A circular or square covering designed to fit atop a six-inch diameter chimney flue, incorporating a mesh screen. This component functions as a barrier, preventing embers and sparks from escaping the chimney system and potentially igniting nearby combustible materials. The specified dimension relates directly to the flue’s internal diameter, ensuring a secure and effective fit.

The installation of such a device contributes significantly to fire safety, mitigating the risk of wildfires caused by chimney emissions. Regulations in many jurisdictions mandate its use, reflecting a recognized need to protect property and the environment. Historically, less sophisticated methods were employed, but modern designs offer improved performance, durability, and ease of installation.

The subsequent sections will delve into the materials used in construction, installation procedures, maintenance requirements, and relevant safety standards for this type of chimney termination.

Essential Considerations

The following guidelines are provided to ensure optimal function and longevity of the selected chimney termination device. Adherence to these points will contribute to safety and regulatory compliance.

Tip 1: Verify Dimensional Accuracy: Prior to procurement, confirm the precise internal diameter of the chimney flue. A mismatch in size can compromise the device’s stability and effectiveness. Measure the flue carefully to ensure a secure fit.

Tip 2: Material Selection Matters: Opt for stainless steel construction. This material provides superior resistance to corrosion and high temperatures, ensuring prolonged service life compared to galvanized steel or other alternatives.

Tip 3: Screen Mesh Specification: Inspect the spark arrestor mesh. The openings should be sufficiently small to prevent the passage of embers, typically no larger than 1/2 inch. Regular inspection of mesh integrity is crucial.

Tip 4: Installation Protocol: Follow the manufacturer’s installation instructions precisely. Secure the device firmly to the flue using appropriate fasteners. Improper installation can lead to dislodgement during high winds or adverse weather conditions.

Tip 5: Periodic Inspection: Conduct routine visual inspections of the device, at least annually. Check for signs of corrosion, damage to the mesh, or obstructions caused by debris. Timely maintenance will prevent potential hazards.

Tip 6: Debris Removal: Clear any accumulated creosote, leaves, or other debris from the screen regularly. Blockages can impede proper ventilation and increase the risk of chimney fires. A chimney sweep can assist with this task.

Tip 7: Regulatory Compliance: Ensure the selected device meets all applicable local and national fire safety regulations. Verify compliance with relevant building codes to avoid penalties and ensure safety.

Consistent application of these recommendations will enhance the safety and efficiency of the chimney system. Proactive maintenance is key to preventing hazards and maintaining code compliance.

The subsequent sections will address troubleshooting common issues and selecting appropriate replacement components.

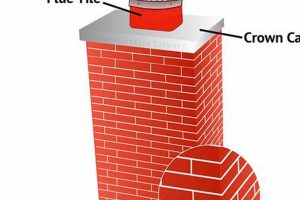

1. Flue Diameter Compatibility

Flue diameter compatibility is paramount to the proper functioning of a six-inch chimney cap with spark arrestor. The six-inch designation of the device indicates its intended use with a chimney flue having a corresponding internal diameter. A mismatch between the flue diameter and the cap’s designated size directly impacts its ability to perform its primary functions: preventing the egress of sparks and embers and protecting the chimney from precipitation and debris. Insufficient diameter leads to an unstable fitting, potentially causing the cap to dislodge in adverse weather conditions. Conversely, an undersized cap will not properly seat on the flue, leaving gaps that allow sparks to escape, thereby negating the fire safety benefits. For example, installing a cap designed for a five-inch flue on a six-inch flue invariably results in a hazardous condition, regardless of how tightly it may appear to fit initially.

The consequences of incompatible dimensions extend beyond immediate fire risks. An improperly fitted cap can contribute to accelerated chimney deterioration. Rainwater entering through gaps can saturate the chimney liner, leading to freeze-thaw damage and structural weakening. Moreover, the escape of flue gases, particularly those containing corrosive elements, can damage surrounding building materials and pose a health hazard to occupants. The long-term operational costs associated with chimney repair and replacement due to diameter incompatibility can far exceed the initial expense of selecting the correctly sized cap. Building codes often specify acceptable tolerances for chimney cap installations; failing to adhere to these standards can result in inspection failures and the requirement for costly remediation.

In summary, ensuring proper flue diameter compatibility is not merely a matter of convenience; it is a critical safety measure. The precise matching of the cap’s six-inch designation with the chimney flue’s internal diameter is essential for effective spark arrestance, chimney protection, and adherence to building regulations. Challenges often arise from inaccurate measurements or the use of non-standard flue sizes. Therefore, careful verification of the flue diameter before selecting a chimney cap with spark arrestor is of utmost importance, mitigating potential risks and ensuring long-term performance.

2. Spark Arrestor Mesh

The spark arrestor mesh is a critical component of a six-inch chimney cap with spark arrestor. Its primary function is to prevent hot embers and sparks from exiting the chimney and potentially igniting surrounding vegetation or structures. Without properly functioning mesh, the chimney cap becomes ineffective as a fire safety device, negating its intended purpose. The mesh acts as a physical barrier, interrupting the trajectory of escaping particles and extinguishing them before they can pose a threat. For example, in areas prone to wildfires, a damaged or missing spark arrestor mesh can significantly increase the risk of igniting dry leaves, pine needles, or other flammable materials on rooftops or in nearby yards. The design and material of the mesh are key determinants of its effectiveness.

The typical mesh size is standardized to prevent the passage of embers exceeding a certain diameter, generally around 1/2 inch, while still allowing for adequate ventilation and exhaust of flue gases. The material used for the mesh is typically stainless steel or galvanized steel, chosen for its resistance to high temperatures and corrosion. Regular inspection and maintenance of the mesh are essential. Creosote buildup, corrosion, or physical damage can compromise its integrity. A clogged mesh can restrict airflow, leading to inefficient combustion and potentially causing dangerous backdrafts of carbon monoxide into the building. Replacing a damaged or corroded mesh is crucial for maintaining fire safety and preventing potential hazards. In regions with strict fire codes, the presence and condition of the spark arrestor mesh are often subject to inspection and enforcement.

In summary, the spark arrestor mesh is an indispensable element of the six-inch chimney cap, providing essential fire safety protection. Its effectiveness hinges on correct mesh size, durable material construction, and consistent maintenance. Ignoring the condition of the mesh can have serious consequences, underscoring the importance of regular inspections and prompt repairs to ensure optimal functionality and regulatory compliance. Its absence or degradation directly elevates the risk of fire hazards, making it a non-negotiable aspect of chimney safety.

3. Material Durability

Material durability, in the context of a six-inch chimney cap with spark arrestor, directly dictates the device’s lifespan, functionality, and sustained ability to provide critical fire safety. The harsh environmental conditions to which these caps are exposed necessitate careful consideration of material selection.

- Corrosion Resistance

The primary threat to a chimney cap’s integrity is corrosion from flue gases and atmospheric moisture. Materials such as stainless steel exhibit superior resistance to this degradation, preventing structural weakening and ensuring the spark arrestor mesh remains intact. Galvanized steel, while offering some protection, degrades more rapidly, leading to premature failure. The implications of corrosion include compromised fire safety and the potential for cap disintegration, requiring costly replacement.

- Thermal Stability

Chimney caps are subjected to wide temperature fluctuations, ranging from sub-zero winter conditions to the high heat of combustion gases. The chosen material must maintain its structural integrity across this temperature spectrum. Materials lacking thermal stability may warp or crack, compromising the cap’s fit and effectiveness. For instance, certain plastics or low-grade metals are unsuitable due to their propensity to deform under high heat, rendering the spark arrestor function ineffective.

- Weather Resistance

Exposure to rain, snow, and ultraviolet radiation contributes to material degradation. Durable materials, such as powder-coated stainless steel, offer enhanced resistance to these elements, preventing rust, fading, and embrittlement. Caps constructed from less durable materials may exhibit cracking, peeling, or other forms of deterioration, leading to reduced functionality and aesthetic appeal. The implications extend beyond mere appearance, as compromised weather resistance can accelerate corrosion and structural weakening.

- Mechanical Strength

A chimney cap must withstand external forces such as wind, falling debris, and ice accumulation. Materials with high mechanical strength, such as heavy-gauge stainless steel, are better equipped to resist damage from these factors. Caps constructed from weaker materials may bend, break, or detach from the chimney, compromising fire safety and potentially causing property damage. The spark arrestor mesh itself must also possess sufficient strength to resist tearing or deformation from wind-blown debris.

The interconnectedness of these facets underscores the importance of material durability in a six-inch chimney cap with spark arrestor. Selecting a cap constructed from robust, corrosion-resistant, and thermally stable materials is an investment in long-term safety, functionality, and cost-effectiveness. Compromising on material quality can lead to premature failure, increased fire risk, and the need for frequent replacements, ultimately negating any initial cost savings.

4. Proper Installation

The correct installation of a six-inch chimney cap with spark arrestor is paramount to its effective operation and contribution to fire safety. Deviations from recommended procedures can negate the device’s protective capabilities and potentially introduce new hazards. The following facets highlight essential elements of a proper installation.

- Dimensional Accuracy Verification

Before commencing installation, verifying the precise internal diameter of the chimney flue and confirming its compatibility with the six-inch designation of the cap is crucial. Discrepancies can result in an insecure fit, allowing sparks to escape or causing the cap to dislodge during high winds. For example, attempting to install a cap designed for a five-inch flue onto a six-inch flue, even with forceful manipulation, will inevitably create gaps compromising spark containment and weather protection.

- Secure Fastening Mechanisms

Employing the appropriate fastening mechanisms, as specified by the manufacturer, is essential for a stable and enduring installation. This may involve using stainless steel screws, clamps, or adhesive sealants designed to withstand high temperatures and corrosive flue gases. Inadequate fastening can lead to cap detachment during inclement weather, rendering it ineffective and potentially causing damage to surrounding structures. A common error is relying solely on friction or makeshift methods, which are prone to failure.

- Clearance from Combustible Materials

Maintaining adequate clearance between the chimney cap and any nearby combustible materials, such as roofing or siding, is a critical fire safety precaution. Insufficient clearance can allow heat radiated from the cap to ignite these materials, particularly during periods of extended use or high flue temperatures. Building codes typically dictate minimum clearance requirements, and adherence to these standards is mandatory. For instance, a cap positioned too close to a wooden roof overhang could initiate a fire over time, particularly in dry conditions.

- Mesh Orientation and Integrity

Ensuring the spark arrestor mesh is correctly oriented and free from damage is vital for its intended function. The mesh should be positioned to effectively block the passage of embers while allowing for unrestricted airflow. Tears, corrosion, or blockages in the mesh can compromise its effectiveness, allowing sparks to escape and increasing the risk of fire. Regular inspection and maintenance of the mesh are essential to ensure its continued integrity.

These facets underscore the critical role of proper installation in realizing the intended benefits of a six-inch chimney cap with spark arrestor. A seemingly minor oversight during installation can have significant consequences, compromising fire safety and potentially leading to property damage or loss. Adherence to manufacturer’s instructions and relevant building codes is paramount for ensuring a safe and effective installation.

5. Regular Maintenance

The operational lifespan and efficacy of a six-inch chimney cap with spark arrestor are inextricably linked to the implementation of a consistent maintenance regimen. The accumulation of debris, such as leaves, twigs, and creosote, directly impedes the device’s functionality. Clogged mesh restricts airflow, leading to inefficient combustion and potentially forcing dangerous combustion byproducts, including carbon monoxide, back into the dwelling. For example, a homeowner neglecting annual chimney inspections may experience reduced heating efficiency and an elevated risk of chimney fires due to creosote buildup obstructing both the flue and the spark arrestor screen. This, in turn, compromises the intended fire-safety benefits of the cap.

Furthermore, corrosion and physical damage necessitate periodic attention. Chimney caps, exposed to extreme temperature fluctuations and corrosive flue gases, are susceptible to material degradation. Stainless steel, while more durable, is not immune to these effects. Regular inspection can identify early signs of rust or structural weakness, enabling timely repairs or replacements. Failing to address corrosion can lead to mesh disintegration, allowing sparks and embers to escape, defeating the cap’s primary purpose. As an example, a homeowner in a coastal environment with high salt content in the air might find that the steel chimney cap will need to be replaced much sooner than in an inland environment due to the faster rate of corrosion. A proactive approach to maintenance not only prolongs the cap’s service life but also ensures continuous compliance with fire safety regulations and prevents costly chimney repairs.

In conclusion, neglecting regular maintenance of a six-inch chimney cap with spark arrestor directly undermines its intended safety functions and contributes to a higher risk of fire hazards. The proactive removal of debris, inspection for corrosion and damage, and prompt repairs are essential for maintaining optimal performance and ensuring long-term protection. Prioritizing maintenance is not merely a matter of upkeep; it is a fundamental component of responsible homeownership and fire safety.

Frequently Asked Questions

The following represents common inquiries regarding chimney caps with integrated spark arrestors, specifically those designed for six-inch diameter flues. Answers provided are intended to offer clear and concise information regarding selection, installation, maintenance, and regulatory compliance.

Question 1: What is the principal function of a six-inch chimney cap with spark arrestor?

The primary purpose is to prevent embers and sparks from escaping the chimney system, mitigating the risk of wildfires or ignition of nearby combustible materials. It also serves to protect the chimney flue from rain, snow, and debris.

Question 2: How frequently should a chimney cap with spark arrestor be inspected?

Annual inspection is recommended as a minimum. More frequent inspections may be necessary in areas with heavy foliage or frequent storms, which can contribute to debris accumulation on the spark arrestor mesh.

Question 3: What materials are best suited for a chimney cap with spark arrestor?

Stainless steel is generally considered the superior material due to its resistance to corrosion and high temperatures. Galvanized steel is a less expensive alternative, but it has a shorter lifespan and is more susceptible to rust.

Question 4: Is professional installation required for a chimney cap with spark arrestor?

While homeowner installation is possible, professional installation is strongly recommended, particularly for those unfamiliar with chimney systems or working at heights. A professional can ensure proper fit, secure attachment, and adherence to relevant building codes.

Question 5: What size spark arrestor mesh is required to meet safety standards?

Most jurisdictions mandate that spark arrestor mesh openings do not exceed 1/2 inch in any dimension. This prevents the passage of embers while allowing for adequate ventilation of flue gases.

Question 6: Can a damaged spark arrestor mesh be repaired, or does the entire cap need replacing?

Minor damage to the mesh may be repairable. However, extensive corrosion or significant tears necessitate replacement of the entire chimney cap to ensure continued fire safety.

Proper selection, installation, and maintenance are critical to ensure the effective performance of a chimney cap with spark arrestor. Regular inspection and prompt attention to any issues can significantly reduce the risk of chimney fires and associated property damage.

The following section will cover common troubleshooting issues encountered with this device and provide potential remedies.

6 inch chimney cap with spark arrestor

This exploration has underscored the critical function of a six-inch chimney cap incorporating a spark arrestor. The device serves as a primary defense against fire hazards stemming from chimney emissions, offering protection to both property and the surrounding environment. Precise fit, durable materials, proper installation, and consistent maintenance are indispensable elements for optimal performance and regulatory compliance. Compromising on any of these aspects increases the risk of fire and diminishes the intended safeguards.

Therefore, responsible homeowners and building managers must recognize the importance of selecting, installing, and maintaining a six-inch chimney cap with spark arrestor with meticulous attention to detail. Adherence to recommended practices is not merely a matter of routine upkeep, but a fundamental responsibility in ensuring fire safety and mitigating potential losses. The continued commitment to these principles will contribute to safer communities and a reduced risk of chimney-related fires.