A compromised junction between a chimney and the roof, allowing water intrusion, is a common cause of building envelope failure. This occurs where the metal sheeting designed to create a watertight seal degrades, is improperly installed, or becomes damaged, thereby permitting moisture to penetrate the structure. One example is water staining on ceilings near the chimney, indicating that external water is entering the building.

The integrity of this roof-chimney interface is paramount for preventing water damage, mold growth, and structural decay. Historically, maintaining this area has been critical for preserving building integrity and preventing costly repairs. Regular inspection and timely repair are essential to protect the value and longevity of a building.

The subsequent sections will delve into the various types of materials used in its construction, the common causes of its failure, methods for its effective repair, and preventative maintenance strategies to ensure long-term protection against water damage.

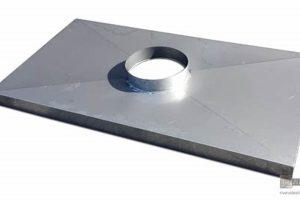

Chimney Flashing Leak

Maintaining a secure seal between the chimney and roofing materials is essential for preventing water intrusion and structural damage. The following tips provide guidance on identifying, preventing, and addressing potential issues.

Tip 1: Regular Inspection: Conduct thorough examinations of the flashing, especially after severe weather events. Look for signs of rust, corrosion, or physical damage like bends or tears in the metal.

Tip 2: Proper Installation: Ensure that the flashing is correctly installed with appropriate overlap and sealing. Improper installation is a primary cause of water infiltration. Consult with a qualified professional for installation or verification.

Tip 3: Material Selection: Utilize durable, corrosion-resistant materials suitable for the climate. Copper or aluminum are often preferred choices due to their longevity and resistance to environmental degradation.

Tip 4: Sealing and Caulking: Maintain a waterproof seal by applying high-quality, flexible caulk along the top edge of the flashing where it meets the chimney. Reapply caulk as needed to prevent water penetration.

Tip 5: Addressing Minor Damage Promptly: Even small signs of damage, such as a loose nail or a hairline crack, should be addressed immediately to prevent escalation. Ignoring minor issues can lead to more significant problems over time.

Tip 6: Professional Assessment: If you suspect a significant breach or are uncomfortable performing repairs, seek a professional inspection from a qualified roofing contractor. They can diagnose the issue and implement the correct solution.

Tip 7: Gutter Maintenance: Keep gutters and downspouts clear of debris. Clogged gutters can cause water to back up and saturate the roof, increasing the likelihood of leaks near the chimney.

Consistent vigilance and proactive maintenance are crucial to preserving the integrity of this critical roof component and protecting the building from costly water damage.

The subsequent sections will further explore repair techniques and long-term preventative measures.

1. Material Deterioration

The degradation of materials used in its construction is a primary catalyst for subsequent water intrusion. Over time, exposure to environmental elements such as rain, snow, ice, and ultraviolet radiation causes metals like aluminum or steel to corrode and crack. Sealants and caulk, crucial for creating a watertight barrier, become brittle and lose their elasticity, compromising the seal. This deterioration creates pathways for water to penetrate the roof-chimney interface, leading to leaks. A real-life example involves rusting steel flashing on older chimneys, where the rust eats through the metal, creating holes and allowing water to seep into the attic or ceilings below.

Understanding the mechanisms and progression of material degradation is essential for effective prevention and repair. The choice of materials significantly impacts the longevity of the system. For instance, copper flashing, while more expensive, resists corrosion far better than galvanized steel. Similarly, using high-quality, flexible sealants designed for exterior use extends the lifespan of the seal. In contrast, using inferior materials accelerates the degradation process, increasing the likelihood of leaks and the need for frequent repairs.

In summary, material deterioration directly contributes to failures. Selecting durable, weather-resistant materials and maintaining them through regular inspections and timely repairs is paramount to preventing water damage and preserving structural integrity. Addressing this key aspect proactively mitigates the risk of expensive repairs and potential health hazards associated with water intrusion.

2. Improper Installation

Improper installation is a principal cause of water intrusion around chimneys. Deficiencies in technique and deviations from best practices during the initial setup directly lead to premature failure and subsequent leaks. When flashing is not correctly integrated with both the roofing material and the chimney masonry, gaps and vulnerabilities are created. These weaknesses allow water to penetrate, bypassing the intended protection and causing damage to underlying structures. One common example involves inadequate overlap between the step flashing and the counter flashing, leaving an exposed seam susceptible to water penetration. Another example is failing to embed the flashing properly into the mortar joints of the chimney, creating a channel for water to seep behind the metal.

The consequences of improper installation extend beyond mere water stains; they encompass structural damage, mold growth, and compromised insulation. Effective flashing requires meticulous attention to detail, including precise cutting, shaping, and sealing. Furthermore, compatibility between the flashing material and the chimney/roofing materials is crucial. Using incompatible materials can accelerate corrosion or create expansion/contraction issues that further compromise the seal. A lack of proper sealing, such as failure to use appropriate caulk or sealant, exacerbates the risk. Furthermore, improper nail placement or using incorrect fasteners can cause the flashing to loosen over time, creating pathways for water.

In summation, proper installation is paramount to achieving a long-lasting, watertight seal. Shortcuts or deficiencies during this critical phase inevitably lead to premature failure. Addressing this issue necessitates employing qualified professionals who possess the requisite knowledge and experience to install flashing correctly, using appropriate materials and techniques. Rectifying improperly installed flashing often requires complete removal and replacement, adding significant cost and inconvenience. Therefore, investing in proper installation from the outset is essential for preventing long-term problems and protecting the integrity of the building envelope.

3. Water Infiltration Points

The compromise of a chimney flashing system invariably results in the creation of water infiltration points. These points represent pathways through which external moisture gains access to the building’s interior. The effectiveness of the flashing lies in its ability to form a continuous, impermeable barrier between the chimney and the roof. When this barrier is breached, whether due to material degradation, improper installation, or physical damage, distinct routes for water ingress are established. A common example is the separation of step flashing pieces, creating gaps where water can flow directly under the roofing shingles and into the underlying structure. Likewise, deteriorated caulk lines along the top edge of counter flashing provide an avenue for water to seep behind the metal and penetrate the building envelope.

Understanding the specific location and nature of water infiltration points is critical for effective repair. Identification often requires a careful, systematic inspection of the flashing, looking for signs of damage, corrosion, or displacement. The presence of water stains on interior ceilings or walls adjacent to the chimney serves as indirect evidence of leaks. Determining the exact source necessitates tracing the water’s path back to its entry point, which may involve removing roofing materials or conducting a water test. In addition to visual inspections, infrared thermography can be used to detect temperature differences caused by moisture accumulation, aiding in the identification of concealed infiltration points. Once identified, targeted repairs, such as replacing damaged flashing sections, re-sealing joints, or reinforcing weak points, can be implemented to restore the system’s integrity.

In summary, water infiltration points represent the culmination of failures in a chimney flashing system. Addressing these points requires a comprehensive approach that encompasses both identifying and rectifying the underlying causes. By understanding the mechanisms through which water penetrates the building envelope, building professionals and homeowners can effectively mitigate the risks associated with water damage and preserve the structural integrity of their properties. This understanding is essential for guiding repair strategies and ensuring that preventative measures are implemented to avoid future issues.

4. Structural Compromise

The ingress of water resulting from a compromised chimney flashing system precipitates structural compromise within a building. A failure to maintain a watertight seal at the junction between the chimney and the roof permits the sustained introduction of moisture into vulnerable building materials. This sustained exposure creates a conducive environment for wood rot, the degradation of insulation, and the corrosion of metallic components. The cumulative effect of these processes undermines the structural integrity of adjacent framing members, sheathing, and roofing materials. For example, prolonged water exposure can cause wooden roof rafters near the chimney to weaken and decay, necessitating costly repairs or even complete replacement. Similarly, water infiltration can saturate insulation, reducing its thermal performance and potentially fostering mold growth, further exacerbating the structural damage.

The extent of structural compromise directly correlates with the duration and severity of the water exposure. Chronic, undetected leaks can result in significant hidden damage before any visible signs manifest on interior surfaces. The presence of mold, often a consequence of persistent moisture, poses additional risks to both the building’s structural components and the health of its occupants. Regular inspections of the chimney flashing and prompt repair of any detected deficiencies are essential for preventing the onset of structural damage. Furthermore, the selection of durable, water-resistant materials for the flashing system contributes significantly to its long-term performance and the mitigation of structural risks. Addressing leaks proactively minimizes the potential for extensive and costly repairs down the line.

In summary, structural compromise represents a significant consequence of a failing chimney flashing system. The introduction of water initiates a cascade of degradation processes that weaken building materials and undermine the structural integrity of the roof and surrounding areas. Vigilant maintenance, timely repairs, and the use of durable materials are crucial for preventing water infiltration and mitigating the risks of structural compromise. This proactive approach safeguards the building’s longevity, protects its value, and ensures the safety and well-being of its occupants.

5. Maintenance Neglect

Maintenance neglect stands as a primary driver of chimney flashing failure, ultimately resulting in leaks. The failure to conduct regular inspections and perform timely repairs permits minor issues to escalate into significant problems that compromise the flashing’s integrity. For instance, a small crack in the caulk sealing the flashing to the chimney, if left unattended, will allow water to seep behind the flashing. This water, over time, erodes the mortar, corrodes the metal, and saturates the surrounding roofing materials. Similarly, the accumulation of debris, such as leaves and branches, around the flashing can trap moisture against the metal, accelerating corrosion and creating pathways for water intrusion. Neglecting to clear such debris during routine gutter maintenance directly contributes to the breakdown of the flashing system.

The absence of routine maintenance not only exacerbates existing problems but also obscures the early warning signs of potential failures. Regular visual inspections can identify corrosion, damaged flashing sections, or compromised seals before they lead to substantial leaks. By addressing these minor issues promptly, the lifespan of the flashing system can be significantly extended and the risk of water damage minimized. For example, replacing a few corroded nails or re-caulking a small crack is far less costly and disruptive than replacing entire sections of damaged flashing and repairing water-damaged interior surfaces. Furthermore, regular cleaning and sealing of the chimney masonry can prevent water absorption, which can weaken the chimney structure and accelerate the deterioration of the flashing system.

In conclusion, maintenance neglect is a critical factor in the development of chimney flashing leaks. The failure to perform routine inspections and timely repairs permits minor issues to escalate, leading to significant water damage and costly repairs. By adopting a proactive maintenance approach, homeowners and building managers can significantly extend the lifespan of their flashing systems, minimize the risk of water intrusion, and preserve the structural integrity of their properties. A commitment to regular maintenance is, therefore, an essential investment in the long-term health and value of any building with a chimney.

Frequently Asked Questions

The following questions address common concerns regarding chimney flashing leaks and their implications for building integrity.

Question 1: What are the primary indicators of a compromised chimney flashing system?

Primary indicators include water stains on ceilings or walls near the chimney, visible rust or corrosion on the flashing material, and the presence of loose or missing flashing components. Dampness or mold growth in the attic space adjacent to the chimney may also signify a leak.

Question 2: How frequently should chimney flashing be inspected?

It is recommended to inspect chimney flashing at least annually, preferably in the spring and fall. Inspections should also be conducted after severe weather events, such as heavy storms or periods of prolonged freezing temperatures.

Question 3: What are the typical materials used in chimney flashing construction, and which offers the best longevity?

Common materials include aluminum, galvanized steel, and copper. Copper is generally considered the most durable due to its superior resistance to corrosion, although aluminum and galvanized steel provide adequate performance when properly installed and maintained.

Question 4: What steps can be taken to prevent chimney flashing leaks?

Preventative measures include ensuring proper installation, using high-quality materials, regularly inspecting for damage, promptly repairing any detected issues, and maintaining clean gutters to prevent water backup.

Question 5: Is a chimney flashing leak a DIY project or should it be addressed by a professional?

Minor repairs, such as re-caulking small cracks, may be suitable for experienced homeowners. However, significant damage, complex installations, or issues involving structural damage should be addressed by a qualified roofing contractor.

Question 6: What are the potential long-term consequences of neglecting a chimney flashing leak?

Neglecting a leak can lead to structural damage to the roof and surrounding areas, mold growth, compromised insulation, and costly repairs. Prolonged water exposure can weaken framing members, leading to safety hazards and diminished property value.

Addressing chimney flashing vulnerabilities requires vigilance and informed decision-making. Prompt action mitigates risks and preserves the building’s integrity.

The subsequent section will elaborate on advanced diagnostic techniques.

Chimney Flashing Leak

This exploration has detailed the mechanisms, consequences, and remediation strategies associated with a compromised chimney flashing system. From material deterioration to improper installation and maintenance neglect, the causes are multifaceted, resulting in water infiltration, structural compromise, and potential health hazards. Vigilant inspection and proactive repair are paramount to mitigating these risks.

The integrity of the roof-chimney interface is non-negotiable for preserving building longevity and occupant safety. Addressing this vulnerability requires diligence, informed decision-making, and a commitment to upholding established building standards. The financial and structural repercussions of neglect far outweigh the cost of preventative measures. A failure to prioritize this critical area ultimately jeopardizes the long-term viability of the structure.