The upkeep of a chimney’s brickwork, stonework, or concrete components is a critical aspect of home maintenance. Deterioration can arise from weathering, age, or structural issues, necessitating specialized attention to restore integrity and functionality. Processes involved may include brick replacement, mortar repair (repointing), and crown reconstruction, tailored to the specific damage present.

Preserving the structural soundness of this system is paramount for preventing water damage, gas leaks, and potential fire hazards. A well-maintained structure ensures proper ventilation, protects the building’s envelope, and contributes to the longevity of the chimney. Historically, the maintenance of these structures has been essential for safe and efficient heating practices, evolving alongside construction techniques and materials.

This article will delve into the causes of damage, common repair techniques, the selection of appropriate materials, and best practices for ensuring long-term structural integrity.

Chimney Masonry Preservation

The following recommendations are provided to ensure the continued integrity of chimney structures, addressing preventative measures and corrective actions applicable to masonry components.

Tip 1: Conduct Regular Inspections: Routine visual assessments, ideally biannually, can identify early signs of deterioration such as cracked bricks, crumbling mortar, or spalling. Address these issues promptly to prevent escalation.

Tip 2: Employ Proper Waterproofing Techniques: Application of a breathable sealant, designed specifically for masonry, can protect against water penetration. Ensure the sealant does not trap moisture within the brickwork.

Tip 3: Address Mortar Joint Deterioration Immediately: Repointing deteriorated mortar joints prevents water infiltration and stabilizes the structure. Use mortar that is compatible with the original materials to avoid differential expansion and contraction.

Tip 4: Ensure Proper Flue Liners are Installed: Functioning flue liners protect the masonry from corrosive byproducts of combustion. Inspect liners regularly and repair or replace them as needed.

Tip 5: Maintain the Chimney Crown: A properly constructed crown prevents water from entering the chimney structure. Regularly inspect the crown for cracks or damage and repair or replace it as required.

Tip 6: Clear Vegetation Around the Structure: Overhanging branches and climbing vines can trap moisture and contribute to masonry deterioration. Keep vegetation trimmed to promote air circulation.

Tip 7: Address Structural Issues Promptly: Cracks or leaning structures require immediate evaluation by a qualified professional. These issues may indicate foundation problems or other serious structural concerns.

Implementing these preventative measures and corrective actions will help ensure the longevity and safety of the chimney structure, preventing costly repairs and potential hazards.

The subsequent sections of this article will elaborate on specific repair methods and material selection for comprehensive maintenance.

1. Structural Stability

Structural stability is paramount in chimney construction and maintenance; its compromise can lead to catastrophic failure. Deterioration of brickwork, mortar, or the foundation directly impacts overall stability. The objective of chimney masonry attention is to restore and maintain this stability, mitigating risks associated with collapse, water damage, and fire hazards. For example, leaning structures caused by foundation settlement require immediate stabilization to prevent further displacement and potential collapse. Comprehensive attention addresses not only the visible damage but also the underlying causes threatening structural integrity.

The absence of structural stability in chimney systems introduces significant risks. Water penetration, accelerated by cracked or weakened masonry, leads to internal damage and freeze-thaw cycles, further compromising the structure. Damaged systems impede proper ventilation, resulting in carbon monoxide buildup and potential health hazards. Ensuring that the structure can withstand wind loads, seismic activity (in relevant regions), and thermal stress is integral to maintaining a safe and functional system. Correct attention involves careful assessment of load-bearing capacity, reinforcement strategies, and the selection of appropriate materials to enhance durability. A poorly executed project, on the other hand, might mask underlying issues, resulting in a recurrence of instability and potential hazards.

Therefore, a comprehensive understanding of the relationship between masonry deterioration and overall structural integrity is critical. By prioritizing structural stability as a core objective, attention efforts can effectively address the root causes of chimney problems, ensuring safety, longevity, and compliance with building codes. This approach requires expertise in masonry principles, structural engineering, and a commitment to using durable and compatible materials.

2. Material Compatibility

The selection of compatible materials is crucial for the longevity and effectiveness of chimney brickwork preservation. Incompatibility can lead to accelerated deterioration, compromising the structural integrity of the entire system. When undertaking attention, the existing brickwork, mortar, and flue liners must be carefully analyzed to determine the appropriate replacement materials. For instance, using a Portland cement-based mortar on a chimney originally constructed with a lime-based mortar can cause the latter to erode due to differential expansion and contraction rates, leading to cracking and water intrusion. This situation exemplifies how incompatible materials can negatively affect the systems structural integrity. Ensuring the chosen materials exhibit similar thermal expansion coefficients, permeability, and chemical properties is paramount to prevent premature failure. Moreover, the physical strength of new materials should align with or be slightly weaker than existing ones to avoid transferring stress and causing damage to the older, more fragile components.

Consideration of material compatibility extends beyond mortar and brick selection. Flue liners must be resistant to the acidic byproducts of combustion generated by the specific fuel source used. For example, a flue liner designed for natural gas may not be suitable for wood-burning appliances, which produce higher levels of creosote and other corrosive compounds. Similarly, if a sealant is applied, it must be breathable, allowing moisture vapor to escape without trapping it within the brickwork, which can accelerate freeze-thaw damage. Understanding the existing system’s composition and the properties of potential replacement materials is therefore essential for preventing long-term problems and ensuring durable, effective workmanship.

In conclusion, material compatibility is not merely a technical detail but a fundamental principle in chimney brickwork preservation. Failing to prioritize compatibility can result in accelerated deterioration, structural instability, and potentially hazardous conditions. A thorough assessment of existing materials and a careful selection of compatible replacements, based on their physical, chemical, and thermal properties, are vital for ensuring the long-term performance and safety of the chimney system. This informed approach contributes significantly to the overall effectiveness and durability of brickwork work.

3. Water Intrusion

Water intrusion is a primary cause of deterioration in chimney structures, necessitating specialized attention. The porous nature of brick and mortar allows water to penetrate the masonry, leading to a range of damaging effects. Freeze-thaw cycles, where absorbed water freezes and expands, exert significant pressure on the masonry, causing cracking, spalling, and eventual structural weakening. Water also acts as a carrier for damaging salts and acids, further accelerating the degradation process. For example, rainwater mixing with flue gases can create acidic solutions that corrode mortar joints. In coastal environments, saltwater intrusion contributes to the breakdown of brickwork. Therefore, addressing water intrusion is a critical component of maintaining chimney integrity.

Effective strategies to mitigate water intrusion include several specific brickwork attention techniques. Repointing deteriorated mortar joints creates a watertight barrier, preventing further water penetration. Applying a breathable sealant to the exterior masonry surface helps to repel water while allowing moisture vapor to escape, preventing internal buildup. Ensuring the chimney crown is properly constructed and maintained prevents water from entering the chimney flue and damaging the internal structure. Furthermore, addressing issues such as damaged flashing around the chimney base prevents water from seeping into the building’s structure. The selection of appropriate materials for brickwork is also crucial, as some materials are more resistant to water absorption than others.

In summary, water intrusion represents a significant threat to chimney masonry, leading to structural damage and potential safety hazards. Addressing water intrusion through preventative measures and appropriate attention techniques is essential for ensuring the longevity and functionality of the chimney system. A comprehensive approach that considers the sources of water intrusion, the condition of the masonry, and the appropriate attention methods is necessary to protect the structure and prevent costly repairs. Proper implementation of these strategies directly impacts the overall safety and efficiency of the chimney.

4. Mortar Deterioration

Mortar deterioration is a primary driver of chimney masonry degradation, necessitating precise attention strategies to preserve structural integrity and prevent further damage. The mortar joints, acting as the binding agent between masonry units, are particularly susceptible to weathering, chemical attack, and physical stress. Addressing mortar deterioration effectively is, therefore, paramount in chimney masonry upkeep.

- Water Penetration Pathways

Compromised mortar joints provide direct pathways for water intrusion into the chimney structure. Water infiltration accelerates freeze-thaw cycles, leading to expansion and contraction within the masonry, further widening cracks and weakening the structure. Persistent moisture also promotes the growth of moss and algae, which retain moisture and contribute to surface degradation. Attention measures, such as repointing, are crucial to restore a watertight barrier and prevent further water-related damage.

- Chemical Degradation from Flue Gases

Mortar can be chemically attacked by acidic flue gases produced during combustion. These gases, containing sulfur dioxide and nitrogen oxides, react with the mortar’s calcium compounds, causing it to dissolve and weaken. This process is particularly prevalent in chimneys serving fuel-burning appliances. Attention often involves replacing deteriorated mortar with materials resistant to acid attack and ensuring proper flue lining to minimize gas contact with the masonry.

- Erosion and Weathering

Exposure to wind, rain, and temperature fluctuations gradually erodes mortar joints, causing them to crumble and recede. This process is exacerbated by poor-quality mortar mixes and inadequate initial construction. Attention efforts include carefully removing the damaged mortar and replacing it with a durable, compatible mix that can withstand the elements. Proper curing techniques are also essential to ensure the new mortar achieves optimal strength and adhesion.

- Structural Instability

Severe mortar deterioration weakens the overall chimney structure, potentially leading to leaning, cracking, or even collapse. As mortar joints lose their load-bearing capacity, stress is transferred to the surrounding masonry units, causing them to crack and spall. Attention may require reinforcing the structure with steel anchors or rebuilding sections of the chimney to restore stability. Addressing mortar deterioration promptly is vital to prevent costly and dangerous structural failures.

In summation, mortar deterioration is a multifaceted issue that significantly impacts chimney masonry integrity. Effective attention strategies must address the underlying causes of mortar degradation, employ compatible and durable materials, and ensure proper construction techniques. Prioritizing mortar brickwork helps to prolong the life of the chimney and maintain the safety of the building it serves.

5. Flue Integrity

Flue integrity is inextricably linked to chimney masonry brickwork. The flue liner’s primary function is to contain and safely vent combustion byproducts, protecting the surrounding masonry from corrosive substances and excessive heat. Damage to the flue, whether through cracking, spalling, or complete collapse, directly exposes the masonry to these harmful elements, accelerating deterioration. For example, if a clay flue liner cracks, acidic condensation can seep into the brickwork, dissolving mortar and weakening the structure. In such cases, chimney masonry attention is necessitated not only to address the superficial damage but also to restore the flue’s integrity, preventing further deterioration. Neglecting flue integrity during masonry attention is akin to treating a symptom without addressing the underlying cause; the masonry damage will inevitably recur.

The interconnectedness extends to the types of masonry brickwork required. If the flue liner is severely compromised, the masonry supporting it may require extensive rebuilding to accommodate a new liner. This may involve dismantling and reconstructing sections of the chimney, demanding specialized skills and materials. Selecting appropriate flue liners that are compatible with both the fuel being burned and the existing masonry is crucial. Stainless steel liners, for instance, offer superior resistance to corrosion and high temperatures, making them a durable choice for many applications. However, their installation requires careful consideration of the chimney’s structural integrity and proper insulation to prevent condensation issues. A thorough inspection of both the flue and the surrounding masonry is, therefore, essential before commencing any brickwork. It also may involve a camera inspection inside the flue.

In summary, maintaining flue integrity is not merely a separate concern from chimney masonry brickwork, but an integral component of comprehensive attention. A damaged flue inevitably leads to accelerated masonry deterioration, necessitating more extensive and costly repairs in the long run. By prioritizing the inspection, brickwork, and appropriate selection of flue liners, property owners can ensure the long-term structural integrity and safety of their chimneys. A holistic approach, recognizing the interdependence of these elements, is crucial for effective and lasting chimney maintenance.

6. Crown Condition

The chimney crown, a concrete or masonry slab at the top of the structure, serves as a critical barrier against water intrusion. Its condition directly impacts the longevity of the chimney masonry below. Cracks, deterioration, or improper construction of the crown allow water to penetrate the brickwork, accelerating freeze-thaw cycles and leading to spalling and structural damage. This necessitates brickwork to address the resultant damage and prevent further deterioration. A properly maintained crown diverts water away from the flue and masonry, significantly reducing the need for extensive brickwork in the future. For instance, a chimney lacking a crown, or one with a severely cracked crown, may experience rapid deterioration of the top several courses of brick, requiring extensive replacement and repointing.

The connection between crown condition and masonry preservation extends beyond simple water protection. A well-designed crown incorporates a drip edge, which directs water away from the chimney’s sides, preventing staining and further protecting the masonry. Conversely, a crown without a drip edge allows water to run down the chimney, saturating the brick and mortar. Selecting appropriate materials for crown construction is equally vital. While concrete is a common choice, its composition and reinforcement must be carefully considered to resist cracking and weathering. A deteriorated crown not only contributes to masonry damage but also compromises the overall structural integrity of the chimney, potentially leading to leaning or even collapse, necessitating extensive and costly brickwork.

In summation, the chimney crown plays an indispensable role in preserving the integrity of the masonry structure. Its condition directly correlates with the extent and frequency of required brickwork. Regular inspections and timely maintenance of the crown, including crack repair or complete replacement when necessary, are essential for minimizing water intrusion and preventing costly masonry deterioration. Therefore, prioritizing crown maintenance as an integral part of chimney care is a proactive strategy that protects the investment in the chimney and ensures its long-term functionality.

7. Qualified Assessment

A qualified assessment is a crucial prerequisite for effective chimney masonry attention. This process involves a detailed inspection by a trained professional to identify the specific causes and extent of damage, which then informs the appropriate attention strategy. For example, a seemingly minor crack in the chimney crown may be indicative of more extensive internal damage caused by water intrusion. Without a proper assessment, the brickwork may only address the visible symptom, leaving the underlying problem unresolved and leading to premature failure. The assessment serves as a diagnostic tool, ensuring that the attention targets the root causes of the issues and prevents future problems.

The benefits of a qualified assessment extend beyond simply identifying damage. A skilled assessor can determine the appropriate brickwork techniques and materials required for each specific situation. Different types of masonry may require different mortar mixes or sealing methods. Furthermore, the assessment can identify potential safety hazards, such as structural instability or carbon monoxide leaks, which must be addressed before any brickwork commences. Consider a scenario where the chimney is leaning due to foundation settlement. A qualified assessor would recognize this structural issue and recommend addressing the foundation before any brickwork, preventing a recurrence of the problem.

In conclusion, a qualified assessment is an indispensable component of chimney masonry work. It ensures that the attention is targeted, effective, and safe. By providing a comprehensive understanding of the chimney’s condition, the assessment enables informed decision-making and prevents costly mistakes. Therefore, engaging a qualified professional for an assessment is not merely an expense, but an investment in the long-term integrity and safety of the chimney structure.

Frequently Asked Questions

The following questions address common concerns regarding the maintenance and attention of chimney masonry systems. The answers provided aim to offer clarity on best practices and potential issues.

Question 1: What are the primary indicators of chimney masonry deterioration?

Key indicators include cracked or crumbling bricks, deteriorated mortar joints, spalling (surface flaking), and staining from water intrusion. A visual inspection of these elements can reveal the need for professional assessment.

Question 2: How frequently should a chimney undergo professional inspection?

Chimneys should be inspected at least annually, ideally before the heating season. More frequent inspections may be warranted if the chimney is used heavily or if signs of deterioration are already present.

Question 3: What are the consequences of neglecting masonry damage?

Neglecting damage can lead to structural instability, water damage to the building’s interior, fire hazards due to compromised flue liners, and carbon monoxide leaks, posing serious health risks.

Question 4: Is attention a task suitable for DIY (Do-It-Yourself)?

While some minor tasks, such as surface cleaning, may be appropriate for DIY, most brickwork requires specialized skills and knowledge. Incorrect techniques or materials can exacerbate damage and create safety hazards. A qualified professional is recommended for comprehensive assessment and attention.

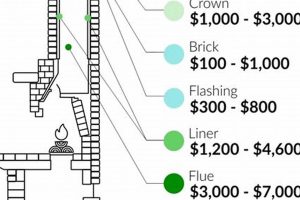

Question 5: What factors influence the cost of masonry preservation?

Cost factors include the extent of the damage, the type of materials required, the accessibility of the chimney, and the geographic location. Obtaining multiple estimates from reputable contractors is advisable.

Question 6: How can future damage to chimney masonry be prevented?

Preventative measures include regular inspections, maintaining a properly functioning chimney crown, ensuring adequate waterproofing, and addressing minor damage promptly. Regular cleaning of the flue can also prevent the buildup of corrosive substances.

These FAQs offer a basic understanding of chimney masonry maintenance. Consulting with a qualified professional remains essential for addressing specific issues and ensuring the safety and longevity of the structure.

The subsequent section will provide information about selecting a qualified chimney professional.

Chimney Masonry Repair

This exploration has addressed the critical importance of maintaining chimney masonry to safeguard structural integrity and occupant safety. Key considerations include conducting regular inspections, addressing water intrusion promptly, employing compatible materials, and ensuring flue integrity. Neglecting chimney masonry can lead to hazardous conditions, necessitating costly and extensive renovations.

Continued vigilance and proactive maintenance are essential for preserving chimney systems. The pursuit of professional expertise and adherence to best practices are strongly encouraged, ensuring the longevity, efficiency, and safety of these vital components of building infrastructure. Prioritizing chimney masonry contributes to the well-being of both the structure and its inhabitants.