these systems.

The following sections will delve into the key components involved, proper installation techniques, relevant safety considerations, and guidelines for selecting the appropriate apparatus for specific applications, ensuring a comprehensive understanding of these venting solutions.

The following guidelines provide essential considerations for the selection, installation, and maintenance of through-wall venting systems, ensuring safe and efficient operation.

Tip 1: Component Compatibility. Verify all components are listed and labeled by a recognized testing laboratory, ensuring they are designed to function together as a certified system. Mixing components from different manufacturers can compromise safety and void warranties.

Tip 2: Proper Clearance. Maintain adequate clearance to combustible materials as specified by the manufacturer’s instructions and relevant building codes. Insufficient clearance can lead to overheating and potentially ignite nearby structures.

Tip 3: Secure Connections. Ensure all pipe sections are securely joined using appropriate locking mechanisms or fasteners as prescribed by the manufacturer. Loose connections can result in exhaust leaks and hazardous conditions.

Tip 4: Thimble Installation. The thimble, which passes through the wall, should be correctly sized and installed with non-combustible materials, creating a fire-resistant barrier between the pipe and the wall structure.

Tip 5: Termination Cap Placement. Position the termination cap away from windows, doors, air intakes, and other potential sources of re-entry of exhaust gases into the building. Adhere to local regulations regarding minimum distances.

Tip 6: Regular Inspection. Periodically inspect the entire system for signs of corrosion, damage, or blockage. Address any issues promptly to maintain optimal performance and safety.

Tip 7: Professional Installation. Consider engaging a qualified professional for installation, particularly if unfamiliar with building codes or mechanical systems. Proper installation is crucial for safety and long-term reliability.

Adhering to these recommendations ensures the safe and effective operation of through-wall venting, minimizing risks associated with combustion appliances.

The next section will address specific scenarios where through-wall venting is most suitable and highlight potential challenges to consider before implementation.

1. Certified Components

The integration of certified components within a through wall chimney kit is paramount to ensuring safe and effective operation. Certification, typically conducted by accredited testing laboratories, validates that each component meets specific performance standards related to heat resistance, structural integrity, and flue gas containment. The absence of certified components introduces a significant risk of system failure, potentially leading to fire hazards or carbon monoxide exposure. For example, using uncertified chimney pipes may result in premature degradation due to excessive heat, compromising the system’s ability to safely vent exhaust gases.

The selection of certified components directly impacts the overall efficiency and longevity of the through wall chimney kit. Certified components undergo rigorous testing to verify their compatibility and performance within the complete system. This validation provides assurance that the individual parts will function cohesively to achieve optimal venting and minimize the risk of hazardous conditions. A real-world illustration involves a homeowner who replaced a damaged, certified chimney pipe with a non-certified alternative. Subsequently, the uncertified pipe exhibited signs of corrosion and leakage within a short period, necessitating a complete system replacement and incurring significant additional expense.

In summary, the utilization of certified components is not merely a recommendation but a critical requirement for the safe and effective operation of a through wall chimney kit. The certification process provides objective validation of performance and compatibility, mitigating the risks associated with substandard or incompatible parts. Prioritizing certified components ensures adherence to safety standards, enhances system longevity, and ultimately safeguards both property and occupants. This understanding underscores the practical significance of selecting certified components for any through wall chimney kit installation or repair.

2. Clearance to Combustibles

Maintaining adequate clearance to combustibles is a paramount safety requirement for any through wall chimney kit installation. This clearance refers to the minimum distance required between the exterior surface of the chimney components and any adjacent materials that are capable of igniting under sustained heat exposure, such as wood framing, drywall, insulation, or roofing materials. Insufficient clearance creates a direct pathway for heat transfer, elevating the risk of a structural fire. The heat generated by the venting of exhaust gases through the chimney can gradually raise the temperature of nearby combustible materials until they reach their ignition point. A properly installed through wall chimney kit, adhering to specified clearance requirements, effectively mitigates this risk. This necessity often dictates the specific design and materials used in the kit itself.

The implications of inadequate clearance to combustibles extend beyond the immediate vicinity of the chimney. A fire originating from insufficient clearance can rapidly spread throughout the building structure, posing a significant threat to occupants and property. Consider a scenario where a through wall chimney kit is installed with insufficient clearance to wood studs in a wall cavity. Over time, the chronic exposure to elevated temperatures causes the wood to dry out and become increasingly susceptible to ignition. Eventually, the wood reaches its ignition temperature, resulting in a smoldering fire within the wall that may go undetected for an extended period. Therefore, adherence to clearance requirements is not merely a code compliance issue; it is a critical component of fire prevention.

In conclusion, clearance to combustibles is an indispensable safety consideration when utilizing a through wall chimney kit. Failure to adhere to the manufacturer’s specified clearance requirements, as well as relevant building codes, directly increases the risk of a structural fire. This understanding underscores the importance of meticulous planning, precise installation, and diligent inspection to ensure that adequate clearance is maintained throughout the life of the venting system. The financial and human cost of a fire caused by inadequate clearance far outweighs the effort required to ensure proper installation and adherence to safety standards.

3. Secure Pipe Connections

The integrity of a through wall chimney kit hinges significantly on the reliability of its pipe connections. These connections form the critical junctions through which exhaust gases are channeled, and their failure can lead to hazardous conditions. Thus, the construction and maintenance of these connections are of paramount importance.

- Gas Leak Prevention

Secure pipe connections are engineered to create a gas-tight seal, preventing the escape of harmful combustion byproducts such as carbon monoxide. A compromised connection can allow these gases to enter the living space, posing a serious health risk to occupants. For example, crimped pipe ends and locking bands provide mechanical stability and seal integrity.

- Structural Stability

Robust connections provide structural support to the chimney system, ensuring it can withstand external forces such as wind and snow loads. A weakly connected system is susceptible to collapse, potentially damaging property and creating a fire hazard. Threaded or bolted joints contribute to overall system strength and durability.

- Thermal Expansion Accommodation

During operation, chimney pipes experience significant temperature fluctuations. Secure connections must accommodate this thermal expansion and contraction without compromising the seal or structural integrity. Expansion joints or slip connectors are often incorporated to allow for this movement.

- Corrosion Resistance

The materials used in pipe connections must be resistant to corrosion from acidic flue gases and environmental factors. Corrosion can weaken the connections, leading to leaks and eventual failure. Stainless steel and other corrosion-resistant alloys are commonly used to ensure longevity and reliability.

In conclusion, the implementation of secure pipe connections within a through wall chimney kit is not merely a matter of convenience but a fundamental safety imperative. Properly designed and maintained connections contribute directly to the system’s ability to safely and efficiently vent exhaust gases, protecting occupants and property from potential harm. Continuous monitoring and regular inspection are recommended to verify the integrity of these connections throughout the system’s lifespan.

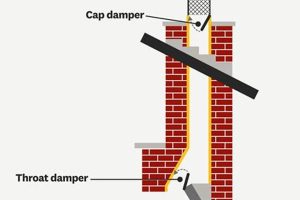

4. Insulated Thimble Barrier

The insulated thimble barrier represents a critical safety component within a through wall chimney kit, addressing the potential fire hazard posed by heat transfer at the point where the chimney pipe penetrates the combustible building structure. Its function is to isolate the high temperatures of the chimney from the surrounding wall materials.

- Thermal Isolation

The primary role of the insulated thimble is to create a thermal break, preventing direct contact between the hot chimney pipe and combustible materials like wood studs or drywall. This isolation is achieved through a combination of non-combustible materials and air space, reducing the conductive heat transfer. For example, a thimble may incorporate ceramic fiber insulation within a double-walled steel construction to minimize heat transmission.

- Fire Resistance

The insulated thimble is designed to provide a specific fire-resistance rating, typically expressed in hours. This rating indicates the length of time the thimble can withstand exposure to high temperatures without allowing the passage of flame or excessive heat to the surrounding structure. Building codes often mandate minimum fire-resistance ratings for thimbles used in through wall chimney installations.

- Code Compliance

The use of an approved and properly installed insulated thimble is essential for compliance with local building codes and regulations. These codes specify the required clearance to combustible materials and the acceptable methods for achieving this clearance. Failure to meet these requirements can result in inspection failures and potential safety hazards.

- Material Integrity

The materials used in the construction of the insulated thimble must be capable of withstanding prolonged exposure to high temperatures and corrosive flue gases without degradation. Common materials include stainless steel, ceramic fiber insulation, and refractory cements, each selected for its heat resistance and durability. Compromised material integrity diminishes the thimble’s capacity for thermal isolation.

The effectiveness of the insulated thimble barrier directly influences the overall safety and performance of the through wall chimney kit. A properly functioning thimble prevents the ignition of combustible materials, mitigating the risk of structural fires and ensuring the safe venting of exhaust gases. Diligence during installation and periodic inspections are paramount to ensure the continued integrity of this crucial component.

5. Proper Termination Placement

Proper termination placement is an indispensable aspect of through wall chimney kit installation, directly impacting both the functionality and safety of the venting system. The termination point, where exhaust gases are discharged, must be strategically positioned to prevent hazards and ensure efficient dissipation of combustion byproducts.

- Preventing Re-entry of Exhaust Gases

The termination point must be located away from windows, doors, air intakes, and other openings in the building envelope to prevent the re-entry of exhaust gases into the living space. Such re-entry can lead to carbon monoxide poisoning and other health risks. Local building codes often specify minimum distances for termination placement relative to these openings. The direction of prevailing winds should also be considered to minimize the potential for backdrafting.

- Minimizing Soot and Debris Deposition

The placement of the termination cap influences the deposition of soot, creosote, and other combustion byproducts on the building’s exterior. Terminating too close to walls or roofing materials can lead to unsightly staining and potential damage. Selecting a termination cap that directs exhaust gases upward and away from the building can mitigate this issue. Additionally, the termination point should be accessible for inspection and cleaning to prevent the buildup of deposits that could obstruct the flue.

- Adhering to Clearance Requirements

The termination point must maintain adequate clearance from combustible materials, such as overhanging eaves, decks, and landscaping. Insufficient clearance can create a fire hazard. Building codes specify minimum clearance distances to prevent the ignition of these materials. The termination cap should also be designed to prevent the accumulation of debris that could obstruct the flue or pose a fire risk.

- Mitigating Nuisance and Environmental Impact

The location of the termination point should consider its potential impact on neighboring properties. Terminating too close to property lines or in areas where exhaust gases can cause a nuisance to neighbors may lead to complaints and legal issues. The termination cap should be designed to minimize noise and visible emissions. Additionally, the type of fuel burned can influence the environmental impact of the exhaust gases, and this should be factored into the termination placement decision.

The strategic selection of a termination point, considering factors such as re-entry prevention, debris deposition, clearance requirements, and nuisance mitigation, is crucial for the safe and efficient operation of a through wall chimney kit. Failure to properly place the termination can result in hazardous conditions, property damage, and legal complications. Therefore, adherence to building codes and manufacturer’s instructions is essential for ensuring proper termination placement.

6. Regular System Inspection

Regular system inspection is a critical component of maintaining a safe and efficient through wall chimney kit. Periodic assessment can identify potential hazards before they escalate, ensuring continued functionality and minimizing risks associated with combustion appliances.

- Creosote Accumulation Monitoring

Creosote, a byproduct of incomplete combustion, can accumulate within the chimney flue. Regular inspections allow for the early detection of creosote buildup, which poses a significant fire hazard. Excessive creosote can ignite, causing a chimney fire that can spread to the building structure. Visual inspection of the flue interior, typically using a mirror and flashlight, reveals the extent of creosote accumulation. Professional chimney sweeps utilize specialized tools to remove creosote, restoring the flue’s drafting efficiency and reducing the risk of fire.

- Component Degradation Assessment

Through wall chimney kits are exposed to harsh environmental conditions and corrosive flue gases. Regular inspections enable the identification of component degradation, such as rust, corrosion, or cracking. Damaged components can compromise the system’s integrity, leading to exhaust leaks or structural failure. For instance, a rusted termination cap can allow rainwater to enter the flue, accelerating corrosion and potentially damaging the connected appliance. Replacing degraded components promptly ensures the continued safe and efficient operation of the chimney system.

- Joint and Connection Security Verification

The joints and connections within a through wall chimney kit must maintain a secure seal to prevent exhaust leaks. Regular inspections involve visually examining all connections for signs of looseness or separation. Exhaust leaks can introduce carbon monoxide into the living space, posing a serious health hazard. Furthermore, loose connections can compromise the structural stability of the chimney system. Tightening loose connections and replacing damaged fasteners are essential maintenance tasks identified through routine inspections.

- Clearance Maintenance Confirmation

Maintaining adequate clearance to combustible materials is paramount for fire safety. Regular inspections involve verifying that the required clearance is maintained between the chimney components and any adjacent combustible materials, such as wood framing or roofing. Over time, structural changes or landscaping growth can reduce the clearance, increasing the risk of fire. Removing obstructions and adjusting the chimney configuration, when possible, ensures continued compliance with safety regulations.

These inspection facets, when integrated into a routine maintenance schedule, contribute significantly to the longevity and safety of a through wall chimney kit. Consistent monitoring allows for proactive intervention, mitigating potential hazards and preserving the integrity of the venting system.

7. Professional Installation Advised

The recommendation of professional installation for a through wall chimney kit stems from the inherent complexities and safety-critical nature of these venting systems. Improper installation can lead to a multitude of hazards, compromising the safety of the building and its occupants. This advice is not merely a suggestion, but a recognition of the specialized knowledge and skills required for a compliant and reliable installation.

- Compliance with Building Codes

Local building codes dictate stringent requirements for chimney installations, including material specifications, clearance to combustibles, and termination placement. Professional installers possess a thorough understanding of these codes and ensure that the installation adheres to all applicable regulations. Non-compliance can result in inspection failures, fines, and potential legal liabilities. For example, an installer will know the specific height requirements for a chimney termination above the roofline to prevent backdrafting, as mandated by the local jurisdiction.

- Safe Venting Practices

Proper venting is crucial for preventing the accumulation of dangerous gases, such as carbon monoxide, within the building. Professional installers are trained in safe venting practices and utilize specialized equipment to ensure a gas-tight seal throughout the chimney system. This includes properly connecting pipe sections, sealing joints, and verifying adequate draft. A professional, for instance, can identify and correct subtle issues like negative pressure within the building that might impede proper venting.

- Combustible Clearance Expertise

Maintaining proper clearance between the chimney components and combustible materials is essential to prevent fire hazards. Professional installers possess the expertise to accurately measure and maintain these clearances, often employing specialized tools and techniques to ensure compliance. They understand the varying heat transfer characteristics of different chimney components and can adjust the installation accordingly. For example, they know how to properly install a through-wall thimble with the correct insulation to protect wood framing from excessive heat.

- Warranty Adherence and System Longevity

Improper installation can void the manufacturer’s warranty on the chimney kit components. Professional installers are familiar with the manufacturer’s requirements and ensure that the installation is performed according to specifications, preserving the warranty coverage. Furthermore, a properly installed chimney system is more likely to function reliably for its intended lifespan, minimizing the need for costly repairs or replacements. This might involve using specific fasteners or sealants recommended by the manufacturer for long-term durability.

In summary, the recommendation of professional installation for a through wall chimney kit underscores the intricate and safety-sensitive nature of these systems. Engaging a qualified professional mitigates the risks associated with improper installation, ensuring code compliance, safe venting practices, proper combustible clearance, and adherence to warranty requirements. The expertise and skills of a professional installer are invaluable in safeguarding the building and its occupants from potential hazards.

Frequently Asked Questions

The following questions address common concerns and misconceptions regarding through wall chimney kits, providing concise answers to enhance understanding of these venting systems.

Question 1: What distinguishes a through wall chimney kit from a traditional chimney system?

A through wall chimney kit vents exhaust gases horizontally through a building’s exterior wall, whereas a traditional chimney system vents vertically through the roof. The former is often employed when a vertical chimney is impractical or structurally infeasible.

Question 2: Are through wall chimney kits suitable for all types of heating appliances?

No, the suitability of a through wall chimney kit depends on the specific heating appliance and local building codes. Compatibility should be verified with the appliance manufacturer and local authorities before installation. Certain appliances may require a traditional chimney for safe and efficient venting.

Question 3: What are the primary safety considerations when installing a through wall chimney kit?

Key safety considerations include maintaining proper clearance to combustible materials, ensuring secure pipe connections, installing an insulated thimble barrier, and positioning the termination cap away from windows, doors, and air intakes. Adherence to manufacturer instructions and building codes is essential.

Question 4: How often should a through wall chimney kit be inspected?

A through wall chimney kit should be inspected at least annually, or more frequently if the appliance is used heavily. Inspections should include checks for creosote accumulation, component degradation, and secure connections.

Question 5: Can a homeowner install a through wall chimney kit, or is professional installation required?

Professional installation is strongly advised due to the complexity and safety-critical nature of through wall chimney kits. Improper installation can lead to fire hazards and carbon monoxide poisoning. Engaging a qualified professional ensures compliance with building codes and safe venting practices.

Question 6: What is the lifespan of a typical through wall chimney kit?

The lifespan of a through wall chimney kit varies depending on the quality of materials, installation practices, and maintenance. With proper installation and regular maintenance, a kit can last for many years. However, components may require replacement over time due to wear and tear.

These FAQs provide a foundational understanding of through wall chimney kits. Selecting the appropriate system and adhering to proper installation and maintenance practices is crucial for safe and efficient venting.

The next section will explore the environmental considerations associated with through wall chimney systems, emphasizing the importance of responsible venting practices.

Conclusion

This exploration has detailed the multifaceted aspects of the through wall chimney kit. From certified components and clearance to combustibles, to secure pipe connections, insulated thimble barriers, proper termination placement, regular system inspections, and the advisory for professional installation, each element plays a critical role. Understanding these elements is essential for ensuring the safe and efficient operation of any appliance utilizing this type of venting system.

Given the potential hazards associated with improper installation and maintenance, diligent adherence to established guidelines and local regulations remains paramount. Prudence and informed decision-making are crucial, as the long-term safety and well-being of occupants depend on the correct application and upkeep of the through wall chimney kit.