An improved flue system represents an enhancement in the structure responsible for venting combustion byproducts from a heating appliance or fireplace. This upgrade often involves modifications to materials, design, or functionality, aiming to optimize performance and safety. For instance, replacing a cracked clay liner with a stainless steel one exemplifies a superior design choice, offering enhanced durability and resistance to corrosive byproducts.

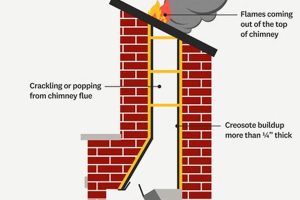

Upgrading this crucial component within a building offers numerous advantages. It increases safety by minimizing the risk of carbon monoxide leaks and chimney fires. Enhanced efficiency in venting reduces the accumulation of creosote and other hazardous materials, potentially lowering maintenance costs and extending the lifespan of connected appliances. Historically, poorly designed systems have contributed to structural damage and health risks, underscoring the importance of consistent improvements.

The subsequent sections will delve into specific advancements in flue design, detailing material considerations, installation best practices, and regulatory compliance standards that define the features and implementation of such systems in both residential and commercial settings.

Enhancing Flue System Performance

Optimizing the performance of a residential or commercial flue requires careful attention to several critical factors. The following tips provide guidance on improving system safety, efficiency, and longevity.

Tip 1: Conduct Regular Inspections: A qualified professional should inspect the entire system annually. These inspections can identify cracks, blockages, or other damage that compromises safety and efficiency. Early detection prevents potentially hazardous situations.

Tip 2: Implement Proper Cleaning Protocols: Regular cleaning removes creosote buildup, a significant fire hazard. The frequency of cleaning depends on fuel type and usage patterns, but professional cleaning at least once per year is recommended.

Tip 3: Ensure Correct Sizing: An improperly sized flue leads to poor draft and increased creosote accumulation. The flues diameter should match the appliance’s requirements, as specified by the manufacturer.

Tip 4: Maintain Adequate Ventilation: Proper airflow is crucial for efficient combustion and venting. Obstructions in the surrounding area should be removed to ensure adequate ventilation. Consider installing an outside air kit for airtight homes.

Tip 5: Use Appropriate Fuel: Burning unseasoned wood or other inappropriate fuels increases creosote production and reduces efficiency. Using dry, seasoned wood significantly improves performance and reduces maintenance requirements.

Tip 6: Address Moisture Issues: Water intrusion accelerates deterioration. A rain cap prevents moisture from entering the flue, minimizing damage and prolonging its lifespan.

Tip 7: Consider Upgrading the Liner: Replacing an old or damaged clay liner with a stainless steel liner enhances safety and durability. Stainless steel resists corrosion and withstands higher temperatures.

Implementing these strategies enhances flue system performance, minimizing hazards, improving efficiency, and extending the system’s operational life. Consistent attention to these details ensures a safer and more effective heating experience.

The following sections will delve into the implications of neglecting these factors, highlighting potential safety risks and increased maintenance costs.

1. Enhanced Draft Performance

Enhanced draft performance is a critical attribute of an optimized flue system, directly influencing combustion efficiency and the safe evacuation of combustion byproducts. Adequate draft ensures that the products of combustion, including harmful gases like carbon monoxide, are effectively drawn up and out of the structure, preventing backdrafting and potential health hazards. A well-designed flue establishes a consistent upward airflow, promoting cleaner and more complete burning of fuel. Without sufficient draft, incomplete combustion results in increased creosote buildup, augmenting the risk of chimney fires. For example, historical instances of poorly designed or obstructed flues have led to tragic cases of carbon monoxide poisoning, highlighting the paramount importance of maintaining proper draft.

Achieving enhanced draft involves several interconnected factors. Proper flue sizing, based on the appliance’s output and fuel type, is fundamental. Oversized flues may not heat up sufficiently to establish a strong draft, while undersized flues restrict airflow, leading to backpressure and inefficient venting. Chimney height also plays a significant role; taller chimneys generally produce a stronger draft due to increased stack effect. Furthermore, maintaining a clean and unobstructed flue passage is crucial. Accumulations of creosote, soot, or debris impede airflow, diminishing draft performance. In practical applications, the installation of a barometric damper can regulate draft, particularly in systems connected to appliances with fluctuating heat outputs, thus preventing over-drafting and maintaining consistent efficiency.

In summary, enhanced draft performance is inextricably linked to the overall safety and effectiveness of a modern flue system. Neglecting draft considerations introduces significant risks and reduces the system’s operational lifespan. Understanding the principles of draft and implementing appropriate design and maintenance practices are essential for ensuring safe and efficient fuel-burning appliance operation. These practices contribute directly to the characteristics of a safer and more efficient flue.

2. Superior Material Integrity

Superior material integrity forms a cornerstone of a high-performing and durable flue system. The materials constituting the flue directly impact its ability to withstand extreme temperatures, corrosive combustion byproducts, and environmental factors. Selecting materials with high resistance to thermal stress and chemical degradation is paramount for ensuring long-term operational safety and minimizing the risk of structural failure. For instance, the shift from traditional clay liners to stainless steel liners exemplifies the importance of material integrity. Clay liners, while historically common, are prone to cracking and disintegration under prolonged exposure to high temperatures and acidic condensates, potentially leading to carbon monoxide leaks or chimney fires. Stainless steel, conversely, offers enhanced corrosion resistance and structural stability, providing a safer and more durable venting solution.

The implications of inadequate material integrity extend beyond safety concerns. Deteriorated flue materials compromise venting efficiency, resulting in incomplete combustion and increased creosote accumulation. Creosote, a highly flammable byproduct of incomplete combustion, poses a significant fire hazard and necessitates frequent professional cleaning. The costs associated with maintenance and potential repairs escalate substantially when substandard materials are used. Furthermore, material failure can necessitate complete flue system replacement, representing a significant financial burden for property owners. Real-world examples of collapsed or severely damaged flues attributable to material degradation underscore the practical significance of prioritizing robust materials in flue construction and rehabilitation projects.

In summary, superior material integrity is not merely a desirable attribute; it is an indispensable component of a safe, efficient, and cost-effective flue system. Careful material selection, based on factors such as operating temperatures, fuel type, and environmental conditions, mitigates the risks associated with material degradation and contributes to the overall longevity and performance of the system. By prioritizing material integrity, property owners can safeguard against potential hazards, reduce maintenance costs, and ensure the reliable operation of heating appliances. This focus translates directly into a safer and more sustainable built environment.

3. Improved Safety Mechanisms

Improved safety mechanisms are integral to the concept of an advanced flue system. These mechanisms directly mitigate the inherent risks associated with combustion processes. The primary function of a flue is to safely vent combustion byproducts, including carbon monoxide, a colorless and odorless gas that poses a significant health hazard. Safety mechanisms incorporated into advanced flue designs, such as advanced chimney caps, prevent the entry of debris, animals, and rainwater, thus maintaining a clear pathway for exhaust gases. This prevents dangerous backdrafts and ensures the effective removal of harmful combustion byproducts. The implementation of positive pressure systems, for example, mechanically force exhaust gases out, eliminating reliance on natural draft and further reducing the risk of carbon monoxide infiltration into living spaces. These systems are vital components of modern flue designs that prioritize occupant safety.

Furthermore, advancements in flue liner materials and construction techniques contribute significantly to improved safety. The transition from traditional clay liners to stainless steel or composite materials enhances the system’s resistance to corrosion, cracking, and the detrimental effects of acidic condensates. This reduces the likelihood of flue breaches, which can lead to gas leaks and structural damage. Moreover, incorporating features like spark arrestors and creosote collection systems further enhances safety by minimizing the risk of chimney fires and facilitating easier maintenance. Regular inspections and maintenance protocols are also essential safety mechanisms, enabling the early detection and correction of potential problems before they escalate into hazardous situations. Examples of effective safety implementations include residences that comply with modern building codes featuring interlocking flue liner sections sealed with high-temperature mortar. This design prevents harmful gases from leaking into the building’s structure, improving air quality and fire safety.

In summary, improved safety mechanisms are not merely add-ons but rather fundamental design elements of an advanced flue system. These mechanisms encompass a range of features and practices, from enhanced materials and construction techniques to proactive inspection and maintenance protocols. The overarching goal is to minimize the risks associated with combustion processes, ensuring the safe and efficient operation of heating appliances and protecting the health and well-being of building occupants. Prioritizing safety in flue design and maintenance is crucial for mitigating potential hazards and maintaining a safe and healthy indoor environment, and is not optional.

4. Optimized Energy Efficiency

Optimized energy efficiency in a flue system directly correlates with its design and operational characteristics. A well-designed flue minimizes energy losses and maximizes the utilization of fuel resources, contributing to reduced heating costs and a smaller environmental footprint. Achieving this optimization requires careful consideration of various interconnected factors.

- Proper Sizing and Insulation

Flue sizing directly impacts combustion efficiency. An oversized flue can lead to excessive heat loss, reducing the overall efficiency of the heating appliance. Conversely, an undersized flue restricts airflow, resulting in incomplete combustion and increased creosote buildup. Proper insulation of the flue also minimizes heat loss, particularly in external chimney installations. This combination of optimized sizing and insulation ensures that heat generated by the appliance is effectively transferred to the living space rather than escaping through the flue system. Examples include modern installations where insulated stainless steel liners are selected to precisely match the output of a high-efficiency furnace, resulting in measurable fuel savings.

- Air Tightness and Draft Control

Air leaks in a flue system compromise draft control and introduce unwanted air currents, leading to energy losses. Sealing any gaps or cracks in the flue construction is essential for maintaining a consistent and controlled draft. Barometric dampers can further regulate draft, preventing excessive airflow and minimizing heat loss during periods of low appliance activity. These mechanisms ensure that only the necessary amount of air is drawn through the system, optimizing combustion efficiency and preventing unnecessary heat dissipation. For example, sealing older, masonry flues with a sealant designed for high-temperature applications can substantially improve energy efficiency by preventing air leakage into the structure of the home.

- Fuel Type and Combustion Efficiency

The type of fuel used in the heating appliance directly influences combustion efficiency. Certain fuels, such as natural gas or propane, burn more cleanly and efficiently than others, such as wood or coal. The design of the flue system must be compatible with the chosen fuel to ensure complete combustion and minimize the production of harmful byproducts. Additionally, proper maintenance, including regular cleaning and inspection, is essential for maintaining optimal combustion efficiency. Accumulations of creosote or soot impede airflow and reduce the system’s ability to effectively vent combustion gases, resulting in decreased energy efficiency. Burning seasoned wood vs wet wood is a clear example of how fuel type increases combustion and thermal efficiency.

- Heat Recovery Systems

Innovative flue designs incorporate heat recovery systems to capture waste heat and transfer it back into the heating system or domestic water supply. These systems, such as heat exchangers, extract thermal energy from the exhaust gases before they are released into the atmosphere, improving the overall energy efficiency of the heating process. While these systems can add complexity and initial cost, they offer significant long-term energy savings and reduced environmental impact. Condensing furnaces exemplify systems where heat is recovered from the flue gases to preheat the water returning to the boiler, or the air entering the combustion chamber, leading to a noticeable increase in efficiency compared to traditional models.

These facets highlight the multifaceted nature of optimized energy efficiency in flue systems. Addressing each of these aspects through careful design, material selection, and maintenance practices leads to a more efficient and sustainable heating system. In doing so, this promotes reduced energy consumption and lower operating costs, with an increase in the operational lifespan of heating appliances, all of which contributes to an overall environment conscious approach.

5. Reduced Maintenance Needs

A significant attribute of an improved flue system lies in its ability to minimize ongoing maintenance requirements. Decreased maintenance translates to lower operational costs, reduced downtime, and enhanced overall system reliability. The features contributing to this reduction are directly linked to design and material advancements.

- Durable Material Selection and Reduced Creosote Buildup

The selection of corrosion-resistant materials, such as stainless steel for flue liners, significantly diminishes the need for frequent repairs and replacements. Unlike traditional clay liners that are susceptible to cracking and deterioration, stainless steel offers superior resistance to acidic condensates and high temperatures. This durability reduces the risk of flue breaches and associated safety hazards. Furthermore, improved combustion efficiency resulting from enhanced draft minimizes creosote buildup. Reduced creosote accumulation translates directly to less frequent chimney cleanings, decreasing maintenance costs and extending the system’s lifespan. Examples are visible in modern installations showing less soot, debris and build up after years of use.

- Improved Accessibility for Inspection and Cleaning

Advanced flue designs incorporate features that enhance accessibility for inspection and cleaning. These features include strategically placed access ports and removable components that facilitate thorough examination and removal of debris. Improved accessibility simplifies maintenance procedures and allows for early detection of potential problems, preventing costly repairs. Older systems lacking such access often necessitate invasive procedures for inspection and cleaning, increasing maintenance costs and disrupting building operations. Simple modifications, like a removable “T” section at the base of a flue, creates a clean out location preventing larger issues.

- Automated Monitoring Systems

Some advanced flue systems integrate automated monitoring systems that provide real-time data on system performance and potential issues. These systems employ sensors to monitor parameters such as flue gas temperature, draft pressure, and carbon monoxide levels. Automated monitoring enables early detection of anomalies, allowing for proactive maintenance and preventing potentially hazardous situations. Data analysis can identify trends and predict future maintenance needs, facilitating efficient resource allocation and minimizing downtime. Systems that trigger alerts when carbon monoxide levels exceed safe standards provide a critical safeguard, preventing poisoning and prompting necessary interventions.

- Simplified Component Replacement

Modular flue system designs simplify component replacement, minimizing downtime and labor costs. Individual components, such as flue sections or rain caps, can be easily replaced without requiring extensive disassembly or modification of the entire system. This modularity reduces the complexity of repairs and allows for targeted maintenance, addressing specific issues without disrupting the overall system operation. Older, monolithic flue constructions often necessitate complete system replacement in the event of a component failure, resulting in significant expense and disruption. This highlights the maintenance benefits associated with a modular approach.

These improvements work together to lower maintenance needs. Enhanced safety, efficiency, and system longevity are all benefits of less time spent performing maintenance. A well-maintained, modern system ensures a safer indoor environment and contributes to the overall value and sustainability of the property. By incorporating these features, improved systems provide a practical solution to reducing operational costs, promoting user convenience, and improving long-term system reliability.

Frequently Asked Questions

The following section addresses common inquiries regarding enhancements to flue systems, providing factual and objective responses to clarify prevalent misconceptions and guide informed decision-making.

Question 1: What constitutes an improved flue system, and how does it differ from a standard flue?

An enhanced flue system incorporates design modifications, material upgrades, or technological advancements aimed at improving safety, efficiency, or durability compared to conventional flue designs. These improvements may include corrosion-resistant liners, enhanced draft mechanisms, or integrated monitoring systems.

Question 2: How does upgrading a flue system improve home safety?

Upgrading a flue system mitigates potential safety hazards associated with combustion byproducts, such as carbon monoxide leaks and chimney fires. Improved materials and construction techniques enhance the system’s resistance to deterioration, reducing the risk of structural failures and gas leaks. Enhanced draft control ensures the efficient removal of combustion gases, preventing backdrafting and potential health risks.

Question 3: What are the energy efficiency benefits associated with an improved flue system?

An optimized flue system minimizes heat loss and maximizes the utilization of fuel resources. Enhanced draft control and proper insulation reduce energy waste, resulting in lower heating costs. Improved combustion efficiency, achieved through proper sizing and design, further contributes to energy savings.

Question 4: What are the common signs that a flue system needs upgrading?

Common indicators of a deteriorating flue system include visible cracks or damage to the flue liner, evidence of water intrusion, excessive creosote buildup, and recurring problems with draft. A professional inspection can assess the system’s condition and determine the necessity of upgrades or repairs.

Question 5: What are the long-term cost benefits of investing in an improved flue system?

While the initial investment may be higher, an improved flue system offers significant long-term cost benefits. Reduced maintenance needs, improved energy efficiency, and extended system lifespan contribute to lower operational costs. Furthermore, mitigating safety hazards can prevent costly repairs and protect against potential liability claims.

Question 6: What regulatory standards govern the installation and maintenance of flue systems?

Flue system installation and maintenance are governed by local building codes, as well as national standards such as those established by the National Fire Protection Association (NFPA). Compliance with these standards ensures safety and performance, and adherence to manufacturer’s instructions is critical for warranty validation.

In summary, enhancing a flue system involves improving both safety and efficiency. Assessing conditions and following established guidelines ensures appropriate implementation.

The following section details case studies of implemented system upgrades.

In Conclusion

This exploration has outlined the essential components and considerations involved in achieving an improved flue system. Superior materials, enhanced draft performance, integrated safety mechanisms, optimized energy efficiency, and reduced maintenance needs collectively define the attributes of a high-performing and reliable flue. These advancements translate into tangible benefits, including enhanced safety, reduced operational costs, and a minimized environmental impact.

The decision to invest in these systems constitutes a commitment to both safety and long-term value. As technology and building standards continue to evolve, prioritizing advancements in venting systems remains crucial. A proactive approach to flue system design, installation, and maintenance protects property, safeguards occupants, and contributes to a more sustainable future. Continued diligence and awareness are vital to ensuring the safe and efficient operation of these critical building components.