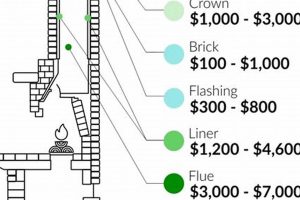

The expense associated with repairing the interior of a flue, the passage within a chimney that directs exhaust gases from a fireplace, furnace, or other appliance to the outside, is a significant consideration for homeowners. This expenditure encompasses labor, materials, and potentially inspection fees, and it varies based on several factors, including the chimney’s height, the type of liner used, and the complexity of the installation. As an example, a simple, straight chimney relining project using a flexible stainless steel liner would typically be less than a project involving a severely damaged chimney requiring extensive preparation and a more robust, rigid liner.

Maintaining the structural integrity of the flue is paramount for safety and efficiency. A compromised flue can lead to dangerous carbon monoxide leaks into the living space and reduce the efficiency of heating appliances. Historically, masonry chimneys were constructed without liners, but over time, the acidic nature of combustion byproducts degrades the mortar joints and brickwork. Relining addresses this deterioration, preventing further damage to the chimney structure and safeguarding the occupants of the building. This also ensures compliance with modern building codes, which often mandate properly lined chimneys.

To understand the total financial commitment, it is necessary to explore the different types of liners available, the factors influencing the labor fees involved, and the potential for hidden costs that might arise during the project. A detailed examination of these components will provide a comprehensive understanding of the overall financial implications of this important home maintenance task.

Essential Considerations for Flue Repair Expenses

Proper management of expenses for flue restoration projects necessitates informed decision-making. Homeowners should carefully consider the following points to ensure a cost-effective and structurally sound outcome.

Tip 1: Obtain Multiple Quotes: Secure estimates from at least three qualified chimney professionals. This allows for comparison of pricing structures, materials, and labor costs. Inquire about the scope of work included in each quote to avoid misunderstandings.

Tip 2: Understand Liner Types: Different liner materials, such as stainless steel, clay, and cast-in-place, have varying costs and suitability for different fuel types and chimney conditions. Research the appropriate liner type for the specific heating appliance and chimney structure.

Tip 3: Inspect the Chimney Thoroughly: Before obtaining quotes, arrange for a comprehensive chimney inspection by a certified professional. This inspection identifies existing damage and potential complications that may influence the overall project cost.

Tip 4: Factor in Labor Rates: Labor costs can significantly impact the total expense. Rates vary based on the complexity of the installation, the chimney’s location and accessibility, and the professional’s experience. Confirm the hourly rate and estimated labor hours upfront.

Tip 5: Address Structural Issues First: Prior to relining, address any structural deficiencies in the chimney, such as crumbling brickwork or damaged crowns. Neglecting these issues can compromise the integrity of the new liner and result in further expenses later.

Tip 6: Consider Long-Term Costs: Evaluate the long-term benefits of a high-quality liner. While initially more expensive, durable liners often provide superior protection and longevity, reducing the need for future repairs.

Tip 7: Check for Rebates and Incentives: Research available rebates or tax incentives for energy-efficient chimney improvements. These incentives can help offset a portion of the total project expenditure.

By carefully evaluating these factors, homeowners can make informed decisions regarding flue restoration expenses, ensuring a safe, efficient, and structurally sound chimney system.

In conclusion, proactive planning and diligent research are crucial steps in managing expenses related to this essential home maintenance task.

1. Liner material selection

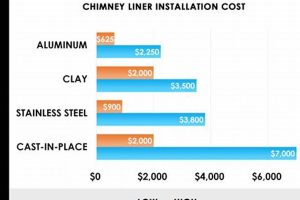

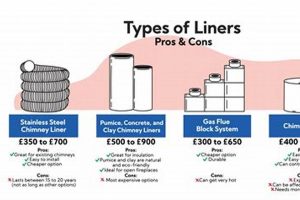

The selection of liner material exerts a direct and substantial influence on the expense associated with chimney relining. Different materials possess varying properties, durability, and installation complexities, which, in turn, translate into differential pricing. For instance, stainless steel liners, known for their corrosion resistance and adaptability to various fuel types, generally incur a higher initial cost compared to clay tile liners. This is due to the material cost and the often more intricate installation process. Conversely, while clay tile liners may be less expensive initially, their susceptibility to cracking and potential incompatibility with certain high-efficiency appliances can necessitate more frequent repairs or replacements, thereby affecting the long-term financial commitment.

The practical significance of understanding this connection lies in making informed decisions tailored to specific needs and budgets. Consider a homeowner using a wood-burning stove; stainless steel is highly recommended. Ignoring this and opting for a cheaper, unsuitable material could result in a premature failure of the liner, leading to carbon monoxide leaks, chimney fires, and expensive rectification work. Similarly, the choice between a rigid and flexible stainless steel liner impacts costs. Flexible liners, easier to install in chimneys with bends, might be less expensive than rigid liners, but rigid liners offer superior structural integrity and may be the only viable option for severely damaged chimneys.

In summary, liner material selection is not merely a technical detail but a crucial financial consideration. It is a multifaceted decision influenced by fuel type, chimney condition, local climate, and long-term cost projections. Careful assessment of these factors, coupled with professional guidance, ensures a safe, efficient, and cost-effective chimney relining solution, preventing potential problems related to the chimney and the expenses that can arise.

2. Chimney accessibility challenges

Chimney accessibility significantly influences the overall expense of relining projects. Difficult access to the chimney increases labor requirements, extends project duration, and potentially necessitates specialized equipment, all of which contribute to higher costs. The challenges arise from various factors associated with the chimney’s location and the surrounding environment.

- Roof Pitch and Height

Steep roof pitches and significant chimney heights pose considerable access challenges. Technicians require specialized safety equipment, such as harnesses and scaffolding, to work safely. The increased time spent setting up safety measures and maneuvering on a steep roof directly translates to higher labor costs. The complexity amplifies with multi-story homes, demanding more elaborate setups and specialized expertise.

- Obstructions and Landscaping

Overhanging trees, dense landscaping, and adjacent structures can obstruct access to the chimney. These obstructions may require removal or trimming, adding to the overall project expense. Limited space for maneuvering equipment and materials also increases labor time and the potential for property damage, which necessitates additional precautions and potentially higher insurance costs for the contractor, reflected in the final price.

- Interior Access Limitations

In some cases, access through the interior of the building is required, particularly for installing or inspecting liners. Limited interior space, narrow stairwells, or the presence of fragile decor can hinder access and prolong the project. This increases labor costs and may necessitate protective measures to prevent damage to the interior, which adds to the overall expenditure.

- Chimney Location and Design

Chimneys located on the sides or rear of a building, rather than on the gable end, often present greater access challenges. Intricate chimney designs, such as those with offsets or unusual flue configurations, also complicate the relining process. These complexities require more skilled technicians and specialized equipment, thereby increasing the associated costs.

In summary, the ease or difficulty of accessing a chimney is a critical determinant of the financial investment required for relining. Addressing accessibility challenges proactively through careful planning and selecting experienced professionals with the appropriate equipment and expertise is essential for managing project costs effectively. Ignoring these factors can lead to unforeseen expenses and potential complications during the relining process.

3. Local labor market rates

Local labor market rates are a primary determinant of the overall expense associated with chimney relining projects. The prevailing wages for skilled tradespeople, including chimney technicians, masons, and general laborers, directly influence the labor component of the project. In regions with high demand for skilled labor or a limited supply of qualified technicians, rates tend to be elevated, resulting in a greater financial investment for homeowners seeking chimney repairs. Conversely, areas with a lower cost of living or a larger pool of available workers may experience more competitive labor prices, thereby reducing the overall project expense. As an example, relining a chimney in a metropolitan area with a robust construction industry, such as New York City or San Francisco, typically incurs higher labor costs than a similar project in a rural area with lower prevailing wages. The practical significance of this understanding lies in the need for homeowners to obtain multiple quotes from local contractors to ascertain the prevailing market rates and make informed decisions.

The impact of labor costs extends beyond the hourly wages of technicians. It encompasses factors such as worker’s compensation insurance, payroll taxes, and overhead expenses borne by contracting companies. These indirect labor costs are invariably factored into the project’s overall pricing. Furthermore, specialized chimney relining techniques or the need for specific certifications and training can command higher labor rates. For instance, a technician certified by the Chimney Safety Institute of America (CSIA) may charge a premium for their expertise and specialized knowledge. The selection of a contractor with extensive experience and proven expertise can ultimately prove cost-effective by minimizing potential errors and ensuring a durable, long-lasting relining solution.

In conclusion, awareness of local labor market conditions is crucial for accurately estimating and managing expenses. Homeowners should actively research prevailing wage rates in their area, solicit quotes from multiple contractors, and inquire about the qualifications and experience of the technicians involved. This proactive approach enables informed decision-making and ensures that the chimney relining project is completed safely, effectively, and within a reasonable budget. Understanding the relationship between local labor rates and total costs is paramount to preventing overspending and securing a reliable, long-term solution for chimney maintenance.

4. Inspection and preparation

Inspection and preparation are integral components influencing the financial outlay associated with chimney relining. A thorough initial inspection directly impacts project expenses by revealing existing structural deficiencies, determining the appropriate relining method, and identifying potential complications that could arise during the process. For instance, an inspection might uncover hidden damage, such as deteriorated mortar joints or a cracked flue liner, necessitating additional repairs before relining can commence. Without this initial assessment, unforeseen problems may surface mid-project, leading to change orders and increased labor costs. As an example, failing to identify water damage beforehand could require extensive masonry repairs, significantly elevating the total cost.

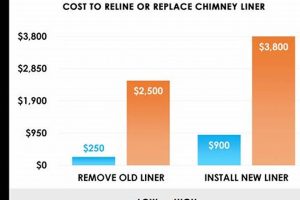

Preparation work, which follows the inspection, includes cleaning the chimney flue, removing debris, and addressing any structural issues identified. The scope and complexity of preparation tasks directly correlate with the final cost. A severely clogged chimney may require specialized cleaning equipment and additional labor hours, increasing the overall project expenditure. Proper preparation ensures that the new liner is installed correctly and functions optimally, preventing future problems and extending its lifespan. Neglecting necessary preparation, such as failing to remove loose debris, can compromise the liner’s integrity and necessitate premature replacement, resulting in avoidable costs.

In conclusion, the investment in a comprehensive inspection and meticulous preparation is a cost-saving measure in the long run. By identifying potential issues upfront and addressing them proactively, homeowners can minimize the risk of unforeseen expenses and ensure a durable, effective chimney relining solution. Skimping on these preliminary steps often results in higher overall costs due to subsequent repairs or premature liner failure, underscoring the critical importance of a thorough inspection and diligent preparation in managing the financial aspects of chimney relining.

5. Chimney height & diameter

The physical dimensions of a chimney, specifically its height and diameter, are fundamental determinants of the overall expense associated with relining procedures. These measurements directly influence the quantity of materials required, the complexity of the installation process, and the labor hours involved, thereby significantly impacting project costs.

- Material Requirements

Chimney height directly correlates with the amount of liner material needed. A taller chimney necessitates a longer liner, increasing material costs. Similarly, the chimney’s diameter dictates the liner’s cross-sectional area, further affecting material requirements. Larger diameters demand more material per unit length, adding to the overall expense. For example, a thirty-foot chimney with a large flue will require significantly more liner material than a fifteen-foot chimney with a smaller diameter, resulting in a substantially higher material cost.

- Installation Complexity

Taller chimneys often present greater installation challenges. Reaching the top of the chimney may require specialized equipment, such as scaffolding or lifts, increasing labor costs and potentially necessitating additional permits. The height also complicates the process of lowering the liner into the flue, demanding more time and skilled labor. Wider diameters, while seemingly less challenging, can present their own difficulties, particularly when maneuvering rigid liners or working in confined spaces.

- Labor Hours

The combined effect of chimney height and diameter directly impacts the labor hours required for relining. Increased material handling, more complex installation procedures, and the need for specialized equipment all contribute to longer project durations. The time spent setting up safety equipment, maneuvering materials, and ensuring proper liner alignment scales with the chimney’s dimensions. Consequently, taller or wider chimneys typically incur higher labor costs due to the increased time and effort involved.

- Liner type suitability

The chimney’s dimensions can also dictate which type of liner is suitable. A very narrow or offset chimney may only accommodate a flexible liner, potentially increasing material costs depending on its composition. Conversely, a very wide or tall chimney might necessitate a more expensive, rigid liner for structural integrity and code compliance. A mismatch between liner type and chimney dimensions can lead to premature failure, which incurs higher maintenance costs or even a complete replacement.

In conclusion, the height and diameter of a chimney are not merely physical attributes but key financial factors in relining projects. Accurate assessment of these dimensions is crucial for estimating material needs, planning the installation process, and determining the overall cost. Neglecting to consider these factors can result in inaccurate cost projections and potentially lead to budget overruns or compromised relining quality, emphasizing the importance of careful evaluation of chimney dimensions in managing relining expenses.

6. Code compliance requirements

Code compliance requirements exert a direct and often substantial influence on the financial commitment associated with chimney relining. Building codes and safety regulations mandate specific standards for chimney construction and maintenance, and these standards invariably impact the materials, labor, and inspection processes involved in relining projects. Failure to adhere to these codes can result in failed inspections, fines, and potentially hazardous conditions, making code compliance a non-negotiable aspect of the relining process. For example, many jurisdictions require stainless steel liners for certain fuel types, even if cheaper alternatives exist. Choosing a non-compliant material, to save initial costs, would necessitate complete replacement later, increasing the total expenditure. Similarly, codes may dictate minimum liner thicknesses or insulation requirements, directly affecting material costs. The practical significance of understanding this connection lies in recognizing that code compliance is not an optional add-on but an integral cost component of any chimney relining project.

Furthermore, code compliance may necessitate additional work beyond the basic relining process. For instance, local regulations could require a chimney to be brought up to current height standards, demanding masonry work that adds to the overall expense. Similarly, inspections mandated by code enforcement agencies may uncover existing structural deficiencies that must be addressed before relining can proceed. These unexpected repairs increase costs, but they are essential for ensuring the chimney’s safety and compliance with legal requirements. The scope of code-related requirements varies by jurisdiction, underscoring the importance of consulting with local building officials or certified chimney professionals to understand the specific regulations governing chimney relining in a given area. Ignoring this step can result in significant financial penalties and potentially dangerous consequences.

In conclusion, adherence to code compliance requirements is a critical, unavoidable cost driver in chimney relining projects. These requirements, encompassing material specifications, installation standards, and inspection protocols, directly affect the financial investment required. While adherence to these standards may increase upfront expenses, it ensures a safe, efficient, and legally compliant chimney system, preventing future complications and potential liabilities. Therefore, understanding and incorporating code compliance requirements into the project’s planning and budgeting phases is essential for a successful and cost-effective chimney relining outcome, avoiding potential costly rework to the chimney in the long run.

Frequently Asked Questions

The following questions and answers provide insights into common concerns related to the financial aspects of chimney relining projects. These aim to clarify uncertainties and inform decision-making.

Question 1: What factors primarily influence the expense?

The cost is primarily influenced by the type of liner material selected, chimney height and diameter, accessibility challenges, local labor market rates, and code compliance requirements. Inspection and preparation work also contribute significantly to the overall price.

Question 2: Is it possible to provide an approximate cost range for chimney relining?

Providing a precise estimate without specific information is not feasible. However, based on industry averages, a typical chimney relining project can range from several hundred to several thousand dollars, depending on the aforementioned factors. Obtaining quotes from qualified professionals is essential for an accurate assessment.

Question 3: What are the common types of liners, and how do their costs compare?

Common types include stainless steel, clay tile, and cast-in-place liners. Stainless steel liners generally incur a higher initial cost due to their durability and versatility. Clay tile liners are typically less expensive but may not be suitable for all applications. Cast-in-place liners offer a durable and custom solution but are often more expensive due to the specialized installation process.

Question 4: Can chimney relining expenses be reduced?

Cost reduction strategies include obtaining multiple quotes, comparing liner materials, addressing structural issues before relining, and inquiring about potential rebates or incentives. Careful planning and proactive maintenance can also minimize long-term expenses.

Question 5: What are the consequences of neglecting chimney relining?

Neglecting chimney relining can lead to various hazards, including carbon monoxide leaks, chimney fires, and structural damage to the chimney. Failure to maintain a properly lined chimney can also result in code violations and increased insurance premiums.

Question 6: How to choose a qualified chimney professional?

Choose a professional that is certified by a reputable organization, such as the Chimney Safety Institute of America (CSIA). Verify insurance and licensing, and request references from previous clients. A thorough inspection and a detailed, written quote are essential for ensuring a successful project.

Understanding the cost and value of maintaining a safe and functional chimney is essential for home safety and long-term home ownership.

The subsequent section will delve into the long-term cost benefits of chimney maintenance.

The preceding exploration has illuminated the multifaceted nature of the expense associated with repairing chimney flues. Understanding the influences of liner materials, accessibility, labor rates, inspection, chimney dimensions, and regulatory compliance is paramount for effective budgetary planning. A comprehensive assessment of these components allows homeowners to prepare for the financial implications of this vital maintenance task.

Proper maintenance of the chimney structure safeguards property and well-being. Addressing potential problems, and understanding the expense related to lining is an important step. By understanding key components, homeowners are empowered to make well-informed choices, ensuring both safety and economic prudence in this crucial home maintenance endeavour.

![Chimney Sweep Cost: Average Cost to Clean a Chimney in [Year] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Chimney Sweep Cost: Average Cost to Clean a Chimney in [Year] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/01/th-216-300x200.jpg)