The act of dismantling and taking away a structure designed for venting smoke and combustion gases from a fireplace, furnace, or other heating appliance, along with any associated offerings constitutes a specialized undertaking. This often involves the physical deconstruction of brick, stone, or metal components, followed by the proper disposal of resulting debris. The work can range from partial demolition above the roofline to complete elimination down to the foundation level.

This action offers several advantages, including increasing usable interior space, improving a building’s aesthetic appearance, and potentially eliminating safety hazards associated with deteriorating structures. Historically, such structures were essential for heating homes, but with the advent of modern heating systems, their functional necessity has diminished, leading some property owners to consider their removal. This decision can also enhance property value by addressing issues like water leaks or structural instability often linked to aged or poorly maintained flues.

The subsequent sections will delve into crucial aspects of this process, exploring methods employed, safety considerations paramount during execution, and the regulatory framework that governs such alterations to a building’s structure. Furthermore, the cost factors influencing pricing and choosing a qualified contractor for successful completion will be examined.

Essential Considerations for Chimney Dismantling

Proper planning and execution are vital when undertaking the dismantling of a flue. The following guidelines provide critical information for homeowners considering this type of project.

Tip 1: Conduct a Thorough Inspection: Before commencing any work, a comprehensive assessment of the entire structure should be performed. This includes checking for structural weaknesses, asbestos contamination (particularly in older structures), and the presence of any nesting animals. Addressing these issues proactively can prevent complications and ensure worker safety.

Tip 2: Obtain Necessary Permits: Local building codes often require permits for structural modifications, including flue dismantling. Failure to secure the appropriate permits can result in fines and delays. Contacting the local building department before beginning work is essential to ensure compliance with all applicable regulations.

Tip 3: Secure the Work Area: Establishing a safe work zone is crucial. This involves roping off the area below the structure, using safety netting to catch falling debris, and ensuring that all workers wear appropriate personal protective equipment (PPE), including hard hats, safety glasses, and dust masks.

Tip 4: Carefully Plan the Demolition Process: The dismantling process should be carefully planned, taking into account the structure’s material composition and height. For brick or stone structures, working from the top down, removing one course at a time, is generally the safest approach. For metal flues, sections can be carefully disconnected and lowered to the ground.

Tip 5: Properly Dispose of Debris: Demolition debris must be disposed of in accordance with local regulations. This may involve separating materials for recycling or transporting them to a designated landfill. Proper disposal is essential for environmental protection and can prevent legal issues.

Tip 6: Consider Interior Modifications: The removal of a chimney often necessitates interior modifications, such as patching walls or ceilings. Planning for these repairs in advance can minimize disruption and ensure a seamless transition.

Tip 7: Consult with Professionals: While some homeowners may be tempted to undertake this project themselves, consulting with experienced contractors is highly recommended. Professionals possess the knowledge, skills, and equipment necessary to complete the job safely and efficiently. They can also provide valuable advice on structural considerations and regulatory compliance.

Adhering to these considerations will help ensure a safe, efficient, and compliant removal project, minimizing risks and maximizing positive outcomes.

The subsequent sections will provide further details concerning the costs associated with chimney dismantling and the selection of a reputable contractor.

1. Structural Integrity Assessment

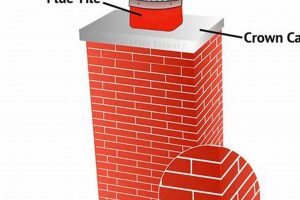

A structural integrity assessment is a foundational component of any reputable service focused on dismantling flues. The rationale is straightforward: these structures, by nature of their exposure to the elements and the corrosive byproducts of combustion, are prone to deterioration over time. Mortar joints weaken, bricks crumble, and the overall stability can be significantly compromised. A professional assessment identifies these vulnerabilities before any physical work begins. This proactive approach is not merely a best practice; it’s a critical safety measure. Failure to accurately gauge the structural condition can lead to unforeseen collapses during the dismantling process, endangering workers and potentially causing damage to surrounding property. For instance, a seemingly sound flue might have internal cracking or water damage hidden beneath the surface. Without a proper inspection, these weaknesses could be missed, leading to a sudden and uncontrolled failure during demolition.

The assessment itself typically involves a visual inspection of the exterior and interior (where accessible) of the flue. This often includes evaluating the condition of the brickwork, mortar joints, crown, and flashing. In some cases, more advanced techniques, such as borescope inspections or thermal imaging, may be employed to detect hidden problems. The findings of this assessment directly inform the dismantling strategy. If significant structural issues are identified, a more cautious and controlled demolition approach is warranted. This might involve using specialized equipment, such as hydraulic jacks or shoring systems, to provide additional support during the process. Conversely, if the flue is found to be in relatively good condition, a more straightforward dismantling approach may be feasible. However, even in these cases, safety protocols must be rigorously followed to prevent accidents.

In summary, the connection between structural integrity assessments and chimney dismantling is one of cause and effect and a critical factor in safety and efficiency. The assessment identifies existing problems (the cause), which then dictate the appropriate dismantling methods (the effect). Neglecting this initial step significantly increases the risk of accidents and structural damage. Therefore, a thorough structural integrity assessment is not just a recommended practice; it is an indispensable element of a responsible and professional removal strategy. Ignoring this crucial step can have severe consequences, undermining the entire project and potentially endangering lives and property.

2. Permitting and Compliance

The removal of a flue is rarely a straightforward demolition task; it often necessitates strict adherence to local building codes and regulations. “Permitting and compliance” represents a critical component of a “chimney removal service” because these structures are integral to a building’s structural integrity and fire safety systems. Failure to obtain the necessary permits before commencing work can result in significant fines, project delays, and even legal action from local authorities. The rationale for these regulations stems from the potential impact on the building’s structural stability and fire safety characteristics following the flue’s elimination. For example, removing a flue may require alterations to the roof structure or the installation of alternative venting systems, all of which must meet specific safety standards.

The permitting process typically involves submitting detailed plans outlining the proposed work, including the method of dismantling, structural modifications, and disposal of debris. These plans are then reviewed by local building inspectors to ensure compliance with relevant codes. This review process can be lengthy, requiring multiple revisions and approvals. Compliance extends beyond simply obtaining a permit; it also entails adhering to the conditions outlined in the permit. This may include specific requirements for dust control, noise mitigation, and the protection of neighboring properties during the dismantling process. Some municipalities also require inspections at various stages of the project to ensure that the work is being performed in accordance with the approved plans.

In conclusion, “permitting and compliance” are not mere bureaucratic hurdles but essential elements of a responsible flue dismantling operation. They safeguard the structural integrity of the building, protect the safety of workers and occupants, and ensure that the work is performed in an environmentally responsible manner. Neglecting these aspects can lead to severe consequences, underscoring the importance of engaging a “chimney removal service” that is well-versed in local regulations and committed to full compliance. The long-term benefits of adherence to permitting requirements far outweigh the short-term convenience of circumventing them.

3. Asbestos Identification and Abatement

The presence of asbestos in flues, particularly in older structures built before the 1980s, establishes a direct link between “asbestos identification and abatement” and “chimney removal service”. Asbestos, a known carcinogen, was commonly used in flue construction materials due to its heat-resistant properties. Therefore, any activity involving the disturbance or demolition of such a structure carries a significant risk of releasing asbestos fibers into the air, posing a serious health hazard to workers and the surrounding environment. Consequently, a responsible service must incorporate a comprehensive asbestos survey as a preliminary step. This survey aims to identify the presence, type, and extent of asbestos-containing materials (ACMs) within the flue’s structure. For instance, flue liners, insulation, and even mortar may contain asbestos fibers. Without proper identification, the subsequent removal process could inadvertently spread these dangerous materials, leading to long-term health consequences.

If asbestos is detected, abatement procedures must be implemented before any dismantling work can proceed. These procedures are governed by strict regulations and typically involve encapsulating or removing the ACMs by trained and certified professionals. Encapsulation involves sealing the asbestos-containing materials to prevent the release of fibers. Removal, on the other hand, requires carefully extracting the ACMs using specialized equipment and techniques, such as wet methods and negative air pressure systems, to minimize airborne fiber release. The removed materials must then be disposed of in designated landfills that are equipped to handle hazardous waste. A real-life example is the improper demolition of an older residential flue without prior asbestos testing, resulting in widespread contamination and costly remediation efforts. Therefore, asbestos identification and abatement are not merely optional add-ons; they are integral components of a safe and compliant removal strategy, dictated by both ethical considerations and legal requirements.

In summary, the connection between asbestos and flue dismantling is critical, emphasizing the importance of integrating thorough asbestos identification and abatement protocols into every “chimney removal service”. Failure to do so not only exposes individuals to significant health risks but also carries severe legal and financial ramifications. The proactive identification and safe removal of asbestos-containing materials are essential to protect workers, the public, and the environment, highlighting the indispensable role of specialized expertise in this area. The ethical and practical significance of this understanding cannot be overstated, as it forms the bedrock of a responsible and professional undertaking.

4. Safe Demolition Methods

The application of appropriate and rigorously enforced dismantling techniques is paramount when providing a flue dismantling. The inherent risks associated with working at height, dealing with potentially unstable structures, and handling heavy materials necessitate a comprehensive approach to worker and public safety. Deviation from established safe demolition methods can lead to serious injuries, property damage, and legal liabilities.

- Controlled Dismantling Techniques

The systematic deconstruction of the structure, typically proceeding from the top down, one section at a time, minimizes the risk of uncontrolled collapse. This often involves the use of hand tools and specialized equipment, such as hydraulic jacks or cranes, to carefully lower materials to the ground. An example is the meticulous removal of brick courses, ensuring that the underlying structure remains stable throughout the process. Neglecting this controlled approach can result in sudden structural failure, endangering workers and causing damage to the surrounding area.

- Dust Suppression and Containment

Demolition activities generate significant amounts of dust, which can contain hazardous materials such as asbestos or lead. Implementing effective dust suppression techniques, such as water spraying or the use of vacuum systems, is crucial for minimizing airborne particulate matter. Containment measures, such as erecting temporary enclosures around the work area, can further prevent the spread of dust to neighboring properties. The absence of these measures can expose workers and nearby residents to harmful substances and violate environmental regulations.

- Structural Support and Shoring

Prior to commencing demolition, it is essential to assess the structural integrity of the structure and provide adequate support to prevent collapse. This may involve installing temporary shoring or bracing to reinforce weakened sections. For instance, if the structure is attached to an adjacent building, shoring may be necessary to prevent damage to the neighboring structure during the dismantling process. Failure to provide adequate support can result in structural instability and increase the risk of accidents.

- Personal Protective Equipment (PPE)

Ensuring that all workers wear appropriate PPE is a fundamental aspect of safe demolition practices. This includes hard hats, safety glasses, respirators, gloves, and steel-toed boots. The specific PPE required will depend on the nature of the hazards present, such as the risk of falling debris, exposure to dust, or contact with hazardous materials. For example, workers handling asbestos-containing materials must wear specialized respirators and protective clothing. Inadequate PPE can significantly increase the risk of injuries and illnesses.

These facets of safe demolition methods are integral to the responsible execution of a flue dismantling. A service that prioritizes safety will meticulously plan and implement these measures, minimizing risks and ensuring a successful project outcome. The investment in these precautions protects workers, the public, and the environment, and underscores a commitment to professional standards.

5. Debris Disposal Regulations

The proper and compliant disposal of demolition waste generated during flue dismantling is intrinsically linked to “chimney removal service.” These projects invariably produce substantial quantities of rubble, brick, mortar, and potentially hazardous materials, the handling and disposal of which are governed by stringent environmental regulations at local, state, and federal levels. Non-compliance with these regulations can result in significant fines, legal penalties, and reputational damage for the service provider.

- Waste Characterization and Segregation

A crucial first step is accurately identifying and segregating the waste materials. This involves determining whether any components contain hazardous substances such as asbestos, lead paint, or creosote. Materials must be separated according to their composition, with hazardous waste requiring specialized handling and disposal methods. For example, asbestos-containing flue liners must be handled and disposed of as hazardous waste, while clean brick and mortar may be suitable for recycling or use as fill material. Improper waste characterization can lead to the illegal disposal of hazardous materials, with potentially severe environmental and legal consequences.

- Permitted Disposal Facilities

Demolition debris must be transported to and disposed of at facilities that are specifically permitted to accept such waste. These facilities are equipped to handle various types of demolition debris in an environmentally responsible manner. Using unpermitted disposal sites, such as illegal dumping grounds, is a violation of environmental laws and can result in significant penalties. For example, using an unpermitted site could lead to contamination of soil and groundwater, requiring extensive and costly remediation efforts. Furthermore, the service provider may be held liable for any environmental damage caused by the illegal disposal.

- Transportation and Manifesting

The transportation of demolition debris is often subject to specific regulations, particularly when hazardous materials are involved. Manifesting systems are used to track the movement of hazardous waste from the point of generation to the point of disposal. These manifests document the type and quantity of waste, the hauler, and the disposal facility. Proper manifesting ensures accountability and helps prevent the illegal dumping of hazardous materials. Failure to comply with manifesting requirements can result in fines and legal action against the service provider.

- Recycling and Reuse

Many demolition materials, such as brick, concrete, and metal, can be recycled or reused, reducing the amount of waste sent to landfills and conserving natural resources. Integrating recycling practices into the flue dismantling process demonstrates a commitment to environmental sustainability and can often reduce disposal costs. For example, crushed concrete can be used as a base material for construction projects, while reclaimed bricks can be used in landscaping or building projects. Maximizing recycling and reuse efforts not only benefits the environment but can also enhance the service provider’s reputation.

In conclusion, “debris disposal regulations” are an integral component of providing a compliant and responsible “chimney removal service.” Adherence to these regulations protects the environment, prevents legal liabilities, and demonstrates a commitment to ethical business practices. Neglecting these considerations can have serious consequences, underscoring the importance of engaging a service provider that is knowledgeable and diligent in all aspects of waste management.

6. Interior Restoration Needs

The act of dismantling a flue invariably creates a disruption within the structure it served, thereby establishing a direct connection between “interior restoration needs” and “chimney removal service.” The physical removal of a flue often leaves behind structural voids in walls, ceilings, and potentially floors, necessitating subsequent repair and cosmetic work. These “interior restoration needs” are not merely aesthetic considerations; they are fundamental to restoring the building’s structural integrity, thermal efficiency, and aesthetic appeal. The absence of proper restoration can lead to air leaks, water damage, and diminished property value. For instance, a flue running through multiple stories leaves openings that, if not properly sealed and patched, can create drafts, allow moisture intrusion, and compromise the building’s insulation.

The specific restoration requirements vary depending on the structure’s original construction, the extent of the flue dismantling (partial or complete), and the desired aesthetic outcome. Common restoration tasks include patching and repairing walls and ceilings, refinishing surfaces to match existing dcor, and potentially reconfiguring interior spaces to accommodate the absence of the flue. Furthermore, the removal of a fireplace can necessitate significant floor repairs and alterations to surrounding wall areas. A real-world example can be found in older homes where flues were often integrated into the building’s structural framework. Removing such flues requires careful consideration of load-bearing elements and may involve installing new supports or redistributing weight to ensure structural stability. Failing to address these structural considerations can lead to long-term problems, such as sagging floors or cracked walls.

In conclusion, “interior restoration needs” constitute an essential and often unavoidable component of a comprehensive “chimney removal service.” Addressing these needs is not simply about cosmetic repairs; it’s about restoring the building’s structural integrity, thermal performance, and aesthetic value. Neglecting these aspects can lead to long-term problems and diminish the overall benefit of the dismantling project. Therefore, a responsible service should include a thorough assessment of restoration requirements and provide comprehensive solutions to ensure a seamless and satisfactory outcome. The long-term benefits of proper interior restoration far outweigh the short-term cost savings of neglecting these crucial elements.

7. Contractor Selection Criteria

The selection of a qualified contractor is a pivotal determinant in the success and safety of any service associated with flue dismantling. The complexity of such projects, involving structural alterations, potential hazardous materials, and stringent regulatory requirements, mandates a meticulous approach to contractor evaluation. A poorly chosen contractor can not only compromise the structural integrity of the building but also create significant safety hazards and incur substantial financial losses. This is not simply a matter of convenience; it’s a critical component of a “chimney removal service” that dictates the overall outcome of the project.

Key factors in contractor selection include verifiable experience, appropriate licensing and insurance, adherence to safety protocols, and a proven track record of successful projects. Verifiable experience signifies the contractor’s familiarity with the specific challenges associated with flue dismantling, such as working at heights, handling heavy materials, and dealing with potential asbestos contamination. Appropriate licensing and insurance provide assurance that the contractor meets the minimum qualifications required by local authorities and is financially responsible for any damages or liabilities incurred during the project. Adherence to safety protocols demonstrates a commitment to worker safety and compliance with industry best practices. A proven track record, often assessed through references and testimonials, provides tangible evidence of the contractor’s ability to deliver satisfactory results. A real-life example illustrates the criticality of these criteria: a homeowner hired an unlicensed contractor for a flue dismantling, resulting in significant structural damage to the roof and costly repairs. This underscores the need for due diligence in contractor selection.

In conclusion, the connection between “contractor selection criteria” and “chimney removal service” is one of direct causality. The careful application of these criteria significantly increases the likelihood of a safe, efficient, and compliant project outcome. Conversely, neglecting these criteria exposes homeowners to unnecessary risks and potential financial losses. Therefore, prioritizing thorough contractor evaluation is not merely a prudent measure; it’s an indispensable element of a successful and responsible engagement. The long-term benefits of selecting a qualified contractor far outweigh the short-term cost savings of opting for a less experienced or unqualified provider.

Frequently Asked Questions About Chimney Removal

The following questions address common concerns and misconceptions surrounding the process of dismantling flues. The information presented aims to provide clarity and inform decision-making related to this service.

Question 1: Does a removal project require a permit?

Typically, modifications involving structural elements of a building, including dismantling a flue, necessitate a permit from the local building authority. Contacting the relevant authorities before commencement is crucial.

Question 2: What are the potential hazards involved?

Potential hazards include structural instability, falling debris, and the presence of hazardous materials such as asbestos. A professional assessment mitigates these risks.

Question 3: How is asbestos handled during dismantling?

If asbestos is identified, it necessitates abatement by certified professionals. Proper encapsulation or removal, adhering to strict safety protocols, ensures minimal risk.

Question 4: What happens to the opening after removing a structure?

The resulting void necessitates proper sealing and structural support. This may involve patching walls, ceilings, and roofs to maintain structural integrity and weather resistance.

Question 5: How long does a typical dismantling take?

The duration varies based on the structure’s size, location, and material. A thorough assessment provides an estimate, factoring in potential complications such as asbestos abatement.

Question 6: Is it possible to remove a portion of a structure above the roofline?

Partial dismantling is feasible, but it necessitates careful assessment of structural implications. Ensuring weatherproofing and maintaining structural stability is paramount.

Thorough preparation and a qualified contractor are vital for a safe and successful outcome. Addressing each element ensures minimal disruption and optimal results.

The subsequent section will delve into cost factors and pricing considerations associated with hiring a qualified service.

Chimney Removal Service

This exposition has comprehensively addressed the multifaceted nature of flue dismantling, extending from initial structural assessments to meticulous debris disposal. Key considerations encompass regulatory compliance, hazardous material abatement, and adherence to rigorous safety protocols. Successful project completion necessitates engaging qualified contractors equipped with the requisite expertise and certifications.

Decisions regarding flue dismantling should be predicated upon a thorough understanding of the associated complexities and potential ramifications. Prioritizing safety, compliance, and structural integrity is paramount. Property owners are encouraged to seek professional guidance to ensure responsible and effective project execution.