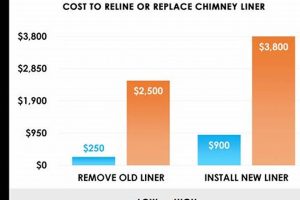

The expense associated with renovating a chimney’s interior structure varies considerably, dependent on several key factors. This investment addresses issues related to deterioration and ensures safe operation of heating appliances. Factors influencing the overall price involve the chosen materials, the chimney’s height and accessibility, and the complexity of the installation.

A structurally sound chimney liner is crucial for efficiently venting combustion byproducts and protecting the house from fire hazards. Historically, clay tiles were the standard lining material; however, modern solutions like stainless steel and cast-in-place liners offer improved durability and safety. Addressing damage promptly mitigates potential risks and preserves the chimney’s integrity, ultimately contributing to a safer and more efficient home heating system.

A detailed breakdown of the cost elements, material options, and installation methods will provide a more complete understanding of what to anticipate when budgeting for this essential home maintenance project. This exploration includes examining common materials used, typical labor costs, and regional price variations that can affect the overall expense.

Important Considerations for Chimney Relining Expenses

Understanding the various elements impacting the investment in chimney relining can facilitate more informed decision-making.

Tip 1: Obtain Multiple Quotes: Seek estimates from at least three qualified chimney professionals. This enables a comparison of pricing and service offerings, ensuring a fair market rate.

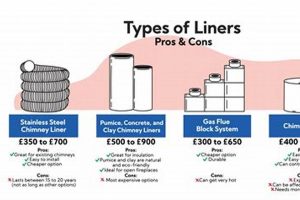

Tip 2: Consider Material Options: Stainless steel liners, while typically more expensive upfront, offer extended lifespans and superior resistance to corrosion compared to aluminum or clay liners. Evaluate long-term value when selecting materials.

Tip 3: Factor in Chimney Height and Accessibility: Taller chimneys and those with difficult access points will increase labor costs. Discuss potential challenges and associated fees with contractors beforehand.

Tip 4: Inspect for Pre-existing Damage: A thorough chimney inspection prior to relining is essential. Addressing any existing structural issues, such as cracks or water damage, will add to the overall expense but prevents future complications.

Tip 5: Verify Contractor Credentials: Ensure that the chosen contractor is licensed, insured, and possesses a proven track record of successful chimney relining projects. Request references and review past work.

Tip 6: Inquire About Warranty Coverage: Understanding the warranty offered on both materials and labor provides protection against defects or premature failure. Clarify the terms and conditions of the warranty before proceeding.

Tip 7: Account for Potential Code Compliance Upgrades: Local building codes may necessitate upgrades to the chimney system during relining. Verify compliance requirements and factor these costs into the budget.

Careful planning and thorough research contribute significantly to managing the expense of chimney relining effectively and ensuring a safe and reliable heating system.

This detailed understanding will aid in approaching the relining process with greater confidence and control over the associated financial commitments.

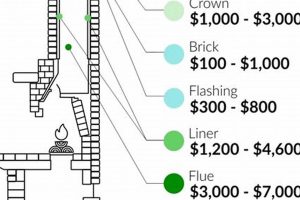

1. Material Selection

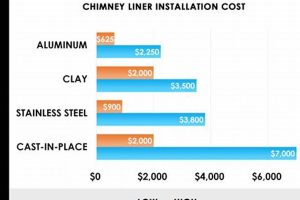

Material selection exerts a direct and substantial influence on the total expenditure for chimney relining. The choice among available materials, such as stainless steel, aluminum, or clay/ceramic, dictates a significant portion of the overall investment. Stainless steel, renowned for its durability and corrosion resistance, typically presents the highest initial cost. Aluminum liners, suited for certain gas appliances, are less expensive but possess a shorter lifespan and limited applicability. Clay or ceramic options may offer a middle ground in terms of cost, but their fragility and susceptibility to cracking must be considered.

For instance, a homeowner opting for a stainless steel liner for a standard-sized chimney might incur a material cost two to three times greater than if selecting an aluminum alternative. However, the extended lifespan and enhanced safety features of stainless steel could translate to long-term cost savings by preventing premature liner failure and the associated repair expenses. The intended use of the chimney, the type of fuel burned, and local building codes further restrict the appropriate material choices, thereby narrowing the price range.

Ultimately, understanding the properties, limitations, and pricing of different liner materials is essential for making informed decisions that align with budgetary constraints and safety requirements. Neglecting to properly assess material options can result in either overspending on unnecessary features or compromising the long-term integrity and safety of the chimney system.

2. Chimney Height

Chimney height correlates directly with the total investment required for relining projects. As the vertical distance increases, a greater quantity of liner material is necessary, resulting in higher material costs. Furthermore, taller structures often present logistical challenges for installation, requiring specialized equipment and potentially increasing labor expenses. For example, a chimney exceeding thirty feet may necessitate scaffolding or the use of a crane to safely and efficiently install the liner.

The relationship between height and expense is not merely linear. Beyond a certain threshold, the complexity of the project amplifies costs disproportionately. Extended work hours, additional personnel, and specialized safety measures contribute to the overall increase. The height also influences the choice of materials, as heavier or more rigid liner components may be required to withstand structural stresses in taller chimneys, again impacting the budget.

In conclusion, chimney height is a significant determinant of the expense involved in relining. Accurate measurement and careful planning are essential for precise cost estimation. Homeowners should solicit detailed proposals from contractors, specifying material requirements, access strategies, and labor projections, to mitigate unforeseen expenses associated with challenging chimney heights.

3. Accessibility Issues

Accessibility issues directly influence the overall expense associated with chimney relining. Complexities in accessing the chimney system invariably translate to increased labor hours and potentially require specialized equipment, ultimately driving up project costs.

- Restricted Roof Access

Limited or difficult roof access due to steep slopes, obstacles, or structural impediments increases labor time. Contractors may require additional safety equipment, such as scaffolding or aerial lifts, to perform the relining safely and efficiently. These measures contribute directly to increased costs.

- Interior Obstructions

Obstructions within the home, such as narrow hallways, limited attic space, or finished interiors surrounding the chimney, impede the movement of materials and equipment. Disassembly and reassembly of interior elements may be necessary, adding significantly to the labor time and associated expenses.

- Chimney Location

Chimneys situated in hard-to-reach locations on the property, such as those integrated into the center of a house or positioned near adjacent structures, create logistical challenges. Maneuvering equipment and materials around obstacles requires additional care and time, influencing the labor component of the overall cost.

- Limited Parking or Staging Areas

Sites with restricted parking or limited staging areas necessitate longer transport distances for materials and equipment. This can increase the time required for each workday, potentially extending the project duration and, consequently, the total cost of relining.

These accessibility concerns serve as crucial variables in estimating the cost of chimney relining. Recognizing and proactively addressing these factors during the initial assessment process is essential for obtaining accurate quotes and mitigating potential budgetary overruns. Detailed discussions with contractors regarding site-specific challenges allow for realistic planning and budgeting, preventing unexpected cost increases as the project progresses.

4. Existing Damage

Existing damage is a pivotal factor influencing the expense of chimney relining. The presence of pre-existing structural defects, such as cracks, spalling, or water damage within the chimney system, necessitates additional preparatory work before a new liner can be installed. This remedial work directly impacts the overall cost. For instance, a chimney with extensive mortar joint deterioration may require tuckpointing or even partial reconstruction before the relining process can commence. Similarly, water damage can lead to the deterioration of surrounding building materials, potentially requiring further repairs to ensure structural integrity and prevent future leaks.

The nature and extent of existing damage dictate the scope of preparatory tasks. Minor cracks might only require patching with specialized mortar, while more severe structural compromises could necessitate the removal and replacement of damaged bricks or flue tiles. The presence of creosote buildup, a common byproduct of wood-burning appliances, also adds to the complexity. Excessive creosote can be difficult to remove and may necessitate professional cleaning or even the replacement of affected components. Ignoring pre-existing damage risks compromising the effectiveness and longevity of the new liner, potentially leading to premature failure and requiring even more costly repairs in the future. Real-life examples include homes where unchecked water infiltration has resulted in the collapse of chimney sections, leading to extensive reconstruction costs far exceeding the initial price of a simple relining.

In summation, a comprehensive assessment of existing damage is paramount in accurately estimating the expense of chimney relining. Addressing pre-existing issues is not merely an optional step but an integral component of ensuring the proper functioning and safety of the chimney system. Failure to do so can result in a flawed installation and potentially hazardous conditions. Therefore, a detailed inspection by a qualified professional is essential to identify and address all existing damage before proceeding with the relining process, mitigating long-term risks and safeguarding the investment.

5. Labor Costs

Labor costs constitute a significant portion of the overall expense to reline a chimney. The complexity of the task, the expertise required, and the duration of the project directly influence the labor component. Experienced chimney technicians are essential for ensuring proper installation and adherence to safety standards. Their hourly rates reflect the specialized skills and knowledge needed to perform the work effectively. A chimney relining project typically involves several stages, including inspection, preparation, liner installation, and final inspection. Each stage demands specific expertise and time, contributing to the cumulative labor expenses. For instance, the installation of a stainless steel liner, requiring precision cutting and fitting, demands more skilled labor and time compared to simpler lining methods.

Furthermore, geographical location impacts labor rates. Areas with a higher cost of living or greater demand for skilled trades often command higher hourly wages for chimney technicians. This regional disparity can lead to substantial differences in the overall cost of the project. Consider two identical chimney relining projects, one in a rural area and another in a metropolitan city. The labor expenses in the metropolitan area are likely to be notably higher due to increased labor costs. Moreover, unforeseen complications, such as unexpected structural issues or challenges related to chimney accessibility, can extend the project duration and consequently increase labor charges. These unforeseen issues often require additional labor hours to resolve, thereby pushing the final cost above the initial estimate.

In summary, the labor associated with relining a chimney is a critical factor in determining the total cost. Understanding the intricacies of the task, the expertise needed, and the potential for unforeseen issues allows for more accurate budgeting and informed decision-making. Homeowners should seek detailed quotes from reputable contractors, clearly outlining the scope of work and associated labor costs. Addressing potential challenges proactively and securing skilled technicians can help mitigate cost overruns and ensure a safe and efficient chimney relining process.

6. Regional Rates

Regional rates represent a geographically determined variable influencing the total expenditure for chimney relining. Cost variations stem from differences in labor costs, material availability, local regulations, and regional economic conditions. Higher labor costs in metropolitan areas, influenced by the prevailing wage rates and demand for skilled trades, often translate directly into increased project expenses. Similarly, material costs fluctuate based on transportation distances, local supply chains, and regional taxation policies. The complexity of local building codes and permitting requirements can also add to the overall expense, particularly if stringent regulations necessitate specialized materials or installation methods.

For example, a chimney relining project in a major urban center, such as New York City or San Francisco, can easily cost significantly more than a comparable project in a rural area of the Midwest. This discrepancy arises not only from higher labor and material costs but also from potential logistical challenges, such as limited access, parking restrictions, and stricter environmental regulations. Insurance costs for contractors often depend on location, impacting pricing structures too. Conversely, regions with lower costs of living and readily available resources tend to offer more competitive pricing for chimney relining services. Real-world data indicates that these regional rate disparities can account for a 20-50% difference in project costs, highlighting the importance of considering location-specific factors when budgeting.

In conclusion, regional rates are a critical component of the overall cost to reline a chimney. Variations in labor costs, material expenses, and regulatory requirements contribute to geographically diverse pricing structures. Understanding these regional nuances enables homeowners to make informed decisions, obtain accurate estimates, and effectively manage their budget. Ignoring regional rates can lead to inaccurate cost projections and unexpected financial burdens. Therefore, diligent research and consultation with local contractors are essential for navigating the complexities of regional pricing and securing a fair value for chimney relining services.

Frequently Asked Questions

The following questions address common concerns regarding the expenses associated with chimney relining projects. Accurate cost assessment is essential for budgeting and ensuring the safe operation of heating systems.

Question 1: What is the primary determinant of chimney relining expense?

Material selection exerts the most significant influence. Stainless steel liners, offering superior longevity, typically present higher upfront costs compared to aluminum or clay alternatives.

Question 2: How does chimney height affect the investment required?

Increased chimney height necessitates a greater quantity of liner material, directly increasing material costs. Furthermore, taller structures may demand specialized equipment and labor, amplifying overall expenses.

Question 3: Do accessibility challenges impact relining expenditures?

Yes. Restricted roof access, interior obstructions, and difficult chimney locations increase labor time and may require specialized equipment, leading to higher project costs.

Question 4: How does pre-existing damage influence the total cost?

Existing structural defects, such as cracks or water damage, necessitate additional preparatory work before liner installation. Remedial tasks like tuckpointing or partial reconstruction add to the overall expense.

Question 5: What role do regional rates play in chimney relining expenses?

Regional variations in labor costs, material availability, and local regulations significantly impact the final price. Metropolitan areas typically exhibit higher expenses than rural regions.

Question 6: Is professional inspection crucial before relining?

A thorough inspection is indispensable for accurately assessing the extent of existing damage and identifying potential challenges. This proactive approach helps prevent unforeseen costs and ensures a safe, effective relining process.

Understanding these key factors will facilitate more informed decision-making when planning and budgeting for a chimney relining project.

The next section will delve into strategies for minimizing costs while ensuring quality and safety.

Concerning the Expense of Chimney Relining

The evaluation reveals that the financial commitment associated with chimney relining is multifaceted, influenced by material selection, chimney height, accessibility, pre-existing damage, labor rates, and regional variations. Understanding these factors is crucial for accurate budgeting and ensuring the structural integrity and safe operation of the chimney system. Prudent decision-making during each stage of the process is vital.

Given the critical role a properly functioning chimney plays in home safety, it is recommended that homeowners prioritize thorough inspections and qualified professional services. Although cost considerations are important, the long-term safety and efficiency of the heating system should remain paramount, warranting a careful and informed approach to chimney relining projects. Proactive maintenance helps prevent escalating expenses.

![Chimney Sweep Cost: Average Cost to Clean a Chimney in [Year] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Chimney Sweep Cost: Average Cost to Clean a Chimney in [Year] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/01/th-216-300x200.jpg)