The provision of comprehensive and extensive care for chimney systems encompasses a range of activities designed to ensure optimal functionality, safety, and longevity. This includes thorough inspections, cleaning, repairs, and potential component replacement, extending to all aspects of the structure from the firebox to the flue termination point. For example, it may involve video scanning the interior of the chimney to identify hidden cracks, removing creosote buildup to prevent fires, repairing damaged brickwork to maintain structural integrity, and installing a new chimney cap to prevent water and animal intrusion.

Proper and complete upkeep of these systems is critical for several reasons. It significantly reduces the risk of chimney fires and carbon monoxide poisoning, ensuring the safety of the occupants. Regular attention to the chimney’s condition also preserves the efficiency of heating appliances and extends the lifespan of the entire chimney structure, preventing costly repairs or replacements down the line. Furthermore, diligent maintenance reflects a responsible approach to property care and may be required to comply with local regulations and insurance policies. The historical context reveals that chimney maintenance has long been recognized as essential for the safe and efficient operation of heating systems.

The following discussion will delve into the specific types of services offered, the importance of regular inspection, the materials and techniques used in chimney repair, and the factors to consider when selecting a qualified chimney professional.

Essential Guidelines for Chimney System Optimization

Adherence to these guidelines promotes safety, efficiency, and longevity in chimney system operation and maintenance.

Tip 1: Schedule Annual Inspections: Conduct a thorough inspection of the chimney system at least once per year. This proactive measure identifies potential issues such as cracks, blockages, or deterioration before they escalate into significant problems.

Tip 2: Prioritize Creosote Removal: Implement regular cleaning to eliminate creosote buildup, a highly flammable byproduct of combustion. The frequency of cleaning depends on appliance usage and fuel type, but consistent removal minimizes the risk of chimney fires.

Tip 3: Address Water Intrusion Promptly: Repair any signs of water damage immediately. Water can accelerate the deterioration of chimney materials, leading to structural instability and costly repairs. Install a chimney cap to prevent rainwater entry.

Tip 4: Ensure Proper Ventilation: Verify that the chimney flue is appropriately sized for the connected appliance. Inadequate ventilation can result in carbon monoxide buildup and inefficient heating performance.

Tip 5: Repair Damaged Brickwork or Mortar: Address any cracks or spalling in the brickwork or mortar joints without delay. Damaged masonry compromises the structural integrity of the chimney and allows moisture penetration.

Tip 6: Use Seasoned Firewood: Burn only properly seasoned firewood with a moisture content of less than 20%. Seasoned wood burns cleaner, producing less creosote and maximizing heating efficiency.

Tip 7: Consider Chimney Liner Installation or Replacement: Evaluate the condition of the chimney liner and consider replacement if it is damaged or deteriorated. A properly functioning liner protects the chimney structure from corrosive flue gases.

Following these recommendations ensures a safer and more efficient chimney system, minimizing the risk of fire, carbon monoxide poisoning, and costly repairs. Regular maintenance and proactive measures are essential for long-term chimney health.

The subsequent section outlines the criteria for selecting a qualified chimney professional to perform inspections, cleaning, and repairs.

1. Comprehensive Inspection

A comprehensive inspection forms the bedrock of optimal chimney system management. It represents the initial and most crucial stage in ensuring the safety, efficiency, and longevity of the chimney. Its direct connection to maximizing these services stems from its proactive nature, identifying potential problems before they escalate into costly repairs or, more seriously, hazardous situations such as chimney fires or carbon monoxide leaks. For example, a thorough inspection might reveal hidden cracks in the flue liner, a condition that, if left unaddressed, could lead to flue gas leakage into the living space. Alternatively, it might detect excessive creosote buildup, indicating a heightened risk of chimney fire. Without this initial in-depth assessment, subsequent maintenance efforts may prove incomplete or misdirected.

The importance of a comprehensive inspection extends beyond simple problem detection. It also enables a more precise and efficient allocation of resources during the provision of chimney services. By accurately assessing the chimney’s condition, technicians can tailor their repair and maintenance strategies to address the specific needs of the system. For instance, if an inspection reveals only minor mortar damage, the focus can be placed on repointing those areas, rather than undertaking a complete chimney rebuild. This targeted approach reduces unnecessary expenses and minimizes disruption to the homeowner. Furthermore, a comprehensive inspection provides a baseline assessment, allowing for tracking changes over time and evaluating the effectiveness of implemented maintenance procedures.

In summary, a comprehensive chimney inspection is not merely a preliminary step but an indispensable component of providing optimal services. It serves as the foundation for informed decision-making, targeted interventions, and ultimately, a safer and more efficient chimney system. The thoroughness of the initial inspection directly dictates the effectiveness and value of all subsequent chimney services, highlighting its critical role in minimizing risks and maximizing the lifespan of the chimney.

2. Creosote Removal

Creosote removal constitutes a vital element within a comprehensive chimney management program. Creosote, a byproduct of incomplete combustion, accumulates within the chimney flue as a dark, tarry residue. Its composition includes condensed wood smoke, volatile gases, and unburned carbon particles. The accumulation rate is directly influenced by factors such as wood type, moisture content, and combustion efficiency. Failure to address creosote buildup elevates the risk of chimney fires. These fires occur when accumulated creosote ignites, creating intense heat that can spread to adjacent structures. The severity of the fire correlates with the thickness and consistency of the creosote deposit. Regular creosote removal directly mitigates this risk, forming an essential component of fire prevention strategies. For example, homes that neglect annual chimney cleaning are statistically more prone to chimney fires compared to those that maintain routine maintenance schedules.

Beyond fire prevention, creosote removal also contributes to optimal appliance efficiency. Excessive creosote layers insulate the flue, restricting airflow and reducing the draft. This impaired draft can lead to inefficient combustion, increased smoke emissions, and potential carbon monoxide buildup within the dwelling. Regular removal restores proper airflow, enhancing combustion efficiency and minimizing the release of harmful pollutants. Furthermore, creosote can be corrosive, contributing to the degradation of chimney liners and other structural components. Certain creosote types, particularly third-degree creosote, exhibit a hardened, glazed consistency that is difficult to remove and can accelerate deterioration. Timely intervention prevents this corrosive action, prolonging the lifespan of the chimney system. This extends the period of operability.

In conclusion, creosote removal is not merely a supplementary service but a cornerstone of comprehensive chimney maintenance. Its significance extends from direct fire risk reduction to enhanced appliance efficiency and structural preservation. A thorough understanding of creosote formation and its potential consequences underscores the necessity of implementing routine removal protocols. This proactive approach safeguards property, promotes occupant safety, and maximizes the functional lifespan of the chimney system. Furthermore, many insurance companies now require documented chimney cleaning and inspection as part of their homeowner insurance policies, highlighting the importance of creosote removal.

3. Structural Repairs

Structural repairs are integral to comprehensive chimney management, directly impacting the safety, functionality, and longevity of the entire system. Neglecting structural deficiencies compromises the integrity of the chimney, potentially leading to hazardous conditions and costly replacements. Therefore, addressing these issues promptly and effectively constitutes a crucial component of providing services that maximize chimney performance and lifespan.

- Masonry Repointing

Mortar joints between bricks or stones deteriorate over time due to weathering and exposure to flue gases. Repointing involves removing the damaged mortar and replacing it with fresh mortar, restoring the structural integrity of the chimney stack. Failure to repoint allows water to penetrate the chimney, leading to further damage from freeze-thaw cycles and compromising the stability of the structure. For example, cracked or missing mortar joints can allow flue gases to escape, potentially exposing occupants to carbon monoxide.

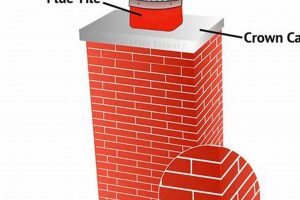

- Crown Repair or Replacement

The chimney crown, the concrete or masonry cap at the top of the chimney, protects the chimney from water intrusion. Cracks or damage to the crown allow water to enter the chimney, accelerating the deterioration of the brickwork and flue liner. Repairing or replacing a damaged crown is essential to prevent water damage and maintain the structural integrity of the chimney. A properly constructed crown should have an overhang to prevent water from running down the sides of the chimney.

- Flue Liner Repair or Replacement

The flue liner protects the chimney from the corrosive effects of flue gases. Damaged or deteriorated flue liners can allow these gases to penetrate the chimney walls, leading to structural damage and potential carbon monoxide leaks. Repairing or replacing a damaged flue liner is crucial for maintaining a safe and efficient chimney system. Depending on the extent of the damage, repair options may include patching or relining the existing flue, while complete replacement involves installing a new liner.

- Chimney Stabilization

In cases where the chimney is leaning or unstable, stabilization measures may be necessary to prevent collapse. This can involve reinforcing the chimney with steel supports, rebuilding sections of the chimney, or anchoring the chimney to the house. Ignoring signs of chimney instability poses a significant safety risk, potentially leading to structural failure and property damage. Addressing these issues requires specialized expertise and careful planning to ensure the long-term stability of the chimney.

These structural repairs are essential elements in maximizing the benefits derived from chimney services. By addressing underlying structural weaknesses, the overall safety, efficiency, and lifespan of the chimney system are enhanced. Regular inspections and prompt attention to structural issues are crucial for maintaining a safe and properly functioning chimney. Furthermore, the implementation of quality materials and adherence to established building codes are paramount for ensuring the longevity and effectiveness of structural repairs.

4. Liner Integrity

Liner integrity is paramount within the realm of chimney management, serving as a critical determinant of system safety and efficiency. The chimney liner, a conduit for combustion byproducts, requires consistent evaluation and maintenance to ensure unimpeded function. Deficiencies within the liner directly compromise the system’s capacity to safely expel harmful gases and maintain structural soundness. As such, the optimization of chimney services hinges significantly on the preservation and restoration of liner integrity.

- Material Deterioration and Corrosion

Chimney liners are susceptible to degradation from acidic flue gases, moisture, and thermal stress. Over time, this leads to cracking, spalling, and eventual failure. For instance, clay tile liners, a common material, can develop cracks due to thermal expansion and contraction. Stainless steel liners, while more durable, are not immune to corrosion, particularly in the presence of specific fuel types. Compromised liners permit flue gas leakage, posing carbon monoxide risks and accelerating chimney structure deterioration. This necessitates material-specific inspection protocols and appropriate repair or replacement strategies as part of any service.

- Joint Separation and Displacement

Segmented liners, such as those constructed from clay tiles or concrete sections, rely on properly sealed joints to maintain gas-tight integrity. These joints are vulnerable to separation due to settling, seismic activity, or freeze-thaw cycles. Displaced or separated joints create pathways for flue gas escape and compromise the structural stability of the liner. Documented cases reveal that seemingly minor joint separations can lead to significant structural damage over time, necessitating costly chimney repairs. Services must therefore incorporate thorough joint inspection and repair techniques using appropriate sealants or mortar.

- Blockages and Obstructions

Foreign objects, animal nests, and creosote buildup can obstruct the chimney liner, impeding proper ventilation and increasing the risk of chimney fires. Blockages restrict the flow of flue gases, potentially leading to carbon monoxide accumulation within the dwelling. For example, a bird’s nest obstructing the liner can create backdrafts, forcing smoke and dangerous gases back into the living space. Comprehensive services must include liner cleaning and obstruction removal as well as the installation of preventative measures such as chimney caps.

- Sizing and Compatibility Issues

An improperly sized or incompatible liner can compromise combustion efficiency and safety. Oversized liners can result in inadequate draft, leading to creosote buildup and inefficient fuel burning. Undersized liners restrict flue gas flow, increasing the risk of carbon monoxide poisoning. Furthermore, the liner material must be compatible with the type of fuel being burned. For instance, certain liner materials are unsuitable for high-efficiency appliances that produce corrosive condensate. Comprehensive chimney services require careful assessment of liner sizing and material compatibility to ensure optimal system performance.

The aforementioned facets of liner integrity underscore the fundamental connection between a well-maintained liner and the provision of effective chimney services. By proactively addressing material deterioration, joint separation, blockages, and sizing issues, service professionals can ensure the safe and efficient operation of chimney systems. Prioritizing liner integrity is thus essential for maximizing the benefits and mitigating the risks associated with chimney operation.

5. Ventilation Assessment

Ventilation assessment forms a critical component of comprehensive chimney management, directly influencing system safety and operational efficiency. It involves a thorough evaluation of the chimney’s capacity to effectively exhaust combustion byproducts from heating appliances. The results of this assessment guide the implementation of tailored solutions designed to optimize airflow and mitigate potential hazards, thus maximizing the overall value of offered services.

- Draft Measurement and Analysis

Draft, the pressure differential that draws combustion gases up the chimney, is a key indicator of ventilation performance. Assessment includes measuring draft using manometers or digital instruments. Insufficient draft can lead to backdrafting, where dangerous gases enter the living space. Excessive draft wastes energy and can overfire the appliance. Analysis of draft readings, considering factors like chimney height, flue size, and appliance type, identifies ventilation deficiencies. For example, a chimney serving a high-efficiency furnace may require a smaller flue liner to maintain adequate draft. Accurate draft assessment is paramount for selecting appropriate ventilation solutions.

- Flue Gas Analysis

Analyzing the composition of flue gases provides insights into combustion efficiency and potential ventilation problems. Instruments measure oxygen, carbon monoxide, carbon dioxide, and other pollutants. High carbon monoxide levels indicate incomplete combustion, potentially due to inadequate draft or a blocked flue. Elevated oxygen levels suggest excessive air infiltration, reducing heating efficiency. By analyzing flue gas composition, service professionals can diagnose combustion issues and recommend adjustments to the heating appliance or chimney system. This analysis ensures optimal combustion and minimizes pollutant emissions.

- Obstruction Detection and Removal

Ventilation assessments involve visual inspection and specialized tools to detect obstructions within the chimney flue. Common obstructions include bird nests, debris accumulation, and creosote buildup. Obstructions restrict airflow, reducing draft and increasing the risk of backdrafting. For instance, a chimney cap clogged with debris can significantly impede ventilation. Removing obstructions restores proper airflow and ensures the safe and efficient venting of combustion gases. Obstruction detection forms an integral part of maintaining optimal ventilation performance.

- Air Infiltration Evaluation

Air infiltration, the uncontrolled flow of air into or out of the chimney system, can compromise ventilation efficiency. Cracks in the chimney masonry, gaps around the flue liner, or poorly sealed cleanout doors allow air infiltration. Excessive air infiltration cools the flue, reducing draft and increasing creosote formation. Evaluating air infiltration involves visual inspection and smoke testing to identify leakage points. Sealing cracks and gaps minimizes air infiltration, improving draft and reducing energy loss. Comprehensive ventilation assessment includes addressing air infiltration to optimize chimney performance.

These facets demonstrate that ventilation assessment is not merely an ancillary procedure, but an essential diagnostic tool for optimizing chimney system performance. By accurately measuring draft, analyzing flue gases, detecting obstructions, and evaluating air infiltration, service professionals can identify ventilation deficiencies and implement targeted solutions. This proactive approach maximizes safety, enhances efficiency, and prolongs the lifespan of the chimney system, thereby amplifying the value and effectiveness of overall service strategies.

6. Waterproofing Measures

Waterproofing measures represent a critical facet of comprehensive chimney management. Their implementation safeguards the chimney structure against water intrusion, a primary cause of deterioration and reduced lifespan. In the context of providing optimal chimney services, addressing waterproofing needs ensures long-term structural integrity and minimizes the potential for costly repairs.

- Chimney Cap Installation

The chimney cap serves as the first line of defense against water entry. It covers the flue opening, preventing rainwater, snow, and debris from entering the chimney. Additionally, a well-designed cap incorporates mesh screening to deter animals from nesting within the flue. Failure to install or maintain a functioning cap exposes the chimney to significant water damage. For example, an uncapped chimney in a region with heavy rainfall can experience accelerated deterioration of the flue liner and masonry due to constant moisture exposure. Implementing cap installation or replacement is a fundamental waterproofing measure.

- Crown Sealing and Repair

The chimney crown, the concrete or masonry cap at the top of the chimney, is particularly vulnerable to water damage. Cracks and deterioration in the crown allow water to penetrate the chimney structure, leading to freeze-thaw damage and structural instability. Sealing the crown with a waterproof coating prevents water infiltration and extends its lifespan. Repairing cracks and spalling ensures the crown effectively protects the chimney from water damage. Neglecting crown maintenance can result in significant water damage to the chimney and adjacent building components.

- Flashing Inspection and Repair

Flashing, the material installed where the chimney meets the roof, prevents water from entering the building at this critical juncture. Damaged or improperly installed flashing allows water to leak into the attic or living spaces, causing structural damage and promoting mold growth. Inspecting and repairing or replacing damaged flashing is essential for maintaining a watertight seal between the chimney and the roof. Improper flashing installation can lead to extensive water damage requiring costly repairs to both the chimney and the roof structure.

- Water Repellent Application

Applying a breathable water repellent to the exterior of the chimney masonry helps prevent water absorption while allowing moisture to escape. This treatment reduces the risk of freeze-thaw damage and extends the lifespan of the chimney structure. It is crucial to use a product specifically designed for masonry chimneys that does not trap moisture within the brick or stone. Improper application of non-breathable sealants can exacerbate water damage by preventing trapped moisture from evaporating.

These waterproofing measures are not isolated procedures but rather interconnected strategies that contribute to the overall health and longevity of the chimney system. Integrating these measures into a comprehensive service approach ensures that the chimney remains structurally sound and resistant to water damage, maximizing its performance and minimizing long-term maintenance costs. Prioritizing waterproofing as part of the broader strategy guarantees resilience against the elements and long-term operational efficiency.

7. Code Compliance

Code compliance constitutes an indispensable element of comprehensive chimney services, directly impacting safety, legality, and insurance coverage. Adherence to relevant building codes and regulations ensures that chimney systems are designed, installed, and maintained according to established safety standards. Failure to comply with these codes can result in hazardous conditions, legal liabilities, and denial of insurance claims. Therefore, integrating code compliance into every aspect of chimney service delivery is paramount for maximizing its benefits and minimizing potential risks. For example, improper chimney height relative to nearby structures, a violation of many building codes, can result in inadequate draft and increased risk of carbon monoxide backdraft.

The practical significance of code compliance extends beyond merely avoiding fines or legal repercussions. It directly enhances the safety and efficiency of the chimney system. Building codes address a wide range of critical issues, including flue liner sizing, chimney clearances, and firestopping requirements. Compliance with these requirements minimizes the risk of chimney fires, carbon monoxide poisoning, and structural damage. For instance, appropriate firestopping around the chimney penetration through combustible building materials prevents the spread of fire in the event of a chimney fire. Regular inspections and adherence to maintenance schedules, as mandated by many codes, ensure that potential problems are identified and addressed before they escalate into hazardous situations. Furthermore, code compliance demonstrates a commitment to quality and professionalism, enhancing trust and confidence among clients. It should be noted that local jurisdictions may have specific amendments or additions to the model codes, necessitating thorough knowledge of local regulations.

In summary, code compliance is not simply a regulatory obligation, but a cornerstone of responsible chimney service provision. It directly contributes to safety, enhances system performance, and protects both property and occupants. Challenges include keeping abreast of evolving code requirements and ensuring that all personnel are adequately trained on relevant regulations. Integrating code compliance into every aspect of service delivery, from initial inspection to final repair, is essential for maximizing the value and effectiveness of services and upholding the highest standards of safety and professionalism. Its role is central to achieving comprehensive and conscientious chimney management.

Frequently Asked Questions about Chimney System Management

This section addresses common inquiries regarding chimney systems, their maintenance, and the services associated with ensuring their safe and efficient operation. The intent is to provide clear and concise information on critical aspects of chimney care.

Question 1: What constitutes a comprehensive chimney inspection, and why is it necessary?

A comprehensive inspection involves a thorough examination of all accessible components of the chimney system, including the flue liner, masonry, and associated hardware. This inspection identifies potential hazards, such as cracks, blockages, or deterioration, that could compromise safety or efficiency. Regular inspections are necessary to detect these issues early, preventing costly repairs and mitigating the risk of chimney fires or carbon monoxide poisoning.

Question 2: How often should a chimney be cleaned, and what factors influence the cleaning frequency?

Chimney cleaning frequency depends on factors such as fuel type, appliance usage, and burning habits. However, a general recommendation is to clean the chimney at least once per year. More frequent cleaning may be necessary for wood-burning systems or those that experience heavy usage. Regular cleaning removes creosote, a highly flammable byproduct of combustion, reducing the risk of chimney fires and ensuring proper draft.

Question 3: What are the potential consequences of neglecting chimney repairs?

Neglecting chimney repairs can lead to a range of serious consequences, including structural damage, water leaks, chimney fires, and carbon monoxide poisoning. Damaged masonry, a cracked flue liner, or a deteriorated chimney crown can compromise the integrity of the system, creating hazardous conditions and potentially leading to costly repairs or even chimney collapse. Prompt attention to repair needs is essential for maintaining safety and preventing further damage.

Question 4: What are the common signs of a chimney problem that warrant professional attention?

Common signs of a chimney problem include visible cracks in the masonry, spalling or crumbling brickwork, water leaks in the attic or around the chimney, a persistent smoky odor in the house, and a noticeable decrease in heating efficiency. The presence of any of these signs warrants a professional inspection to determine the extent of the problem and recommend appropriate repairs.

Question 5: How does water intrusion damage a chimney, and what measures can be taken to prevent it?

Water intrusion damages a chimney by accelerating the deterioration of masonry and causing freeze-thaw damage. Water seeps into cracks and pores in the brickwork, expanding as it freezes and causing the masonry to crack and crumble. Preventive measures include installing a chimney cap, sealing the chimney crown, repairing or replacing damaged flashing, and applying a breathable water repellent to the exterior of the chimney.

Question 6: What are the key considerations when selecting a chimney service provider?

Key considerations when selecting a service provider include experience, certifications, insurance coverage, and references. The provider should possess the necessary expertise and qualifications to perform the required services safely and effectively. Verifying insurance coverage protects against liability in case of accidents or property damage. Checking references provides insights into the provider’s reputation and quality of work.

Chimney systems demand consistent monitoring and prompt maintenance. Engaging qualified professionals ensures extended lifespan and optimal performance.

The subsequent section offers a conclusive review of vital components and suggestions to enhance chimney system robustness and performance.

Realizing Optimal Chimney Performance

This exploration has detailed the multifaceted nature of realizing maximum chimney services, emphasizing the crucial roles of comprehensive inspection, diligent creosote removal, timely structural repairs, guaranteed liner integrity, thorough ventilation assessments, effective waterproofing measures, and unwavering code compliance. Each element contributes to the overall safety, efficiency, and longevity of chimney systems. Neglecting any of these areas can compromise the system’s performance and pose significant risks.

As emphasized, proactive chimney management is not merely a routine task, but an essential responsibility. Consistent adherence to the guidelines and practices outlined herein safeguards property, protects occupants, and ensures the continued efficient operation of heating appliances. Prudent property owners will prioritize these services to maximize the lifespan and safe functionality of their chimney systems, ensuring years of reliable and efficient service. The future outlook hinges on continuing education and adaptation to evolving technologies and building codes within the chimney service industry. Only through such commitment can maximum chimney services become the norm, ensuring the safety and well-being of communities.