The preparation instructions for a specific type of pastry, characterized by its conical or cylindrical shape and cooked traditionally over an open flame or in a specialized oven, dictate the ingredients and methodology required. These instructions detail the process of creating the dough, its application to a rotating spit or form, and the subsequent baking or roasting until a caramelized crust forms. An example would involve precise measurements of flour, sugar, yeast, and milk, followed by proofing, shaping, and coating with sugar and nuts prior to baking.

The availability of detailed guidance is crucial for achieving a consistent and desirable outcome when producing this unique confectionery. The documented process ensures reproducibility, allowing individuals to recreate a traditional treat or to experiment with variations in flavor and presentation. Historically, this type of baked good has been a significant part of culinary traditions in Central and Eastern Europe, often associated with festivals and celebrations. Access to reliable preparation methods enables the preservation and continuation of these cultural practices.

This discourse now shifts to the specific elements involved in preparing this specialized baked item. Key considerations will include variations in dough composition, the application of diverse coatings and toppings, as well as alternative cooking techniques applicable in a modern kitchen environment. Further exploration will encompass troubleshooting common issues encountered during the baking process and strategies for achieving optimal results.

Essential Guidelines for Crafting Authentic Baked Confections

The following recommendations aim to enhance the success rate in preparing this traditionally baked good. Adherence to these guidelines contributes to improved texture, flavor, and overall presentation.

Tip 1: Precise Ingredient Measurement: Utilizing accurate measuring tools is paramount. Variations in ingredient ratios, particularly flour and liquid, can significantly impact dough consistency and final product texture. A kitchen scale is recommended for optimal precision.

Tip 2: Dough Temperature Control: Maintaining the correct dough temperature during proofing is crucial for proper yeast activation. An environment between 24-27C (75-80F) is generally optimal. Excessive heat can kill the yeast, while insufficient warmth retards its activity.

Tip 3: Uniform Dough Application: When applying the dough to the baking form, ensure a consistent thickness. Irregularities in thickness can lead to uneven baking and potential tearing during the cooking process.

Tip 4: Even Heat Distribution: Regardless of the baking method employed open flame, specialized oven, or conventional oven ensuring even heat distribution is critical. Rotate the baking form regularly to promote uniform browning and prevent burning.

Tip 5: Sugar Coating Application: Apply the sugar coating evenly and generously after the initial baking phase. This ensures thorough caramelization and contributes to the characteristic sweet crust. Use a high-quality sugar for optimal results.

Tip 6: Monitoring Internal Temperature: While visual cues are helpful, monitoring the internal temperature of the baked confection can prevent under-baking. An internal temperature of approximately 85-90C (185-194F) is indicative of complete baking.

Tip 7: Cooling Rack Utilization: Allowing the baked confection to cool on a wire rack after removal from the baking form prevents moisture accumulation and maintains the crisp texture. Avoid placing it directly on a solid surface.

Adhering to these seven points will improve the odds of successfully recreating the traditional version of this treat. Proper technique and careful execution are essential.

The subsequent segment of this discourse focuses on common variations in this methodology and the adjustments necessary to adapt the process to various kitchen settings.

1. Precise Measurements

The attainment of desired characteristics in chimney cakes relies heavily on the accurate measurement of ingredients. This requirement extends beyond a general approximation, demanding adherence to specific quantities of each component. The cause-and-effect relationship is direct: deviations from recommended measurements invariably impact dough consistency, baking properties, and ultimately, the sensory attributes of the final product. For example, an excess of flour can yield a dry, dense cake, while insufficient flour results in a sticky dough that fails to hold its shape during baking. The accurate measurement of ingredients stands as a fundamental component, and is vital in this endeavor.

The importance of precision is amplified by the chemical reactions that occur during baking. Yeast activation, gluten development, and caramelization processes are all influenced by the ratios of ingredients. Consider the role of sugar: an insufficient quantity will limit the browning reaction and detract from the characteristic sweetness, while an excess may lead to premature burning. A real-world example can be found in comparing recipes using volume measurements versus weight measurements. Recipes employing volume (e.g., cups and spoons) are inherently less consistent due to variations in how ingredients are packed. Recipes using weight (e.g., grams and ounces) offer greater reproducibility and control.

In summary, the relationship between precise measurements and the successful execution of this baked good creation is critical. Inaccurate measurements compromise the desired outcome, leading to inconsistent texture, flavor, and appearance. Challenges in achieving precision can be mitigated through the use of reliable measuring tools, adherence to weight-based recipes, and meticulous attention to detail during ingredient preparation. By prioritizing accuracy, one maximizes the probability of producing a high-quality confectionery that aligns with established standards.

2. Dough preparation

Dough preparation stands as a critical determinant in the success of creating the distinctive confectionery. The characteristics of the final product are directly contingent upon the quality and treatment of the dough throughout its formative stages.

- Ingredient Incorporation and Hydration

The method and sequence of incorporating ingredients significantly impact gluten development and dough hydration. Proper hydration is essential for achieving the desired elasticity and extensibility in the dough. For instance, adding cold liquids to the dry ingredients can inhibit gluten formation, leading to a less cohesive dough, whereas gradually adding warm liquids can enhance gluten development, producing a more structured result. Insufficient mixing can result in pockets of dry flour, compromising texture. Incomplete or improper hydration directly affects the final texture and rise of the cooked item.

- Kneading and Gluten Development

Kneading promotes the formation of gluten, a protein complex that provides structure and elasticity to the dough. Insufficient kneading results in a weak gluten network, leading to a cake that lacks volume and has a crumbly texture. Conversely, over-kneading can cause the gluten to become tight and break down, producing a tough and dense product. The duration and technique of kneading are crucial. Manual kneading requires skill and experience to judge the dough’s readiness, while mechanical mixers offer consistency but demand careful monitoring to prevent over-kneading.

- Proofing and Fermentation

Proofing, the fermentation stage, allows yeast to produce carbon dioxide, causing the dough to rise and develop flavor. Inadequate proofing results in a dense, under-risen cake with a bland flavor. Over-proofing, on the other hand, can lead to a collapsed structure and a sour, yeasty taste. Temperature control is paramount during proofing; excessively high temperatures can accelerate fermentation to an undesirable extent, while low temperatures retard yeast activity. Observing the dough’s volume and texture provides valuable cues for determining the optimal proofing duration.

- Dough Consistency and Handling

The final dough consistency must be amenable to shaping and adherence to the baking form. A dough that is too stiff will be difficult to manipulate and may crack during baking, while a dough that is too slack will sag and lose its shape. The appropriate dough consistency is achieved through precise ingredient ratios, proper kneading, and careful control of hydration levels. The dough’s ability to maintain its form throughout the baking process is essential for the final product’s visual appeal and structural integrity.

These interconnected factors collectively define the quality of dough preparation. Precise control over ingredient incorporation, kneading, proofing, and dough consistency contributes directly to achieving the characteristic texture, flavor, and structural integrity. Skillful and attentive preparation of the dough is the cornerstone to creation, ensuring the success and authentic character of the finished product.

3. Baking Temperature

Baking temperature is a critical factor in the successful execution of a traditional confection. It directly influences the texture, color, and structural integrity. Precise control over this variable is essential for achieving a product that meets established quality standards. Variations in temperature can result in a suboptimal outcome, affecting both the aesthetic appeal and the palatability of the final product.

- Surface Caramelization and Crust Formation

The exterior color and crispness are a direct result of the Maillard reaction, a chemical process that occurs between amino acids and reducing sugars at elevated temperatures. An insufficient temperature will result in a pale and under-caramelized surface, lacking the characteristic golden-brown hue. Excessive temperature, conversely, can lead to rapid burning and a bitter taste. The ideal baking temperature promotes gradual caramelization, creating a crisp, flavorful crust while preventing charring.

- Internal Dough Cookery and Texture Development

Consistent and thorough cooking of the interior dough relies on maintaining an appropriate baking temperature. An inadequate temperature will lead to an undercooked center, resulting in a doughy or gummy texture. Conversely, an excessively high temperature can cause the exterior to overcook before the interior is fully baked. This leads to a dry and brittle outcome. Uniform heat penetration ensures that the internal dough reaches the appropriate temperature for complete gelatinization of starches and coagulation of proteins, contributing to a tender and structurally sound interior.

- Yeast Activity and Leavening Control

Baking temperature exerts control over yeast activity, a crucial component of leavening. The proper temperature provides optimal conditions for yeast to produce carbon dioxide, which contributes to the dough’s rise and overall volume. Insufficient temperature retards yeast activity, resulting in a dense, under-risen cake. Excessive temperature kills the yeast prematurely, halting leavening before the cake has fully expanded. Maintaining an appropriate temperature allows for controlled expansion and prevents the cake from collapsing during baking.

- Moisture Content Regulation

Baking temperature plays a vital role in regulating the moisture content of the final baked item. A suitably calibrated temperature allows for gradual evaporation of moisture from the dough, preventing a soggy or waterlogged texture. An inadequate temperature hinders moisture evaporation, leaving the interior damp. An excessively high temperature causes rapid surface drying, potentially leading to a tough crust. The baking environment must facilitate optimal water removal to achieve the desired texture.

These interconnected facets of baking temperature demonstrate its central importance in production. The Maillard reaction is critical to color and flavor, uniform heating is essential for consistent internal texture, yeast performance needs regulated temperatures, and a controlled process for water evaporation is required for desired mouthfeel. Understanding and controlling these variables ensures a successful product.

4. Coating application

Coating application represents a crucial stage in the preparation of this specific type of baked confectionery, directly influencing its sensory characteristics and overall appeal. The uniform and consistent application of various coatings contributes to the characteristic sweetness, texture, and visual presentation.

- Adhesion and Surface Preparation

Effective adhesion of the coating depends upon appropriate surface preparation. The surface of the baked confectionery must possess a degree of tackiness or slight moisture to facilitate bonding with the coating material, typically sugar-based. The absence of this surface preparation can result in uneven coating distribution and subsequent detachment, compromising the intended sensory experience. Applying a light mist of water or egg wash prior to coating application enhances adhesion and promotes a more uniform distribution.

- Coating Material Composition and Properties

The composition and physical properties of the coating material significantly influence the final product. Traditional coatings often consist of granulated sugar, cinnamon, and chopped nuts. The particle size of the sugar and the uniformity of the nut pieces directly impact the texture and visual uniformity of the coating. Variations in the sugar type, such as using coarse sugar versus fine sugar, affect the degree of caramelization and the overall sweetness intensity. Proper selection and preparation of the coating materials are essential for achieving the desired characteristics.

- Application Technique and Uniformity

The technique employed for applying the coating significantly influences the uniformity of coverage. Rolling the freshly baked item in the coating material ensures even distribution and complete coverage of the surface. Manual application, using a brush or sieve, allows for greater control over the amount and placement of the coating but requires precision and skill to achieve uniformity. Uneven or incomplete coating application detracts from the visual appeal and creates inconsistencies in the distribution of flavor and texture.

- Caramelization and Setting Process

The subsequent caramelization and setting of the coating contribute to the overall structural integrity and flavor development. During baking, the sugar within the coating melts and caramelizes, forming a crisp, caramelized crust. The temperature and duration of baking influence the degree of caramelization and the resulting flavor profile. Over-caramelization leads to a bitter taste, while under-caramelization results in a lack of crispness. Proper control of the baking process is essential for achieving the optimal balance between sweetness, texture, and caramelized flavor.

These facets of coating application collectively determine the final quality and presentation of this baked confectionery. Precise control over surface preparation, material selection, application technique, and caramelization process results in a uniform, flavorful, and visually appealing product. Deviations from these established practices invariably detract from the overall sensory experience and compromise the integrity of the confection.

5. Even caramelization

Even caramelization is a critical attribute directly influencing the final quality of chimney cakes. It is the result of the Maillard reaction, a chemical process between amino acids and reducing sugars accelerated by heat. Uniform heat distribution is paramount; inconsistencies result in uneven browning and a lack of textural homogeneity. For example, if a portion of the cake is closer to the heat source, that area will caramelize more rapidly, potentially burning before other areas achieve the desired color. A rotating spit, as traditionally used, is intended to promote even heat exposure and therefore, uniform caramelization across the entire surface. The visual appeal and flavor profile are directly linked to the attainment of even browning.

The practical application of this understanding is significant in both commercial and domestic settings. Commercial bakers rely on specialized ovens with precise temperature controls and rotational mechanisms to ensure consistency in large-scale production. In a home kitchen, replicating this evenness requires careful attention to oven settings, rotation of the cake during baking, and potentially, the use of a baking stone or other heat-distributing material. Furthermore, the composition of the dough and the sugar coating plays a crucial role. A dough with an uneven distribution of sugars will caramelize erratically. The type of sugar used in the coating also affects the caramelization process; coarser sugars may require higher temperatures or longer baking times to achieve full caramelization.

In summary, even caramelization is not merely a cosmetic detail but an integral component directly impacting the flavor, texture, and overall quality. Achieving this requires precise control over heat distribution, careful selection of ingredients, and adherence to established baking techniques. Challenges in achieving uniform caramelization highlight the importance of understanding the underlying scientific principles and implementing appropriate strategies to mitigate inconsistencies. Mastery of this element is key to producing superior chimney cakes.

6. Cooling process

The cooling process, often overlooked, represents a critical phase impacting the final texture and structural integrity of a baked confection. In the context of preparation, its influence is multifaceted, affecting the retention of crispness, prevention of moisture accumulation, and overall palatability.

- Prevention of Moisture Condensation

The primary objective of controlled cooling is to mitigate moisture condensation on the exterior. Placing a freshly baked, still-warm item directly onto a solid surface, such as a plate or countertop, restricts airflow and promotes the trapping of steam released from the interior. This trapped moisture subsequently condenses on the surface, resulting in a softened crust and a loss of the desired crispness. Elevating the baked item on a wire rack allows for unrestricted airflow, facilitating the dissipation of steam and preventing moisture accumulation. The absence of a proper cooling rack invariably results in a textural degradation of the confection.

- Maintenance of Structural Integrity

The structural integrity of the finished item is also influenced by the cooling process. As the baked confection cools, the internal starches and proteins undergo a process of retrogradation, solidifying the structure and preventing collapse. Allowing the item to cool undisturbed on a wire rack minimizes stress on the structure during this critical phase. Premature handling or stacking of the warm items can distort their shape or cause structural damage. Consequently, proper cooling contributes to the maintenance of the desired form and overall visual appeal.

- Flavor Development and Stabilization

While not as pronounced as in some other baked goods, a degree of flavor development and stabilization occurs during the cooling process. The internal temperature gradually decreases, allowing volatile flavor compounds to equilibrate and meld together. Rapid cooling can disrupt this process, potentially leading to a less harmonious flavor profile. Gradual cooling at room temperature allows for optimal flavor development and contributes to a more balanced and nuanced taste.

- Optimization of Crust Texture

The ultimate texture of the crust, a defining characteristic, is substantially influenced by controlled cooling. The porous structure of the crust allows for the escape of moisture during baking, resulting in the desired crispness. Rapid temperature changes or restricted airflow during cooling can impede this process, leading to a softened or even soggy crust. Slow, even cooling on a wire rack promotes the retention of crispness and prevents moisture-related textural degradation. The achieved crispness is directly linked to optimal conditions during the cooling stage.

These factors collectively underscore the significance of the cooling process in the creation of this type of traditional confection. The proper execution of this phase is not merely a procedural step but a fundamental element in achieving the desired textural characteristics and maintaining the overall quality of the finished product. Deviations from recommended cooling practices can significantly detract from the intended sensory experience.

7. Equipment selection

Appropriate apparatus is a key determinant in the successful preparation of this specialized confectionery. The choice of tools directly impacts dough consistency, uniform baking, and the final presentation. Suboptimal equipment can lead to inconsistent results and a departure from traditional characteristics.

- Dough Preparation Implements

The selection of mixing equipment significantly affects dough development. A stand mixer facilitates thorough ingredient incorporation and gluten development, resulting in a consistent dough structure. Inadequate mixing, often associated with manual methods or lower-powered mixers, can lead to uneven hydration and a poorly developed gluten network, impacting the baked item’s texture. For example, a dough that is insufficiently mixed may lack the elasticity necessary to properly adhere to the baking form.

- Baking Form Specifications

The traditional baking form is a truncated cone or cylindrical shape, typically constructed from wood or stainless steel. The material properties and dimensions of this form influence heat transfer and structural support during baking. Forms constructed from materials with poor heat conductivity can lead to uneven baking and localized burning. Furthermore, variations in the form’s diameter and taper affect the final shape and size of the baked confectionery. The baking form must be appropriately sized and constructed to ensure uniform baking and structural integrity.

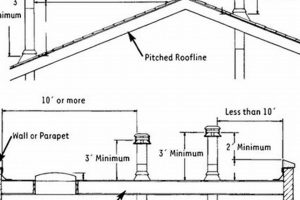

- Heat Source Configuration

Historically, an open fire or specialized oven was utilized for the preparation. Modern adaptations often employ conventional ovens or grilling devices. The heat source configuration significantly affects caramelization and overall baking uniformity. Open-flame cooking provides intense radiant heat, promoting rapid surface caramelization. Conventional ovens rely on convection heat, which may require adjustments in baking time and temperature to achieve the desired caramelization. Inconsistent heat distribution, common in some home ovens, can lead to uneven baking and localized burning. Careful monitoring and adjustment of the heat source are essential for optimal results.

- Coating Application Tools

The tools used for applying the sugar coating influence the uniformity and coverage of the coating layer. A shallow dish or tray is commonly used to roll the freshly baked item in the coating material. A sieve or shaker can be used to apply the coating more precisely. The choice of tools depends on the desired texture and thickness of the coating. Uneven coating application, resulting from inadequate tools or improper technique, detracts from the visual appeal and creates inconsistencies in the flavor profile.

The selection of appropriate implements is therefore crucial for successful baking. The mixing equipment must facilitate optimal dough development, the baking form must ensure uniform baking, the heat source needs appropriate configuration, and the coating tools are required for correct and consistent application. Compromises in equipment quality invariably affect the final product, highlighting the critical link between equipment and outcome.

Frequently Asked Questions Regarding Chimney Cakes Recipe

This section addresses common inquiries pertaining to the creation of these baked goods, aiming to clarify misconceptions and provide concise, factual responses.

Question 1: What is the optimal type of flour for crafting the dough?

A high-gluten flour, such as bread flour, is recommended. This promotes the development of a strong gluten network, essential for achieving the characteristic elasticity and structural integrity of the baked product.

Question 2: Is fresh or active dry yeast preferable?

Both fresh and active dry yeast are suitable. However, active dry yeast requires rehydration prior to use, following the manufacturer’s instructions. Fresh yeast offers a slightly different flavor profile, but requires careful handling and storage.

Question 3: What is the ideal proofing temperature?

An environment between 24-27C (75-80F) is generally considered optimal for proofing. This temperature range promotes efficient yeast activity and prevents excessive fermentation. Monitoring the dough’s volume is crucial for determining the appropriate proofing duration.

Question 4: Can a conventional oven be used in lieu of a specialized oven?

A conventional oven can be used, but modifications to the baking process are necessary. Lowering the temperature and increasing the baking time may be required to ensure uniform cooking and prevent burning. Rotating the baked item frequently is essential for even caramelization.

Question 5: What is the best method for applying the sugar coating?

Rolling the freshly baked item in a shallow dish of sugar mixture, while the surface is still slightly moist, ensures the most even and thorough coating. Gentle pressure can be applied to encourage adhesion of the sugar crystals.

Question 6: How should the baked good be stored to maintain its quality?

Storage in an airtight container at room temperature is recommended. However, its crispness diminishes over time. Consumption within one to two days of baking is advised for optimal texture and flavor.

These responses offer guidance for consistent and successful preparation. Attention to detail and adherence to established methods are critical for achieving desired results.

This discourse now transitions to potential variations in formulation and technique, accommodating dietary restrictions and personal preferences.

Chimney Cakes Recipe

The preceding exposition has systematically examined numerous facets involved in producing this distinct baked confectionery. From the pivotal role of precise ingredient measurements and meticulous dough preparation to the critical influence of baking temperature, coating application, caramelization, cooling procedures, and equipment selection, each element contributes significantly to the final outcome. Successful execution hinges on a thorough understanding of these interdependencies, adherence to established techniques, and consistent application of best practices.

The pursuit of culinary excellence in recreating this traditionally prepared item necessitates a commitment to precision and attentive execution. Further investigation into regional variations and innovative adaptations remains a worthwhile endeavor. Careful application of the knowledge presented will allow the baker to successfully recreate this classic confection.