Vertical structures that exhaust combustion byproducts from a heating appliance or fireplace exist in a variety of forms, each designed for specific applications and architectural styles. These structures facilitate the safe and efficient removal of smoke, gases, and other harmful substances from a building. Examples include masonry constructions built from brick or stone, metal flues often prefabricated and used with stoves, and factory-built systems designed for specific appliances.

The efficient operation of a heating system is directly related to the effective draft created by these structures. Proper construction and maintenance are crucial for preventing carbon monoxide poisoning and reducing the risk of chimney fires. Historically, these structures have been integral to building design, evolving from simple smoke holes to sophisticated systems that contribute to both functionality and aesthetic appeal.

The following sections will delve into the construction materials, design variations, and operational considerations of various chimney designs. This exploration will cover factors influencing selection, installation best practices, and maintenance requirements for each type.

Chimney System Best Practices

Ensuring the longevity and safe operation of a chimney necessitates adherence to specific guidelines. These recommendations cover aspects from initial selection to ongoing maintenance.

Tip 1: Material Compatibility: Select chimney materials appropriate for the fuel being burned. For instance, a stainless steel liner is often required for gas-burning appliances due to the corrosive nature of the exhaust gases.

Tip 2: Proper Sizing: The flue size must be properly matched to the appliance it serves. An undersized flue can lead to inadequate draft and potential carbon monoxide buildup, while an oversized flue can result in creosote condensation.

Tip 3: Regular Inspections: Schedule annual professional inspections to identify potential structural weaknesses, blockages, or creosote accumulation. Early detection prevents costly repairs and safety hazards.

Tip 4: Creosote Removal: Regularly remove creosote buildup, particularly with wood-burning appliances. Creosote is highly flammable and a primary cause of chimney fires.

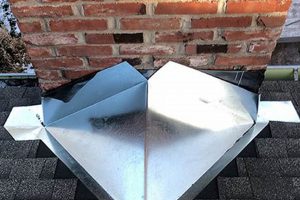

Tip 5: Cap Installation: Install a chimney cap to prevent rainwater, debris, and animals from entering the flue. A cap also helps to prevent downdrafts.

Tip 6: Code Compliance: Ensure all chimney installations and repairs adhere to local building codes and regulations. This guarantees safety and structural integrity.

Tip 7: Professional Installation: Engage qualified professionals for installation and major repairs. Proper expertise minimizes risks associated with improper construction.

Adherence to these best practices significantly reduces the risk of chimney-related hazards and prolongs the lifespan of the entire heating system.

The subsequent sections will provide specific details on advanced maintenance and troubleshooting techniques, ensuring the ongoing safety and effectiveness of various systems.

1. Material Composition

The selection of materials significantly dictates the performance, durability, and overall suitability of chimney structures. Different fuels and heating appliances generate varying exhaust temperatures and corrosive byproducts, making material choice a critical design consideration.

- Masonry Chimneys

Constructed from brick, stone, or concrete blocks, masonry chimneys offer excellent thermal mass and fire resistance. These structures are typically site-built and can be adapted to various architectural styles. However, masonry is porous and susceptible to degradation from moisture and acidic condensation, necessitating a protective flue liner made of ceramic or stainless steel.

- Factory-Built Metal Chimneys

These chimneys are prefabricated systems constructed from stainless steel or aluminized steel. They offer a lightweight and modular alternative to masonry, simplifying installation and reducing construction time. Metal chimneys are classified based on their temperature rating and are suitable for various fuels, including wood, gas, and oil. Double-wall and triple-wall designs provide insulation and reduce the risk of fire.

- Chimney Liners

Liners serve as a protective barrier within the chimney, preventing corrosive flue gases from damaging the chimney structure. Clay tile liners are a traditional and cost-effective option for wood-burning appliances. Stainless steel liners offer superior resistance to corrosion and are often required for gas-burning appliances due to the acidic nature of their exhaust. Flexible liners are used for relining existing chimneys with irregular shapes.

- Specialty Materials

In specific applications, specialty materials are employed to address unique challenges. For instance, high-temperature refractory cement is used to repair damaged masonry and create smoke chambers. Lightweight insulating concrete is used in some prefabricated chimney systems to enhance thermal performance and reduce weight.

The interplay between material composition and chimney design is fundamental to ensuring the safe and efficient venting of combustion byproducts. Proper material selection, coupled with adherence to building codes and industry best practices, is essential for the long-term performance and safety of these structures.

2. Construction Method

The method of construction directly influences the performance and longevity of chimney systems. Construction techniques are intrinsically linked to the materials used, regulatory compliance, and the intended appliance served. For instance, a site-built masonry construction necessitates skilled bricklaying or stonemasonry, ensuring proper mortar joints and structural integrity. Deviations from established techniques can result in weakened structures susceptible to moisture penetration and eventual collapse. Conversely, a prefabricated metal chimney requires precise assembly according to the manufacturer’s specifications. Improper assembly can compromise the system’s ability to contain high temperatures and corrosive gases, potentially leading to fire hazards or carbon monoxide leakage.

Consider the example of a chimney relining project. Inserting a stainless steel liner into an existing masonry chimney requires careful measurement and installation to ensure a tight seal and prevent the escape of flue gases into the living space. If the liner is improperly sized or installed without adequate insulation, condensation can occur, accelerating corrosion and reducing the system’s efficiency. The practical significance lies in understanding that selecting the correct construction method, and executing it with precision, directly affects the safety and efficiency of the entire heating system, mitigating risks associated with improper combustion venting.

In summary, the construction method is not merely a procedural step, but a critical component defining a chimney’s effectiveness. Challenges arise from varying skill levels among installers and the complexity of code compliance. Understanding this connection reinforces the need for qualified professionals and rigorous adherence to established building practices, ensuring the safe and reliable operation of chimney systems across different architectural designs and fuel types. The correlation between the method of construction and the specific style dictates overall durability.

3. Appliance Compatibility

Ensuring the safe and effective removal of combustion byproducts hinges significantly on the proper matching of heating appliances with chimney systems. Appliance compatibility dictates material selection, flue sizing, and overall chimney design.

- Fuel Type and Exhaust Gases

Different fuelswood, natural gas, oil, and propaneproduce distinct exhaust gases with varying temperatures and chemical compositions. Wood combustion, for instance, generates creosote, a flammable byproduct that necessitates regular removal and a chimney designed to withstand high temperatures. Natural gas and propane combustion produce acidic condensation, which can corrode certain chimney materials. Chimney selection must consider the specific properties of the fuel being burned.

- Appliance Venting Requirements

Manufacturers specify venting requirements, including minimum flue size and chimney height, to ensure proper draft and complete combustion. These requirements are typically outlined in appliance installation manuals and must be strictly adhered to for safe operation. Under- or over-sizing the flue can lead to incomplete combustion, carbon monoxide production, and reduced heating efficiency.

- Positive vs. Negative Draft Systems

Some appliances, such as high-efficiency furnaces, utilize positive draft systems, where a fan forces exhaust gases through the chimney. These appliances often require specialized venting materials, such as sealed PVC or CPVC piping, to prevent leakage and corrosion. Conversely, traditional appliances rely on negative draft, where the natural buoyancy of hot gases creates a draft up the chimney.

- Appliance BTU Input

The British Thermal Unit (BTU) input rating of a heating appliance directly influences the volume of exhaust gases produced. Chimney systems must be sized appropriately to accommodate the expected exhaust volume. A chimney that is too small can restrict airflow, leading to backdrafting and potential carbon monoxide poisoning.

The interdependence of appliance characteristics and chimney system design underscores the need for careful consideration during installation or replacement. Selecting the correct chimney system based on appliance compatibility is paramount to achieving safe, efficient, and reliable heating performance.

4. Lining Requirements

Flue liners are integral components of chimney systems, serving as a protective barrier against the corrosive effects of combustion byproducts. The necessity for a liner, and the specific type required, is directly linked to the chimney’s material, construction, and the type of appliance it serves. For instance, unlined masonry chimneys are particularly susceptible to deterioration from acidic condensation produced by gas-burning appliances. This can lead to structural damage and the potential leakage of carbon monoxide into the building. The installation of a stainless steel liner in such cases is not merely an upgrade, but a critical safety measure mandated by many building codes. Similarly, older chimneys constructed with substandard mortar may require relining to prevent flue gas escape, irrespective of the fuel type.

Factory-built metal chimneys, while often incorporating integrated liners, must still adhere to stringent material specifications based on the intended application. A chimney designed for wood-burning appliances will necessitate a liner capable of withstanding high temperatures and the accumulation of creosote, a highly flammable substance. In contrast, a chimney intended for a modern, high-efficiency gas furnace might utilize a specialized liner made from PVC or CPVC, materials resistant to the acidic condensation but unsuitable for high-temperature applications. The absence of an appropriate liner, or the use of a compromised liner, can have significant implications, potentially leading to chimney fires, structural damage requiring extensive repairs, or, more critically, carbon monoxide poisoning of occupants.

In summation, lining requirements are not arbitrary additions, but essential design considerations directly influencing chimney performance and safety. Selecting the appropriate liner material and ensuring its proper installation are crucial steps in safeguarding property and human life. Furthermore, regular inspections and maintenance are vital for detecting liner deterioration and ensuring continued protection against the hazards associated with combustion byproducts.

5. Termination Style

Termination style, referring to the design and positioning of a chimney’s outlet above a roofline, is a critical factor influencing the draft, weather resistance, and overall safety of various chimney systems. The specific design is often dictated by chimney type, appliance requirements, and local building codes. For instance, masonry chimneys typically feature a projecting cap to prevent rainwater from entering the flue, while metal chimneys may utilize a simple conical termination. The height of the termination above the roof is crucial for ensuring adequate draft, mitigating the effects of wind turbulence, and preventing smoke from re-entering the building. Failure to adhere to proper termination guidelines can lead to backdrafting, reduced heating efficiency, and increased creosote accumulation.

Consider a scenario where a prefabricated metal chimney, improperly terminated below the roofline of a multi-story structure, experiences persistent downdrafts. This negative pressure can force exhaust gases back into the living space, creating a hazardous environment due to carbon monoxide exposure. A masonry chimney lacking a cap is susceptible to water damage, accelerating deterioration of the brickwork and mortar joints. The practical consequence of such deficiencies is not only compromised safety but also increased maintenance costs and potential structural repairs. Therefore, the integration of termination style as a fundamental design element is essential for the safe and efficient operation of all chimney types.

In summary, the appropriate termination style, carefully matched to the chimney type and appliance served, is paramount for optimal performance and safety. Compliance with local building codes and manufacturer specifications is vital for ensuring adequate draft, weather resistance, and the prevention of hazardous conditions. Neglecting this aspect can result in significant safety risks, reduced heating efficiency, and increased maintenance expenses, underscoring the importance of proper termination design for all chimney systems.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, maintenance, and safety aspects of various chimney systems.

Question 1: What are the primary factors in determining the appropriate chimney type for a specific heating appliance?

Fuel type, appliance BTU input, and venting requirements are the primary determinants. Different fuels generate varying exhaust temperatures and chemical compositions, necessitating specific materials and construction methods. Appliance BTU input dictates the required flue size, while manufacturer-specified venting requirements must be strictly adhered to for safe and efficient operation.

Question 2: How frequently should a chimney be professionally inspected?

Annual professional inspections are recommended. Regular inspections can identify structural weaknesses, blockages, and creosote accumulation, preventing costly repairs and potential safety hazards.

Question 3: What are the key indicators of potential chimney problems?

Visible cracks in masonry, excessive creosote buildup, water leaks, damaged flue liners, and unusual smoke patterns are key indicators. These issues warrant immediate investigation and potential repair.

Question 4: Does the type of chimney affect its energy efficiency?

Yes, the type of chimney can influence energy efficiency. Properly insulated chimneys reduce heat loss and prevent condensation, improving overall system efficiency. An improperly sized or damaged chimney can lead to draft problems and incomplete combustion, reducing efficiency.

Question 5: Are prefabricated metal chimneys as safe as masonry chimneys?

When properly installed and maintained, prefabricated metal chimneys can be as safe as masonry chimneys. They must meet stringent safety standards and be installed according to manufacturer specifications. Regular inspections are essential to ensure the integrity of the system.

Question 6: What are the risks associated with neglecting chimney maintenance?

Neglecting maintenance can lead to chimney fires, carbon monoxide poisoning, structural damage, and reduced heating efficiency. Regular cleaning, inspections, and repairs are essential for mitigating these risks.

Proper chimney selection, regular maintenance, and adherence to safety guidelines are critical for ensuring the safe and efficient operation of heating systems.

The subsequent section provides a concise summary of chimney-related safety protocols and emergency procedures.

Conclusion

This exposition has detailed the significance of the structures responsible for venting combustion byproducts. From material composition and construction methods to appliance compatibility, lining requirements, and termination styles, a comprehensive understanding is crucial. The safety and efficiency of heating systems directly correlate with proper selection, installation, and maintenance protocols. The various designs each possess distinct characteristics necessitating careful consideration.

Due diligence in chimney system management is not merely a matter of regulatory compliance but a fundamental responsibility for safeguarding property and human life. Continued adherence to established best practices and proactive engagement with qualified professionals are essential for mitigating the inherent risks associated with combustion venting. Prioritizing diligence ensures prolonged system functionality and minimizes potential hazards.