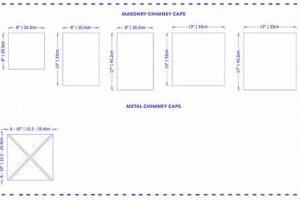

A structure designed to cover the top of a chimney with dimensions of 24 inches by 24 inches protects the flue from environmental elements. These elements include rain, snow, and debris, and from animals entering the chimney. As an example, a homeowner might select this size to appropriately fit a standard-sized chimney opening.

Its implementation offers several advantages, including preventing water damage to the chimney’s internal structure and improving draft efficiency by minimizing downdrafts. Historically, rudimentary forms of chimney protection have been employed, but modern iterations utilize materials like stainless steel to enhance durability and longevity. This form of protection provides structural integrity and prevents costly repairs.

Consideration of appropriate sizing, material selection, and installation methods is crucial when implementing this protective measure. Factors such as regional climate and specific chimney construction influence optimal design and material choices.

Essential Considerations

The following recommendations offer guidance for the selection and proper application of a covering of specified dimensions.

Tip 1: Accurate Measurement: Precise measurement of the chimney’s external dimensions is paramount to ensure proper fit and functionality.

Tip 2: Material Selection: Evaluate environmental conditions to select a material resistant to corrosion and weathering. Stainless steel is often favored for its durability.

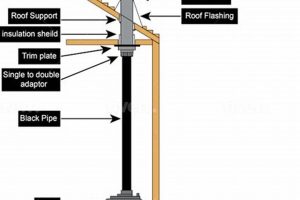

Tip 3: Secure Installation: Employ appropriate fastening methods to secure the covering to the chimney structure, preventing dislodgement by wind or other external forces.

Tip 4: Spark Arrestor Integration: Consider incorporating a spark arrestor screen to prevent the emission of embers, mitigating fire hazards. This is especially important in areas prone to wildfires.

Tip 5: Regular Inspection: Conduct routine inspections to identify potential damage or deterioration. Address any issues promptly to maintain optimal performance and prevent further degradation.

Tip 6: Professional Consultation: When uncertain about selection or installation procedures, consult a qualified professional to ensure code compliance and optimal performance.

Adherence to these guidelines will maximize the protective benefits and extend the lifespan of the chimney system.

These measures contribute to the overall safety and efficiency of the structure.

1. Precise Sizing

The dimensional accuracy of a chimney covering, specifically one designated as “24 x 24,” directly impacts its functionality and protective capacity. Improper sizing, even by a small margin, can negate the intended benefits, rendering the covering ineffective against environmental elements and potential hazards. A covering that is too small will leave gaps, allowing rain, snow, and debris to enter the chimney flue. Conversely, a covering that is too large may not properly secure to the chimney structure, increasing the risk of dislodgement during high winds or inclement weather. For instance, a 23 x 23 inch covering installed on a 24 x 24 inch chimney would fail to completely cover the opening, resulting in water ingress and accelerated deterioration of the internal chimney components. Precise sizing is, therefore, an indispensable component of effective chimney protection.

The practical significance of understanding this relationship is evident in both new installations and replacement scenarios. In new construction, accurate measurements must be taken to ensure the specified dimensions of the covering align precisely with the chimney opening. In replacement situations, existing chimney coverings must be carefully measured to determine the appropriate replacement size. Failure to adhere to precise sizing specifications can lead to ongoing maintenance issues, compromised chimney performance, and potentially hazardous conditions, such as carbon monoxide buildup due to improper venting.

In summary, precise sizing represents a critical factor in the effectiveness of chimney coverings. Deviation from the specified dimensions can compromise the integrity and functionality of the chimney system, leading to a range of adverse consequences. Therefore, meticulous attention to measurement accuracy and adherence to dimensional specifications are paramount for ensuring long-term chimney protection and safety.

2. Material Durability

The longevity and effectiveness of a 24 x 24 chimney covering are intrinsically linked to the durability of the materials used in its construction. The harsh environmental conditions to which these structures are exposed necessitate careful consideration of material properties to ensure sustained performance and structural integrity.

- Corrosion Resistance

The chimney covering is subjected to constant exposure to moisture, acidic precipitation, and flue gases, all of which contribute to corrosion. Materials exhibiting superior corrosion resistance, such as stainless steel alloys, are essential for preventing premature degradation and maintaining structural stability. For example, a 304 stainless steel covering will exhibit greater resistance to rust and pitting compared to galvanized steel, resulting in extended service life.

- Thermal Stability

Chimney coverings experience significant temperature fluctuations due to the combustion process within the chimney and variations in ambient weather conditions. Materials must possess adequate thermal stability to withstand expansion and contraction cycles without cracking or warping. High-grade stainless steel and certain ceramics offer superior thermal stability compared to less robust materials.

- Mechanical Strength

Wind loads, snow accumulation, and impact from debris can exert considerable stress on the chimney covering. Materials must exhibit sufficient mechanical strength to resist deformation or failure under these conditions. For instance, a thicker gauge of stainless steel will provide greater resistance to bending and denting compared to a thinner gauge. This ensures that the covering can withstand environmental stresses without compromising its protective function.

- UV Resistance

Prolonged exposure to ultraviolet radiation from sunlight can degrade certain materials, leading to discoloration, embrittlement, and reduced structural integrity. Materials with inherent UV resistance or those treated with UV-protective coatings are preferred for chimney coverings to mitigate these effects. Without UV resistance, a polymeric covering can become brittle and crack over time, reducing its ability to protect the chimney.

The interplay of corrosion resistance, thermal stability, mechanical strength, and UV resistance determines the overall lifespan and performance of a 24 x 24 chimney covering. Selecting materials that excel in these properties ensures a durable and reliable solution for protecting the chimney system from environmental damage and maintaining its operational efficiency.

3. Weather Protection

A primary function of a 24 x 24 chimney covering is to provide weather protection, shielding the chimney flue from the detrimental effects of environmental elements. The absence of adequate protection results in a cascade of negative consequences, impacting the chimney’s structural integrity and operational efficiency. Rainwater penetration, for example, saturates the porous brickwork, leading to freeze-thaw cycles that cause cracking and spalling. Snow accumulation can similarly compromise the structure. Animal nesting and debris accumulation obstruct the flue, impeding proper ventilation and increasing the risk of carbon monoxide buildup. Thus, the dimensions of 24 x 24 are critical for providing sufficient coverage and preventing these issues from arising.

The selection of appropriate materials further enhances the effectiveness of weather protection. Stainless steel, due to its resistance to corrosion and weathering, is often the preferred choice. Its ability to withstand prolonged exposure to moisture and temperature fluctuations ensures long-term performance. The design of the covering also plays a role, with features such as angled tops and drip edges directing water away from the chimney structure. Consider a scenario where a covering lacking these features allows rainwater to run down the chimney walls, accelerating deterioration and potentially damaging interior components.

In conclusion, the weather protection offered by a 24 x 24 chimney covering represents a critical component of chimney maintenance. The covering acts as a barrier against environmental elements, mitigating the risk of structural damage and operational inefficiencies. Regular inspection and maintenance of the covering are essential to ensure its continued effectiveness in providing this vital weather protection, linking directly to the longevity and safe operation of the chimney system. The precise dimensions and material selection are key to fulfilling this function.

4. Animal Deterrent

The incorporation of animal deterrent features into a 24 x 24 chimney covering serves as a critical component in maintaining the structural integrity and functional efficiency of a chimney system. The open flue presents an accessible entry point for various animals, leading to potential blockages, structural damage, and health hazards.

- Physical Barrier Effectiveness

A properly designed covering, specifically with a mesh or grid structure, prevents animals, such as birds, squirrels, and raccoons, from entering the chimney. The 24 x 24 dimensions must be fully covered by this barrier. The mesh size should be small enough to exclude common pests while allowing for adequate airflow. For instance, a covering with a -inch mesh effectively deters most birds and squirrels without significantly impeding chimney draft.

- Material Resistance to Animal Damage

Animals may attempt to gnaw or claw at the covering to gain entry. Therefore, the material used in its construction must exhibit resistance to such damage. Stainless steel, due to its inherent durability and resistance to corrosion, is a preferred material choice. A galvanized steel covering, while less expensive, may be more susceptible to damage from persistent animal activity, compromising its effectiveness as a deterrent. Stainless steel is, therefore, more effective in preventing damage.

- Impact on Chimney Draft

An effective animal deterrent should not significantly restrict airflow within the chimney flue. A poorly designed or obstructed covering can impede draft, leading to inefficient combustion and potential carbon monoxide buildup. The mesh or grid structure must be optimized to balance animal deterrence with adequate ventilation. Periodic cleaning of the covering is necessary to remove accumulated debris and maintain optimal airflow.

- Long-Term Cost Implications

The initial cost of a chimney covering incorporating animal deterrent features may be higher than that of a basic covering. However, the long-term cost implications of preventing animal infestations, including potential structural repairs and health hazards, often justify the investment. Replacing damaged chimney liners or removing animal nests from the flue can be significantly more expensive than the cost of a robust animal deterrent covering. This presents a cost-benefit balance.

The integration of these facets into the design and maintenance of a 24 x 24 chimney covering ensures a reliable and cost-effective solution for preventing animal intrusions. Proper selection and installation of the covering, along with regular inspection and cleaning, contribute to the long-term safety, efficiency, and structural integrity of the chimney system, preventing many issues from occurring. This is how it helps to protect the system.

5. Draft Improvement

The implementation of a 24 x 24 chimney covering significantly influences chimney draft, a crucial factor in fireplace and heating appliance performance. Optimal draft ensures efficient exhaust of combustion byproducts, preventing backdrafting and promoting safe and effective operation.

- Covering Height and Design

The height of the covering above the flue outlet impacts airflow dynamics. A covering that is too low can restrict the upward movement of exhaust gases, hindering draft. Conversely, excessive height may create turbulence, also negatively affecting draft. The design of the covering, including the presence of openings or vents, directly influences airflow patterns. A covering with well-placed vents facilitates smooth and consistent draft, while one with poorly designed vents can create resistance and impede the flow of exhaust gases. A properly sized and well-designed covering minimizes turbulence and allows for optimal air movement, ensuring efficient draft.

- Material Impact on Flow Resistance

The material of the covering and its surface characteristics affect flow resistance. A smooth, non-porous material, such as stainless steel, minimizes friction and promotes efficient airflow. In contrast, a rough or porous material can increase friction, hindering draft. Accumulation of soot or debris on the covering further increases flow resistance. Regular cleaning of the covering maintains a smooth surface, minimizing friction and optimizing draft performance. Maintaining a smooth surface of covering is, therefore, important.

- Wind Effects and Downdrafts

The covering’s design mitigates the effects of wind on chimney draft. Wind blowing across the top of the chimney can create downdrafts, forcing exhaust gases back down the flue. A well-designed covering incorporates features, such as angled tops or wind directional vanes, to deflect wind and prevent downdrafts. These features maintain a consistent upward draft, even in windy conditions. For example, a covering with a conical top deflects wind from all directions, minimizing downdraft potential. Proper design can prevent downdrafts.

- Chimney Location and Surrounding Structures

The location of the chimney and the presence of nearby structures influence wind patterns and draft performance. A chimney located in a sheltered area may experience reduced draft due to insufficient wind exposure. Conversely, a chimney located in an exposed area may experience excessive downdrafts. The height of surrounding trees or buildings can also affect wind patterns and draft. In such cases, a taller chimney covering may be necessary to extend above surrounding obstructions and ensure adequate draft. Therefore, location also affects the draft.

The interplay of covering height, design, material properties, and environmental factors determines the overall impact on chimney draft. Selecting a covering with appropriate features and dimensions, coupled with regular maintenance, ensures optimal draft performance, promoting safe and efficient operation of the fireplace or heating appliance. Addressing all the points discussed will ensure an optimal chimney draft.

6. Spark Prevention

Spark prevention represents a critical safety measure associated with chimney operation, and its effective implementation is intrinsically linked to the design and functionality of a chimney covering. A 24 x 24 chimney covering integrated with spark prevention features mitigates the risk of fire hazards associated with the emission of embers from the chimney flue.

- Spark Arrestor Mesh Size and Material

The primary mechanism for spark prevention is the incorporation of a spark arrestor mesh within the chimney covering. This mesh, typically constructed of stainless steel, features small openings that prevent the passage of embers while allowing for adequate airflow. The size of the mesh openings is critical; excessively large openings permit ember emission, while excessively small openings impede draft. A commonly employed mesh size is 1/2 inch, which effectively arrests most sparks while maintaining acceptable draft performance. The choice of stainless steel ensures durability and resistance to corrosion from flue gases and environmental elements. Example: A covering lacking a properly sized and maintained spark arrestor allowed embers to ignite nearby roofing materials, resulting in a house fire.

- Covering Design and Ember Trapping

The overall design of the chimney covering influences its effectiveness in ember trapping. Coverings with enclosed tops and downward-facing vents minimize the potential for sparks to escape. Internal baffles or deflectors can further enhance ember capture by redirecting airflow and increasing the residence time of hot particles within the covering. Example: A covering with an open top design allowed embers to be carried aloft by wind, posing a fire hazard to neighboring properties. An enclosed design offers better ember containment.

- Maintenance and Soot Accumulation

Regular maintenance of the chimney covering is essential for maintaining its spark prevention capabilities. Soot and creosote accumulation on the spark arrestor mesh can impede airflow and increase the risk of chimney fires. Periodic cleaning removes these deposits, ensuring optimal spark arrestor performance. Example: A homeowner neglected to clean the spark arrestor mesh, resulting in creosote buildup that ignited and caused a chimney fire. Regular maintenance prevents these issues.

- Local Fire Codes and Regulations

Many jurisdictions have specific fire codes and regulations regarding spark arrestors on chimneys. Compliance with these regulations is mandatory to ensure public safety. These codes typically specify the required mesh size, material standards, and installation guidelines for spark arrestors. Example: A homeowner installed a chimney covering that did not meet local fire code requirements, resulting in a citation and the need for corrective action.

These elements are fundamentally connected to the design and maintenance of a 24 x 24 chimney covering to prevent fire hazards associated with the emission of sparks. Proper mesh size, covering design, regular maintenance, and compliance with local codes collectively contribute to a safe and effective chimney operation.

Frequently Asked Questions

This section addresses common inquiries and misconceptions regarding chimney coverings of the specified dimensions. The information presented aims to provide clarity and promote informed decision-making.

Question 1: What constitutes the primary function of a chimney covering?

The fundamental purpose is to protect the chimney flue from environmental elements such as rain, snow, and debris, as well as prevent animal intrusion. This protection contributes to the longevity and operational efficiency of the chimney system.

Question 2: How does the size, 24 x 24, influence its effectiveness?

Dimensional accuracy is paramount. Deviations from the specified dimensions compromise the covering’s ability to effectively seal the chimney opening, potentially allowing ingress of water or debris. Ensure precise measurements prior to installation.

Question 3: What materials are best suited for constructing a chimney covering?

Materials exhibiting resistance to corrosion, thermal stress, and mechanical damage are preferred. Stainless steel alloys are frequently employed due to their superior durability and resistance to environmental degradation.

Question 4: How does a chimney covering contribute to draft efficiency?

A properly designed covering minimizes downdrafts caused by wind, promoting consistent and efficient venting of combustion byproducts. The covering’s height and vent configuration influence airflow dynamics.

Question 5: Is a spark arrestor necessary, and what are its functional requirements?

Spark arrestors are strongly recommended to mitigate the risk of fire hazards associated with the emission of embers. The arrestor mesh must meet specified size and material standards to effectively trap sparks without impeding draft.

Question 6: How frequently should a chimney covering be inspected and maintained?

Routine inspections are essential to identify potential damage, soot accumulation, or structural deterioration. Cleaning should be performed periodically to maintain optimal performance and prevent airflow obstruction.

In summary, the proper selection, installation, and maintenance of a chimney covering are crucial for ensuring the safety, efficiency, and longevity of the chimney system.

The subsequent sections will delve into the practical aspects of chimney covering installation and maintenance procedures.

Conclusion

The preceding exploration of the 24 x 24 chimney cap underscores its critical role in safeguarding chimney systems. The specific dimensions, material composition, design features, and maintenance protocols outlined are not merely recommendations but essential considerations for ensuring structural integrity, operational efficiency, and fire safety. Its absence or improper implementation precipitates a cascade of potential problems, ranging from water damage and animal infestations to compromised draft and heightened fire risk.

Therefore, diligent attention to these facets is paramount. A 24 x 24 chimney cap is not merely an accessory; it represents a vital component of a well-maintained and safely functioning chimney system. Understanding its importance and adhering to best practices for its selection, installation, and maintenance is imperative for all stakeholdershomeowners, contractors, and inspectorsinvolved in chimney management. This understanding ensures the longevity and safe operation of the associated structure.

![Local Chimney Liner Installers Near Me: [Cost & Quality] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Local Chimney Liner Installers Near Me: [Cost & Quality] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-512-300x200.jpg)

![Protect Your Chimney: 9 Inch Round Chimney Cap [Debris Free] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Protect Your Chimney: 9 Inch Round Chimney Cap [Debris Free] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/02/th-483-300x200.jpg)