The expenditure associated with installing a flue liner within a chimney structure encompasses the materials, labor, and potentially permits required for the project. This investment is often necessary to ensure the safe and efficient venting of combustion byproducts from heating appliances. For example, a homeowner might incur this expense when converting from an older, less efficient furnace to a modern, high-efficiency model that requires a specific type of venting system.

Undertaking this improvement offers several advantages, including enhanced safety by preventing carbon monoxide leaks into the living space, improved appliance performance by ensuring proper draft, and prolonged chimney lifespan by protecting the masonry from corrosive combustion gases. Historically, older chimneys were constructed without liners, leading to deterioration and potential hazards; modern building codes often mandate liner installation for new construction and appliance upgrades to mitigate these risks.

The subsequent sections will detail the factors influencing the overall price, the various lining materials available, the typical installation process, and methods for obtaining accurate estimates to facilitate informed decision-making regarding this crucial home improvement.

Important Considerations Regarding Chimney Lining Expenses

The following points provide guidance on approaching the financial aspects of chimney relining to ensure a sound investment in home safety and heating efficiency.

Tip 1: Obtain Multiple Estimates: Secure quotes from at least three qualified chimney professionals. This comparative analysis will provide a realistic understanding of the prevailing market rates and help identify any outliers that may warrant further scrutiny.

Tip 2: Factor in Material Selection: The chosen liner material significantly impacts the overall expenditure. Stainless steel liners offer durability and compatibility with various fuels, while less expensive options, such as aluminum, may be suitable for specific gas appliances but less versatile overall.

Tip 3: Consider Chimney Accessibility: Difficult-to-access chimneys may require specialized equipment or techniques, increasing labor costs. Assess the chimney’s location and any potential obstructions that could complicate the installation process.

Tip 4: Investigate Potential Rebates and Incentives: Some utility companies or government programs offer financial incentives for energy-efficient home improvements, including chimney relining. Research available programs to potentially offset a portion of the expense.

Tip 5: Prioritize Certified Professionals: Employing a certified chimney sweep or technician ensures adherence to industry standards and local building codes. While professional services may represent a higher upfront investment, it mitigates the risk of improper installation and subsequent safety hazards.

Tip 6: Inspect for Necessary Repairs: Before lining, a thorough inspection may reveal masonry damage requiring remediation. Addressing these issues proactively prevents further deterioration and ensures the structural integrity of the chimney, avoiding more extensive and costly repairs later.

Careful consideration of these factors allows for informed budgeting and minimizes unforeseen expenditures when addressing chimney lining requirements. Proper planning and execution are essential for a successful and cost-effective project.

The article will now proceed to a detailed examination of the diverse materials used and an overview of the installation process.

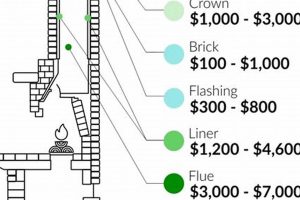

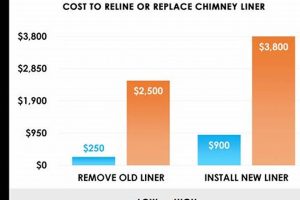

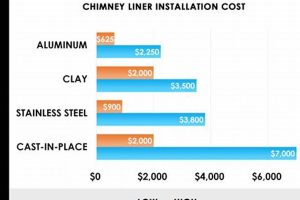

1. Material type.

The selection of lining material is a primary determinant in the expense associated with relining a chimney. Different materials offer varying degrees of durability, heat resistance, and compatibility with different fuel types, all of which directly correlate with their price point.

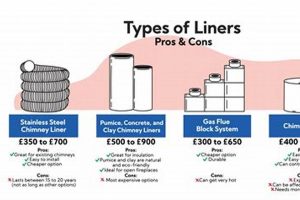

- Stainless Steel Liners

Stainless steel liners are generally the most expensive option due to their robust construction and versatility. They exhibit excellent resistance to corrosion and high temperatures, making them suitable for use with wood, gas, and oil-burning appliances. The higher material and manufacturing expenditures translate to a greater initial investment, but their extended lifespan and suitability for multiple fuel types can offer long-term cost benefits.

- Aluminum Liners

Aluminum liners represent a more economical choice, primarily used for venting specific gas appliances. Their lower material cost reflects their limited application, as they are not suitable for high-temperature or corrosive environments created by wood or oil combustion. Utilizing aluminum where stainless steel is required will require an early and unnecessary second lining project. While providing a lower initial investment, the limited application demands careful attention to intended use.

- Clay Tile Liners

Clay tile liners, while often present in older chimneys, are generally not the preferred choice for relining due to their susceptibility to cracking and spalling. Relining with clay tiles is less common due to their rigidity and the labor-intensive installation process involved. Due to this challenging installation, they may, in some instances, prove more expensive than alternatives, while simultaneously presenting lower performance characteristics.

- Cast-in-Place Liners

Cast-in-place liners involve pouring a specialized concrete-like material into the chimney flue to create a seamless lining. The cost of these systems can vary widely depending on the complexity of the installation, the required volume of material, and the labor involved in preparing and pouring the liner. They offer good insulating properties and can improve chimney draft, making them a mid-range expenditure that balances performance and.

The impact of material selection on the total expenditure is significant. While less expensive materials may offer initial cost savings, their limited applications and potentially shorter lifespans should be carefully weighed against the long-term benefits of more durable and versatile options like stainless steel. A thorough assessment of the appliance type, usage frequency, and chimney condition is essential to determine the most cost-effective lining material.

2. Chimney Height.

Chimney height is a significant factor directly influencing the overall expense of flue lining. As the vertical distance increases, the quantity of liner material required proportionally increases. This direct relationship presents a clear cause-and-effect dynamic: a taller chimney necessitates more liner, driving up material costs. The importance of chimney height within the cost equation cannot be overstated; it serves as a fundamental multiplier in calculating material needs. For instance, a 40-foot chimney will invariably require twice the liner material of a 20-foot chimney, with corresponding labor increases for installation.

Furthermore, practical considerations related to installation also impact the expenditure based on height. Higher chimneys often present greater accessibility challenges, requiring specialized equipment, such as scaffolding or lifts, to safely transport materials and personnel. The time required for installation also typically increases with height, resulting in elevated labor expenses. A historical building with a particularly tall and ornate chimney might require significantly more specialized care and time, resulting in costs that dwarf those of a standard residential chimney.

In conclusion, chimney height is an unavoidable and critical component in determining the final expenditure of lining a flue. It not only dictates the volume of materials needed but also contributes to labor costs through increased installation time and potential accessibility complexities. Understanding this relationship is paramount for accurate budget planning and for appreciating the overall scope of the project, linking directly to the broader theme of informed decision-making when undertaking chimney maintenance.

3. Accessibility Challenges

Accessibility challenges related to a chimney’s location and structural characteristics significantly influence the expenditure required for lining the flue. Difficult access invariably increases labor costs and may necessitate specialized equipment, thereby impacting the overall project budget.

- Restricted Access to the Chimney Crown

Limited or obstructed access to the chimney crown, the top portion of the structure, presents logistical complications for material delivery and technician maneuvering. Instances where the chimney is situated on a steep roof, surrounded by dense foliage, or adjacent to power lines require additional safety precautions and specialized equipment such as aerial lifts or scaffolding. These measures increase labor hours and equipment rental fees, directly elevating the expense of lining.

- Confined Interior Spaces

Interior accessibility challenges, such as narrow passageways, tight stairwells, or obstructions within the building, complicate the process of transporting lining materials and equipment to the chimney base. These constraints may necessitate manual handling of materials, increasing the time required for the project. Older homes with limited interior space often present these challenges, leading to higher labor expenses due to the increased physical effort and time investment.

- Chimney Obstructions and Structural Issues

Pre-existing chimney obstructions, such as collapsed flue tiles, debris accumulation, or significant structural damage, hinder the lining installation process. These issues require preliminary remediation efforts, including debris removal and structural repairs, before the liner can be installed. Discovering such problems during an inspection inevitably increases the overall project expense due to the added labor and material costs associated with addressing these unforeseen complications. The costs of demolition and disposal contribute to this increase.

- Remote Location

A chimney located in a remote or difficult-to-reach area will invariably increase the “cost to line chimney”. The added logistical challenges of transporting materials and personnel to the site increase both labor costs and transportation fees, making even a seemingly straightforward lining project more expensive.

In essence, accessibility challenges transform a standard chimney lining project into a more complex and labor-intensive undertaking. Understanding and anticipating these challenges through thorough pre-project inspections is crucial for accurate cost estimation and effective project management. Failure to account for these factors can lead to budget overruns and project delays.

4. Local labor rates.

Local labor rates exert a direct influence on the expenditure associated with chimney lining. These rates, which represent the hourly or project-based compensation for skilled technicians, are geographically variable, reflecting regional economic conditions, prevailing wage standards, and the supply and demand for qualified chimney professionals. Consequently, identical chimney lining projects undertaken in different locales can incur significantly divergent overall expenditures solely due to disparities in labor costs. For example, chimney lining performed in a metropolitan area with a high cost of living will generally involve higher labor rates compared to the same service performed in a rural region with a lower cost of living.

The practical significance of local labor rates extends beyond the direct monetary impact. Higher rates may incentivize skilled tradespeople to concentrate their services in specific areas, potentially leading to a shortage of qualified professionals in regions with lower prevailing wages. This scarcity, in turn, can further elevate labor costs due to increased demand and reduced competition. Moreover, the quality of workmanship can also be indirectly linked to labor rates. Technicians commanding higher compensation are often more experienced and possess advanced certifications, potentially leading to more efficient and reliable project execution. A failure to adequately research and factor in local labor rates can lead to significant budget miscalculations and project delays.

In summary, local labor rates are a fundamental determinant of the overall expenditure for chimney lining, reflecting regional economic conditions and impacting the availability and quality of skilled professionals. Comprehensive project planning necessitates thorough investigation into prevailing labor rates within the specific geographic area to ensure accurate cost estimation and informed decision-making, therefore preventing budget overruns. The importance of understanding their effect to the overall costs, also prevents potential exploitation.

5. Code compliance.

Adherence to local building codes and regulations directly influences the cost associated with chimney lining projects. Code compliance mandates specific materials, installation techniques, and safety standards designed to ensure the safe and efficient operation of the chimney system. Failure to comply with these regulations can result in rejected inspections, costly rework, and potential safety hazards, thereby increasing the overall financial burden. For example, local codes may require the use of stainless steel liners for certain fuel types or mandate specific clearances between the liner and combustible materials. These requirements directly impact material selection and installation procedures, thus affecting the final expenditure.

The importance of code compliance as a component of the “cost to line chimney” stems from its role in preventing future problems and ensuring the long-term integrity of the chimney system. While opting for non-compliant, less expensive materials or installation methods may offer short-term cost savings, the potential consequences of doing so can be significant. A real-life example would be the installation of an undersized liner, failing to meet draft requirements outlined in the code, and resulting in carbon monoxide backdraft into the living space, necessitating immediate and expensive remediation. Furthermore, insurance companies may deny claims related to chimney fires or carbon monoxide poisoning if the chimney system does not meet code requirements.

In conclusion, code compliance is not merely an optional consideration but an integral component of the overall cost associated with chimney lining. It dictates the materials and methods employed, ensures the safety and efficiency of the system, and protects homeowners from potential hazards and liabilities. Therefore, comprehensive project planning must incorporate a thorough understanding of local building codes and regulations to ensure accurate cost estimation and prevent unforeseen expenses stemming from non-compliance. Ignoring code requirements in an effort to save money typically leads to greater expenditure in the long run due to necessary repairs, legal repercussions, and potentially, safety hazards.

Frequently Asked Questions

This section addresses prevalent inquiries regarding the financial aspects of chimney lining, providing objective and factual responses to aid in informed decision-making.

Question 1: What factors primarily influence the cost to line chimney?

The primary cost drivers encompass the type of lining material selected, the chimney’s overall height, the accessibility of the chimney structure, local labor market rates, and compliance requirements with local building codes.

Question 2: Is stainless steel always the most expensive lining material?

While stainless steel generally presents a higher upfront expenditure compared to aluminum, its long-term durability and compatibility with various fuel types may offer a more cost-effective solution over time. Cast-in-place liners can, in some situations, present similar or higher total costs. The economic advantage depends on the specific application and lifespan expectations.

Question 3: Does chimney height significantly impact the overall expenditure?

Yes, chimney height has a direct and substantial impact. Increased height necessitates a greater quantity of lining material, directly increasing the material cost. Furthermore, taller chimneys may present accessibility challenges, potentially escalating labor expenses.

Question 4: How do accessibility challenges affect the “cost to line chimney?”

Limited or obstructed access to the chimney crown, confined interior spaces, and pre-existing chimney obstructions complicate the installation process. These factors may necessitate specialized equipment and additional labor, consequently increasing the overall project expenditure.

Question 5: Why do labor rates vary so widely geographically?

Labor rates are influenced by regional economic conditions, prevailing wage standards, and the supply and demand for qualified chimney professionals. Metropolitan areas with higher costs of living generally exhibit elevated labor rates compared to rural regions.

Question 6: What are the implications of non-compliance with local building codes?

Failure to adhere to local building codes can result in rejected inspections, costly rework, and potential safety hazards. Furthermore, insurance companies may deny claims related to chimney fires or carbon monoxide poisoning if the chimney system does not meet code requirements.

Understanding these common questions and their corresponding answers provides a solid foundation for accurately budgeting and planning a chimney lining project. The key is careful consideration of all relevant factors.

The following section provides guidance on finding qualified chimney professionals.

Cost to Line Chimney

The investigation into the cost to line chimney has revealed a multifaceted expense influenced by a confluence of factors. Material selection, chimney dimensions, accessibility, local labor markets, and regulatory compliance each contribute to the final expenditure. Prudent homeowners must meticulously evaluate these elements to develop an accurate budgetary projection. The long-term financial and safety implications of choosing cheaper, non-compliant options often outweigh any initial savings. Prioritizing a thorough chimney inspection and engaging qualified professionals are essential steps in managing this expense effectively.

Ultimately, the decision to invest in chimney lining represents a commitment to safety, structural integrity, and operational efficiency. While the initial expenditure may appear substantial, the long-term benefits of a properly lined chimney, including enhanced safety and prolonged appliance lifespan, contribute to a worthwhile home improvement. Homeowners are encouraged to view this investment not merely as an expense but as a critical measure for safeguarding property and ensuring the well-being of occupants, therefore protecting the long-term value and safety of the residence.

![Chimney Sweep Cost: Average Cost to Clean a Chimney in [Year] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Chimney Sweep Cost: Average Cost to Clean a Chimney in [Year] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/01/th-216-300x200.jpg)