These manufactured products are designed to reduce creosote buildup in chimneys. They contain chemical additives that, when burned, catalyze a reaction aimed at modifying the structure of existing creosote, making it more brittle and easier to remove during subsequent cleanings or even causing it to flake off naturally. For instance, a homeowner might use such a log several times during the burning season to mitigate creosote accumulation.

Maintaining a clean chimney is crucial for preventing chimney fires, which can result in significant property damage and pose safety risks. Historically, manual cleaning by a chimney sweep was the primary method for creosote removal. The introduction of chemical chimney cleaning logs offered a convenient alternative, providing homeowners with a proactive way to manage creosote between professional sweeps. This approach contributes to a safer and more efficient fireplace operation.

The following sections will delve into the science behind these products, examine their effectiveness compared to traditional methods, discuss proper usage and safety precautions, and explore the environmental impact associated with their use.

Usage Tips for Chimney Cleaning Logs

Proper application of creosote modification logs is essential for maximizing their efficacy and ensuring safe operation of the fireplace.

Tip 1: Follow Manufacturer’s Instructions: Adhere strictly to the guidelines provided by the log manufacturer regarding frequency of use and burning duration. Deviations from these instructions can lead to ineffective creosote modification or, in some cases, increased risk of chimney issues.

Tip 2: Burn Hot Fires Regularly: Creosote formation is often accelerated by slow-burning, smoldering fires. Prioritize burning hotter fires, when possible, to minimize initial creosote buildup, thereby reducing the burden on the chemical log.

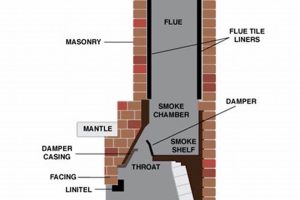

Tip 3: Ensure Adequate Airflow: Open the fireplace damper fully and ensure adequate airflow during burning. Insufficient oxygen impedes complete combustion and can increase creosote deposition, counteracting the effects of the cleaning log.

Tip 4: Schedule Professional Inspections: Chemical logs are designed to supplement, not replace, professional chimney inspections and cleanings. Maintain a regular inspection schedule with a qualified chimney sweep to assess the chimney’s condition and address any potential hazards.

Tip 5: Consider Wood Seasoning: Burn only seasoned firewood with a moisture content below 20%. Wet or unseasoned wood produces significantly more smoke and creosote, diminishing the effectiveness of the chemical log.

Tip 6: Understand Limitations: These products primarily modify existing creosote. They are less effective at preventing the initial formation of creosote. Therefore, combine log usage with best practices for clean burning.

Effective utilization of creosote modification logs requires a commitment to following recommended procedures and integrating their use into a comprehensive chimney maintenance strategy. This approach can contribute to a safer and more efficient fireplace operation.

The final section will summarize the key findings of this discussion and offer concluding thoughts on the role of these products in modern chimney care.

1. Creosote Modification

Creosote modification represents the core function of fireplace logs designed for chimney cleaning. These logs do not eliminate creosote instantaneously but, instead, aim to alter its chemical structure. This alteration is intended to make the creosote more brittle and less adhesive to the chimney walls. The underlying mechanism typically involves the combustion of chemical additives within the log, releasing compounds that react with the existing creosote deposits. A successful modification reduces the risk of chimney fires by rendering the creosote less flammable and easier to remove through subsequent cleaning efforts or even natural detachment.

For instance, a homeowner experiencing recurring creosote buildup might use these logs as a preventative measure between professional chimney sweeps. The modified creosote, having a more friable consistency, may then be dislodged more effectively during a sweep or gradually crumble and fall into the firebox over time. The degree of modification depends on factors such as the log’s chemical composition, the existing creosote’s composition and age, and the chimney’s construction. A heavily encrusted chimney may require multiple treatments and, ultimately, a professional cleaning to ensure complete creosote removal.

In summary, creosote modification, while not a complete solution, is a significant component of the chimney-cleaning log’s functionality. The effectiveness hinges on a complex interaction of factors, and understanding its role is critical for homeowners to manage their fireplace safety responsibly. Combining log usage with regular professional inspections and cleanings remains the most prudent approach to mitigating chimney fire risks associated with creosote accumulation.

2. Chemical Composition

The chemical composition of fireplace logs designed for chimney cleaning is paramount to their functionality. These logs typically contain a mixture of combustible materials (often compressed sawdust or wax) and chemical additives that facilitate creosote modification. The specific chemical compounds determine the log’s effectiveness in altering creosote’s structure and reducing its flammability. For example, some logs incorporate metallic catalysts, such as manganese or copper compounds, which promote oxidation reactions within the creosote deposits. These reactions break down complex organic molecules in creosote into simpler, less flammable substances. Without the appropriate chemical constituents in the correct proportions, the log’s ability to modify creosote is severely compromised, rendering it largely ineffective.

The precise formulation of these logs varies among manufacturers, but a common objective is to introduce chemicals that sublimate or vaporize upon heating and then deposit onto the creosote layer within the chimney. The deposited chemicals then react with the creosote, ideally weakening its bond to the chimney liner and converting it into a more easily removable form. Boron-containing compounds are sometimes employed for their flame-retardant properties, contributing to a reduction in chimney fire risk. The selection and concentration of these chemicals are critical to achieving the desired effect without causing damage to the chimney structure or releasing harmful emissions. A poorly formulated log may not only fail to modify creosote effectively but could also contribute to corrosion or other forms of chimney degradation.

In summary, the chemical composition of chimney cleaning logs is a crucial determinant of their performance and safety. Understanding the role of specific chemical additives and their interactions with creosote is essential for evaluating the efficacy of these products. However, relying solely on chemical logs without regular professional inspections and cleanings is ill-advised. A comprehensive chimney maintenance strategy should integrate both chemical treatments and mechanical cleaning to ensure optimal safety and performance.

3. Combustion Efficiency

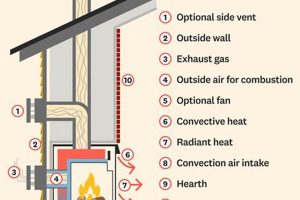

Combustion efficiency is a critical factor influencing the performance and effectiveness of fireplace logs designed to clean chimneys. The degree to which these logs burn completely directly impacts the release and distribution of their active chemical components, which are intended to modify creosote buildup within the chimney flue. Incomplete combustion reduces the efficacy of these logs and can potentially contribute to increased particulate emissions.

- Release of Active Ingredients

Efficient combustion ensures that the chemical additives within the log are fully volatilized and carried up the chimney flue. Incomplete burning leaves a portion of these chemicals unreleased, diminishing the log’s ability to treat creosote deposits effectively. A log that smolders rather than burns cleanly will not deliver the intended chemical payload to the areas requiring treatment. Examples include catalytic converters within the logs; if the log does not burn correctly, the catalyst is not properly dispersed.

- Temperature Distribution

Higher combustion temperatures facilitate a more even distribution of the released chemicals throughout the chimney. Efficient burning generates a consistent upward draft, carrying the active compounds to the upper reaches of the flue. Conversely, cooler, smoldering fires result in a more localized deposition of chemicals, potentially leaving significant portions of the chimney untreated. This emphasizes the importance of a strong, sustained fire to achieve optimal creosote modification.

- Formation of Byproducts

Incomplete combustion leads to the creation of undesirable byproducts, such as smoke and particulate matter, which can negate the benefits of the chimney cleaning log. These byproducts can contribute to further creosote buildup, exacerbate air pollution, and potentially create fire hazards. An efficiently burning log minimizes these byproducts, ensuring that the focus remains on creosote modification. Properly seasoned wood and adequate airflow are essential for achieving efficient combustion.

- Catalytic Action Enhancement

Certain chimney cleaning logs rely on catalytic agents to modify creosote. Efficient combustion can enhance the activity of these catalysts, promoting a more rapid and complete breakdown of creosote deposits. Higher temperatures and a sustained burn contribute to optimal catalytic performance. This highlights the synergistic relationship between combustion efficiency and the chemical action of the logs. A properly burning log maximizes the effectiveness of its catalytic components.

In essence, combustion efficiency serves as a foundation for the successful operation of fireplace logs designed to clean chimneys. A log that burns cleanly and completely maximizes the release and distribution of its active chemical components, minimizes the formation of undesirable byproducts, and enhances the overall efficacy of the chimney cleaning process. Homeowners should prioritize proper burning techniques, including using seasoned wood and ensuring adequate airflow, to optimize the performance of these products and maintain a safe and efficient fireplace operation.

4. Chimney Safety

Chimney safety is intrinsically linked to the use of fireplace logs designed for chimney cleaning. These logs are intended to mitigate the risks associated with creosote accumulation, a primary contributor to chimney fires. However, their effectiveness and appropriate application are critical for ensuring that they enhance, rather than compromise, overall chimney safety.

- Creosote Modification and Fire Risk Reduction

The primary function of these logs is to alter the composition of existing creosote, rendering it less flammable and easier to remove. If successful, this reduces the likelihood of a chimney fire. An example is a log that contains catalysts designed to break down creosote into a less combustible form. Conversely, an ineffective log may provide a false sense of security, masking the continued presence of hazardous creosote deposits. This necessitates regular professional inspections regardless of log usage.

- Proper Usage and Prevention of Hazards

Adhering to the manufacturer’s instructions is crucial for safe and effective operation. Overuse or improper burning techniques can lead to the release of harmful chemicals or contribute to chimney blockages. An example of improper use is burning multiple logs simultaneously in an attempt to accelerate creosote removal, which can potentially damage the chimney liner or increase the risk of carbon monoxide poisoning. Thus, precise adherence to guidelines is paramount.

- Limitations and the Importance of Professional Inspections

These logs are not a substitute for professional chimney inspections and cleanings. They primarily address existing creosote and may not prevent its future accumulation. A homeowner relying solely on these logs may overlook structural issues or blockages that could lead to chimney fires or carbon monoxide infiltration. Therefore, regular inspections by qualified professionals are essential for comprehensive chimney safety.

- Material Compatibility and Chimney Integrity

The chemical composition of these logs must be compatible with the chimney’s construction materials. Certain chemicals can corrode or degrade specific chimney liners, such as aluminum or certain types of stainless steel. An incompatible log could compromise the structural integrity of the chimney, increasing the risk of fire or collapse. Evaluating material compatibility is a vital safety consideration.

In conclusion, fireplace logs designed for chimney cleaning can contribute to chimney safety when used correctly and in conjunction with professional inspections and maintenance. However, they are not a panacea, and relying solely on these products can create a false sense of security. A holistic approach to chimney safety, encompassing proper usage, regular inspections, and material compatibility assessments, is essential for mitigating fire risks and ensuring the safe operation of fireplaces.

5. Usage Frequency

The frequency with which fireplace logs designed for chimney cleaning are employed directly influences their effectiveness, the overall safety of the chimney system, and the potential for unintended consequences. Determining an appropriate usage schedule requires careful consideration of factors such as the type of wood burned, the frequency of fireplace use, and the chimney’s overall condition.

- Creosote Buildup Rate and Log Application

The rate at which creosote accumulates within the chimney dictates the need for intervention. A fireplace used frequently with wood that produces high levels of creosote necessitates more frequent log applications than a fireplace used sparingly with drier, seasoned wood. For example, a homeowner burning softwood daily might require monthly log usage, whereas someone burning hardwood only on weekends might only need quarterly application. Adjusting log usage to match creosote accumulation is essential for optimal effectiveness.

- Manufacturer’s Recommendations and Deviation Risks

Adhering to the log manufacturer’s recommended usage frequency is paramount. Deviating from these instructions can result in either under-treatment, leading to continued creosote buildup, or over-treatment, potentially damaging the chimney liner or releasing excessive chemicals. A manufacturer might specify using one log per month during periods of active fireplace use. Exceeding this frequency in an attempt to accelerate cleaning could prove detrimental. Sticking to the guidelines is critical for safe and effective operation.

- Inspection Schedule and Log Usage Adjustment

Regular professional chimney inspections provide valuable insights into the effectiveness of the cleaning log regimen. If an inspection reveals significant creosote buildup despite regular log usage, the frequency of application may need to be increased, or alternative cleaning methods may need to be considered. Conversely, if the chimney remains relatively clean, the frequency may be reduced. These inspections provide a feedback loop for optimizing log usage and maintaining chimney safety. Adjustments based on professional assessment are crucial.

- Long-Term Effects and Chimney Material Compatibility

The long-term effects of repeated log usage on various chimney materials should be considered. Certain chemicals within the logs may, over time, corrode or degrade specific chimney liners, particularly those made of metal. While a single log application might pose minimal risk, repeated exposure could lead to structural damage. Therefore, assessing chimney material compatibility and adjusting log usage to minimize potential adverse effects is essential for maintaining long-term chimney health. This highlights the importance of consulting with chimney professionals.

In summary, determining the appropriate usage frequency for fireplace logs designed for chimney cleaning requires a multifaceted approach. Factors such as creosote buildup rate, manufacturer’s recommendations, professional inspection findings, and long-term material compatibility must all be taken into account. A balanced and informed approach to log usage ensures optimal chimney cleaning effectiveness without compromising safety or structural integrity.

Frequently Asked Questions

The following questions address common inquiries regarding the usage, effectiveness, and safety aspects of fireplace logs designed to reduce creosote buildup in chimneys.

Question 1: Are chimney cleaning logs a substitute for professional chimney sweeping?

No. These logs are designed to reduce creosote accumulation and modify its composition. They are not a replacement for the physical removal of creosote and other debris that occurs during a professional chimney sweep. Regular inspections and cleanings by a qualified chimney sweep remain essential.

Question 2: How frequently should these logs be used?

The frequency depends on several factors, including the type of wood burned, the frequency of fireplace use, and the manufacturer’s recommendations. Overuse can potentially damage the chimney liner, while underuse may not adequately address creosote buildup. Consulting the log’s instructions and a chimney professional is advisable.

Question 3: Do these logs prevent chimney fires?

These logs can reduce the risk of chimney fires by modifying creosote and making it less flammable. However, they do not eliminate the risk entirely. Chimney fires can still occur if sufficient creosote accumulates, or if other flammable materials are present in the chimney.

Question 4: Are there any safety precautions to consider when using these logs?

Always follow the manufacturer’s instructions carefully. Ensure adequate ventilation while the log is burning. Do not use more logs than recommended in an attempt to accelerate the cleaning process. Inspect the chimney regularly for signs of damage or creosote buildup.

Question 5: Are these logs environmentally friendly?

The environmental impact of these logs varies depending on their chemical composition and combustion characteristics. Some logs may release pollutants into the atmosphere. Consider choosing logs certified by environmental organizations, and ensure complete combustion by using seasoned wood and maintaining proper airflow.

Question 6: Can these logs damage my chimney?

Improper use or incompatibility with the chimney liner can potentially cause damage. Some chemicals within the logs may corrode certain materials over time. Consult a chimney professional to ensure compatibility and to avoid potential damage to the chimney structure.

Chimney cleaning logs can be a useful tool in maintaining a safe and efficient fireplace. However, they should be used responsibly and in conjunction with regular professional inspections and cleanings.

The next section will offer concluding thoughts on the role of these products in modern chimney care.

Conclusion

This examination of fireplace logs that clean chimney has highlighted their role as a supplementary tool in chimney maintenance, emphasizing both their potential benefits and inherent limitations. The effectiveness of these products hinges on creosote modification through chemical action, proper combustion efficiency for chemical release, and careful adherence to usage guidelines to ensure chimney safety. Crucially, these logs are not a replacement for professional inspections and cleaning.

While these logs offer a convenient means to mitigate creosote buildup, homeowners must remain vigilant in their approach to fireplace safety. Regular professional evaluations are essential to assess chimney health and address potential hazards that chemical logs alone cannot resolve. The judicious and informed application of these products, combined with comprehensive maintenance practices, is paramount for safe and efficient fireplace operation. Prioritizing chimney safety remains the ultimate responsibility of the homeowner.