A vertical structure protruding from a building, typically made of brick, that is colored primarily red is the subject of this discussion. These structures serve to expel combustion byproducts, such as smoke and gases, from a fireplace, furnace, or boiler. A typical example would be the structure atop a residential dwelling constructed of red brick, used for venting the fireplace.

The prominence of these structures stems from both functional necessity and aesthetic considerations. Historically, the color arises from the natural hue of the clay used in brick production. Beyond their primary function, such structures often contribute to the architectural character of a building, adding visual interest and a sense of tradition. Their visibility and design can also serve as a landmark or point of reference within a community.

Therefore, this composition will now delve into the specific aspects of materials used in the construction of these structures, consider maintenance strategies to preserve their integrity, and outline the regulatory standards governing their safe operation.

Red Chimney

The following guidelines aim to ensure the structural integrity and operational safety of structures that vent combustion byproducts. Adherence to these recommendations will contribute to prolonged service life and minimize potential hazards.

Tip 1: Regular Inspection: Conduct a thorough visual inspection at least annually, or more frequently if the system is used heavily. Examine for cracks, spalling, or any signs of deterioration in the brickwork and mortar joints. Address any issues promptly to prevent further damage.

Tip 2: Mortar Joint Repair: Deteriorated mortar joints should be repointed immediately. Use a mortar mix compatible with the existing brickwork to ensure proper bonding and prevent future cracking. Proper repointing techniques are essential for long-term stability.

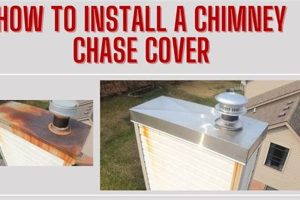

Tip 3: Crown Maintenance: The crown, located at the top of the structure, is particularly vulnerable to weather damage. Ensure the crown is properly sealed and free from cracks. Apply a waterproof sealant specifically designed for masonry to protect against water intrusion.

Tip 4: Flue Cleaning: Schedule professional cleaning by a certified chimney sweep at least once per year, or more often if using solid fuels. Creosote buildup is a significant fire hazard and can also corrode the flue liner.

Tip 5: Water Diversion: Ensure proper drainage around the base of the structure to prevent water from saturating the foundation. Install gutters and downspouts to direct water away from the building’s perimeter.

Tip 6: Animal Intrusion Prevention: Install a chimney cap to prevent birds and other animals from nesting within the flue. Animal nests can obstruct airflow and create a fire hazard.

Tip 7: Fuel Type Consideration: Utilize fuels appropriate for the appliance and venting system. Burning inappropriate fuels can lead to excessive creosote buildup and corrosion.

Consistent application of these maintenance procedures will contribute significantly to extending the lifespan of these structures, minimizing safety risks, and preserving their aesthetic appeal.

The subsequent sections will address relevant building codes and regulatory requirements pertaining to these structures, ensuring compliance and promoting safe operation.

1. Brick Composition

The enduring prevalence of structures constructed from brick, particularly those designated for venting combustion byproducts, arises directly from the material’s inherent properties and suitability for the task. Brick composition significantly influences the performance, safety, and longevity of these structures.

- Clay Mineralogy and Firing Temperature

The specific types of clay minerals present within the brick and the temperature at which the brick is fired determine its final strength, porosity, and color. Higher firing temperatures typically result in a denser, more durable brick with reduced water absorption. The presence of iron oxides within the clay contributes to the characteristic reddish hue commonly associated with these structures. The firing process vitrifies the clay, creating a hard, weather-resistant material necessary for enduring the harsh conditions associated with combustion byproducts.

- Thermal Resistance and Insulation

Brick possesses inherent thermal resistance, providing a degree of insulation to the structure. This thermal mass helps to maintain stable flue temperatures, promoting efficient draft and reducing condensation. The composition of the brick influences its thermal conductivity; denser bricks generally exhibit higher thermal conductivity compared to more porous varieties. Proper selection of brick based on thermal properties contributes to the overall efficiency of the venting system.

- Resistance to Acidic Gases and Corrosion

Combustion processes generate acidic gases, such as sulfur dioxide and nitrogen oxides, which can corrode the internal surfaces of the structure. The composition of the brick, specifically its resistance to chemical attack, plays a vital role in preventing premature degradation. Bricks with a higher silica content tend to exhibit greater resistance to acidic corrosion. The use of acid-resistant mortar is also critical in protecting the mortar joints, which are often the weakest points in the structure.

- Structural Integrity and Load-Bearing Capacity

The compressive strength of the brick is a crucial factor in determining the overall structural integrity of the unit. The composition and firing process directly impact the brick’s ability to withstand compressive loads. Well-fired, high-density bricks provide superior structural support, ensuring the stability and safety of the structure, particularly in areas subject to seismic activity or high winds. Proper bricklaying techniques are essential to maximize the load-bearing capacity of the brickwork.

The selection of appropriate brick composition is paramount to ensuring the safe and efficient operation of these structures. Understanding the interplay between clay mineralogy, firing temperature, thermal resistance, chemical resistance, and structural integrity is essential for designing and maintaining robust and durable venting systems. Failure to consider these factors can result in premature failure, posing significant safety hazards and requiring costly repairs.

2. Flue Integrity

Flue integrity constitutes a critical safety parameter for structures designed to vent combustion byproducts. Compromised flue integrity within these structures can lead to hazardous conditions and structural deterioration.

- Gas Leakage Prevention

An intact flue liner prevents the escape of carbon monoxide and other toxic gases into the building’s interior. Cracks or breaches in the liner create pathways for these gases to infiltrate living spaces, posing a significant health risk. Regular inspections and timely repairs are essential for maintaining a gas-tight seal.

- Protection of Masonry

The flue liner shields the surrounding brickwork from the corrosive effects of flue gases and condensation. Without a properly functioning liner, acidic compounds can attack the mortar joints, leading to spalling and structural weakening. This degradation can compromise the stability and longevity of the entire structure.

- Draft Optimization

A continuous and unobstructed flue ensures proper draft, facilitating efficient removal of combustion byproducts. A damaged or deteriorated flue can impede airflow, resulting in backdrafting, reduced appliance efficiency, and increased creosote buildup. Maintaining a smooth and unobstructed flue passage is vital for optimal system performance.

- Fire Safety

An intact flue liner contains sparks and hot embers, preventing them from escaping into the surrounding structure. Cracks or gaps in the liner can allow these sparks to ignite combustible materials, such as wood framing or insulation, leading to a potentially catastrophic fire. Regular cleaning and maintenance are necessary to remove creosote buildup, which is a highly flammable substance.

These considerations highlight the inextricable link between flue integrity and overall system safety. Consistent adherence to recommended inspection and maintenance protocols is paramount to ensure the safe and efficient operation of any structure designed for exhausting combustion byproducts.

3. Draft Regulation

Draft regulation within structures designed for exhausting combustion byproducts is a critical factor in ensuring efficient and safe operation. It directly impacts the removal of combustion gases, appliance performance, and overall system longevity. The following points explore the multifaceted relationship between draft regulation and these structures.

- Natural Draft Enhancement

The height and cross-sectional area of the structure directly influence natural draft. A taller structure generally generates a stronger draft due to the greater temperature differential between the flue gases and the ambient air. The internal dimensions must be appropriately sized to accommodate the volume of exhaust gases produced by the appliance. Insufficient height or an undersized flue can result in inadequate draft, leading to incomplete combustion and the potential for backdrafting.

- Barometric Damper Integration

A barometric damper can be integrated into the system to regulate draft, particularly in situations where excessive draft is present. This device automatically adjusts to maintain a consistent draft level, preventing over-firing and improving appliance efficiency. Proper installation and calibration of the barometric damper are essential for optimal performance and safety.

- Mechanical Draft Inducers

In cases where natural draft is insufficient, a mechanical draft inducer can be employed. This device utilizes a fan to create a negative pressure within the flue, actively drawing combustion gases away from the appliance. Mechanical draft inducers are often used in situations where the structure is too short, or the flue is obstructed. Proper selection and installation of a mechanical draft inducer are crucial to prevent over-pressurization or under-pressurization of the venting system.

- Impact of External Factors

External factors, such as wind conditions and the presence of nearby obstructions, can significantly impact draft. Strong winds can create downdrafts, forcing combustion gases back into the building. Tall trees or other structures in close proximity can also disrupt airflow, reducing draft efficiency. Addressing these external factors through proper site planning and shielding can help to maintain consistent draft performance.

Effective draft regulation is paramount to ensuring the safe and efficient operation of structures venting combustion byproducts. Proper design, maintenance, and the integration of appropriate draft control devices are essential for optimizing system performance and mitigating potential hazards.

4. Weather Resistance

The ability of a structure, particularly those constructed of red brick and designed for venting combustion byproducts, to withstand the effects of environmental elements is a critical determinant of its longevity and operational safety. Exposure to rain, snow, ice, wind, and temperature fluctuations can significantly impact the integrity of the structure over time.

- Freeze-Thaw Cycles and Brick Deterioration

Water absorbed into the porous structure of brick and mortar expands upon freezing, exerting internal pressure that can lead to cracking, spalling, and eventual disintegration of the material. Regions with frequent freeze-thaw cycles present a particularly challenging environment for these structures. The selection of frost-resistant bricks and the application of appropriate sealants can mitigate the damaging effects of this phenomenon. For example, a structure in a northern climate experiencing repeated freeze-thaw cycles without proper weatherproofing will exhibit accelerated deterioration of its brickwork.

- Wind-Driven Rain and Water Infiltration

Wind-driven rain can penetrate even seemingly impermeable surfaces, leading to moisture accumulation within the structure. Prolonged exposure to moisture can promote the growth of mold and mildew, corrode metal components, and weaken the structural integrity of the masonry. Proper flashing around the base and cap is essential to divert water away from vulnerable areas. The presence of efflorescence, a white, powdery deposit on the brick surface, is often indicative of water infiltration and the leaching of soluble salts.

- Thermal Expansion and Contraction

Daily and seasonal temperature fluctuations cause the materials to expand and contract. This continuous cycle of expansion and contraction can create stress within the brickwork, leading to cracking and separation of mortar joints. The use of expansion joints in larger structures can accommodate these movements and prevent stress buildup. The differential expansion rates of brick and mortar must be considered during construction to minimize the risk of cracking.

- Acid Rain and Chemical Erosion

Acid rain, resulting from atmospheric pollution, contains acidic compounds that can chemically erode brick and mortar. These acids react with the calcium carbonate in the mortar, dissolving it and weakening the structure. Regular cleaning and the application of protective coatings can help to mitigate the effects of acid rain. Structures located in industrial areas or urban environments are particularly susceptible to chemical erosion.

These factors underscore the importance of proactive weatherproofing strategies in preserving the integrity of structures that vent combustion byproducts. Neglecting weather resistance considerations can lead to premature failure, requiring costly repairs or complete replacement of the structure. A comprehensive approach, encompassing material selection, design details, and ongoing maintenance, is essential for ensuring the long-term durability and safe operation.

5. Structural Stability

Structural stability is a paramount consideration in the design, construction, and maintenance of any vertical structure, particularly those constructed of brick and used to vent combustion byproducts. Its enduring function necessitates the ability to withstand a variety of static and dynamic loads while maintaining its intended form and operational integrity. Compromised stability can lead to hazardous conditions, including collapse, gas leakage, and fire hazards.

- Foundation Integrity and Soil Interaction

The foundation serves as the primary load-bearing element, transferring the structure’s weight to the underlying soil. Adequate foundation depth, proper soil compaction, and appropriate footing design are essential to prevent settlement or tilting. Soil erosion, water infiltration, and seismic activity can compromise foundation stability, leading to cracking or shifting. A structure exhibiting signs of foundation distress requires immediate evaluation and remediation to prevent further damage and potential collapse. A deteriorated foundation directly jeopardizes the stability of the entire structure above it.

- Mortar Joint Strength and Brick Bonding

The mortar joints are critical for distributing loads evenly throughout the brickwork and providing lateral support. Deteriorated mortar joints, characterized by cracking, crumbling, or loss of adhesion, weaken the overall structural capacity. Repointing, the process of removing and replacing deteriorated mortar, is essential for maintaining joint integrity. The type of mortar used must be compatible with the brick to ensure proper bonding and prevent premature failure. Insufficient mortar strength or improper application techniques can lead to structural instability and eventual collapse.

- Wind Load Resistance and Lateral Bracing

Vertical structures are susceptible to wind loads, which can exert significant lateral forces. Adequate lateral bracing, such as steel reinforcement or tie rods, is necessary to resist these forces and prevent overturning. The height-to-width ratio influences its susceptibility to wind damage; taller, slender structures require more robust bracing systems. Structures located in areas prone to high winds or hurricanes must be designed to withstand extreme wind loads to ensure structural stability and prevent collapse.

- Flue Liner Support and Anchorage

The flue liner, typically constructed of clay tiles or metal, must be properly supported and anchored within the structure to prevent movement or collapse. Improper installation or deterioration of the liner supports can lead to liner failure, creating a pathway for gas leakage and compromising structural integrity. The weight of the liner, combined with the forces exerted by thermal expansion and contraction, necessitates a robust support system. Regular inspection of the flue liner and its supports is essential for maintaining structural stability and preventing hazardous conditions.

These facets underscore the interconnected nature of structural stability within the context of structures venting combustion byproducts. Each component contributes to the overall integrity of the system, and any compromise in one area can jeopardize the stability of the entire structure. Adherence to sound engineering principles, proper construction practices, and regular maintenance protocols is paramount to ensuring the long-term safety and performance of these vital architectural elements. A well-maintained structure not only ensures the safe venting of combustion gases but also preserves the aesthetic character and historical significance of the building it serves.

6. Creosote Management

Structures designed to vent combustion byproducts, particularly those constructed of brick, require diligent creosote management to ensure operational safety and prevent structural degradation. Creosote, a highly combustible byproduct of incomplete combustion, accumulates within the flue liner, posing a significant fire risk. The composition of the fuel, the efficiency of the appliance, and the temperature of the flue gases all influence the rate of creosote deposition. Failure to address creosote buildup can lead to chimney fires, which can damage the flue liner, ignite surrounding building materials, and result in property damage and personal injury. The accumulation acts as an accelerant, escalating the temperature rapidly and potentially causing ignition of adjacent structural elements. Therefore, the consistent and proactive removal of creosote is critical for mitigating these risks.

Effective creosote management involves a multi-faceted approach. Regular inspection of the flue liner by a certified chimney sweep allows for the early detection of creosote buildup. Professional cleaning removes accumulated creosote, restoring proper draft and reducing the risk of fire. The frequency of cleaning depends on the type of fuel used, the efficiency of the appliance, and the usage patterns. For example, wood-burning stoves used frequently throughout the winter months require more frequent cleaning than fireplaces used only occasionally. Furthermore, ensuring proper air supply to the appliance promotes more complete combustion, reducing creosote formation. Using seasoned wood with low moisture content also minimizes creosote production. In addition to physical removal, some chemical treatments can be used to modify the composition of creosote, making it easier to remove and less flammable.

In summary, creosote management is an indispensable component of the safe and effective operation of these vertical structures. Neglecting creosote buildup not only increases the risk of chimney fires but can also accelerate the deterioration of the structure itself. Consistent inspection, professional cleaning, and proper fuel management are essential for mitigating these risks and ensuring the long-term performance and safety of the venting system. The integration of creosote management protocols into routine maintenance schedules is crucial for preserving the structural integrity and fire safety of these ubiquitous architectural features.

7. Height requirements

The height of a structure designed for venting combustion byproducts, often constructed of brick and visually characterized by a red hue, is a critical determinant of its operational effectiveness and the surrounding environment’s air quality. Regulatory bodies establish minimum height requirements based on factors such as roof pitch, proximity to adjacent structures, and the type of fuel being burned. These regulations are intended to ensure adequate draft, proper dispersion of combustion gases, and minimize the potential for smoke or odors to impact neighboring properties. A structure that fails to meet these height requirements may experience inadequate draft, leading to incomplete combustion and the release of harmful pollutants into the atmosphere. For example, a residential unit venting a wood-burning stove requires a specific height above the roofline, ensuring the smoke is carried away from the building and does not re-enter through windows or ventilation systems. In essence, the height serves as a crucial component in the overall functionality and environmental responsibility of these structures.

Furthermore, height limitations also exist, often dictated by local zoning ordinances or aviation regulations. Excessive height can create aesthetic concerns, obstruct views, or pose hazards to aircraft. Therefore, balancing the need for adequate venting with these external constraints is crucial in the design process. The materials used in construction must also be capable of withstanding the loads imposed by wind and gravity, particularly in taller structures. This necessitates careful engineering considerations to ensure structural integrity and prevent collapse. A deviation from the established height standards could have legal ramifications and require costly modifications to bring the structure into compliance.

In summary, height requirements for brick structures used for venting combustion byproducts represent a critical intersection of functionality, environmental protection, and regulatory compliance. Adherence to these requirements ensures safe and efficient operation, minimizes air pollution, and protects the health and well-being of the surrounding community. Challenges arise in balancing these requirements with aesthetic considerations and potential limitations imposed by external factors. A thorough understanding of these factors is essential for architects, builders, and homeowners to ensure responsible design and operation of these essential building components.

Frequently Asked Questions About “Red Chimney”

The following section addresses common inquiries and misconceptions regarding brick structures, often displaying a reddish hue, used to vent combustion byproducts.

Question 1: What causes the reddish color commonly observed in brick structures used for venting combustion byproducts?

The characteristic reddish color typically arises from the presence of iron oxides within the clay used to manufacture the bricks. During the firing process, these iron oxides react with oxygen, resulting in a reddish or brownish coloration. The specific shade of red can vary depending on the concentration of iron oxides and the firing temperature.

Question 2: Are structures of this type solely constructed from brick, or are other materials also employed?

While brick is a common material, these structures may incorporate other materials, such as concrete, stone, or metal flue liners. The primary structural component is often brick, providing durability and aesthetic appeal. However, the flue liner, which protects the brickwork from corrosive combustion gases, may be constructed from a different material to enhance its resistance to heat and chemical attack.

Question 3: How often should these structures undergo professional inspection?

A professional inspection by a certified chimney sweep is recommended at least annually, or more frequently if the appliance is used extensively. Regular inspections allow for the early detection of creosote buildup, structural damage, or other potential hazards. Early detection and remediation can prevent costly repairs and ensure the safe operation of the venting system.

Question 4: What are the primary safety concerns associated with a deteriorating structure of this kind?

Deterioration can lead to several safety concerns, including gas leakage, fire hazards, and structural collapse. Cracks or breaches in the flue liner can allow carbon monoxide and other toxic gases to enter the building. Creosote buildup can ignite, leading to a chimney fire. Structural instability can result in partial or complete collapse of the structure, posing a significant risk to occupants and surrounding property.

Question 5: What factors contribute to the longevity of these venting systems?

Several factors contribute to longevity, including proper construction techniques, regular maintenance, appropriate fuel selection, and weather protection. High-quality brick, sound mortar joints, a well-maintained flue liner, and a chimney cap to prevent water intrusion all contribute to extending the lifespan. Burning seasoned wood, using a properly sized appliance, and scheduling routine cleaning and inspection are also crucial.

Question 6: Are there specific regulations governing the height of such structures?

Yes, building codes and local ordinances typically regulate the height. These regulations are intended to ensure adequate draft, prevent smoke from impacting neighboring properties, and comply with aviation safety requirements. The specific height requirements vary depending on the roof pitch, the proximity to adjacent structures, and the type of fuel being burned. Failure to comply with these regulations can result in fines or legal action.

Consistent maintenance and adherence to safety guidelines are vital for the safe and efficient operation of all structures designed for venting combustion byproducts.

The subsequent section will explore advanced diagnostic techniques used to assess the condition of these structures.

Red Chimney

This examination has elucidated the multifaceted nature of the structure, characterized by its brick construction and often reddish coloration, used for venting combustion byproducts. The discussion has encompassed essential aspects, including material composition, structural stability, draft regulation, weather resistance, and creosote management. The functionality depends on meticulous design, consistent maintenance, and adherence to regulatory standards. These elements collectively determine the structure’s safety, efficiency, and longevity, highlighting its significance within both residential and industrial contexts. Proper assessment and ongoing upkeep, performed by qualified professionals, are essential.

Therefore, recognizing the critical role these structures play in public safety and environmental responsibility is paramount. Continued research and development in materials science and engineering are needed to enhance their performance and sustainability. Proactive measures, including regular inspections, timely repairs, and adherence to best practices, must be prioritized to safeguard both property and human health. The long-term integrity hinges on a collective commitment to informed decision-making and responsible stewardship.