A crucial component in high-temperature applications, particularly in systems designed to contain and exhaust extreme heat, is a specifically engineered structure that facilitates the controlled release of thermal energy and combustion byproducts. Functionally, it serves as a protective barrier, mitigating the impact of intense heat on surrounding structural elements while simultaneously channeling exhaust gases away from sensitive areas. Consider, for instance, its utilization in spacecraft re-entry systems, where it safeguards the vehicle from the scorching temperatures generated during atmospheric entry, allowing for controlled dissipation of heat and exhaust.

The employment of such a component offers numerous advantages. It enhances system safety by preventing structural failures caused by overheating, extends the lifespan of critical components by reducing thermal stress, and improves overall operational efficiency through optimized heat management. Historically, the concept evolved from simple venting systems to sophisticated designs incorporating advanced materials and aerodynamic principles to maximize performance and reliability in demanding environments. Its development reflects a growing understanding of thermodynamics and material science, leading to progressively more effective solutions for managing extreme thermal conditions.

Further discussion will delve into the specific design considerations, material selection criteria, and performance characteristics relevant to these specialized heat management systems. Subsequent sections will examine variations in architecture and application, including their role in industrial furnaces, combustion engines, and other high-temperature processes, showcasing the adaptability and widespread utility of this essential engineering element.

Guidance on Implementing Heatshield Chimney Systems

The following guidelines provide critical insights for effective implementation and maintenance, ensuring optimal performance and longevity of heat management systems.

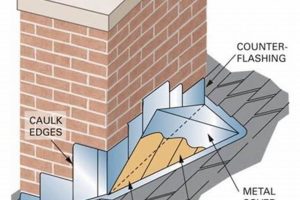

Tip 1: Material Selection: Employ materials with documented high-temperature resistance, low thermal expansion coefficients, and resistance to thermal shock. For example, ceramic composites or specialized alloys are often favored over conventional metals in extreme heat environments.

Tip 2: Aerodynamic Optimization: Design the structure to minimize turbulent flow and pressure drop, thereby reducing thermal stress and improving exhaust gas scavenging. Computational Fluid Dynamics (CFD) analysis is recommended for accurate flow field prediction.

Tip 3: Thermal Insulation Integration: Incorporate effective thermal insulation materials to minimize heat transfer to surrounding structures. Ensure the insulation is compatible with the operating temperature range and resistant to degradation from exhaust gases.

Tip 4: Structural Integrity Assessment: Conduct thorough structural analyses, including Finite Element Analysis (FEA), to verify the system’s ability to withstand mechanical and thermal loads. Pay particular attention to stress concentrations at joints and interfaces.

Tip 5: Corrosion Protection: Implement corrosion-resistant coatings or materials to protect against degradation from corrosive combustion byproducts. Regular inspections for corrosion are essential for maintaining structural integrity.

Tip 6: Regular Inspection and Maintenance: Establish a routine inspection schedule to identify potential issues such as cracks, erosion, or material degradation. Timely repairs can prevent catastrophic failures and extend the operational lifespan.

Tip 7: Monitoring Temperature and Pressure: Install sensors to continuously monitor temperature and pressure within the system. This data can provide early warning signs of potential problems and inform maintenance schedules.

Adhering to these guidelines will contribute to the enhanced safety, reliability, and efficiency of high-temperature systems, minimizing risks associated with uncontrolled heat release and extending the operational life of critical components.

The subsequent sections will explore specific applications and case studies, demonstrating the practical implications of these recommendations in diverse engineering contexts.

1. Thermal Protection

Effective operation of a heat management system is inextricably linked to its capacity for thermal protection. The primary function of such a system is to shield surrounding structures and components from the deleterious effects of extreme heat. Failure to provide adequate thermal protection can lead to structural failure, material degradation, and, in some cases, catastrophic system collapse. A practical illustration can be found in rocket engine design. The component channeling exhaust gases must possess sufficient thermal resistance to prevent melting or deformation of the surrounding engine structure. The effectiveness of thermal protection, therefore, directly determines the operational lifespan and safety of the overall system.

The implementation of robust thermal protection relies on several factors, including material selection, insulation design, and aerodynamic considerations. Materials with high melting points, low thermal conductivity, and resistance to thermal shock are essential. Insulation layers further minimize heat transfer, while optimized aerodynamic designs reduce the buildup of localized hot spots. In industrial furnaces, for example, ceramic linings combined with air gaps provide a multi-layered approach to thermal protection, significantly reducing heat loss and protecting the outer furnace shell from excessive temperatures. Similarly, advanced composite materials are employed in aerospace applications, utilizing ablative properties to dissipate heat through controlled surface decomposition.

In summary, thermal protection represents a cornerstone in the effective operation of any heat management system. Optimizing thermal protection through strategic material selection, intelligent insulation design, and aerodynamic refinement is crucial for ensuring system reliability, extending component lifespan, and preventing potentially hazardous failures. Continuous monitoring of temperature gradients and regular inspections are essential for maintaining the integrity of the thermal protection system throughout its operational lifecycle.

2. Exhaust Gas Management

Efficient exhaust gas management is intrinsically linked to the function of a heat management system, particularly in high-temperature environments. The controlled removal of combustion byproducts and hot gases is paramount for maintaining system integrity and preventing detrimental effects on surrounding structures and the environment. A well-designed exhaust system optimizes performance, reduces thermal stress, and mitigates potential hazards associated with the release of these gases.

- Controlled Flow Dynamics

The manipulation of exhaust gas flow is essential to prevent localized hot spots and ensure uniform heat distribution. Strategic shaping of the internal structure minimizes turbulence and backpressure, optimizing the convective heat transfer process. For example, in industrial incinerators, baffles and diverters are incorporated to promote thorough mixing and combustion, ultimately reducing emissions and improving overall efficiency. Similarly, the geometry of a rocket nozzle is critical for achieving optimal thrust and directing exhaust gases away from the spacecraft body.

- Thermal Quenching Techniques

Lowering the temperature of exhaust gases before release can significantly reduce thermal stress on downstream components and the surrounding environment. This can be achieved through various cooling mechanisms, such as air dilution, water injection, or heat exchangers. In power generation plants, for example, selective catalytic reduction (SCR) systems are used to reduce nitrogen oxide emissions by reacting them with ammonia in the presence of a catalyst, simultaneously reducing the temperature of the exhaust gases.

- Particulate Matter Filtration

Effective particulate matter filtration is crucial for minimizing air pollution and preventing the buildup of debris within the system. Filters and scrubbers are employed to remove solid particles from the exhaust stream, preventing them from being released into the atmosphere or causing erosion and clogging of downstream components. In diesel engines, diesel particulate filters (DPFs) are utilized to trap soot and other particulate matter, reducing emissions and improving air quality.

- Corrosion Mitigation Strategies

Many exhaust gases contain corrosive components that can degrade the structural integrity of the system over time. Implementing corrosion-resistant materials and coatings is essential for extending the lifespan and reliability. In chemical processing plants, specialized alloys and protective linings are used to withstand the corrosive effects of acid gases and other aggressive chemicals present in the exhaust stream.

The proper management of exhaust gases directly influences the overall effectiveness and safety of a heat management system. By controlling flow dynamics, implementing thermal quenching techniques, filtering particulate matter, and mitigating corrosion, these systems can reliably operate in demanding environments while minimizing their environmental impact. The interplay of these facets is integral to the design and performance of a heat management system across various applications, underscoring the importance of a holistic approach to its engineering.

3. Material Integrity

The operational effectiveness of a heat management structure is inextricably linked to the integrity of its constituent materials. The capacity of these materials to withstand extreme temperatures, thermal cycling, and corrosive environments dictates the longevity and reliability of the entire system. Degradation or failure of the material compromises its ability to protect surrounding components, potentially leading to catastrophic consequences. For example, a heatshield component used in aerospace applications must maintain its structural integrity throughout the re-entry phase, enduring temperatures exceeding thousands of degrees Celsius. Any weakening or ablation beyond design tolerances risks the failure of the entire mission.

Material selection for such demanding applications involves a rigorous process of evaluation, considering factors such as melting point, thermal conductivity, thermal expansion coefficient, and resistance to oxidation and chemical attack. Advanced ceramics, carbon-carbon composites, and high-temperature alloys are frequently employed due to their superior properties. Furthermore, manufacturing processes play a crucial role in ensuring material integrity. Defects such as voids, cracks, or inclusions can significantly reduce the material’s strength and resistance to thermal stress. Non-destructive testing methods, including ultrasonic inspection and radiographic analysis, are employed to detect such flaws before deployment. Regular in-service inspections are also necessary to monitor material degradation and identify potential issues before they escalate.

In conclusion, maintaining material integrity is paramount for the safe and reliable operation of heat management structures. A comprehensive approach, encompassing careful material selection, rigorous manufacturing controls, and diligent inspection protocols, is essential for mitigating the risks associated with extreme thermal environments. The practical significance of this understanding is evident in various high-temperature applications, from aerospace to industrial processing, where the integrity of these components directly impacts safety, efficiency, and overall system performance.

4. Aerodynamic Efficiency

Aerodynamic efficiency plays a critical role in the performance and longevity of structures designed for high-temperature applications. Specifically, in the context of a thermal management system, the way air flows around and through the system dictates how effectively heat is dissipated and exhaust gases are managed, directly impacting overall operational effectiveness and component lifespan.

- Minimizing Pressure Drop

Optimizing the aerodynamic design to reduce pressure drop is crucial for efficient exhaust gas removal. High pressure drops increase the energy required to move gases, potentially leading to higher operating temperatures and reduced system efficiency. Streamlined designs, smooth internal surfaces, and strategically placed vents can minimize resistance to airflow, allowing for more effective heat dissipation. For example, in industrial furnaces, a well-designed exhaust stack with minimal bends and constrictions ensures efficient removal of hot gases, preventing overheating and maintaining stable operating conditions.

- Controlling Boundary Layer Separation

Boundary layer separation, where the flow of air detaches from the surface, can lead to increased drag and reduced heat transfer. Careful shaping of the exterior surfaces can delay or prevent boundary layer separation, ensuring a smoother, more efficient airflow. In aerospace applications, the aerodynamic design of a heat shield aims to maintain a stable boundary layer, minimizing turbulence and maximizing the transfer of heat away from the vehicle’s surface. This is crucial for protecting the structure from extreme heat during atmospheric re-entry.

- Optimizing Surface Area for Heat Transfer

The amount of surface area exposed to airflow directly influences the rate of heat transfer. Increasing the surface area can enhance heat dissipation, but it is essential to balance this with aerodynamic considerations to avoid increasing drag. Fin designs, for example, can significantly increase the surface area available for heat transfer, but their shape and spacing must be carefully optimized to minimize airflow resistance. In electronic cooling systems, heat sinks with complex fin geometries are used to maximize heat dissipation while maintaining acceptable aerodynamic performance.

- Managing External Flow Interference

External airflow patterns can significantly impact the performance of a system. Interference from surrounding structures or environmental conditions can disrupt airflow, leading to increased drag, reduced heat transfer, and uneven temperature distribution. Careful placement and shielding can mitigate these effects, ensuring a more stable and predictable aerodynamic environment. In data centers, for instance, strategic placement of cooling systems and the use of baffles can optimize airflow patterns, preventing hot spots and maintaining consistent temperatures throughout the facility.

These elements underscore the importance of aerodynamic efficiency in the effective operation of systems. By minimizing pressure drop, controlling boundary layer separation, optimizing surface area, and managing external flow interference, the systems ability to manage heat and exhaust gases is enhanced, leading to improved performance and reliability across various high-temperature applications.

5. Structural Stability

Structural stability is an indispensable attribute of systems engineered for high-temperature applications, particularly concerning specialized components designed for heat management. The capacity of these components to maintain their physical form and load-bearing capabilities under extreme thermal conditions is paramount to the safety and effectiveness of the entire system. Any deformation, buckling, or fracture resulting from thermal stress or mechanical loading can compromise the system’s performance, leading to catastrophic failures. For instance, in the context of a spacecraft’s thermal protection system, the heat shield’s structural integrity must be maintained throughout atmospheric re-entry, ensuring the vehicle is protected from intense aerodynamic heating. Deviation from the designed structural properties can result in localized hot spots, compromised insulation, and ultimately, the loss of the spacecraft.

Achieving requisite structural stability necessitates the careful selection of materials with high yield strength, creep resistance, and thermal fatigue endurance. Additionally, robust structural design and rigorous testing are essential. Finite Element Analysis (FEA) is commonly employed to simulate the thermal and mechanical stresses experienced during operation, allowing engineers to identify potential weak points and optimize the design for maximum stability. Welding techniques and joining methods also demand meticulous attention, as these interfaces are often susceptible to failure under extreme conditions. Consider the construction of industrial furnaces: the refractory lining must withstand not only high temperatures but also the mechanical stresses imposed by the weight of the charge and the expansion and contraction of the furnace structure. Proper anchoring and support systems are critical to prevent cracking and spalling of the refractory material, maintaining the furnace’s structural integrity and thermal efficiency.

In summary, structural stability is not merely a desirable characteristic but an essential prerequisite for the reliable and safe operation of heat management components. The ability of these components to withstand the combined effects of thermal stress and mechanical loading is critical for preventing failures and ensuring the intended performance of high-temperature systems. Meticulous material selection, advanced structural design, and comprehensive testing are indispensable for guaranteeing the necessary level of structural integrity. The consequences of neglecting this aspect can be severe, underscoring the importance of prioritizing structural stability in the design and maintenance of these systems.

Frequently Asked Questions

This section addresses common inquiries regarding the functionality, design considerations, and applications of heatshield chimney systems. The information provided aims to clarify key aspects and dispel potential misconceptions.

Question 1: What constitutes the fundamental purpose of a heatshield chimney?

The core function is to protect adjacent structures from extreme heat, while simultaneously channeling exhaust gases away from sensitive areas. This dual role ensures both thermal isolation and controlled release of combustion byproducts.

Question 2: Which materials are commonly employed in the construction of heatshield chimney systems?

Material selection hinges upon the operating temperature and corrosive environment. High-temperature alloys, ceramics, and composite materials are frequently utilized due to their thermal resistance and structural integrity.

Question 3: How does aerodynamic design influence the performance of a heatshield chimney?

Aerodynamic efficiency minimizes pressure drop, prevents turbulent flow, and optimizes heat transfer. A well-designed system reduces thermal stress and enhances overall efficiency.

Question 4: What role does insulation play in heatshield chimney systems?

Insulation minimizes heat transfer to surrounding structures, preventing overheating and extending the lifespan of critical components. The type of insulation must be compatible with the operating temperature and exhaust gas composition.

Question 5: How is the structural integrity of a heatshield chimney assessed?

Structural analyses, including Finite Element Analysis (FEA), are conducted to verify the system’s ability to withstand thermal and mechanical loads. Regular inspections are also essential for identifying potential weaknesses.

Question 6: What are the primary applications of heatshield chimney systems?

These systems find application in diverse fields, including aerospace, industrial furnaces, combustion engines, and power generation, wherever the controlled management of extreme heat is critical.

In summary, heatshield chimney systems are engineered to provide robust thermal protection and efficient exhaust gas management in demanding environments. Understanding the underlying principles and design considerations is crucial for their effective implementation and maintenance.

The subsequent section will present detailed case studies illustrating the application of these systems in real-world scenarios.

Conclusion

This exploration has detailed the critical function of the heatshield chimney in managing extreme thermal environments. The analysis encompassed design considerations, material science implications, and performance characteristics essential for ensuring operational safety and longevity in high-temperature applications. Factors ranging from aerodynamic efficiency to structural stability, alongside thorough exhaust gas management, were examined as fundamental components contributing to the effective performance of heatshield chimney systems.

The inherent complexities of thermal management necessitate ongoing research and development to optimize the design and application of heatshield chimney technology. As technological demands continue to evolve, a sustained commitment to innovation in this field will be vital for addressing increasingly challenging thermal control requirements across diverse industries and ensuring the reliable operation of high-temperature systems.