The expense associated with the installation or replacement of ceramic flue lining in a chimney is a significant consideration for homeowners. This outlay encompasses materials, labor, and potentially, permitting fees depending on local regulations. The amount can vary based on chimney height, diameter, accessibility, and geographic location. For instance, a straightforward relining project on a single-story home will generally be less expensive than relining a taller chimney with limited access.

Employing such liners is crucial for safety and structural integrity. These liners protect the chimney structure from corrosive byproducts of combustion, preventing deterioration and potential fire hazards. Historically, clay was a primary material for flue lining due to its heat resistance and relative affordability. Its usage has contributed significantly to maintaining safer and more durable chimney systems over time.

This information sets the stage for a more in-depth discussion regarding the various factors that influence pricing, exploring different installation methods, and outlining crucial considerations for homeowners when budgeting for this essential home maintenance task. A detailed examination of cost variables, alternative lining materials, and long-term savings is warranted for a thorough understanding.

Important Considerations Regarding Ceramic Flue Expense

Prudent management of funds allocated to chimney maintenance necessitates a comprehensive understanding of cost factors. Careful planning and informed decision-making are vital when addressing issues related to ceramic flue systems.

Tip 1: Obtain Multiple Quotes: Secure estimates from several qualified chimney professionals. Variations in pricing may reflect differing labor rates, material choices, or project assessments. Comparative analysis is crucial.

Tip 2: Assess Chimney Condition Thoroughly: Prior to initiating any work, a certified chimney sweep should conduct a detailed inspection. Identifying existing damage informs the scope of the repair and prevents unforeseen expenses.

Tip 3: Understand Material Grades: Ceramic liners are available in varying grades and thicknesses. Select materials appropriate for the type of fuel burned, ensuring longevity and optimal performance. Inquire about ASTM standards.

Tip 4: Verify Contractor Credentials: Ensure the chosen contractor possesses the requisite licenses, insurance, and certifications. Competent professionals provide quality workmanship and adhere to safety regulations.

Tip 5: Inquire About Warranty Coverage: Review warranty terms offered by both the manufacturer and the installer. Comprehensive coverage safeguards against material defects and installation errors.

Tip 6: Consider Accessibility Challenges: Chimney access significantly impacts labor costs. Complex accessibility issues, such as steep roofs or obstructions, increase project complexity and associated expenses.

Tip 7: Factor in Permitting Costs: Research local building codes and permitting requirements. Failure to obtain necessary permits can result in fines and project delays. Include these costs in the overall budget.

These considerations facilitate informed decisions, enabling homeowners to optimize the allocation of funds and ensure the safe and efficient operation of their chimney systems. By diligently researching and planning, expenditure can be managed effectively.

The preceding information provides a foundation for further exploration of alternative flue lining materials and long-term maintenance strategies. A proactive approach to chimney care minimizes potential hazards and maximizes the lifespan of the system.

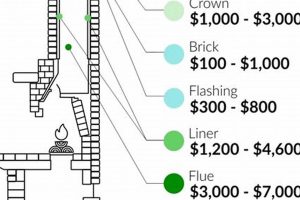

1. Material acquisition expense

Material acquisition expenditure constitutes a foundational element within the overall structure. The cost of securing the ceramic flue liners directly influences the total outlay for a chimney relining project, serving as a primary determinant of the overall financial commitment.

- Liner Grade and Quality

The grade and quality of ceramic liners significantly impact material acquisition expenditure. Higher-grade liners, often boasting enhanced durability and heat resistance, command a premium. Selection of lower-grade materials may reduce initial costs, but could lead to premature failure and necessitate subsequent replacement. Example: Choosing a liner rated for high-efficiency appliances incurs a greater initial expense compared to a standard liner.

- Liner Dimensions and Quantity

Liner dimensions and the quantity required directly correlate with material acquisition expenditure. Larger diameter liners, used for accommodating specific appliance venting requirements, inherently cost more. The height of the chimney dictates the total linear feet of liner necessary, further influencing material outlay. Example: A taller chimney requires more liner sections, escalating the expense of materials procurement.

- Supplier and Geographic Location

The chosen supplier and geographic location contribute to variances in material acquisition expenditure. Different suppliers may offer varying price points based on volume discounts, shipping costs, and inventory levels. Geographic location impacts transportation costs and regional pricing fluctuations. Example: Obtaining liners from a local supplier may reduce shipping costs compared to ordering from a distant vendor.

- Market Dynamics and Availability

Prevailing market dynamics and liner availability influence the material expenditure. Fluctuations in raw material prices, seasonal demand, and supply chain disruptions can all impact liner pricing. Limited availability of specific liner sizes or grades may drive up acquisition expenses. Example: Increased demand during peak heating season may lead to higher liner prices and potential delays in procurement.

In synthesis, effective management of ceramic material acquisition expenditure hinges on a comprehensive understanding of liner grade, dimensions, supplier options, and prevailing market conditions. Prioritization of quality, accurate dimensioning, and strategic sourcing can optimize expenditure and ensure long-term chimney system integrity. Neglecting these factors can inadvertently escalate the expenses.

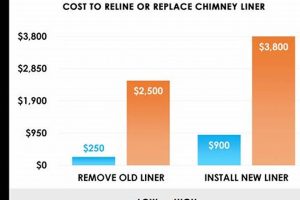

2. Installation labor charges

Installation labor charges constitute a significant portion of the overall expenditure for ceramic flue liner replacement or installation. These charges directly correlate with the complexity and duration of the project, encompassing tasks such as chimney preparation, liner insertion, and system sealing. Increased project complexity inevitably leads to elevated labor costs. For example, a chimney requiring extensive cleaning or repair prior to liner installation will accrue higher labor charges than one in relatively good condition.

The expertise and certification of the installation team also influence these charges. Certified chimney professionals, equipped with specialized knowledge and tools, often command higher rates due to their proven competence and adherence to safety standards. Employing unqualified or inexperienced individuals may appear cost-effective initially, but could result in substandard workmanship, necessitating costly repairs or even complete system replacement down the line. Furthermore, specialized techniques, such as the use of scaffolding or roping systems for chimneys in difficult-to-access locations, contribute to increased labor costs.

In conclusion, mindful consideration of labor expenses and their relationship with project intricacies is crucial. Evaluating contractor qualifications, assessing the required preparation work, and understanding potential access challenges facilitate more accurate budgeting. Prioritizing skilled labor ensures proper installation, thereby maximizing the lifespan of the liner and mitigating long-term expenses related to repairs or premature replacement. A comprehensive understanding of these factors empowers homeowners to make well-informed decisions regarding chimney maintenance and cost management.

3. Chimney accessibility impact

Chimney accessibility exerts a considerable influence on the ultimate outlay associated with ceramic flue lining endeavors. Physical access to the chimney structure, encompassing factors such as roof pitch, height, obstructions, and surrounding terrain, plays a pivotal role in determining the labor intensiveness of the project and, consequently, the overall expense.

- Roof Pitch and Height

Steep roof pitches and considerable chimney heights increase the difficulty and risk associated with accessing the chimney. Specialized equipment, such as scaffolding or aerial lifts, may be required to ensure worker safety, adding to the project cost. Furthermore, the time needed to navigate and work on a steep or high roof increases labor hours and associated charges. Example: A two-story home with a 45-degree roof pitch will likely incur higher labor costs compared to a single-story home with a low-sloped roof.

- Obstructions and Landscaping

Overhanging trees, power lines, and dense landscaping around the chimney base impede access, requiring additional time and effort to clear the work area. Obstructions may necessitate the manual transport of materials and equipment, further increasing labor hours. Example: A chimney surrounded by mature trees requiring extensive trimming to allow safe access will incur higher labor costs.

- Chimney Location and Design

The chimney’s location on the roof, proximity to property lines, and architectural design can impact accessibility. Chimneys located near the edge of a roof or with complex architectural features require specialized access techniques and precautions, leading to increased labor charges. Example: A chimney nestled between two dormers on a complex roofline poses greater accessibility challenges compared to a chimney situated on a clear, open section of the roof.

- Interior Access Limitations

Limited interior access to the chimney base, such as in finished basements or homes with intricate ductwork, can complicate liner installation. Restricted access may necessitate the use of specialized tools or require the demolition and reconstruction of interior structures to facilitate liner insertion, significantly increasing project expense. Example: A chimney running through a fully finished basement with limited crawl space access will likely incur higher labor costs than a chimney accessible from an unfinished basement.

Consequently, a comprehensive evaluation of chimney accessibility is essential during the project planning phase. Understanding the specific access challenges allows for accurate cost estimation and the selection of appropriate equipment and techniques. Neglecting to assess accessibility can lead to unexpected expenses and project delays. Therefore, homeowners should ensure that contractors thoroughly evaluate accessibility limitations before providing a binding quote.

4. Regional pricing variances

Geographic location is a significant determinant of the overall expense associated with ceramic flue liner projects. Regional pricing variances stem from several interconnected factors, each contributing to fluctuations in both material and labor expenditure. The cost of raw materials, such as clay, varies depending on proximity to production centers and transportation infrastructure. Regions with readily accessible clay deposits or efficient transportation networks often benefit from lower material costs, which subsequently influence the price of the liners themselves. Furthermore, local demand and supply dynamics can exacerbate these pricing differences. Areas with a high concentration of older homes relying on traditional chimney systems may experience increased demand for ceramic liners, potentially driving prices upward. Conversely, regions with newer housing stock or a greater prevalence of alternative heating systems may see lower demand and corresponding price reductions. The impact of these variances should not be underestimated, as they can contribute significantly to the overall project expenditure.

Labor costs also exhibit significant regional variations, influenced by factors such as the local cost of living, prevailing wage rates for skilled tradespeople, and the level of competition among chimney service providers. Areas with a higher cost of living, such as major metropolitan centers, typically command higher labor rates compared to rural or suburban locations. Additionally, the presence of stringent licensing requirements or specialized training programs for chimney technicians can further impact labor costs. In some regions, labor unions may play a significant role in setting wage standards, further influencing the overall expense of chimney services. Practical examples abound; for instance, a ceramic flue liner project in New York City is likely to incur significantly higher labor costs than a comparable project in a smaller town in the Midwest.

In summary, regional pricing variances represent a crucial consideration when budgeting for ceramic flue liner installation or replacement. Variations in material costs, labor rates, and local market dynamics contribute to significant differences in project expenditure across different geographic areas. Homeowners should obtain multiple quotes from local chimney service providers to gain a realistic understanding of prevailing prices in their region. Failure to account for these regional variations can lead to inaccurate budgeting and potentially derail the project. Understanding these dynamics enables homeowners to make informed decisions and effectively manage the financial implications of chimney maintenance.

5. Code compliance expenses

Compliance with local building codes and safety regulations introduces a series of expenses directly impacting the overall expenditure for ceramic flue liner projects. These costs are not optional; adherence to established standards is mandatory to ensure the safe and efficient operation of the chimney system, avoiding potential hazards and legal repercussions.

- Permitting Fees

Most municipalities mandate the acquisition of building permits prior to commencing chimney work. Permitting fees vary widely depending on location and project scope, representing a direct cost component. Failure to obtain necessary permits can result in fines, project delays, and potential legal liabilities. For example, a homeowner undertaking liner replacement without a permit may face stop-work orders and costly remediation efforts.

- Inspection Costs

Local building codes often require inspections at various stages of the chimney work to verify compliance with safety standards. Inspection fees add to the overall expenditure. These inspections ensure proper liner installation, adequate clearances from combustible materials, and correct venting configurations. Instances of non-compliance identified during inspections necessitate corrective actions, further increasing project expenditure.

- Material Standards Compliance

Building codes typically specify minimum material standards for flue liners, including requirements for heat resistance, durability, and chemical compatibility with combustion byproducts. Compliance with these standards may necessitate the selection of higher-grade liners, increasing material costs. The use of substandard or non-compliant materials can lead to premature liner failure, safety hazards, and code violations.

- Labor for Code-Required Modifications

Existing chimney systems may require modifications to meet current code requirements. This can include alterations to flue size, chimney height, or the installation of safety devices such as spark arrestors or cleanout doors. Labor costs associated with these code-required modifications contribute to the overall project expenditure. Neglecting to address code deficiencies can jeopardize safety and result in enforcement actions.

In conclusion, code compliance expenses are an integral and unavoidable aspect of ceramic flue liner projects. Permitting fees, inspection costs, material standards compliance, and labor for code-required modifications all contribute to the overall expenditure. While these expenses may seem burdensome, they are essential for ensuring safety, preventing code violations, and maintaining the long-term integrity of the chimney system. Failure to prioritize code compliance can result in significant financial penalties and jeopardize the well-being of occupants.

Frequently Asked Questions

The following section addresses common inquiries regarding the financial implications associated with the installation, repair, or replacement of ceramic chimney liners. It aims to provide clarity and factual information to assist homeowners in making informed decisions.

Question 1: What is the average range for a professional ceramic flue liner installation?

The typical outlay can fluctuate substantially based on chimney dimensions, accessibility constraints, geographic location, and the prevailing labor rates within a particular region. Minor repairs or relining of shorter flues generally result in decreased expenditures compared to relining a taller, more complex masonry structure. Obtaining multiple estimates from qualified contractors is recommended.

Question 2: Does chimney height materially affect the overall ceramic flue expense?

The vertical dimension is a critical factor. Greater heights necessitate larger quantities of lining material and increased labor hours for installation. Specialized equipment, such as scaffolding or aerial lifts, may be required for taller chimneys, further elevating project expense. This contrasts with relatively easier single-story projects.

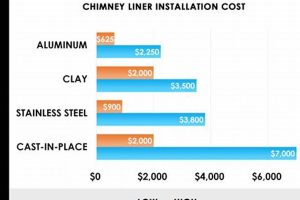

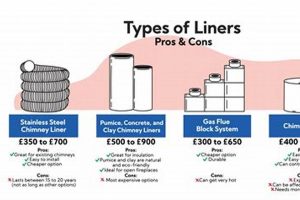

Question 3: Are there discernible pricing differences amongst various ceramic liner types?

While ceramic liners are generally uniform in material composition, variations in diameter and thickness influence the acquisition expense. Larger flue diameters and thicker liner walls tend to command higher prices. Furthermore, some specialized liners, designed for specific fuel types or high-efficiency appliances, may carry a premium.

Question 4: How do regional labor rates impact a ceramic flue liner project’s overall expenditure?

Labor rates for skilled tradespeople, including chimney technicians, exhibit significant regional variations. Areas with a higher cost of living or a greater demand for skilled labor typically have higher labor rates. Urban centers often present higher charges than rural areas. These differences contribute substantially to the final project cost.

Question 5: What role does chimney accessibility play in determining project costs?

Physical accessibility to the chimney significantly impacts labor hours and the need for specialized equipment. Steep roof pitches, overhanging obstructions, and difficult terrain all increase the complexity of the project and, consequently, the overall expenditure. Restricted access to the chimney base also increases costs.

Question 6: What are some often-overlooked factors that impact the final ceramic flue expense?

Permitting fees, pre-existing chimney damage requiring repair, and code compliance upgrades are often underestimated. Thorough chimney inspections are essential to identify these potential cost drivers early in the project planning phase. Homeowners should factor in potential unforeseen structural needs.

Understanding these factors enables homeowners to better anticipate and manage the financial investment associated with maintaining a safe and efficient chimney system. Prudent planning and informed decision-making are crucial for optimizing expenditure.

The subsequent section explores alternative chimney lining materials and their respective financial implications, providing a broader perspective on chimney maintenance options.

Clay Chimney Liner Cost

The preceding discussion has illuminated the various factors influencing the expenditure associated with clay chimney liners. Material quality, installation complexity, regional economic conditions, and code compliance requirements each contribute significantly to the final project expense. A comprehensive understanding of these elements is crucial for homeowners seeking to make informed decisions regarding chimney maintenance and safety. Neglecting to account for these variables can lead to inaccurate budgeting and potentially compromise the integrity of the chimney system.

Ultimately, prudent investment in chimney maintenance is an investment in the long-term safety and structural integrity of a home. Homeowners are strongly encouraged to consult with qualified chimney professionals to conduct thorough inspections and obtain accurate cost estimates tailored to their specific needs. Proactive measures are paramount to preventing costly repairs and ensuring the continued safe operation of the chimney system. Prioritizing professional expertise ensures long-term home well-being.

![Chimney Sweep Cost: Average Cost to Clean a Chimney in [Year] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Chimney Sweep Cost: Average Cost to Clean a Chimney in [Year] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2026/01/th-216-300x200.jpg)