Constructing a vertical structure designed to expel combustion byproducts from a fireplace is a complex undertaking. This structure, typically made of brick, stone, or metal, creates a draft that draws smoke and gases upward, preventing them from entering the living space. Proper construction is crucial for safe and efficient fireplace operation.

A correctly built and maintained system is vital for home safety, preventing carbon monoxide poisoning and house fires. Historically, these structures have been essential for heating homes, evolving in design and materials over centuries to improve functionality and reduce hazards. Efficient smoke removal contributes significantly to indoor air quality and overall comfort.

The subsequent sections will detail the essential elements involved in the process. Considerations such as foundational support, flue liner installation, proper height and termination, as well as local building codes and safety regulations, will be addressed comprehensively. Attention to these details ensures a safe and functional fireplace.

Essential Considerations for Fireplace Chimney Construction

Careful planning and execution are paramount for safe and effective fireplace chimney construction. The following recommendations serve to guide this intricate process.

Tip 1: Ensure a Solid Foundation: A level and robust foundation is critical. The foundation must bear the entire weight of the structure without settling or shifting. Consult structural engineering guidelines to determine appropriate dimensions and load-bearing capacity.

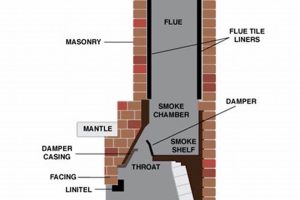

Tip 2: Select Appropriate Flue Liners: The flue liner protects the chimney structure from corrosive combustion byproducts. Clay tile, stainless steel, or cast-in-place liners are common choices; ensure compatibility with the intended fuel source. Compliance with Underwriters Laboratories (UL) standards is mandatory.

Tip 3: Maintain Proper Chimney Height: The chimney must extend at least three feet above the highest point where it penetrates the roof and two feet higher than any structure within ten feet. This requirement ensures adequate draft and prevents downdrafts caused by surrounding obstructions.

Tip 4: Incorporate a Spark Arrestor: Installing a spark arrestor at the chimney termination prevents embers from escaping and potentially igniting nearby combustible materials. Select a spark arrestor constructed of durable, non-corrosive materials and ensure regular inspection and cleaning.

Tip 5: Implement Proper Weatherproofing: Seal all joints and connections to prevent water penetration. Water damage can compromise the structural integrity of the chimney over time. Consider using a chimney cap to further protect the flue from rain, snow, and debris.

Tip 6: Adhere to Local Building Codes: Obtain all necessary permits and strictly adhere to local building codes and regulations. These codes specify minimum safety standards for chimney construction and are designed to protect occupants and property.

Tip 7: Professional Inspection and Testing: Upon completion, engage a qualified chimney sweep or inspector to conduct a thorough inspection and draft test. This will identify any potential issues and ensure the system functions correctly and safely. A written report documenting the inspection findings is essential.

Diligent application of these guidelines enhances the safety and longevity of the structure. Compliance with established standards ensures a functional and reliable system.

The succeeding sections elaborate on specific aspects of chimney maintenance and troubleshooting.

1. Foundation Stability

The stability of a fireplace chimney foundation is paramount to the overall integrity and longevity of the structure. A compromised foundation directly threatens the stability of the entire system, potentially leading to catastrophic failure. Careful consideration of soil conditions, load-bearing requirements, and appropriate construction techniques are mandatory.

- Soil Bearing Capacity

The soil’s capacity to bear the imposed load dictates the foundation’s design. Soil testing determines the allowable bearing pressure. Insufficient bearing capacity results in settling, cracking, and eventual collapse. For example, clay soils exhibit lower bearing capacity than bedrock, necessitating a larger, more robust foundation.

- Frost Heave Protection

In regions subject to freezing temperatures, frost heave presents a significant threat. Water within the soil freezes and expands, exerting upward pressure on the foundation. Constructing the foundation below the frost line mitigates this risk. Failure to do so can cause significant structural damage over time.

- Load Distribution

The foundation must distribute the chimney’s weight evenly across the underlying soil. This requires precise calculations to determine the appropriate footing size and reinforcement. Uneven load distribution can lead to differential settling and structural instability.

- Material Selection and Construction

The choice of materials and construction methods directly impacts foundation stability. Reinforced concrete is a common choice due to its high compressive strength and resistance to cracking. Proper curing and compaction are essential for achieving optimal performance. Deviations from accepted construction practices compromise the foundation’s load-bearing capacity.

Addressing these facets of foundation stability ensures that the chimney structure will perform safely and reliably for its intended lifespan. Neglecting any of these aspects can result in costly repairs, hazardous conditions, and ultimately, a complete failure of the fireplace system.

2. Flue Liner Selection

The selection of appropriate flue liners is intrinsically linked to the successful construction of a fireplace chimney. The flue liner, a critical component of the overall system, serves as a protective barrier, isolating the chimney structure from the corrosive effects of combustion byproducts, including creosote, acids, and high temperatures. Improper selection can precipitate rapid deterioration of the chimney, leading to structural instability and increased risk of fire. For example, using a liner incompatible with the fuel source (e.g., a liner not rated for high temperatures when burning wood) will significantly shorten the chimney’s lifespan and increase maintenance requirements.

Different materials offer varying degrees of resistance and suitability for different fuel types. Clay tile liners, a traditional choice, are cost-effective but susceptible to cracking due to thermal shock. Stainless steel liners provide superior resistance to corrosion and temperature fluctuations, making them ideal for a variety of fuels. Cast-in-place liners offer structural reinforcement but require specialized installation techniques. Furthermore, the size and shape of the flue liner must be appropriately matched to the fireplace opening and chimney dimensions to ensure proper draft and efficient removal of combustion gases. A too-small liner restricts airflow, causing smoke to back up into the living space, while an overly large liner reduces draft effectiveness and can promote creosote buildup. Consequently, the choice of flue liner material, dimensions, and installation method profoundly affects the chimney’s performance and safety.

In summary, flue liner selection is not merely an ancillary detail but a fundamental aspect of competent fireplace chimney construction. Considering factors such as fuel type, anticipated usage, and environmental conditions, coupled with adherence to relevant safety codes and standards, is imperative. Failing to prioritize proper flue liner selection jeopardizes the longevity and safety of the entire fireplace system, underscoring the need for informed decision-making and skilled execution during construction.

3. Proper Chimney Height

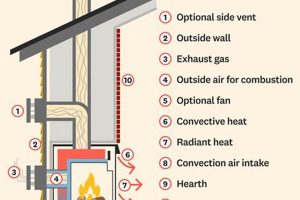

Proper chimney height is not merely an aesthetic consideration, but a critical functional element in chimney construction. Adequate height ensures efficient draft, which is the driving force for expelling combustion byproducts from the fireplace and preventing hazardous backdrafts into the living space. The correlation between chimney height and draft is foundational to safe and effective fireplace operation.

- Minimum Height Requirements

Building codes universally stipulate minimum height requirements for chimneys, typically mandating that the chimney extend at least three feet above the highest point where it penetrates the roof and two feet higher than any structure within ten feet. These specifications are not arbitrary; they are grounded in fluid dynamics principles. A shorter chimney is more susceptible to downdrafts caused by wind turbulence around the roof or nearby structures, leading to smoke entering the house.

- Impact of Surrounding Structures

The proximity of trees, adjacent buildings, or even substantial landscaping features can significantly influence chimney draft. Tall obstructions deflect wind downward, potentially creating negative pressure at the chimney outlet. In such cases, increasing the chimney height may be necessary to overcome these downdraft-inducing conditions. A taller chimney effectively extends into a zone of less turbulent airflow.

- Flue Diameter and Height Relationship

The diameter of the flue liner must be properly matched to the chimney height to achieve optimal draft. A flue that is too narrow for a given chimney height restricts airflow, while an excessively wide flue reduces draft velocity. The ideal ratio between flue area and chimney height is determined by the fireplace opening size and expected fuel consumption rate. Failure to consider this relationship results in inefficient combustion and increased creosote buildup.

- Topographical Considerations

Local topography can also affect chimney performance. Chimneys located in valleys or areas prone to high winds may require additional height to mitigate downdrafts. Wind direction and intensity are influenced by terrain features, and these factors should be considered during chimney design and construction. A thorough site assessment helps identify potential issues related to topography and wind patterns.

These interconnected facets of chimney height demonstrate that its specification goes beyond simple code compliance. Proper height, informed by site-specific factors and fluid dynamics principles, ensures safe and efficient fireplace operation. Alterations or shortcuts to chimney height during construction can compromise its ability to function effectively, leading to potential hazards. Therefore, adherence to recommended guidelines is indispensable in constructing a reliable and safe fireplace system.

4. Spark Arrestor Installation

Spark arrestor installation is an integral component of chimney construction, significantly impacting fire safety and code compliance. The device prevents the emission of embers from the chimney, mitigating the risk of igniting surrounding vegetation or combustible building materials. Its correct placement and maintenance are critical for safe fireplace operation.

- Compliance with Fire Safety Regulations

Many jurisdictions mandate the installation of spark arrestors on chimneys serving fireplaces or wood-burning stoves. These regulations aim to reduce the incidence of wildfires and structural fires caused by airborne embers. Failure to comply can result in fines or legal liabilities. Verification of local requirements is a prerequisite during chimney design and construction.

- Material Selection and Durability

Spark arrestors are typically constructed of stainless steel or galvanized steel mesh. The material must withstand high temperatures, corrosive flue gases, and environmental exposure. Regular inspection and replacement are necessary to maintain effectiveness. Deteriorated or damaged spark arrestors compromise their ability to contain embers.

- Mesh Size and Ember Containment

The mesh size of the spark arrestor directly affects its ability to prevent ember escape. Too large an opening permits embers to pass through, negating its purpose. Conversely, excessively fine mesh can restrict airflow, impairing draft and potentially leading to creosote buildup. Optimal mesh size balances ember containment and draft efficiency.

- Installation and Maintenance Procedures

Proper installation is essential for spark arrestor effectiveness. Secure attachment to the chimney crown or flue liner prevents dislodgement during high winds or storms. Regular cleaning removes accumulated creosote and debris, maintaining airflow and preventing fire hazards. Neglecting maintenance compromises the device’s functionality.

Therefore, integration of a suitable spark arrestor, correctly installed and diligently maintained, is not merely an optional addition but a fundamental aspect of responsible chimney construction. It enhances fire safety, ensures regulatory compliance, and contributes to the overall longevity and reliable operation of the fireplace system. The integration should be considered at the design phase.

5. Weatherproofing Techniques

Weatherproofing techniques, when applied to chimney construction, represent a proactive strategy for mitigating the deleterious effects of environmental exposure. The chimney structure, constantly subjected to rain, snow, ice, and temperature fluctuations, is vulnerable to deterioration. Effective weatherproofing extends its lifespan, maintains structural integrity, and prevents water damage within the building.

- Chimney Cap Installation

A chimney cap serves as the primary defense against precipitation. It shields the flue from rain and snow, preventing water infiltration that can cause spalling and freeze-thaw damage to brickwork. A properly sized and installed cap also deters birds and animals from nesting within the chimney, obstructing airflow and creating fire hazards. An example is selecting a stainless steel cap in coastal environments to resist corrosion from salt air.

- Crown Sealing and Repair

The chimney crown, the concrete or masonry slab at the top of the chimney, is a common entry point for water. Cracks and deterioration allow moisture to penetrate the chimney structure, leading to internal damage. Applying a waterproof sealant to the crown, or repairing cracks with masonry patching compounds, prevents water intrusion and preserves the structural integrity of the chimney. Regular inspections help identify and address crown issues before they escalate.

- Flashing Inspection and Maintenance

Flashing, typically made of metal, creates a watertight seal between the chimney and the roof. Deteriorated or improperly installed flashing allows water to seep into the roof structure, causing leaks and wood rot. Regular inspection of the flashing, along with resealing or replacement as needed, prevents water damage and maintains the structural integrity of both the chimney and the roof. Copper flashing, while more expensive, offers superior durability and resistance to corrosion.

- Water Repellent Application

Applying a breathable water repellent to the exterior masonry surfaces of the chimney can further enhance weather protection. These sealants prevent water absorption while allowing moisture vapor to escape, reducing the risk of freeze-thaw damage. Select a water repellent specifically designed for masonry and apply it according to the manufacturer’s instructions. The application must be reapplied periodically to maintain its effectiveness. For instance, use silane-siloxane water repellents to prevent the chimney from absorbing water.

These facets, when integrated into the chimney construction and maintenance process, collectively provide a robust defense against weather-related damage. Prioritizing weatherproofing ensures the longevity, safety, and operational efficiency of the fireplace system, preventing costly repairs and preserving the structural integrity of the building.

6. Code Compliance

Adherence to building codes is a non-negotiable aspect of constructing a fireplace chimney. The established codes are not arbitrary; they represent a compilation of best practices, engineering principles, and safety standards designed to protect life and property. Failure to comply with these regulations introduces significant risks, potentially leading to structural failures, fire hazards, and health concerns related to improper ventilation. The codes dictate specific requirements for foundation design, material selection, flue liner installation, chimney height, spark arrestor implementation, and weatherproofing techniques. For example, a code might specify the minimum fire rating for materials used in proximity to the fireplace opening, or mandate the use of a specific type of flue liner based on the intended fuel source. Deviation from these codified requirements carries severe consequences, including legal penalties, insurance claim denials, and, most importantly, increased risk of fire or carbon monoxide poisoning.

The practical application of code compliance extends beyond simply meeting the minimum standards. It involves a thorough understanding of the relevant codes, proper plan review and permitting processes, and meticulous execution during the construction phase. Municipal building inspectors play a critical role in verifying code compliance, ensuring that the chimney is built according to the approved plans and specifications. Regular inspections are conducted at various stages of construction to identify potential deficiencies and ensure that corrective actions are taken. Ignoring code requirements to save time or money is a shortsighted approach that jeopardizes the safety and well-being of occupants. For example, attempting to bypass a required inspection or using unapproved materials can lead to costly rework and potential legal ramifications. Professional chimney sweeps often report code violations during routine maintenance inspections, highlighting the long-term implications of non-compliance.

In summary, code compliance is an indispensable element of fireplace chimney construction. It necessitates a comprehensive understanding of applicable regulations, diligent adherence to approved plans, and rigorous inspection processes. The benefits of code compliance extend far beyond simply avoiding penalties; it provides a framework for constructing a safe, durable, and efficient fireplace system that protects life, property, and the environment. Challenges in achieving compliance often stem from outdated knowledge of evolving codes, inadequate training, or a lack of attention to detail. However, prioritizing code compliance from the outset ensures a reliable and safe fireplace for years to come.

7. Professional Inspection

The integration of professional inspection into the process of constructing a fireplace chimney is not an optional addendum, but rather a crucial safeguard against potential hazards and structural deficiencies. A chimney, regardless of construction materials or design, presents inherent risks associated with combustion byproducts and structural integrity. Professional inspection serves as a critical verification step, ensuring that the construction adheres to established safety standards and local building codes. For instance, an inspector might identify improper flue liner installation that, while appearing sound upon cursory examination, could lead to carbon monoxide leaks or chimney fires. Without such a thorough assessment, these latent defects may remain undetected until they manifest as significant problems, potentially endangering occupants and property.

The benefits of professional inspection extend beyond immediate safety concerns. A qualified inspector possesses specialized knowledge and tools to assess the chimney’s structural soundness, draft efficiency, and overall functionality. This assessment can uncover subtle issues that might otherwise escape notice, such as improper mortar joints that compromise the chimney’s weather resistance or inadequate insulation around the flue liner that increases the risk of creosote buildup. By identifying and addressing these issues early, professional inspection can prevent costly repairs down the line and extend the lifespan of the chimney. Consider a scenario where an inspector discovers that the chimney foundation is settling unevenly. This early detection allows for corrective measures to be taken before the chimney’s structural integrity is severely compromised.

In summary, professional inspection is an indispensable element in the construction of a fireplace chimney. It serves as a crucial checkpoint, verifying code compliance, identifying potential safety hazards, and ensuring long-term structural integrity. The cost of inspection is minimal compared to the potential consequences of overlooking hidden defects. Therefore, engaging a qualified chimney sweep or inspector is a prudent investment that protects both property and the well-being of its occupants.

Frequently Asked Questions Regarding Fireplace Chimney Construction

The following addresses frequently encountered inquiries related to fireplace chimney construction, providing clarity and guidance on key considerations.

Question 1: What foundational elements are crucial for a stable structure?

The foundation must extend below the frost line, rest on undisturbed soil, and adequately support the entire weight of the chimney. Soil testing is recommended to determine appropriate footing dimensions.

Question 2: What are the implications of selecting an inappropriate flue liner?

Incompatible flue liners may corrode prematurely, leading to structural damage and increased risk of fire. The liner must be compatible with the intended fuel type and operating temperatures.

Question 3: What is the rationale behind minimum chimney height requirements?

Adequate chimney height ensures sufficient draft for proper smoke evacuation, mitigating backdraft and potential carbon monoxide exposure. These requirements account for roof pitch and proximity to adjacent structures.

Question 4: What are the potential consequences of omitting a spark arrestor?

Absence of a spark arrestor increases the risk of wildfires caused by escaping embers. Local regulations often mandate spark arrestor installation.

Question 5: How does water infiltration affect the structural integrity?

Water penetration causes freeze-thaw damage, leading to spalling and deterioration of masonry materials. Weatherproofing measures, such as chimney caps and sealant applications, are essential.

Question 6: What measures ensure compliance with local building codes?

Acquisition of necessary permits, adherence to approved plans, and inspections by qualified building officials are mandatory for code compliance. Non-compliance may result in fines and necessitate corrective actions.

Proper attention to these questions during planning and execution can mitigate potential issues.

The succeeding segments provide a summary of key factors in overall chimney building.

How to Build a Fireplace Chimney

The construction of a fireplace chimney necessitates meticulous planning and execution. Key aspects include ensuring a stable foundation, selecting appropriate flue liners, adhering to height regulations for optimal draft, implementing spark arrestors for fire safety, employing weatherproofing techniques to prevent deterioration, and, critically, complying with all applicable building codes. Professional inspection serves as a crucial final step in validating the integrity of the construction.

Prioritizing these elements ensures not only the functionality of the fireplace but also the safety and well-being of the occupants. Ignoring these standards poses significant risks. Therefore, understanding and implementing these principles is paramount for anyone undertaking this endeavor.