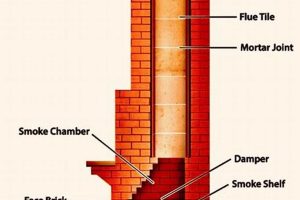

A conduit installed inside a chimney is designed to protect the chimney structure from the corrosive byproducts of combustion. These conduits are typically made of materials such as stainless steel, aluminum, or clay, and are sized to match the appliance they serve. They function as a barrier, preventing harmful gases and creosote from penetrating the chimney’s masonry or other materials. As an example, if a home is converted from using a wood-burning stove to a gas-burning furnace, it is often necessary to install such a conduit, as the flue gases produced by gas appliances are more acidic and can rapidly degrade an unlined chimney.

Its importance stems from the need to maintain structural integrity and prevent fire hazards. Without such protection, corrosive flue gases can deteriorate the mortar and brickwork of the chimney, leading to cracks and structural weakening. This deterioration can allow dangerous carbon monoxide to leak into the home, posing a serious health risk. Historically, chimneys were often built without these protective measures, leading to frequent repairs and a shorter lifespan for the chimney structure. Modern building codes often require the installation of these conduits to enhance safety and efficiency.

Understanding this basic component is crucial when considering topics like chimney repair, appliance efficiency, and home safety inspections, which will be explored in more detail in the subsequent sections.

Installation and Maintenance Considerations

Proper installation and consistent maintenance are paramount for ensuring the longevity and effectiveness of this critical component of a chimney system. Addressing potential issues proactively can prevent costly repairs and significantly enhance safety.

Tip 1: Select the Correct Material: Choose a material compatible with the type of fuel being burned. Stainless steel is generally suitable for wood, gas, and oil, while aluminum is typically only appropriate for certain gas appliances. Incompatibility can lead to rapid corrosion and failure.

Tip 2: Ensure Proper Sizing: The diameter of the conduit must be appropriately sized for the appliance it serves. An undersized conduit can restrict airflow and lead to incomplete combustion, while an oversized conduit can result in excessive creosote buildup. Refer to the appliance manufacturer’s specifications.

Tip 3: Conduct Regular Inspections: Annual inspections by a qualified professional are crucial. These inspections can identify signs of damage, corrosion, or creosote accumulation. Early detection allows for timely repairs and prevents escalation of problems.

Tip 4: Address Creosote Buildup Promptly: Creosote is a highly flammable byproduct of wood combustion. Regular cleaning is necessary to remove creosote deposits and mitigate the risk of chimney fires. The frequency of cleaning depends on the type of wood burned and the frequency of use.

Tip 5: Monitor for Signs of Deterioration: Be vigilant for any signs of deterioration, such as cracks, rust, or missing mortar around the chimney. These signs may indicate underlying problems that require immediate attention. Delaying repairs can compromise the structural integrity of the entire chimney system.

Tip 6: Maintain Proper Ventilation: Ensure that the chimney cap is in good condition and free of obstructions. A damaged or obstructed cap can prevent proper ventilation and lead to moisture intrusion, which can accelerate corrosion and damage.

Tip 7: Professional Installation is Recommended: While DIY installation may seem appealing, improper installation can be dangerous and ineffective. Hiring a certified professional ensures that the conduit is installed correctly and meets all applicable building codes.

By adhering to these considerations, homeowners can maximize the lifespan and effectiveness of this vital component, ensuring the safety and efficiency of their heating systems.

The upcoming sections will further explore specific maintenance procedures and common issues that may arise, offering practical solutions for addressing these challenges.

1. Protection

The primary function is safeguarding the chimney structure from the corrosive byproducts of combustion. Without this protection, acidic flue gases, moisture, and creosote would directly interact with the chimney’s masonry, leading to deterioration. This deterioration manifests as cracks, spalling, and weakening of the overall structure. The corrosive action, particularly from gas appliances producing acidic condensate, accelerates the breakdown of mortar and brick, compromising the chimney’s ability to safely vent combustion gases. A real-life example is the rapid degradation of unlined chimneys serving high-efficiency furnaces, where the acidic condensate quickly erodes the internal structure, necessitating costly repairs or even complete chimney rebuilds. Understanding this protective role is fundamentally important in maintaining chimney health and preventing potential hazards.

The protection extends beyond the chimney itself to the inhabitants of the building. A compromised chimney can allow carbon monoxide, a colorless and odorless gas, to leak into living spaces. Carbon monoxide poisoning poses a serious health risk and can be fatal. By providing a sealed pathway for flue gases, the chimney liner prevents this leakage, ensuring the safety of occupants. Furthermore, it reduces the risk of chimney fires by containing creosote buildup, a flammable byproduct of wood-burning. In instances where a fireplace or wood stove is heavily used, the accumulation of creosote poses a significant fire hazard. The liner helps contain this buildup, making it easier to manage and reducing the likelihood of a fire spreading to the rest of the house.

In summary, the essence of its design lies in its protective capabilities. It shields the chimney from corrosive damage, safeguards occupants from carbon monoxide poisoning, and mitigates the risk of chimney fires. Recognizing its vital role in ensuring safety and structural integrity is paramount. Challenges often arise from improper material selection or inadequate maintenance, highlighting the need for professional installation and regular inspections. Its importance underscores the broader theme of preventative maintenance in preserving home safety and structural well-being.

2. Material Compatibility

The selection of an appropriate material is paramount to the long-term performance and safety of a chimney’s internal protection. The material must withstand the specific corrosive conditions generated by the type of fuel being burned. Incompatibility can lead to rapid degradation and system failure, negating the benefits of having a protective layer.

- Fuel Type Specificity

Different fuels produce different combustion byproducts. Wood combustion generates creosote, a flammable substance, along with moisture. Gas combustion produces acidic condensate. Oil combustion creates sulfurous compounds. Stainless steel is generally resistant to the byproducts of all three fuel types, making it a versatile option. Aluminum, however, is only suitable for certain gas appliances where the exhaust temperatures are low and the condensate is minimal. Installing an aluminum structure with a wood-burning appliance would result in rapid corrosion and eventual failure of the system.

- Corrosion Resistance

The ability of a material to resist corrosion from flue gases and condensates is a critical factor. Stainless steel alloys are chosen for their inherent resistance to acidic compounds and high temperatures. However, not all stainless steel is created equal; the specific grade of stainless steel used can significantly impact its corrosion resistance. For instance, 316L stainless steel is more resistant to chloride corrosion than 304 stainless steel and is therefore a better choice in coastal environments or when burning fuels with higher sulfur content. Regular inspections are crucial to identify any signs of corrosion early on.

- Temperature Tolerance

Chimneys experience a wide range of temperatures, particularly during rapid heating and cooling cycles. The chosen material must be capable of withstanding these temperature fluctuations without cracking, warping, or otherwise deteriorating. Clay tiles, while historically used, are susceptible to cracking from thermal shock, making them less durable than stainless steel options in modern installations. The material’s ability to maintain its structural integrity under extreme temperature variations is essential for safe and reliable operation.

- Building Codes and Regulations

Local and national building codes often dictate the permissible materials for chimney liners based on fuel type and appliance characteristics. Compliance with these codes is essential for ensuring safety and obtaining necessary permits. Some jurisdictions may require specific types of stainless steel or restrict the use of aluminum altogether. Understanding and adhering to these regulations is a critical aspect of selecting the appropriate material. Consulting with a qualified professional can help ensure compliance and avoid costly mistakes.

The interplay between the fuel type, corrosion resistance, and temperature tolerance of materials directly affects its longevity. Selecting the wrong material not only undermines the safety and effectiveness of the chimney system but can also lead to costly repairs or replacements. The consideration of these factors underscores the importance of professional assessment and installation in ensuring a safe and efficient chimney operation.

3. Proper Sizing

The dimensions of a chimney’s internal protective component must be precisely matched to the appliance it serves. Inadequate sizing leads to operational inefficiencies and poses significant safety risks. An undersized component restricts the flow of combustion gases, leading to incomplete combustion and the potential for carbon monoxide buildup within the dwelling. Conversely, an oversized component allows for the excessive cooling of flue gases, promoting creosote condensation in wood-burning systems and acid condensation in gas-burning systems, accelerating corrosion and potentially blocking the chimney. As an illustrative case, installing an incorrectly sized protector for a high-efficiency furnace can negate the furnace’s energy-saving benefits and simultaneously increase the risk of chimney deterioration. The principle of this element is an integral part of the chimney system function.

Practical implications of incorrect measurements are far-reaching. Over time, creosote buildup in an oversized one connected to a wood-burning appliance can drastically increase the risk of chimney fires, endangering the structure and its occupants. Acid condensation in an oversized component connected to a gas-burning appliance can corrode the chimney masonry, causing structural damage and allowing dangerous gases to leak into the home. Accurate sizing, therefore, is not merely a matter of optimizing efficiency; it is a critical safety measure. Professionals consider the appliance’s BTU input, fuel type, and venting requirements when determining the correct diameter and height to achieve optimal performance and safety. Correct measurements guarantee a reliable venting system.

The challenges related to this aspect often stem from outdated or incomplete information about the appliance’s specifications, alterations to the heating system without proper chimney adaptation, or cost-cutting measures that compromise safety. Addressing these challenges requires a thorough assessment of the heating system, adherence to relevant building codes, and the engagement of qualified professionals for installation and inspection. Ultimately, meticulous attention to dimension is essential for ensuring the safe and efficient operation of the chimney system, reinforcing the importance of professional expertise in this area.

4. Structural Integrity

Maintaining the soundness of a chimney structure is inextricably linked to the presence and condition of its internal protective component. The component acts as a primary defense against corrosive elements, directly influencing the chimney’s ability to withstand environmental stressors and combustion byproducts over time. Its role is paramount in preventing deterioration and ensuring the safe discharge of exhaust gases.

- Prevention of Mortar Degradation

The mortar joints between bricks or stones are particularly vulnerable to acidic flue gases and moisture. Without a protective layer, these gases can penetrate the mortar, causing it to crumble and weaken. This degradation leads to cracks and instability in the chimney structure. Consider an older home where the original mortar has been exposed to years of unfiltered flue gases; the mortar may be so deteriorated that bricks become loose, posing a collapse hazard. A properly installed and maintained liner prevents this direct exposure, preserving the integrity of the mortar joints.

- Protection Against Thermal Stress

Chimneys endure significant temperature fluctuations during the heating season. Rapid heating and cooling cycles can cause expansion and contraction of the masonry, leading to cracks and structural weakening. An appropriate system acts as a buffer, moderating temperature extremes and minimizing the stress on the chimney’s brickwork. For instance, a stainless steel component expands and contracts at a rate closer to that of the surrounding masonry compared to unlined clay flues, reducing the risk of thermal stress-induced cracking.

- Mitigation of Moisture Damage

Rainwater and condensation can infiltrate a chimney, especially when the chimney cap is damaged or missing. This moisture can freeze and thaw within the masonry, causing it to crack and spall. The protective element creates a barrier against moisture intrusion, preventing water from reaching the brickwork. In colder climates, this protective function is crucial for preventing freeze-thaw damage that can quickly compromise the chimney’s structural integrity.

- Prevention of Gas Leaks

Cracks and deterioration in a chimney’s structure can create pathways for dangerous gases, such as carbon monoxide, to leak into the living spaces of a building. A well-maintained protective system ensures a sealed pathway for exhaust gases, preventing leaks and protecting the health of occupants. The case of a family experiencing carbon monoxide poisoning due to a cracked chimney underscores the critical role of a functional element in maintaining structural integrity and ensuring safety.

The interplay between these facets demonstrates that this protective layer is indispensable for maintaining a structurally sound and safe chimney. Neglecting the maintenance or proper installation compromises the chimney’s ability to withstand environmental and operational stressors, resulting in costly repairs, potential safety hazards, and ultimately, a diminished lifespan for the entire chimney system.

5. Safety Enhancement

The installation and maintenance of a chimney’s internal protective component is directly correlated with improved safety outcomes. The element’s integrity and functionality are essential for preventing a range of hazards, including structural failures, carbon monoxide intrusion, and chimney fires. Properly designed, installed, and maintained, this component significantly reduces risks associated with chimney operation.

- Prevention of Carbon Monoxide Intrusion

A compromised chimney structure, particularly one lacking a functional protector, can permit the leakage of carbon monoxide into living spaces. Carbon monoxide is a colorless, odorless gas produced by incomplete combustion, posing a severe health risk and potentially resulting in fatalities. A properly installed and maintained protector provides a sealed conduit for exhaust gases, preventing their escape into the dwelling. For example, consider a scenario where a homeowner experiences persistent flu-like symptoms; investigation reveals a cracked chimney lacking a functional element, allowing carbon monoxide to seep into the house. Installing a new, properly sealed chimney liner rectifies the situation, eliminating the risk of carbon monoxide poisoning. This illustrates the direct link between the element and the prevention of a potentially deadly hazard.

- Mitigation of Chimney Fire Risks

Creosote, a flammable byproduct of wood combustion, accumulates within chimneys. Without a suitable protective layer, creosote buildup poses a significant fire hazard. A chimney fire can rapidly spread to the rest of the structure, causing extensive damage and endangering lives. The component contains creosote within a defined space, making it easier to manage and inspect. Further, materials such as stainless steel are less prone to cracking or disintegration in the event of a chimney fire, minimizing the risk of the fire spreading beyond the chimney itself. Regular cleaning and inspection of the element are crucial to prevent creosote accumulation and maintain its effectiveness in containing potential fires.

- Structural Integrity and Collapse Prevention

Deterioration of the chimney structure due to exposure to corrosive flue gases and moisture can lead to structural instability and eventual collapse. A collapsing chimney poses a direct threat to surrounding property and individuals. The element protects the chimney’s masonry from these corrosive elements, preventing cracks, spalling, and weakening of the overall structure. For instance, in older buildings with unlined chimneys, the gradual erosion of mortar joints and brickwork can lead to partial or complete chimney collapse. Installing a proper internal protective layer mitigates this risk by shielding the masonry from damaging byproducts, thereby reinforcing the chimney’s structural integrity and preventing potentially catastrophic failures.

- Improved Appliance Efficiency and Safety

A properly sized and installed protector ensures efficient venting of combustion gases, promoting optimal appliance performance. When the venting system is inadequate, appliances may operate inefficiently, leading to increased fuel consumption and the potential for incomplete combustion. A properly functioning element optimizes airflow, ensuring complete combustion and reducing the risk of dangerous gas buildup. A homeowner notices that their furnace is running inefficiently and emitting a strange odor. An inspection reveals an improperly sized and damaged element. Replacing it with one of the correct size and material restores the furnace’s efficiency and eliminates the safety hazard, underscoring the direct link between the internal component and appliance safety.

These facets collectively demonstrate the critical role that a properly designed and maintained chimney’s internal layer plays in safety enhancement. From preventing carbon monoxide intrusion and mitigating chimney fire risks to preserving structural integrity and improving appliance efficiency, the element functions as a safeguard, ensuring that chimneys operate safely and effectively. Its importance cannot be overstated, and regular inspections and maintenance are essential for maximizing its benefits and minimizing potential hazards.

Frequently Asked Questions

The following addresses common inquiries regarding chimney’s internal safeguard, their function, maintenance, and associated safety concerns.

Question 1: What is the purpose of a flue’s internal component?

Its primary function is to protect the chimney’s masonry from the corrosive byproducts of combustion, such as flue gases, creosote, and moisture. It also provides a sealed pathway for exhaust gases, preventing carbon monoxide intrusion.

Question 2: What materials are commonly used to construct a flue’s internal structure?

Common materials include stainless steel, aluminum, and clay. Stainless steel is versatile and suitable for various fuel types, while aluminum is generally restricted to specific gas appliances. Clay tiles were historically used, but are less durable than modern materials.

Question 3: How is the correct size determined for a flue’s internal protective shield?

Proper sizing depends on the appliance’s BTU input, fuel type, and venting requirements. An undersized shield restricts airflow, while an oversized one can lead to excessive creosote or acid condensation. Consulting with a qualified professional is essential for accurate sizing.

Question 4: How often should a flue’s internal layer be inspected?

Annual inspections by a qualified professional are recommended. More frequent inspections may be necessary depending on the frequency of use and the type of fuel being burned.

Question 5: What are the potential consequences of neglecting the care of a flue’s internal protector?

Neglecting maintenance can lead to structural deterioration of the chimney, carbon monoxide leaks, chimney fires, and reduced appliance efficiency. Timely repairs are essential to prevent escalation of these problems.

Question 6: Can a flue’s internal component be installed as a do-it-yourself project?

While DIY installation may seem appealing, improper installation can be dangerous and ineffective. Hiring a certified professional ensures that the protector is installed correctly and meets all applicable building codes. Professional installation is strongly advised.

The aforementioned points underscore the critical role in maintaining the safety and efficiency of a chimney system. Regular inspections, proper maintenance, and professional installation are essential for mitigating potential hazards.

The subsequent section will delve into specific case studies illustrating the importance of properly functioning chimney structures and internal protection.

In Conclusion

This discussion has elucidated that what is a chimney liner encompasses a critical safety component within a chimney system. It is designed to protect the chimney structure from corrosive byproducts of combustion, ensure proper venting of exhaust gases, and prevent hazards such as carbon monoxide intrusion and chimney fires. Material selection, proper sizing, regular inspections, and professional maintenance are paramount to its effective function and longevity.

Therefore, recognizing the vital role of what is a chimney liner is imperative for homeowners and building professionals alike. Neglecting its maintenance or proper installation can have severe consequences, compromising structural integrity and endangering lives. Prioritizing the care and upkeep of this essential element is an investment in safety, efficiency, and the long-term well-being of the building and its occupants.