A vertical structure designed for expelling exhaust gases or smoke from a building’s heating appliance or fireplace, integrated as a singular, prefabricated unit, exemplifies modern construction techniques. These systems offer simplified installation procedures compared to traditional, multi-component chimney assemblies. As an example, a factory-built, all-metal venting system directly connected to a high-efficiency furnace and extending through the roof serves as a practical application of this technology.

The utilization of such integrated venting solutions provides several advantages. Reduced installation time and labor costs represent significant economic benefits. Enhanced safety through precise manufacturing and minimized on-site assembly errors is crucial. The controlled production environment ensures consistent material quality and structural integrity, leading to improved performance and longevity. Historically, chimney construction involved extensive bricklaying and mortar work, prone to inconsistencies and potential failures. This approach addresses these shortcomings through standardized production and readily available replacement components.

The subsequent sections will delve into specific material considerations, applicable building codes and regulations, performance characteristics under varying environmental conditions, and lifecycle cost analyses related to the adoption of these unified venting systems in residential and commercial construction projects.

Essential Considerations for Integrated Chimney Systems

This section provides crucial guidance for specifying, installing, and maintaining prefabricated, single-unit venting systems. Adherence to these points enhances safety, performance, and longevity.

Tip 1: Material Compatibility: Ensure the selected venting material is fully compatible with the fuel type of the connected appliance. For instance, stainless steel is generally required for condensing gas furnaces due to the corrosive nature of flue gases. Incorrect material selection can lead to rapid deterioration and potential hazards.

Tip 2: Code Compliance Verification: Rigorously confirm that the chosen system is listed and labeled to meet all applicable local and national building codes and standards. This includes certifications from recognized testing agencies. Documentation of compliance is essential for inspections and insurance purposes.

Tip 3: Professional Installation Mandate: Installation should be performed exclusively by qualified and certified professionals. Improper installation can compromise the system’s integrity, leading to leaks, carbon monoxide exposure, and structural damage. Documentation of professional installation is vital.

Tip 4: Proper Sizing and Draft: Accurate sizing of the venting system is paramount for optimal appliance performance. An undersized system can cause incomplete combustion and backdrafting, while an oversized system may lead to condensation problems. Consult appliance specifications for precise sizing requirements.

Tip 5: Regular Inspection and Maintenance: Conduct annual inspections of the entire system, including connections, supports, and terminations. Address any signs of corrosion, damage, or blockage promptly. Regular cleaning removes accumulated soot and debris, preventing chimney fires and maintaining efficiency.

Tip 6: Clearance to Combustibles: Strictly adhere to the manufacturer’s specified clearance requirements to combustible materials. Insufficient clearance can result in overheating and potential fire hazards. These clearances are typically detailed in the installation manual and must be followed meticulously.

Tip 7: Termination Height and Location: Ensure the termination point is located at the appropriate height and distance from building openings, neighboring structures, and vegetation. Improper termination can lead to nuisance odors, re-entry of flue gases into the building, and potential fire hazards.

Proper implementation of these considerations will contribute to the safe, efficient, and long-lasting operation of the integrated venting system, safeguarding occupants and property.

The following sections will provide a comprehensive examination of troubleshooting common issues and future trends in venting technology.

1. Simplified Installation

The streamlined installation process represents a core advantage of integrated, single-unit chimney systems. This simplification stems directly from the pre-engineered and prefabricated nature of these components. Unlike traditional chimney construction, which necessitates extensive on-site assembly of individual bricks, mortar, and liners, these systems arrive as complete, ready-to-install modules. This characteristic significantly reduces the time and labor required for installation, leading to cost savings and minimizing potential errors associated with manual assembly. For example, the installation of a multi-story brick chimney might take several days and involve a team of skilled masons, whereas a corresponding integrated system can be installed within a few hours by a smaller team.

The benefits of simplified installation extend beyond mere time savings. The reduced complexity translates to a lower risk of installation errors, which can compromise the chimney’s structural integrity and safety. Pre-engineered systems are designed to ensure proper fit and alignment of components, minimizing the potential for leaks or structural weaknesses. In practical applications, this translates to improved safety and reliability for homeowners and building occupants. The ease of installation also makes these systems particularly attractive for retrofit projects or new construction where time and budget constraints are significant factors.

In summary, the simplified installation inherent in integrated chimney systems is a direct consequence of their prefabricated design. This attribute not only reduces installation time and labor costs but also enhances safety by minimizing the potential for human error. While proper adherence to manufacturer’s instructions and local building codes remains essential, the inherent simplicity of these systems makes them a compelling alternative to traditional chimney construction methods, contributing to both economic efficiency and improved safety standards within the construction industry.

2. Material compatibility

Material compatibility is a critical factor in the performance and longevity of integrated chimney systems. The prefabricated nature of these units demands careful selection of materials that can withstand the corrosive effects of flue gases produced by various fuel types. Failure to ensure compatibility leads to premature degradation, compromising structural integrity and posing significant safety risks. The type of fuel used in the heating appliance directly influences the required material composition of the vent system.

For instance, high-efficiency natural gas furnaces generate acidic condensate as a byproduct of combustion. This condensate necessitates the use of stainless steel or specialized plastic venting materials resistant to corrosion. Using standard galvanized steel in such applications will result in rapid deterioration and eventual failure. Similarly, wood-burning appliances produce creosote, a highly flammable substance that accumulates within the chimney. The selected material must be capable of withstanding high temperatures and resisting creosote buildup to prevent chimney fires. The single-unit design further emphasizes material considerations, as any failure within the system necessitates replacement of the entire module rather than a localized repair.

Therefore, adherence to manufacturer’s specifications and relevant building codes regarding material compatibility is paramount for ensuring the safe and efficient operation of integrated chimney systems. Careful consideration of fuel type and potential corrosive byproducts is essential for selecting the appropriate venting material and preventing premature system failure, which can lead to costly repairs and hazardous conditions.

3. Code Compliance

Adherence to established building codes and safety regulations is paramount in the implementation of integrated, single-unit chimney systems. These codes dictate the design, installation, and performance requirements for venting systems to ensure the safe and efficient removal of combustion byproducts. Code compliance directly impacts the structural integrity, fire safety, and overall performance of these systems. The prefabricated nature necessitates verification against standardized requirements.

- Material Standards

Building codes specify acceptable material types for chimney systems based on the fuel being vented and the potential for corrosion. These standards outline minimum requirements for heat resistance, chemical stability, and structural strength. For example, codes may mandate the use of stainless steel for venting high-efficiency gas appliances due to the corrosive nature of the condensate produced. Deviation from these material standards can result in premature degradation, leading to hazardous conditions. Compliance is verified through product certifications and listings by recognized testing agencies.

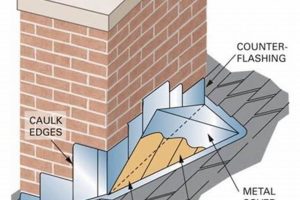

- Installation Procedures

Codes prescribe detailed installation procedures to ensure proper assembly and connection of chimney components. These procedures address critical aspects such as clearance to combustibles, support requirements, and sealing of joints. Improper installation can compromise the system’s integrity, leading to leaks, backdrafting, and potential fire hazards. Code compliance necessitates adherence to these prescribed installation methods, typically enforced through inspections by local building officials. Manufacturers often provide detailed installation manuals to facilitate compliance.

- Performance Requirements

Building codes define performance criteria for chimney systems, including minimum draft requirements, maximum allowable temperatures, and resistance to wind and seismic forces. These criteria are designed to ensure that the system effectively removes combustion gases and withstands environmental stresses. Compliance with performance requirements is often verified through laboratory testing and field evaluations. Failure to meet these standards can result in inefficient combustion, indoor air quality problems, and structural damage.

- Listing and Labeling

Code compliance necessitates that integrated chimney systems be listed and labeled by a recognized testing agency, such as UL or Intertek. This listing signifies that the system has been tested and certified to meet applicable safety standards and performance requirements. The label provides essential information, including the system’s intended use, material specifications, and installation instructions. Building inspectors rely on these listings to verify code compliance during the permitting and inspection process.

The multifaceted nature of code compliance underscores its importance in ensuring the safe and reliable operation of integrated chimney systems. Adherence to material standards, installation procedures, and performance requirements, as verified through listing and labeling, is essential for mitigating risks associated with combustion byproducts and safeguarding building occupants. The single-unit design necessitates that the system meet a series of performance requirements for all the materials. These standards are frequently updated, requiring constant attention to the most recent criteria.

4. Enhanced Safety

Integrated, single-unit chimney systems offer inherent safety advantages compared to traditional multi-component installations. These advantages stem from the controlled manufacturing processes, pre-engineered design, and reduced potential for on-site errors, directly contributing to a safer venting solution.

- Reduced Leak Potential

The pre-fabricated nature of these systems minimizes the number of joints and connections required during installation. Each connection represents a potential leak point for combustion gases, including carbon monoxide. By reducing the number of joints, the risk of gas leakage into the building is significantly diminished. For example, a traditional masonry chimney has numerous mortar joints that can crack over time, whereas a single-unit system has fewer seams, often utilizing airtight seals.

- Consistent Material Quality

Manufacturing takes place in controlled environments, ensuring consistent material quality and adherence to stringent specifications. This contrasts with traditional chimney construction, where material variations and on-site mixing of mortar can introduce inconsistencies. Standardized production leads to predictable performance characteristics and reduces the likelihood of material defects compromising safety. As an example, steel thickness and weld integrity are precisely controlled in factory settings.

- Minimized Installation Errors

Pre-engineered designs simplify the installation process, reducing the potential for human error. Clear instructions and standardized components facilitate proper assembly, minimizing the risk of incorrect connections or improper clearances. This is particularly important for ensuring adequate separation from combustible materials, a critical safety factor in preventing chimney fires. The single-unit approach reduces the number of decision-points that on-site installers need to consider and address, leading to more reliable outcomes.

- Improved Draft Control

The precise engineering of these systems optimizes draft, which is crucial for efficient removal of combustion gases. Insufficient draft can lead to backdrafting, where gases enter the building, posing a carbon monoxide poisoning risk. Consistent internal dimensions and smooth surfaces within the single-unit design promote predictable and reliable draft performance. Testing is also often done with the materials used so that the quality and performance are standardized.

In summary, the enhanced safety associated with integrated chimney systems arises from the combination of reduced leak potential, consistent material quality, minimized installation errors, and improved draft control. These factors contribute to a safer and more reliable venting solution compared to traditional chimney construction, safeguarding building occupants from the hazards of combustion byproducts. The integration in single-unit design allows for strict quality and safety procedures.

5. Lifecycle cost

Lifecycle cost analysis offers a comprehensive economic evaluation of integrated chimney systems, encompassing all expenses incurred throughout the system’s lifespan, from initial acquisition to eventual disposal. This approach provides a more accurate representation of the true cost compared to solely considering the initial purchase price, offering a valuable perspective for informed decision-making.

- Initial Investment

The initial cost of a prefabricated, single-unit chimney system often reflects a higher upfront investment compared to traditional masonry chimneys. This cost includes the system components, delivery, and professional installation. However, the reduced labor required for installation can partially offset this higher initial expense. For instance, while a custom-built brick chimney may appear less expensive initially, the cost of skilled masons and extended construction time can significantly increase the total initial investment.

- Maintenance and Repairs

Maintenance costs associated with integrated chimney systems are typically lower than those of traditional chimneys. The durable materials and fewer joints reduce the likelihood of cracks, leaks, and other common issues requiring repair. Regular inspections and cleaning are still necessary to remove soot and debris, but the frequency and complexity of these tasks are often reduced. As an example, stainless steel liners in integrated systems resist corrosion better than clay liners in masonry chimneys, extending their lifespan and reducing repair needs.

- Energy Efficiency

The design and materials used in prefabricated chimney systems can contribute to improved energy efficiency. Properly insulated systems minimize heat loss, reducing energy consumption and lowering heating costs. A well-sealed chimney also prevents drafts and air leakage, further improving energy performance. For instance, a single-unit chimney with integrated insulation can significantly reduce heat loss compared to an uninsulated masonry chimney, resulting in long-term savings on energy bills.

- Longevity and Replacement

The lifespan of an integrated chimney system is a critical factor in lifecycle cost analysis. High-quality systems constructed from durable materials can last for several decades with proper maintenance. However, eventual replacement is inevitable, and the cost of removal and disposal must be considered. The extended lifespan and easier replacement process of prefabricated systems compared to dismantling a masonry chimney can result in overall cost savings. For example, a stainless-steel, single-unit chimney might have a lifespan of 30-50 years, while a traditional chimney could require significant repairs or rebuilding within that timeframe.

Analyzing the lifecycle costs associated with integrated chimney systems provides a holistic view of their economic viability. While the initial investment may be higher, the reduced maintenance, improved energy efficiency, and extended lifespan can result in significant long-term savings. This comprehensive evaluation enables informed decision-making, highlighting the economic benefits of these systems over traditional alternatives. The streamlined installation of chimney one piece saves time and labor.

Frequently Asked Questions About Integrated Chimney Systems

This section addresses common inquiries regarding the selection, installation, and maintenance of single-unit, prefabricated chimney systems. The information provided aims to clarify misconceptions and provide factual guidance.

Question 1: What is the typical lifespan of an integrated chimney system?

Lifespan varies depending on the materials used and the operating conditions. Systems constructed from stainless steel, properly installed and maintained, can last 30 to 50 years. Routine inspections and cleaning are crucial for maximizing longevity.

Question 2: Are integrated chimney systems suitable for all types of heating appliances?

Suitability depends on the fuel type and appliance characteristics. Specific systems are designed for use with gas, oil, wood, or pellet-burning appliances. Consulting the manufacturer’s specifications and local building codes is essential to ensure compatibility.

Question 3: Can an integrated chimney system be installed by a homeowner?

Professional installation is strongly recommended and often mandated by building codes. Proper installation requires specialized knowledge and tools to ensure safe and efficient operation. Incorrect installation can compromise the system’s integrity and pose significant safety risks.

Question 4: What are the key indicators of a failing chimney system?

Indicators include visible cracks, rust, or corrosion, as well as draft problems, unusual odors, or excessive soot accumulation. Any of these signs warrant immediate inspection by a qualified professional.

Question 5: How often should an integrated chimney system be inspected and cleaned?

Annual inspections are recommended as a minimum. Cleaning frequency depends on the fuel type and usage patterns. Wood-burning systems typically require more frequent cleaning than gas-fired systems.

Question 6: Are integrated chimney systems more expensive than traditional masonry chimneys?

The initial cost may be higher, but reduced installation time and lower maintenance expenses can offset this difference over the system’s lifespan. Lifecycle cost analysis provides a more accurate comparison of the total economic impact.

In summary, integrated chimney systems offer a safe and efficient venting solution when properly selected, installed, and maintained. Adherence to building codes and manufacturer’s specifications is paramount for ensuring optimal performance and longevity.

The subsequent section will explore the future trends and advancements in chimney technology.

Conclusion

This exploration has detailed the attributes, benefits, and considerations surrounding integrated chimney systems, often referred to as “chimney one piece” solutions. From simplified installation and material compatibility to code compliance, enhanced safety, and lifecycle cost analysis, these pre-engineered systems offer a distinct alternative to traditional chimney construction. The analysis underscores the importance of selecting appropriate materials, adhering to building codes, and ensuring professional installation for optimal performance and longevity.

The adoption of these integrated venting technologies represents a commitment to enhanced safety and efficiency in building design and maintenance. Ongoing advancements in materials and manufacturing processes promise to further improve the performance and reliability of these systems. Building professionals and homeowners are encouraged to stay informed regarding the latest developments and to consult with qualified experts to ensure the safe and effective implementation of these innovative solutions for their specific needs.