These manufactured fireplace accessories are designed to aid in the removal of creosote and soot buildup within a chimney. Combustion of the specially formulated log releases chemical additives that work to loosen deposits, allowing them to detach and either fall into the firebox or be swept away more easily during a subsequent manual cleaning.

Maintaining a clean chimney is critical for preventing dangerous chimney fires and ensuring efficient fireplace operation. Regular use of such products can reduce the risk of creosote accumulation, a major contributor to chimney fires, and improve overall draft, leading to more effective heating and reduced smoke within the living space. Historically, manual chimney sweeping was the only available method, but these chemical treatments offer a supplementary approach to chimney maintenance.

The following sections will delve into the composition of these logs, their proper usage, safety precautions to observe, and a comparison with traditional chimney sweeping methods.

Tips for Effective Chimney Maintenance

Optimizing the performance and safety of a fireplace system necessitates consistent upkeep. The following guidelines outline strategies to effectively leverage chemical chimney cleaning products.

Tip 1: Select the Appropriate Product: Verify the product’s compatibility with the fireplace and chimney type. Different formulations may be required for masonry chimneys versus metal flue systems.

Tip 2: Follow Manufacturer’s Instructions Precisely: Adherence to the manufacturer’s guidelines regarding usage frequency and burn duration is paramount. Deviation may compromise effectiveness or introduce safety hazards.

Tip 3: Prepare the Fireplace Adequately: Ensure the firebox is clear of excessive ash and debris prior to initiating the burn. This will promote optimal airflow and chemical distribution.

Tip 4: Establish Proper Ventilation: Confirm the damper is fully opened before and during the burn. Adequate ventilation facilitates the removal of loosened deposits and prevents smoke accumulation within the dwelling.

Tip 5: Monitor the Burn Process: Observe the burning log periodically to ensure consistent and complete combustion. Irregular burning patterns may indicate insufficient airflow or product malfunction.

Tip 6: Allow Sufficient Cooling Time: Following the burn, allow ample time for the fireplace and chimney to cool completely before conducting any inspection or manual cleaning.

Tip 7: Supplement with Professional Inspection: While these logs can aid in maintenance, they do not replace the need for regular inspections by a qualified chimney sweep. Professional evaluations can identify structural issues or hazards not addressed by chemical treatments.

Consistent implementation of these guidelines can contribute to a safer and more efficient fireplace operation. Regular maintenance reduces the risk of chimney fires and enhances heating performance.

The subsequent sections will explore potential safety concerns and address common misconceptions surrounding these chimney cleaning methods.

1. Creosote Modification

Creosote modification is the central mechanism by which manufactured chimney sweeping logs, such as those produced by Duraflame, aim to improve fireplace safety and efficiency. The objective is to alter the chemical and physical properties of creosote, the hazardous byproduct of incomplete combustion in wood-burning fireplaces, making it easier to remove and less prone to ignition.

- Chemical Decomposition

The primary action involves introducing chemical catalysts during combustion that react with creosote deposits. These additives disrupt the complex molecular structure of creosote, breaking down long-chain hydrocarbons into less flammable compounds. The process weakens the adherence of creosote to the chimney flue, facilitating its removal.

- Drying and Flaking

Some components within the sweeping log promote the desiccation of creosote layers. This drying effect causes the creosote to become brittle and flaky, rather than the sticky, tar-like substance it initially forms. As the modified creosote dries, it is more likely to detach from the chimney walls due to the chimney’s natural expansion and contraction during heating and cooling cycles, or during a subsequent manual cleaning.

- Reduction of Ignition Temperature

While seemingly counterintuitive, the chemicals can reduce the ignition temperature of the modified creosote. The intent is not to make the chimney more flammable, but to ensure that any remaining creosote is more likely to undergo complete combustion during subsequent fires, further reducing the overall buildup. The modified creosote will burn more easily and completely instead of smoldering and adding to the build-up.

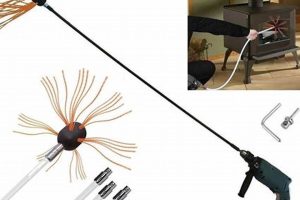

- Enhanced Sweepability

The altered consistency of the creosote, resulting from decomposition and drying, significantly improves its “sweepability.” Manual chimney sweeping becomes more effective because the loosened deposits are easier to dislodge and remove with brushes and other cleaning tools. This reduced effort minimizes the risk of damaging the chimney liner during cleaning.

Ultimately, the success of a Duraflame chimney sweeping log depends on a comprehensive approach. Although creosote modification aids in reducing fire hazards and simplifies cleaning, it is not a substitute for regular professional chimney inspections and manual cleaning. These professional services can identify structural problems or extensive creosote accumulation not addressed by chemical treatments alone.

2. Chemical Composition

The chemical composition of a Duraflame chimney sweeping log is deliberately formulated to facilitate the reduction of creosote buildup within a fireplace chimney. Understanding these components is crucial for appreciating the product’s function and safety considerations.

- Catalytic Agents

These agents, often metallic salts or other chemical compounds, accelerate the decomposition of creosote during the log’s combustion. They lower the activation energy required for creosote to break down, promoting a more complete combustion of existing deposits. For instance, manganese compounds are frequently employed for this purpose, reacting with creosote to weaken its structure. The effectiveness of these agents depends on their concentration and distribution within the log.

- Combustible Materials

The base of the log consists of combustible materials such as waxes, sawdust, and other organic compounds. These materials provide the necessary fuel to sustain the combustion process and distribute the chemical additives throughout the chimney. The composition and density of these materials influence the log’s burn time and the dispersion of the catalytic agents.

- Binding Agents

Binding agents hold the various components of the log together, ensuring structural integrity during handling and combustion. These agents are typically non-toxic and designed to burn cleanly, minimizing the production of additional soot or residue. Examples include modified starches or plant-based gums. The selection of these agents is vital for maintaining the log’s shape and preventing premature disintegration.

- Oxidizing Agents

Some formulations incorporate oxidizing agents to enhance the completeness of combustion. These agents supply additional oxygen to the burning process, reducing the formation of carbon monoxide and other incomplete combustion byproducts. Common oxidizing agents include nitrates or perchlorates, though their use is carefully controlled to prevent uncontrolled or excessively rapid burning. The presence of these agents contributes to a cleaner burn and reduced environmental impact.

The interaction of these components within a Duraflame chimney sweeping log is designed to provide a controlled and effective method for creosote reduction. However, the product’s efficacy remains contingent on adherence to manufacturer guidelines and the overall condition of the chimney system. Chemical treatments are intended as a supplement to, not a replacement for, professional chimney inspections and cleanings.

3. Combustion Process

The effectiveness of a Duraflame chimney sweeping log hinges directly on a controlled and complete combustion process. The combustion process is not merely incidental but constitutes the driving mechanism for the log’s intended function. During combustion, the chemical additives within the log are released as gases and fine particulates. These substances then interact with existing creosote deposits lining the chimney flue. For example, if the combustion is incomplete, the chemical additives are not fully activated, diminishing their capacity to modify the creosote. This, in turn, reduces the likelihood of the creosote drying, flaking, and becoming easier to remove.

Moreover, the temperature attained during combustion is crucial. Insufficient temperature compromises the activation of catalytic agents designed to break down the complex hydrocarbons in creosote. A sustained, high-temperature burn, as specified by the manufacturer, is necessary to facilitate the chemical reactions. Real-world examples demonstrate that chimneys with poor draft or excessive air leaks often experience incomplete combustion of the sweeping log. This is evidenced by a significantly reduced impact on creosote levels compared to chimneys with properly functioning airflow. Understanding the combustion process allows for better application of the Duraflame chimney sweeping log and consequently contributes to a safer fireplace system. Ensuring proper ventilation, using dry firewood, and maintaining a clean firebox are all practical steps that support the log’s combustion.

In summary, the combustion process is an integral component of the Duraflame chimney sweeping log’s functionality. A controlled and complete burn is essential for the successful release and activation of the chemical additives designed to modify creosote. Understanding and optimizing the combustion process enhances the effectiveness of the log, reduces the risk of chimney fires, and contributes to a safer and more efficient fireplace system. Challenges remain in ensuring consistent and complete combustion across various fireplace and chimney configurations, highlighting the need for regular inspections and supplementary maintenance practices.

4. Chimney Compatibility

The effectiveness and safe operation of a Duraflame chimney sweeping log are intrinsically linked to chimney compatibility. Chimney construction, flue liner type, and overall system condition significantly influence the log’s performance and potential impact. For instance, a severely damaged or improperly sized flue can impede the proper draft, leading to incomplete combustion of the log and reduced creosote modification. Conversely, using a product formulated for masonry chimneys in a metal chimney system may result in corrosion or other material degradation. The selection of an appropriate chimney sweeping log must, therefore, commence with a thorough assessment of the chimney’s specifications and condition.

A real-world example illustrates this point: A homeowner with a stainless steel chimney liner used a sweeping log designed for traditional masonry chimneys. The higher temperatures generated by the log, combined with chemical additives incompatible with stainless steel, accelerated corrosion of the liner, ultimately necessitating costly repairs. Another instance involves a chimney with significant creosote buildup due to years of neglect. While the sweeping log may loosen some deposits, the sheer volume of creosote overwhelms the log’s capacity, potentially leading to a chimney fire as large chunks of creosote dislodge and ignite. These examples underscore the practical significance of verifying chimney compatibility before deploying a chemical sweeping log.

In summary, chimney compatibility represents a critical determinant of a Duraflame chimney sweeping log’s success and safety. Matching the product to the chimney’s construction, flue liner material, and overall condition is essential for maximizing creosote reduction and minimizing the risk of adverse effects. While these logs can contribute to chimney maintenance, they are not a panacea and must be used judiciously, in conjunction with professional inspections, to ensure comprehensive system integrity and safe operation.

5. Manufacturer Instructions

Adherence to the manufacturer’s instructions is paramount for the safe and effective utilization of a Duraflame chimney sweeping log. These instructions are not merely suggestions but represent carefully calculated guidelines designed to optimize product performance and minimize potential hazards.

- Log Placement and Firebox Preparation

The instructions dictate the precise placement of the log within the firebox to ensure proper airflow and combustion. For instance, some instructions mandate elevating the log on a grate to promote optimal oxygen circulation. Furthermore, they typically require the removal of excessive ash buildup before initiating the burn. Failure to comply may lead to incomplete combustion, reduced chemical effectiveness, and increased risk of carbon monoxide production. A real-world example might involve placing the log directly on a thick layer of ash, thereby suffocating the flame and preventing the release of the intended creosote-modifying agents.

- Burn Duration and Ventilation

Manufacturer instructions specify the recommended burn time, which is calibrated to release the appropriate concentration of chemical additives into the chimney. Exceeding or falling short of this duration may compromise the log’s efficacy or introduce safety concerns. The instructions invariably emphasize the importance of maintaining adequate ventilation during the burn, typically requiring a fully opened damper. Insufficient ventilation can result in the accumulation of smoke and harmful gases within the living space, potentially posing a health hazard to occupants.

- Post-Burn Procedures and Timing

The instructions often detail post-burn procedures, such as allowing sufficient cooling time before inspecting the chimney or initiating a manual cleaning. Premature inspection can expose individuals to residual heat and potentially harmful chemicals. Furthermore, some manufacturers recommend a waiting period before burning another fire to allow the loosened creosote deposits to fully detach from the chimney walls. Neglecting these post-burn instructions can undermine the product’s effectiveness and increase the risk of chimney fires.

- Safety Precautions and Limitations

The manufacturer’s instructions explicitly outline essential safety precautions, including warnings against using the log in gas fireplaces or unapproved appliances. They also typically address limitations, emphasizing that the log is intended as a supplementary maintenance tool and not a substitute for professional chimney inspections and cleanings. Ignoring these safety warnings can lead to equipment damage, property loss, or even personal injury. A common misconception is that these logs eliminate the need for professional chimney sweeping, a belief that can result in dangerous creosote accumulation and increased fire risk.

In conclusion, strict adherence to the manufacturer’s instructions is not optional but an integral component of safely and effectively utilizing a Duraflame chimney sweeping log. Compliance maximizes the product’s creosote-reducing capabilities while mitigating potential hazards associated with improper use. These instructions, coupled with regular professional inspections, contribute to a comprehensive chimney maintenance strategy.

6. Ventilation Requirements

Adequate ventilation is a non-negotiable prerequisite for the safe and effective use of any Duraflame chimney sweeping log. The combustion process necessitates a sufficient supply of oxygen to ensure complete burning of the log’s components and the proper activation of its creosote-modifying chemicals. Insufficient ventilation leads to incomplete combustion, resulting in the production of carbon monoxide, a colorless, odorless, and highly toxic gas. Furthermore, it hinders the dispersion of the chemical additives intended to break down creosote deposits within the chimney flue. The causal relationship is direct: restricted airflow impedes complete combustion, diminishing both the intended benefits of the log and creating a significant health hazard. The manufacturer’s instructions uniformly emphasize the need for a fully open damper during the entire burn process, underscoring the critical nature of this ventilation requirement.

The practical implications of neglecting ventilation requirements are readily demonstrable. A homeowner who burns a Duraflame chimney sweeping log in a fireplace with a partially closed damper is likely to experience several adverse effects. First, the log may smolder rather than burn cleanly, releasing acrid smoke into the living space. Second, the incomplete combustion diminishes the log’s effectiveness in loosening creosote deposits. Third, and most critically, the buildup of carbon monoxide poses a serious threat to the health and safety of the occupants. Real-world incidents frequently involve individuals experiencing symptoms of carbon monoxide poisoning, such as headaches, dizziness, and nausea, after burning a fire in a poorly ventilated fireplace. These incidents highlight the tangible risks associated with ignoring ventilation requirements.

In conclusion, proper ventilation is an indispensable component of utilizing Duraflame chimney sweeping logs safely and effectively. It ensures complete combustion, maximizes the dispersion of creosote-modifying chemicals, and prevents the buildup of hazardous gases, such as carbon monoxide. Challenges remain in educating users about the crucial role of ventilation and ensuring consistent adherence to manufacturer instructions. A comprehensive approach to fireplace safety necessitates not only the use of these logs but also a thorough understanding of their ventilation requirements and the potential consequences of non-compliance.

7. Professional Inspection

Professional chimney inspections are a critical complement to the use of a Duraflame chimney sweeping log. While the logs offer a method for reducing creosote buildup, they do not substitute for a comprehensive evaluation by a qualified chimney sweep. The inspection serves to identify structural issues, assess creosote accumulation levels, and ensure the overall safety and functionality of the fireplace system.

- Structural Integrity Assessment

A professional inspection includes a thorough examination of the chimney’s structural components, such as the masonry, flue liner, and chimney cap. Cracks, spalling, or other forms of deterioration can compromise the chimney’s ability to safely vent combustion gases and increase the risk of fire. A Duraflame log cannot address these structural deficiencies. For example, a cracked flue liner may allow combustion gases to leak into the building, posing a carbon monoxide hazard, regardless of the log’s effectiveness in reducing creosote.

- Creosote Accumulation Evaluation

Chimney sweeps possess specialized tools and expertise to accurately assess the amount and type of creosote present in the chimney. The buildup is graded into three stages, with third-degree creosote representing the most hazardous form due to its hard, glazed consistency and high flammability. A Duraflame log may assist in loosening some creosote, but it may not effectively remove heavy accumulations of third-degree creosote. A professional cleaning is often necessary to address these severe cases.

- Obstruction Detection

Chimney inspections can identify obstructions within the flue, such as bird nests, animal carcasses, or fallen debris. These obstructions can impede the proper venting of combustion gases, increasing the risk of carbon monoxide poisoning and chimney fires. A Duraflame chimney sweeping log will not remove these physical obstructions. The inspection can determine what is the possible obstructions, or it may be just a bad design/built that need to be addressed.

- Appliance Compatibility Verification

Professional inspections ensure the fireplace and chimney system are appropriately matched and that all components are functioning correctly. This includes verifying the proper size and type of flue liner for the appliance, as well as assessing the condition of the damper and other related components. A Duraflame log cannot rectify issues related to appliance incompatibility or malfunctioning components. These logs should always be used to assist in prevention not a complete solution.

In summary, professional chimney inspections provide a level of assessment that a Duraflame chimney sweeping log cannot replicate. The inspection addresses structural integrity, creosote accumulation levels, obstruction detection, and appliance compatibility, contributing to a safer and more efficient fireplace system. The logs serve as a supplementary maintenance tool, while the professional inspection provides a comprehensive evaluation and ensures long-term system integrity.

Frequently Asked Questions about Duraflame Chimney Sweeping Logs

The following addresses common inquiries regarding the usage, safety, and effectiveness of Duraflame chimney sweeping logs as part of a comprehensive chimney maintenance plan.

Question 1: Are these logs a substitute for professional chimney sweeping?

No, chimney sweeping logs are not a replacement for professional chimney inspections and cleanings. These logs serve as a supplementary maintenance tool to help reduce creosote buildup, but a qualified chimney sweep can identify structural issues, assess the extent of creosote accumulation, and perform a thorough cleaning that a log cannot achieve.

Question 2: How often should a Duraflame chimney sweeping log be used?

The frequency of use depends on the amount of wood burned, the type of wood, and the efficiency of the fireplace. Refer to the log’s instructions for specific guidance, but a general recommendation is to use one log after every 50 fires, or at least once per burning season. More frequent use may be necessary if burning unseasoned wood or operating an inefficient fireplace.

Question 3: Can these logs prevent chimney fires?

These logs can reduce the risk of chimney fires by helping to loosen and modify creosote deposits, making them less flammable. However, they cannot guarantee complete prevention of chimney fires, especially if the chimney has significant creosote buildup or structural deficiencies. Regular professional inspections and cleanings remain crucial for minimizing fire hazards.

Question 4: Are these logs safe to use in all types of fireplaces and chimneys?

No, these logs are not universally compatible. It is imperative to verify the log’s suitability for the specific type of fireplace and chimney system. Some logs are designed for masonry chimneys, while others are formulated for metal chimneys. Using the wrong type of log can damage the chimney or reduce its effectiveness. Always consult the manufacturer’s guidelines.

Question 5: What precautions should be taken when using a Duraflame chimney sweeping log?

Follow all manufacturer instructions, including ensuring proper ventilation by fully opening the damper. Avoid using the log in gas fireplaces or unapproved appliances. Monitor the burning process and allow sufficient cooling time before inspecting the chimney. Keep a fire extinguisher nearby and be aware of the signs of carbon monoxide poisoning.

Question 6: Will these logs remove existing heavy creosote buildup?

Chimney sweeping logs are more effective at preventing creosote buildup than removing extensive existing deposits. While they may loosen some accumulation, a professional cleaning is typically necessary to eliminate heavy creosote layers and ensure the chimney’s safe operation. Consider using these logs on a seasonal basis for the maintenance or to assist a recent professional chimney cleaning session.

These FAQs offer insights into the responsible use of chimney sweeping logs, reinforcing the importance of professional oversight in maintaining a safe and efficient fireplace system.

The subsequent section will summarize the key takeaways and provide a concluding perspective on the role of these products in chimney maintenance.

Conclusion

This exploration of the Duraflame chimney sweeping log underscores its role as a supplementary tool in chimney maintenance. Key points addressed include the log’s composition, intended function in creosote modification, the critical importance of proper usage including ventilation, and the absolute necessity of professional inspections to identify structural issues. These logs contribute to fire safety by loosening creosote, however they are not a standalone solution.

Responsible use of these products, guided by expert advice and regular professional evaluations, is paramount. Fireplace safety and efficiency depend on a holistic approach, of which the duraflame chimney sweeping log is only one element. Consistent vigilance and proactive maintenance provide the greatest protection against the hazards associated with wood-burning appliances.