A heating appliance employing natural gas or propane as fuel, vented through a vertical duct designed to expel combustion byproducts, offers a contained and controlled flame for aesthetic appeal and supplemental warmth. This system typically incorporates a firebox, gas burner, and a flue specifically engineered to manage and exhaust fumes safely outside the building envelope.

Such a system provides several advantages. It combines the ambiance of a traditional fire with increased convenience and ease of use. Unlike wood-burning options, this type eliminates the need for firewood storage and reduces particulate emissions. Historically, these heating solutions have evolved from simple, inefficient open hearths to sophisticated, energy-efficient appliances that meet stringent safety and environmental standards.

The following sections will delve into the selection criteria, installation considerations, maintenance requirements, and safety protocols associated with these heating appliances. This detailed examination provides a complete understanding of the factors necessary for optimal performance and longevity.

Optimizing a Vented Gas Heating Appliance

The following guidelines offer practical advice to ensure the safe and efficient operation of a gas-fueled appliance that utilizes a vertical venting system. Adherence to these tips can prolong the lifespan of the unit and maximize its heating potential.

Tip 1: Regular Professional Inspection: Schedule annual inspections by a certified technician. A qualified professional can identify potential problems, such as gas leaks, flue blockages, or burner malfunctions, before they escalate into serious hazards or costly repairs.

Tip 2: Maintain Venting Integrity: The venting system must be free from obstructions and corrosion. Inspect the chimney or flue for signs of damage, such as cracks or loose mortar. Any compromise in the venting system can lead to dangerous carbon monoxide buildup.

Tip 3: Proper Burner Maintenance: Clean the burner assembly regularly to remove dust, debris, and soot. A clean burner ensures efficient combustion and reduces the risk of incomplete combustion, which can produce carbon monoxide. Follow the manufacturer’s instructions for cleaning procedures.

Tip 4: Carbon Monoxide Detection: Install and maintain carbon monoxide detectors on every level of the dwelling, particularly near sleeping areas. Test the detectors regularly to ensure they are functioning correctly. Replace batteries annually or as recommended by the manufacturer.

Tip 5: Verify Proper Airflow: Ensure adequate airflow around the appliance. Do not obstruct vents or openings that provide combustion air. Insufficient airflow can lead to incomplete combustion and carbon monoxide production.

Tip 6: Professional Installation: Proper installation is paramount. Employ a qualified and licensed technician to install the appliance according to local codes and manufacturer’s specifications. Incorrect installation can compromise safety and efficiency.

Tip 7: Adhere to Manufacturer’s Instructions: Always follow the manufacturer’s operating and maintenance instructions. These guidelines are specific to the appliance model and provide critical information for safe and efficient operation. Disregarding these instructions can void warranties and increase the risk of malfunctions.

By consistently implementing these maintenance and safety measures, the efficiency and safety of this heating appliance can be greatly enhanced.

The subsequent sections will cover more specific topics, providing greater details.

1. Proper Ventilation

Proper ventilation is intrinsically linked to the safe and effective operation of gas-fueled hearth systems that rely on a chimney. The chimney serves as the primary exhaust pathway for combustion byproducts, ensuring these potentially hazardous gases are safely expelled from the occupied space. Without adequate ventilation, these gases can accumulate indoors, posing serious health risks.

- Chimney Draft

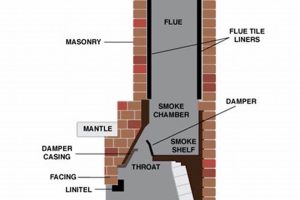

Chimney draft refers to the pressure differential that draws combustion gases up and out of the flue. Factors influencing draft include chimney height, diameter, and insulation, as well as prevailing weather conditions. Insufficient draft can result in backdrafting, where exhaust gases are forced back into the building. Proper chimney design and maintenance are essential to ensuring adequate draft and preventing backdrafting scenarios.

- Flue Liner Integrity

The flue liner serves as a protective barrier within the chimney, preventing corrosive combustion gases from damaging the chimney structure itself. Cracks or deterioration in the flue liner can compromise its integrity, allowing gases to leak into the surrounding masonry and potentially into the living space. Regular inspections and timely repairs of the flue liner are crucial for maintaining safe and efficient ventilation.

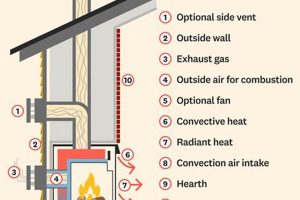

- Air Supply for Combustion

In addition to exhausting combustion byproducts, adequate ventilation also requires sufficient air supply for the combustion process itself. Gas-fueled appliances require oxygen to burn fuel efficiently. Insufficient air supply can lead to incomplete combustion, resulting in the production of carbon monoxide, an odorless and deadly gas. Proper sizing of air inlets and ensuring they remain unobstructed are vital for complete and safe combustion.

- Obstructions and Blockages

Chimneys can become obstructed by debris such as leaves, bird nests, or animal carcasses. These obstructions can impede airflow, reducing draft and potentially leading to backdrafting. Regular chimney sweeping and inspection are necessary to identify and remove any obstructions, ensuring the free flow of exhaust gases. Additionally, creosote buildup in wood-burning systems (though less of a concern for gas systems) can also act as an obstruction and a fire hazard if not addressed.

In summary, proper ventilation is not merely an ancillary consideration but a fundamental requirement for any gas-fueled heating appliance connected to a chimney. Its efficacy directly influences the safety of the occupants and the efficient operation of the equipment. Therefore, diligent attention to chimney draft, flue liner integrity, air supply, and the prevention of obstructions are paramount for the responsible use of such systems.

2. Combustion Efficiency

Combustion efficiency, in the context of a gas fireplace vented through a chimney, represents the degree to which fuel is converted into usable heat while minimizing wasted energy and harmful emissions. Maximizing combustion efficiency is crucial for cost-effectiveness, environmental responsibility, and safe operation.

- Air-to-Fuel Ratio Optimization

Achieving an optimal air-to-fuel ratio is fundamental to complete combustion. An insufficient air supply leads to incomplete combustion, producing carbon monoxide and soot, while an excess of air cools the flame, reducing heat output and potentially increasing nitrogen oxide (NOx) emissions. Modern gas fireplaces often incorporate engineered burner designs and air intake systems to regulate this ratio precisely, improving efficiency and reducing pollutant formation. These systems might include adjustable air shutters or electronically controlled air dampers.

- Burner Technology and Design

The design and materials of the burner directly influence combustion efficiency. Advanced burner technologies, such as ribbon burners or ceramic radiant burners, promote more uniform flame distribution and higher combustion temperatures. These designs encourage complete oxidation of the fuel, reducing unburned hydrocarbons and improving overall heat transfer to the surrounding environment. Some newer models also utilize modulating burners, adjusting fuel input to match heat demand, further enhancing efficiency.

- Venting System Design and Maintenance

The venting system, specifically the chimney, plays a role in combustion efficiency by ensuring proper draft and removal of combustion byproducts. A properly sized and maintained chimney promotes efficient gas flow, preventing backdrafting and ensuring sufficient oxygen supply to the burner. Blockages or deterioration in the venting system can impede airflow, leading to incomplete combustion and reduced efficiency. Regular chimney inspections and cleaning are essential to maintain optimal venting performance.

- Heat Exchanger Efficiency

While not present in all gas fireplace designs, some models incorporate heat exchangers to further enhance efficiency. These components capture waste heat from the exhaust gases and transfer it to the circulating air, increasing the overall heat output and reducing energy loss through the chimney. The design and surface area of the heat exchanger are critical factors in determining its effectiveness. Models with efficient heat exchangers can achieve higher overall thermal efficiency ratings.

The factors detailed above illustrate the interconnectedness of various components in achieving high combustion efficiency in a gas fireplace system. By optimizing the air-to-fuel ratio, employing advanced burner technologies, maintaining a properly functioning venting system, and incorporating heat exchangers where applicable, the overall performance and sustainability of the appliance can be significantly enhanced, contributing to both economic savings and reduced environmental impact.

3. Safe Operation

The secure functionality of a gas-fueled hearth system with chimney venting is predicated on stringent adherence to established safety protocols. This symbiotic relationship hinges on several factors, where a deviation from established procedures can lead to potentially hazardous outcomes. Examples include carbon monoxide poisoning resulting from incomplete combustion due to inadequate ventilation, or fire hazards stemming from improper installation or maintenance of the gas lines and venting system. The importance of safe operation is paramount; it directly mitigates risks associated with fuel combustion and ensures the wellbeing of occupants.

Effective safeguarding necessitates comprehensive understanding and implementation of preventive measures. Regular inspection of the chimney and venting system is critical to prevent blockages and ensure proper draft. Gas leak detection through professional servicing is essential, as is the correct installation of carbon monoxide detectors to provide early warning of dangerous gas levels. Furthermore, adherence to local building codes and manufacturer’s specifications during installation and maintenance constitutes a vital layer of protection. Real-world incidents involving gas leaks or carbon monoxide poisoning highlight the practical significance of these measures; neglecting them can result in severe health consequences or property damage.

In summation, the safe operation of a gas-fueled hearth appliance with chimney ventilation is not merely a regulatory requirement but an ethical imperative. This entails proactive measures encompassing routine inspections, professional maintenance, and unwavering adherence to safety standards. Challenges exist in ensuring widespread compliance and public awareness regarding these crucial aspects. However, a concerted effort to promote responsible usage and diligent maintenance practices is essential to realizing the benefits of gas fireplaces while minimizing the inherent risks associated with their operation.

4. Code Compliance

Adherence to established codes is an indispensable element in the installation and operation of gas fireplaces employing chimney venting systems. These regulations, developed and enforced by jurisdictional authorities, aim to ensure public safety, minimize environmental impact, and promote the efficient use of energy resources.

- Installation Standards

Local and national building codes dictate precise installation requirements for gas fireplaces and their associated chimneys. These standards encompass flue sizing, chimney height, clearances from combustible materials, gas line specifications, and ventilation provisions. Non-compliance can lead to hazardous conditions, including gas leaks, carbon monoxide poisoning, and structural fires. Inspections by certified professionals are typically mandated to verify adherence to these standards before the appliance is commissioned. For example, the National Fuel Gas Code (NFGC) provides detailed guidelines on gas piping and appliance venting.

- Venting Requirements

Specific codes govern the materials, construction, and termination of chimneys used with gas fireplaces. Regulations often stipulate the use of listed and labeled venting systems designed for use with specific types of gas appliances. Chimney height requirements are intended to ensure adequate draft and proper dispersion of combustion byproducts. Local amendments to model codes may address specific environmental conditions or architectural considerations. Failing to comply with these requirements may result in improper venting, leading to the accumulation of toxic gases within the dwelling.

- Safety Devices and Controls

Codes mandate the inclusion of specific safety devices and controls within gas fireplace systems. These may include automatic shut-off valves that interrupt the gas supply in the event of a flameout, oxygen depletion sensors (ODS) that detect low oxygen levels and shut down the appliance, and carbon monoxide detectors to alert occupants to the presence of dangerous gas concentrations. The proper functioning and regular maintenance of these safety features are crucial for preventing accidents and ensuring occupant safety. Building codes often require periodic testing of these devices to verify their operational status.

- Permitting and Inspections

Most jurisdictions require homeowners or contractors to obtain permits before installing or modifying a gas fireplace with a chimney. The permitting process allows building officials to review the proposed installation plans and ensure compliance with applicable codes. Inspections are conducted at various stages of the installation process to verify that the work is performed correctly and that all safety requirements are met. Failure to obtain necessary permits or undergo required inspections can result in fines, legal liabilities, and potential safety hazards.

These codified standards are not arbitrary constraints, but rather a synthesis of best practices and engineering principles designed to mitigate inherent risks associated with gas appliance operation. Adherence to these regulations is a critical component of responsible homeownership and ensures that these heating appliances operate safely and efficiently within the built environment.

5. Heat Output

Heat output is a critical performance parameter for gas fireplaces vented through a chimney, quantifying the amount of thermal energy the appliance delivers to the surrounding space. It dictates the fireplace’s ability to provide supplemental heating and contributes significantly to user satisfaction. Proper understanding of heat output characteristics is essential for selecting an appropriately sized unit and optimizing its operation.

- BTU Rating and its Significance

The British Thermal Unit (BTU) rating is the standard measure of heat output for gas fireplaces. A higher BTU rating indicates a greater capacity to generate heat per unit of time. The BTU rating must be considered in relation to the room size to be heated; an undersized fireplace will be ineffective, while an oversized unit may lead to overheating and inefficient fuel consumption. For instance, a small room (e.g., 200 sq ft) might only require a 10,000 BTU fireplace, whereas a larger space (e.g., 500 sq ft) could necessitate a 25,000 BTU model. Proper matching of BTU rating to space volume ensures optimal comfort and energy efficiency.

- Factors Affecting Heat Output Efficiency

Several factors influence the effective heat output of a gas fireplace beyond its nominal BTU rating. These include the fireplace’s design, the efficiency of the burner, the type of venting system, and the insulation characteristics of the room. Direct-vent fireplaces, for example, tend to be more efficient as they draw combustion air from outside and vent exhaust gases directly outdoors, minimizing heat loss through the chimney. Room insulation plays a crucial role in retaining heat; poorly insulated spaces will require higher heat output to maintain a comfortable temperature. Fireplace design elements, such as heat exchangers and blowers, can also enhance heat distribution and overall efficiency.

- Impact of Chimney Design and Condition

The chimney’s design and condition significantly influence the heat output of a gas fireplace. An improperly sized or poorly maintained chimney can reduce draft, leading to incomplete combustion and reduced heat output. Obstructions within the chimney, such as debris or creosote buildup (though more relevant to wood-burning systems), can impede airflow and further diminish heating efficiency. A well-designed chimney ensures efficient removal of combustion gases while minimizing heat loss through conduction. The chimney liner material also affects heat retention and draft performance.

- Adjusting Heat Output and User Control

Many gas fireplaces offer adjustable heat output settings, allowing users to tailor the heating level to their specific needs. These controls may involve adjusting the gas flow rate, modulating the burner flame, or utilizing a thermostat to maintain a desired room temperature. Proper use of these controls can optimize energy consumption and enhance comfort. Some models also incorporate remote control functionality, providing added convenience. Understanding the relationship between control settings and heat output is essential for maximizing energy efficiency and achieving desired heating performance.

The interplay between BTU rating, factors influencing efficiency, chimney characteristics, and user control mechanisms collectively determines the overall heat output performance of a gas fireplace with a chimney. Selecting an appropriate unit, ensuring proper installation and maintenance, and utilizing the available control features are vital steps in achieving optimal heating efficiency and maximizing user satisfaction.

6. Maintenance Schedule

A meticulously planned maintenance schedule is not merely advisable but rather a fundamental prerequisite for ensuring the safe, efficient, and prolonged operation of a gas fireplace with chimney. The appliance’s reliance on gas combustion and chimney venting necessitates proactive attention to prevent malfunctions, mitigate hazards, and maintain optimal performance.

- Annual Professional Inspection

An annual inspection conducted by a certified technician forms the cornerstone of a robust maintenance schedule. This assessment encompasses a comprehensive evaluation of all critical components, including the gas lines, burner assembly, venting system, and safety controls. Technicians utilize specialized equipment to detect gas leaks, assess flue integrity, and measure carbon monoxide levels. This proactive approach facilitates the early detection and remediation of potential problems, averting costly repairs and preventing hazardous conditions such as gas explosions or carbon monoxide poisoning. A real-world example is the identification of a corroded gas line during an annual inspection, preventing a potentially catastrophic gas leak within a residence.

- Chimney Cleaning and Inspection

The chimney, responsible for venting combustion byproducts, requires periodic cleaning and inspection. Over time, deposits such as soot and debris can accumulate, constricting airflow and increasing the risk of backdrafting. A professional chimney sweep removes these deposits, ensuring unimpeded venting. The inspection component involves a thorough assessment of the chimney’s structural integrity, identifying cracks, deterioration, or obstructions that could compromise its function. Neglecting this facet of maintenance can lead to reduced heating efficiency, increased carbon monoxide exposure, and even chimney fires. For instance, creosote buildup (though less common in gas fireplaces than wood-burning ones) can still occur and cause drafting issues. Similarly, animal nests or debris can completely block the flue.

- Burner and Pilot Light Maintenance

The burner and pilot light assembly, responsible for igniting and sustaining the flame, require regular maintenance to ensure optimal combustion efficiency. This involves cleaning the burner ports to remove dust and debris, adjusting the pilot light flame to ensure proper ignition, and inspecting the thermocouple or thermopile for signs of wear or corrosion. A malfunctioning burner or pilot light can lead to incomplete combustion, resulting in increased carbon monoxide production and reduced heating efficiency. Regular maintenance can prevent these issues, optimizing fuel consumption and minimizing pollutant emissions. For example, a clogged burner port can cause an uneven flame, reducing heat output and increasing the risk of carbon monoxide production.

- Carbon Monoxide Detector Verification

While not directly part of the fireplace itself, a properly functioning carbon monoxide detector is an indispensable component of a comprehensive safety plan. Regular testing of the carbon monoxide detector is essential to ensure its operational status. Batteries should be replaced annually or as recommended by the manufacturer. The detector should be strategically located near sleeping areas to provide early warning of dangerous gas levels. This simple yet crucial maintenance step can be the difference between a safe environment and a life-threatening situation. Numerous instances exist where functional carbon monoxide detectors have alerted occupants to the presence of deadly gas, allowing them to evacuate and seek medical attention.

In conclusion, the implementation and diligent execution of a well-defined maintenance schedule are paramount for the enduring safety and operational effectiveness of a gas fireplace with chimney. The facets outlined above professional inspection, chimney maintenance, burner upkeep, and carbon monoxide detection collectively form a protective framework that minimizes risks, maximizes efficiency, and extends the lifespan of the appliance. A failure to embrace this proactive approach compromises the integrity of the system and jeopardizes the wellbeing of those within the dwelling.

7. Fuel Consumption

Fuel consumption is a key consideration in the operation of a gas fireplace employing a chimney. Understanding the factors influencing fuel usage is critical for budgeting, energy efficiency, and minimizing environmental impact. The following sections will explore several facets of this critical aspect.

- BTU Input Rating and Fuel Usage Correlation

A direct correlation exists between a fireplace’s BTU input rating and its fuel consumption rate. A higher BTU rating signifies a greater amount of fuel consumed per hour of operation to generate the corresponding heat output. Manufacturers typically specify the fuel consumption rate in cubic feet per hour (CFH) for natural gas or gallons per hour (GPH) for propane. For example, a 30,000 BTU gas fireplace might consume approximately 30 CFH of natural gas. Understanding this correlation enables informed decisions about fuel costs and the potential environmental footprint. Disregarding this fundamental relationship can lead to unexpected fuel expenses and inaccurate estimations of long-term operational costs.

- Impact of Pilot Light Operation

Traditional gas fireplaces with standing pilot lights continuously consume fuel, even when the main burner is inactive. This pilot light consumption, while relatively small, can contribute significantly to overall fuel usage over time. Electronic ignition systems offer an alternative, eliminating the continuous pilot flame and reducing standby fuel consumption. Switching from a standing pilot to an electronic ignition system can yield considerable savings in fuel costs, particularly in regions with extended heating seasons. Newer models may offer intermittent pilot ignition (IPI) or direct spark ignition (DSI) which only ignite the pilot when heat is required.

- Influence of Venting System Efficiency

The efficiency of the chimney and venting system indirectly influences fuel consumption. A properly designed and maintained chimney ensures efficient removal of combustion byproducts, preventing backdrafting and promoting optimal burner performance. An obstructed or poorly sized chimney can lead to incomplete combustion, reducing heat output and requiring the fireplace to consume more fuel to achieve the desired temperature. Therefore, maintaining chimney integrity is not only crucial for safety but also for minimizing fuel waste. For example, a blocked chimney flue necessitates increased fuel input to compensate for reduced heat transfer efficiency.

- Thermostat Settings and Usage Patterns

User behavior plays a significant role in determining fuel consumption. Employing a thermostat to regulate room temperature can significantly reduce fuel usage by preventing the fireplace from operating continuously at maximum output. Strategic use of timers and setback thermostats can further optimize fuel consumption by automatically adjusting the heating schedule based on occupancy patterns. Neglecting to manage thermostat settings effectively can lead to unnecessary fuel waste and increased heating costs. For instance, setting the thermostat too high or leaving the fireplace operating unattended for extended periods contributes to inefficient fuel consumption.

These various elements collectively contribute to the overall fuel consumption profile of gas-fueled hearth appliances employing a chimney venting system. A thorough awareness of these factors enables homeowners to optimize their fuel usage, minimize their environmental impact, and reduce their long-term operating costs. Therefore, proactive attention to these areas becomes essential for responsible appliance operation.

Frequently Asked Questions

The following questions and answers address common concerns and misconceptions regarding gas fireplaces that utilize a chimney for venting combustion byproducts. The information presented aims to provide clarity and promote safe and efficient operation.

Question 1: What are the key differences between a direct-vent and a natural-vent (chimney) gas fireplace?

Direct-vent systems draw combustion air from outside and vent exhaust gases directly outdoors through a sealed system, typically horizontally. Chimney-vented systems, also known as natural-vent systems, rely on a chimney to exhaust combustion gases vertically. Direct-vent models are generally more energy-efficient due to the sealed combustion process, whereas chimney-vented types utilize existing chimney structures, sometimes making installation simpler, assuming the chimney is in good repair.

Question 2: How frequently should a gas fireplace with a chimney undergo professional inspection?

A gas fireplace and its associated chimney should be professionally inspected at least annually. This inspection should include a thorough assessment of the gas lines, burner assembly, venting system, and safety controls. More frequent inspections may be warranted in cases of heavy use or suspected malfunctions.

Question 3: What are the primary indicators of a potential carbon monoxide leak from a gas fireplace?

Indicators of a carbon monoxide leak may include a persistent, unexplained headache, nausea, dizziness, or flu-like symptoms. Other signs may include a yellow or orange flame (instead of a blue flame), excessive soot accumulation around the fireplace, or a damaged venting system. The presence of a functional carbon monoxide detector is crucial for early detection.

Question 4: Can a wood-burning fireplace chimney be used for a gas fireplace?

Potentially, but requires a specific liner. Consult a professional and check local codes, since using a chimney built for wood-burning appliances may not be suitable without proper inspection, cleaning and lining. Some wood-burning chimneys can be used if they are properly cleaned, inspected, and lined with a flue liner specifically designed for gas appliances. Direct connection to the bare brick of a masonry chimney is usually against code. A proper lining helps prevent condensation and corrosion.

Question 5: What measures can be taken to improve the energy efficiency of a gas fireplace with a chimney?

Several measures can enhance energy efficiency. Ensuring proper insulation around the fireplace, sealing air leaks in the room, utilizing a thermostat to regulate temperature, and employing an electronic ignition system (instead of a standing pilot light) can all contribute to reduced energy consumption. Regular maintenance of the burner and venting system is also crucial.

Question 6: What are the safety precautions to observe during a power outage when a gas fireplace is in use?

During a power outage, ensure that carbon monoxide detectors are functioning properly (most have battery backups). Avoid using the fireplace as a primary heat source for extended periods, as this can deplete backup power supplies. Do not attempt to modify the fireplace or its venting system. If any unusual odors or symptoms of carbon monoxide poisoning are detected, immediately evacuate the premises and contact emergency services.

The information provided in these FAQs serves as a general guide and should not substitute for professional advice or adherence to local building codes and regulations. Consistent maintenance and responsible operation are essential for the safe and efficient use of gas fireplaces with chimneys.

The subsequent section will provide guidance about choosing and working with professional companies.

Concluding Remarks on Gas Fireplaces with Chimneys

The preceding discussion has comprehensively examined critical facets of the gas fireplace with chimney. Emphasis has been placed on proper ventilation, combustion efficiency, code compliance, safe operation, heat output characteristics, maintenance schedules, and fuel consumption dynamics. Adherence to established safety protocols, regular maintenance practices, and informed decision-making regarding installation and operation are paramount for responsible utilization of these heating appliances.

The long-term viability and safety of gas fireplaces with chimneys hinge on continuous advancements in technology, stringent regulatory oversight, and heightened public awareness. Proactive engagement with qualified professionals, coupled with a commitment to responsible operation, remains essential to ensuring both efficient performance and mitigation of potential hazards. Continued vigilance and informed action are therefore necessary to realizing the benefits of gas fireplaces with chimneys while safeguarding public health and safety.