A vital component within a masonry chimney system, this is a liner typically made of sections of ceramic material. These sections are stacked inside the chimney structure to create a continuous, heat-resistant passageway. This passageway is designed to safely vent combustion byproducts from fireplaces, wood stoves, furnaces, and other heating appliances to the outside atmosphere. The material’s composition ensures it can withstand high temperatures and corrosive gases produced during the combustion process, protecting the chimney’s masonry structure from damage.

The integrity of this internal lining is crucial for both efficiency and safety. A properly installed and maintained system helps to ensure efficient draft, maximizing the performance of heating appliances. More importantly, it protects the chimney structure from the damaging effects of heat, creosote buildup, and corrosive combustion gases, preventing deterioration of the masonry and reducing the risk of chimney fires and carbon monoxide leaks. Historically, their introduction marked a significant advancement in chimney design, improving both safety and longevity compared to earlier, unlined chimneys.

Given its significant role, understanding the construction, inspection, and maintenance of this type of lining is essential for homeowners and professionals alike. The following sections will delve into the specifics of installation best practices, common problems identified during inspections, and recommended repair or replacement strategies to ensure the continued safe and efficient operation of residential and commercial heating systems.

Essential Guidelines for Optimal Performance

Maintaining the integrity of the internal lining is paramount for chimney safety and efficiency. The following guidelines provide critical insights for homeowners and professionals involved in chimney maintenance.

Tip 1: Regular Inspection: Schedule annual inspections by a qualified chimney sweep. These inspections should identify cracks, spalling, or missing sections within the lining. Early detection allows for prompt repair and prevents further deterioration.

Tip 2: Creosote Management: Implement best practices for minimizing creosote buildup. Burn seasoned wood in fireplaces and wood stoves to promote more complete combustion and reduce creosote formation. Regular cleaning is crucial.

Tip 3: Proper Appliance Sizing: Ensure heating appliances are appropriately sized for the structure and are compatible with the chimney system. Oversized or inefficient appliances can contribute to excessive condensation and accelerate deterioration.

Tip 4: Water Intrusion Prevention: Address any sources of water entry into the chimney. Install or repair chimney caps to prevent rain and snow from entering and damaging the lining. Water accelerates the freeze-thaw cycle and can significantly reduce lifespan.

Tip 5: Mortar Joint Maintenance: Pay close attention to the mortar joints between individual sections. Deteriorated mortar joints can allow combustion gases to escape into the chimney structure, leading to masonry damage and potential safety hazards. Repair or repoint deteriorated joints promptly.

Tip 6: Consider Lining Replacement: When extensive damage is present, consider relining the chimney with a stainless-steel liner. A stainless-steel liner offers superior protection and longevity compared to traditional materials, especially in harsh environments.

Adhering to these guidelines ensures that the chimney operates safely and efficiently, protecting the structure and its occupants from potential hazards. Prioritizing inspection and maintenance is a cost-effective approach to preserving the longevity and reliability of the system.

The next section will cover the repair and replacement of components, outlining the procedures and considerations involved in ensuring the continued safe operation of the chimney system.

1. Heat Resistance

Heat resistance is a foundational characteristic governing the performance and safety of a ceramic chimney liner. Its ability to endure extreme temperatures generated by combustion processes directly influences the structural integrity and operational effectiveness of the entire chimney system.

- Material Composition and Firing Process

The composition of the ceramic material, typically a mixture of clay and other refractory materials, is critical. The firing process, where the clay is heated to high temperatures, vitrifies the material, increasing its density and rendering it resistant to thermal shock. This vitrification process strengthens the material and enhances its ability to withstand intense heat without cracking or degrading.

- Thermal Shock Resistance

Sudden temperature fluctuations, common in chimney environments during rapid heating or cooling cycles, can induce thermal stress. A material’s thermal shock resistance determines its capacity to withstand these rapid temperature changes without fracturing. Quality clay liners are formulated and manufactured to exhibit high thermal shock resistance, preventing cracking and spalling that could compromise the liner’s integrity.

- Maximum Operating Temperature

Each liner has a maximum operating temperature, which denotes the highest temperature it can safely withstand without undergoing structural changes or losing its protective properties. Exceeding this limit can lead to irreversible damage, including cracking, warping, and eventual failure. Proper selection of the liner material is essential to ensure it is suitable for the temperatures produced by the connected heating appliance.

- Protection of Surrounding Structures

The primary benefit of heat resistance is its protective role for adjacent combustible materials within the building. Without a robust, heat-resistant liner, the intense heat from combustion could ignite nearby wooden framing or other combustible elements, leading to a fire. The liner acts as a barrier, preventing heat transfer and significantly reducing the risk of structural fires.

These facets illustrate the critical role of heat resistance in the safe and effective operation of a ceramic chimney liner. The material’s inherent ability to withstand extreme temperatures protects the chimney structure and prevents potential fire hazards. Choosing a product with adequate heat resistance, coupled with proper installation and maintenance, is paramount for ensuring the longevity and safety of residential and commercial heating systems.

2. Corrosion Protection

Corrosion protection is a critical attribute of ceramic chimney liners, directly impacting their lifespan and ability to safely vent combustion byproducts. The corrosive nature of these byproducts necessitates that the liner material possess inherent resistance to chemical degradation.

- Resistance to Acidic Condensates

Combustion processes generate acidic condensates, including sulfuric and carbonic acids, which can aggressively attack the liner material. High-quality liners are formulated to resist these acids, preventing erosion and weakening of the liner structure. The liner’s composition and manufacturing process determine its capacity to neutralize or withstand these corrosive substances. Example: Low-grade liners may exhibit surface pitting and accelerated degradation when exposed to acidic flue gases from gas-fired appliances.

- Impermeability to Corrosive Gases

The liner must be impermeable to corrosive gases, preventing them from penetrating the liner walls and attacking the surrounding masonry. Porous or cracked liners allow these gases to seep into the chimney structure, leading to deterioration of the mortar joints and bricks, ultimately compromising the chimney’s integrity. Liners that meet industry standards are tested for gas tightness to ensure minimal permeability. Example: Creosote, a byproduct of wood combustion, contains acids that can corrode both the liner and the chimney structure if the liner is compromised.

- Protection of Chimney Structure

The primary function of corrosion protection is to safeguard the chimney’s structural components from the damaging effects of combustion byproducts. By containing these corrosive substances within the liner, the surrounding brickwork, mortar, and other materials are shielded from premature degradation. This prolongs the chimney’s lifespan and reduces the risk of costly repairs. Example: Unlined chimneys are highly susceptible to corrosion, leading to spalling, cracking, and eventual collapse of the masonry structure.

- Impact on Appliance Efficiency

A corroded liner can negatively impact the efficiency of connected heating appliances. Cracks or breaches in the liner allow for heat loss and reduced draft, causing the appliance to work harder to maintain the desired temperature. This increased energy consumption translates to higher fuel bills and reduced appliance lifespan. Example: A severely corroded liner can lead to backdrafting of flue gases into the living space, posing a serious safety hazard and reducing appliance efficiency.

The facets of corrosion protection highlight its importance for the overall performance and longevity of a chimney system. Properly installed and maintained liners that exhibit high resistance to corrosive combustion byproducts are essential for ensuring safe and efficient venting, preventing structural damage, and protecting both the building and its occupants.

3. Structural Integrity

The structural integrity of a flue liner is paramount for ensuring the safe and efficient operation of a chimney system. The liner’s capacity to maintain its physical form under the stresses of heat, corrosive gases, and environmental factors directly influences the chimney’s overall performance and longevity. Failure of the liner compromises its ability to contain combustion byproducts, potentially leading to hazardous conditions.

- Resistance to Cracking and Spalling

Cracking and spalling are common modes of failure in liners, often resulting from thermal shock or moisture penetration. The material must possess inherent resistance to these stresses to prevent the formation of cracks that could allow flue gases to escape into the chimney structure. High-quality liners are designed with specific material properties to minimize the risk of cracking, ensuring the continuous containment of combustion byproducts. Example: Extensive cracking necessitates liner replacement to prevent carbon monoxide leakage.

- Joint Stability and Mortar Integrity

The joints between individual sections are potential weak points in the system. The mortar used to seal these joints must maintain its integrity under thermal cycling and exposure to corrosive gases. Deteriorated mortar joints can compromise the liner’s structural stability, allowing flue gases to escape and moisture to penetrate the chimney structure. Proper mortar selection and installation techniques are crucial for ensuring joint stability. Example: Failing mortar joints can lead to chimney settling and eventual collapse.

- Load-Bearing Capacity

The flue liner must be able to withstand the weight of the chimney structure above it, particularly in taller chimneys. A liner with insufficient load-bearing capacity can buckle or collapse under the weight, leading to catastrophic failure of the chimney. The liner’s dimensions and material properties must be carefully considered to ensure it can support the imposed loads. Example: A liner that is too thin or improperly supported may crumble under the weight of the chimney.

- Resistance to Seismic Activity

In regions prone to earthquakes, the liner must exhibit sufficient resistance to seismic forces to prevent cracking or collapse during ground shaking. Seismic bracing or other reinforcement techniques may be necessary to enhance the liner’s stability in earthquake-prone areas. Example: Unreinforced liners are particularly vulnerable to damage during seismic events, potentially leading to chimney collapse.

These factors collectively underscore the critical role of structural integrity in the safe and reliable performance of a flue liner. The liner’s ability to withstand various stresses and maintain its physical form is essential for preventing hazardous conditions and ensuring the long-term functionality of the chimney system. Regular inspections and timely repairs are crucial for preserving structural integrity and preventing costly failures.

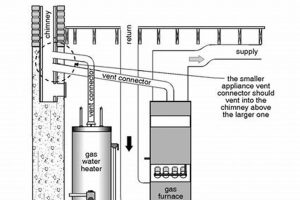

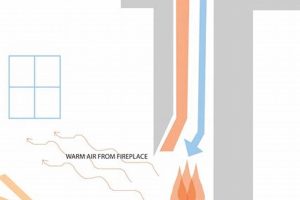

4. Efficient Venting

Optimal venting through a chimney system is intrinsically linked to the design and condition of its flue. The primary purpose is to safely expel combustion byproducts from heating appliances to the external environment. This process prevents the accumulation of hazardous gases within a building and ensures the heating appliance operates at its intended efficiency. The performance of a clay flue significantly influences the efficiency of this venting process.

- Flue Sizing and Appliance Compatibility

Proper flue sizing is critical for efficient venting. A flue that is too small restricts airflow, leading to incomplete combustion and the potential for backdrafting. Conversely, an oversized flue can result in excessive cooling of flue gases, promoting condensation and creosote buildup. A clay flue should be sized appropriately for the connected heating appliance to ensure optimal draft and efficient removal of combustion byproducts. Example: Connecting a small wood stove to an oversized flue will likely result in poor draft and increased creosote formation.

- Smooth Interior Surface and Draft Optimization

The interior surface of the flue influences airflow resistance. A smooth interior promotes a more efficient draft, facilitating the upward movement of flue gases. Imperfections or irregularities in the clay flue’s surface can create turbulence and impede airflow. The material properties and installation methods should minimize surface irregularities to maximize draft efficiency. Example: A cracked or spalled flue liner can significantly increase airflow resistance and reduce draft efficiency.

- Flue Height and Natural Draft Enhancement

The height of the chimney, including the clay flue, plays a crucial role in establishing natural draft. A taller chimney generates a greater pressure differential between the base and the top, enhancing the upward movement of flue gases. Minimum height requirements are typically specified in building codes to ensure adequate draft. The height must be sufficient to overcome downdrafts caused by nearby obstructions. Example: A chimney that is too short may experience downdrafts, particularly in windy conditions, leading to inefficient venting and potential backdrafting.

- Prevention of Condensation and Creosote Buildup

Efficient venting helps to minimize condensation and creosote buildup within the flue. Proper draft ensures that flue gases are quickly expelled, reducing the time available for cooling and condensation. Clay flues are resistant to the corrosive effects of creosote, but excessive buildup can still impede airflow and increase the risk of chimney fires. Regular cleaning and maintenance are essential for preventing excessive creosote accumulation. Example: Inefficient venting can lead to thick creosote deposits that restrict airflow and pose a significant fire hazard.

These facets demonstrate the interconnectedness between a clay flue and efficient venting. Proper sizing, a smooth interior surface, adequate flue height, and strategies for minimizing condensation all contribute to the safe and effective removal of combustion byproducts. Maintaining the integrity of the flue through regular inspections and repairs is essential for ensuring optimal venting efficiency and preventing potential hazards.

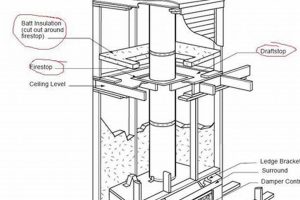

5. Proper Installation

The meticulous installation of flue components is essential for ensuring the safety and efficiency of a chimney system. Deviations from established procedures can compromise the system’s structural integrity and increase the risk of hazardous conditions. Specifically, the careful installation of individual sections is paramount for the effective operation of the entire chimney.

- Mortar Joint Integrity

The application of appropriate mortar between sections creates a gas-tight seal, preventing the escape of combustion byproducts into the chimney structure. Improperly filled or cured mortar joints can lead to corrosion of the surrounding masonry and potential carbon monoxide leakage into the building. Mortar should be specifically formulated for high-temperature applications and applied according to manufacturer specifications. Example: Using standard brick mortar instead of refractory mortar can result in premature joint failure due to thermal stress.

- Proper Alignment and Section Support

Precise alignment of sections is necessary to ensure a continuous, unobstructed flue passage. Misaligned sections can create turbulence and impede airflow, reducing venting efficiency. Adequate support must be provided to each section to prevent settling or shifting, which could compromise the integrity of the joints. This is particularly important in taller chimneys, where the weight of the structure can exert significant stress on the lower sections. Example: Failure to properly support can lead to cracking and eventual collapse of the flue liner.

- Adequate Clearance to Combustibles

Maintaining sufficient clearance between the exterior of the chimney and any combustible materials, such as wood framing, is critical for preventing fire hazards. Building codes typically specify minimum clearance requirements to ensure that heat transfer from the chimney does not ignite nearby combustibles. Improper installation that violates these clearance requirements can significantly increase the risk of structural fires. Example: Direct contact between a chimney and wooden framing members is a common cause of chimney fires.

- Flue Size Compatibility

The inner diameter must be appropriately sized for the heating appliance it serves. An undersized inner diameter restricts the proper venting of exhaust, potentially leading to carbon monoxide poisoning. An oversized inner diameter may result in a slow draft, leading to more creosote buildup. The flue size must be carefully selected to match the requirements of the heating appliance for safe and efficient operation. Example: Connecting a high-output wood stove to an undersized can result in dangerous backdrafting of exhaust gases.

In conclusion, the discussed facets underscore the significance of proper installation practices in ensuring the long-term safety and efficiency of any chimney system. Adhering to established procedures and utilizing appropriate materials are essential for preventing hazardous conditions and maintaining the structural integrity of the chimney.

6. Regular Inspection

The correlation between routine examination and the longevity and safety of a chimney lined with ceramic material is direct and substantial. Consistent evaluation serves as a preventative measure, enabling the early detection of defects within the structure. Cracks, spalling, or deterioration of mortar joints, all indicators of potential failure, are often identifiable during routine inspections, allowing for timely intervention. Without regular checks, minor issues can escalate, leading to significant structural compromise and posing potential fire hazards or carbon monoxide leaks. For instance, creosote buildup, a byproduct of wood combustion, is visually identifiable during inspections. Its accumulation can obstruct the flue, reducing venting efficiency and increasing the risk of chimney fires. Addressing creosote through cleaning, prompted by a routine inspection, mitigates this risk.

Furthermore, regular assessment ensures the continued compatibility between the flue dimensions and the connected heating appliance. Changes in appliance type or performance can impact the necessary flue size for optimal venting. An inspection can reveal whether the existing configuration remains appropriate, preventing inefficient combustion or backdrafting of hazardous gases. Consider a scenario where a homeowner replaces a low-efficiency fireplace insert with a high-efficiency model. A regular inspection should determine if the existing ceramic lining is adequately sized to handle the altered exhaust volume and temperature, preventing potential condensation issues within the chimney.

In summary, routine assessment functions as a critical safeguard for ceramic chimney liners. It provides opportunities for early detection of structural deficiencies, allows for proactive management of creosote buildup, and ensures ongoing compatibility between the flue and the connected appliance. The absence of regular inspection substantially increases the risk of chimney failure, potentially leading to costly repairs, fire hazards, or exposure to harmful combustion byproducts. Prioritizing consistent evaluation represents a cost-effective strategy for preserving the integrity and safety of the system.

Frequently Asked Questions

The following questions address common concerns and provide information regarding ceramic chimney liners, their function, maintenance, and safety implications.

Question 1: What is the primary function of a liner?

The primary function is to contain and safely vent combustion byproducts from heating appliances to the outside atmosphere, protecting the chimney structure from heat and corrosive gases.

Question 2: How often should a be inspected?

A professional inspection should be conducted annually to identify any signs of damage or deterioration that could compromise its integrity.

Question 3: What are common signs of damage to a ?

Common signs include cracks, spalling, missing sections, and deteriorated mortar joints. Any of these issues warrant further investigation and potential repair.

Question 4: Can a be repaired, or does it always require replacement?

Minor damage can sometimes be repaired with patching or relining techniques. However, extensive damage typically necessitates complete replacement to ensure continued safety.

Question 5: What are the risks associated with a damaged liner?

A damaged liner can lead to chimney fires, carbon monoxide leaks, and deterioration of the chimney structure, all posing significant safety hazards.

Question 6: Are there alternative lining materials to ceramic?

Yes, stainless steel liners are a common alternative, offering enhanced durability and resistance to corrosion in certain applications.

Maintaining a properly functioning ceramic chimney liner is crucial for the safe and efficient operation of any heating system. Regular inspection and prompt repairs are essential for preventing potential hazards.

The subsequent section will address specific repair and replacement strategies for liners, providing detailed guidance on ensuring their continued safe and effective operation.

Conclusion

The preceding exploration has detailed the critical role of the ceramic component in a masonry chimney system. Its functionality encompasses heat resistance, corrosion protection, structural integrity, and efficient venting. Maintaining its integrity through proper installation, regular inspection, and timely repair is paramount for ensuring safe and effective operation of residential and commercial heating systems. Deterioration of this lining poses significant risks, including chimney fires and carbon monoxide intrusion, necessitating diligent attention to its condition.

Given the potential consequences of failure, prioritizing the ongoing assessment and maintenance of the internal ceramic lining is not merely advisable, but essential. Safeguarding this critical element ensures the continued safe and efficient operation of the chimney system, protecting both property and occupants from potential hazards. Ignoring this imperative invites unnecessary risk and potentially devastating outcomes.