A circular protective covering, measuring nine inches in diameter, designed to be fitted atop a flue. This component prevents the ingress of precipitation, debris, and animals into the chimney system. An example application includes its installation to safeguard a residential heating appliance’s exhaust passage from external elements.

The implementation of such a safeguard offers multiple advantages. It mitigates the risk of water damage to the chimney’s interior structure, potentially prolonging its lifespan and reducing costly repairs. Furthermore, it acts as a barrier against obstructions, maintaining optimal draft and combustion efficiency of the connected appliance. Historically, similar protective measures have been employed to shield open flues from the elements and improve heating performance.

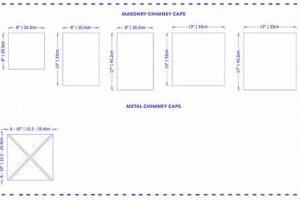

Understanding the dimensions, materials, and installation methods relevant to flue coverings is crucial for effective chimney maintenance and safety. Further discussion will cover suitable materials for fabrication, proper installation techniques, and considerations for selecting the appropriate model based on specific chimney characteristics.

Installation and Maintenance Tips

Proper installation and routine maintenance are vital to ensure the longevity and effectiveness of a flue’s protective cover. Adherence to best practices will safeguard against premature degradation and potential hazards.

Tip 1: Verify Dimensional Compatibility: Prior to installation, confirm the internal diameter of the chimney opening matches the specified dimensions of the protective cover. An improper fit compromises functionality and could lead to instability.

Tip 2: Employ Corrosion-Resistant Materials: Select a protective cover constructed from materials like stainless steel, known for their resistance to corrosive byproducts of combustion and weathering. Galvanized steel provides a lower-cost alternative, but with reduced lifespan.

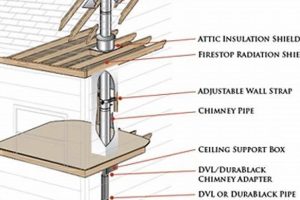

Tip 3: Ensure Secure Attachment: Utilize appropriate fasteners, such as stainless steel screws or clamps, to securely affix the protective cover to the flue. Loose or inadequately secured components pose a safety risk.

Tip 4: Inspect Annually: Conduct a visual inspection of the protective cover at least once per year, preferably during the pre-heating season chimney sweep. Check for signs of rust, damage, or obstruction.

Tip 5: Remove Debris Regularly: Clear any accumulated debris, such as leaves, twigs, or animal nests, from the mesh or openings. Obstructions impede proper draft and increase the risk of chimney fires.

Tip 6: Consider Professional Installation: If unsure about proper installation techniques or working at heights, engage a qualified chimney professional to perform the installation and ensure compliance with local building codes.

Tip 7: Replace When Necessary: Even with diligent maintenance, flue protective covers eventually require replacement. Address any signs of significant corrosion, structural damage, or compromised functionality promptly.

Following these guidelines will optimize performance, extend the lifespan, and contribute to the safe and efficient operation of the chimney system. The succeeding section will address common problems and troubleshooting techniques.

1. Dimensional Accuracy

Dimensional accuracy is a critical parameter directly impacting the performance and functionality of a nine-inch round flue terminal. A deviation from the specified nine-inch diameter, either in the terminal’s construction or the flue’s opening, results in a compromised seal. This lack of precision allows the ingress of rainwater, snow, and debris into the chimney system. The consequences include accelerated deterioration of the flue liner, reduced heating efficiency, and potential safety hazards. For instance, if the terminal is undersized, it may slip inside the flue, rendering it completely ineffective. Conversely, an oversized terminal might not securely attach, risking displacement by wind and allowing unrestricted entry of unwanted elements.

The importance of dimensional accuracy extends beyond simple weather protection. A precisely fitted terminal aids in maintaining optimal draft. An ill-fitting terminal can disrupt the flow of exhaust gases, leading to backdrafting and the potential introduction of carbon monoxide into the dwelling. Real-world examples of this include situations where incorrectly sized aftermarket terminals have been installed, resulting in homeowner complaints of poor appliance performance and heightened carbon monoxide levels. These instances underscore the need for precise measurements and adherence to manufacturing specifications during both production and installation.

In summary, dimensional accuracy is not merely a superficial detail but a fundamental requirement for the proper operation of a nine-inch round flue terminal. Failure to achieve dimensional precision can negate the terminal’s intended purpose, leading to costly repairs, safety risks, and diminished appliance performance. Proper measurement, selection of appropriately sized terminals, and professional installation are essential steps in ensuring chimney system integrity and homeowner safety.

2. Material Durability

Material durability is a foundational attribute influencing the longevity and effectiveness of a circular flue termination device designed for nine-inch diameter chimney systems. The environment atop a chimney presents a harsh combination of high temperatures, corrosive combustion byproducts, and exposure to the elements. Therefore, the choice of material dictates the lifespan and performance of the cap.

- Corrosion Resistance

Resistance to corrosion is paramount. Flue gases contain acidic compounds that can rapidly degrade susceptible materials. For example, unprotected steel will quickly rust and fail, leading to structural compromise and loss of function. Stainless steel, particularly 304 or 316 grades, exhibits superior corrosion resistance compared to galvanized steel or painted surfaces, resulting in a significantly extended service life. Instances of using inadequate materials have resulted in premature cap failure, necessitating costly replacements.

- Thermal Stability

Thermal stability refers to the material’s ability to withstand repeated cycles of heating and cooling without significant degradation. Chimneys experience substantial temperature fluctuations, especially during periods of active use. Materials with poor thermal stability can crack, warp, or otherwise deform, compromising the cap’s integrity and effectiveness. High-quality stainless steel and certain high-temperature alloys demonstrate excellent thermal stability compared to plastics or low-grade metals. Cases of warped and cracked caps fabricated from unsuitable materials exemplify the importance of this characteristic.

- Weather Resistance

Weather resistance involves the material’s ability to withstand prolonged exposure to environmental factors such as rain, snow, UV radiation, and wind. Materials that are prone to degradation from these factors will exhibit reduced longevity. For example, plastic caps can become brittle and crack under prolonged UV exposure, while improperly coated metals can rust and corrode from moisture. High-quality stainless steel provides superior weather resistance compared to alternatives. Examples of plastic caps failing prematurely due to weather exposure highlight the need for durable materials.

- Structural Integrity

Structural integrity is the material’s capacity to maintain its shape and resist physical damage. A structurally weak material can be easily deformed by wind, impact from debris, or ice accumulation. This deformation can compromise the cap’s ability to effectively prevent the entry of rain, snow, and animals. High-gauge stainless steel offers greater structural integrity compared to thinner, less robust materials. Instances of caps being damaged by falling branches or heavy snow loads demonstrate the necessity of selecting materials with adequate structural strength.

In summary, selecting materials with adequate corrosion resistance, thermal stability, weather resistance, and structural integrity is crucial for maximizing the lifespan and ensuring the reliable performance of any nine-inch round flue termination device. The choice of material directly impacts the cap’s ability to protect the chimney system, maintain proper draft, and ensure safe and efficient operation of the connected appliance. Compromising on material quality can lead to premature failure, costly repairs, and potential safety hazards.

3. Secure Attachment

Secure attachment is paramount to the functionality and safety of a nine-inch round flue termination device. The efficacy of the cap in preventing ingress of precipitation, debris, and animals is directly contingent upon its firm and unwavering connection to the chimney flue. A compromised attachment invites a cascade of potential problems, impacting both the chimney system and the connected appliance.

- Fastener Selection

The choice of fasteners plays a critical role in maintaining a secure attachment. Stainless steel screws or clamps are preferred due to their resistance to corrosion, a common issue in the harsh chimney environment. Improper fastener selection, such as using standard steel, can lead to rapid degradation and eventual failure of the connection. Cases of caps detaching during high winds due to corroded fasteners highlight the importance of using appropriate materials. The fastener must also be appropriately sized and rated for the materials being joined.

- Proper Installation Technique

Even with high-quality fasteners, incorrect installation can undermine the security of the attachment. Over-tightening can strip threads or damage the cap’s structure, while insufficient tightening can lead to looseness and eventual detachment. Following manufacturer’s instructions and employing appropriate tools, such as torque wrenches, are crucial for achieving the correct tightness. Incorrect installation is often observed during amateur installations leading to premature failure.

- Wind Load Resistance

The attachment method must withstand prevailing wind loads. Chimneys are often located in exposed areas, making them susceptible to strong winds that can exert significant force on the cap. Secure attachment design should account for local wind conditions and chimney height. Areas with frequent high winds require robust attachment methods and potentially additional bracing or support structures. Cases of caps blown off during severe storms are testament to the significance of wind load considerations.

- Material Compatibility

Compatibility between the cap material, the flue material, and the fasteners is essential. Dissimilar metals can react electrochemically, leading to corrosion and weakening of the connection. Understanding galvanic corrosion principles and selecting compatible materials is critical for ensuring long-term secure attachment. For example, attaching a stainless steel cap to an aluminum flue with standard steel fasteners can result in rapid corrosion of the aluminum.

The multifaceted nature of secure attachment underscores its importance in the overall performance and safety of a nine-inch round flue termination device. Neglecting any of these facets can compromise the cap’s functionality, leading to potential safety hazards and costly repairs. Ensuring robust and reliable attachment demands careful consideration of materials, installation techniques, and environmental factors.

4. Debris Prevention

Debris prevention is an integral function of a nine-inch round flue terminal. The primary objective of such a protective device is to mitigate the accumulation of foreign materials within the chimney system. Failure to prevent debris ingress results in reduced draft, increased risk of chimney fires, and accelerated degradation of the flue liner. The nine-inch round design, when properly implemented with a mesh or louvered structure, acts as a physical barrier against leaves, twigs, animal nests, and other obstructions that compromise airflow. The absence of effective debris prevention mechanisms directly correlates with increased maintenance requirements and potential safety hazards.

The effectiveness of debris prevention measures directly influences the operational efficiency of the connected appliance. For instance, a chimney obstructed by debris requires the appliance to work harder to exhaust combustion gases, leading to increased fuel consumption and the potential for incomplete combustion. Furthermore, the accumulation of flammable debris, such as dried leaves, significantly elevates the risk of chimney fires. Examples include situations where neglected chimneys, lacking adequate protective devices, have experienced rapid debris accumulation, resulting in dangerous and costly fires. Therefore, a well-designed nine-inch round flue terminal incorporates features specifically engineered to minimize the risk of debris-related problems.

In summary, debris prevention is not merely a desirable feature, but a critical component of a properly functioning nine-inch round flue terminal. Its effectiveness directly impacts chimney system performance, safety, and longevity. Neglecting debris prevention leads to increased maintenance costs, potential safety hazards, and reduced operational efficiency. Thus, the design and selection of such a terminal must prioritize effective debris management to ensure the long-term health and safety of the chimney system.

5. Draft Optimization

Draft optimization, pertaining to a nine-inch round flue terminal, involves ensuring an unobstructed and efficient flow of combustion gases from the appliance, through the chimney, and into the atmosphere. The geometry and design of such a cap directly influence the chimney’s draft. Inadequate design can impede airflow, leading to backdrafting, reduced appliance efficiency, and potential carbon monoxide hazards. Conversely, a well-designed cap facilitates optimal draft, promoting efficient combustion and mitigating safety risks. Real-world examples include situations where incorrectly designed or damaged flue terminals have restricted airflow, resulting in homeowner complaints of poor heating appliance performance and elevated carbon monoxide levels detected by safety monitors. Draft optimization is, therefore, a crucial design consideration for any flue terminal.

Further examination reveals that draft optimization is achieved through several design elements within a nine-inch round cap. The cap’s opening size must be sufficient to accommodate the exhaust volume produced by the connected appliance. Additionally, the cap’s shape should minimize resistance to airflow. Some designs incorporate angled vanes or louvers to enhance draft by channeling wind currents upward. These features promote a natural upward flow of exhaust gases, even under adverse wind conditions. Furthermore, the cap’s internal volume should be adequate to prevent pressure buildup and turbulence, both of which can impede draft. For instance, a cap with a constricted outlet or internal obstructions can significantly reduce draft, leading to appliance malfunction. Practical application of these principles involves selecting a cap specifically designed for the appliance’s exhaust requirements and ensuring proper installation to avoid any obstructions that could impede airflow.

In conclusion, draft optimization is an essential consideration in the design and selection of a nine-inch round flue terminal. Its impact on appliance performance, safety, and overall chimney system efficiency cannot be overstated. Challenges in achieving optimal draft often stem from improper cap design or installation. By understanding the principles of draft optimization and carefully selecting a cap that meets the specific needs of the appliance and chimney system, homeowners can ensure safe and efficient operation while mitigating potential hazards. The broader theme emphasizes the importance of comprehensive chimney system maintenance, including proper selection and installation of all components, to ensure long-term safety and efficiency.

Frequently Asked Questions

This section addresses common inquiries regarding protective terminals specifically designed for circular, nine-inch diameter chimney flues. The answers provided aim to clarify misconceptions and provide factual information for informed decision-making.

Question 1: What constitutes an acceptable material for the construction of a 9 inch round chimney cap?

Acceptable materials include stainless steel (304 or 316 grades), known for its corrosion resistance and longevity, and galvanized steel, offering a more economical alternative but with a shorter lifespan. Other materials may be suitable depending on specific environmental conditions, but should be assessed for resistance to heat, corrosion, and weathering.

Question 2: How frequently should a 9 inch round chimney cap be inspected for damage or degradation?

A visual inspection of the cap should be conducted at least annually, preferably before the start of each heating season. More frequent inspections may be warranted in areas with severe weather conditions or high levels of air pollution.

Question 3: What are the potential consequences of failing to install a 9 inch round chimney cap on a compatible flue?

Failure to install a cap can lead to the ingress of rainwater, snow, debris, and animals into the chimney system. This can result in damage to the flue liner, reduced draft, increased risk of chimney fires, and accelerated deterioration of the chimney structure.

Question 4: Can a 9 inch round chimney cap be installed by a homeowner, or is professional installation required?

While some homeowners with adequate skills and experience may be capable of installing a cap, professional installation is generally recommended. This ensures proper fit, secure attachment, and compliance with local building codes. Furthermore, working at heights presents inherent safety risks that are best mitigated by trained professionals.

Question 5: How does the design of a 9 inch round chimney cap contribute to the prevention of backdrafting?

A well-designed cap facilitates the efficient expulsion of exhaust gases, minimizing resistance to airflow. Features such as angled vanes or louvers can enhance draft by channeling wind currents upward. Proper sizing and internal volume also prevent pressure buildup and turbulence, which can impede draft and lead to backdrafting.

Question 6: What are the signs that a 9 inch round chimney cap needs to be replaced?

Signs indicating the need for replacement include significant corrosion, structural damage (e.g., cracks, dents, or warping), loose or missing components, and evidence of compromised functionality (e.g., water leakage or debris accumulation within the chimney). Delaying replacement can exacerbate existing problems and lead to more costly repairs.

These FAQs offer a concise overview of essential information regarding nine-inch round flue terminal devices. Addressing these considerations is critical for maintaining a safe and efficient chimney system.

The subsequent section will delve into troubleshooting common issues encountered with these protective terminals.

Conclusion

The preceding analysis has elucidated the critical attributes and functions of a nine-inch round flue termination device. The importance of material durability, secure attachment, debris prevention, and draft optimization cannot be overstated. A properly selected and maintained protective terminal of this configuration contributes significantly to the safety, efficiency, and longevity of the chimney system.

Ignoring the principles outlined herein carries potential consequences ranging from diminished appliance performance to heightened safety risks. Therefore, diligent adherence to best practices regarding selection, installation, and maintenance is paramount for all stakeholders invested in the integrity of chimney systems. Further research and consultation with qualified professionals are encouraged for informed decision-making.