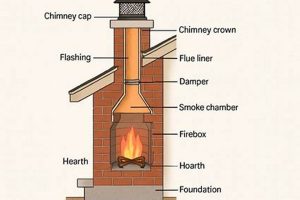

The optimal substance for creating a waterproof barrier between a chimney and its adjacent roofing material is crucial for preventing leaks and subsequent structural damage. This material must effectively adhere to both the chimney and roofing surfaces, maintain its integrity over time despite exposure to weather elements, and accommodate the expansion and contraction that occurs with temperature fluctuations. An example is a high-quality, polyurethane-based product applied carefully to the junction of the chimney and roof.

Effective protection against water intrusion at the chimney flashing is paramount to preserve the integrity of a building’s structure. Water infiltration can lead to rot, mold growth, and deterioration of surrounding building materials, resulting in costly repairs. Historically, various materials have been used for this purpose, but modern sealants offer improved durability, flexibility, and adhesion compared to traditional methods, ensuring a longer-lasting weather-tight seal.

Selecting the appropriate product requires careful consideration of factors such as material compatibility, environmental conditions, and application techniques. Evaluating the specific properties of different sealant types, including their resistance to UV degradation and temperature extremes, is essential for making an informed decision. Proper surface preparation and application are also critical steps in ensuring a durable and effective seal.

Tips for Selecting and Applying Chimney Flashing Sealant

Effective application of sealant at the chimney flashing requires careful planning and execution to ensure a long-lasting, watertight barrier. Adhering to best practices during selection and application maximizes protection against water damage.

Tip 1: Choose a Compatible Sealant: Prioritize sealants specifically formulated for roofing applications and compatible with both the chimney and roofing materials. Incompatible materials may result in adhesion failure and premature degradation. For example, silicone-based sealants may not adhere well to certain masonry surfaces.

Tip 2: Thoroughly Clean and Prepare Surfaces: Remove all loose debris, dirt, and existing sealant from the application area. A clean, dry surface is essential for optimal adhesion. Use a wire brush or scraper to remove loose material, followed by a solvent cleaner to remove any remaining residue.

Tip 3: Apply Sealant in Dry Weather: Avoid applying sealant when rain is imminent or when surfaces are wet. Moisture can interfere with the sealant’s ability to bond properly, compromising its effectiveness. Allow ample drying time according to the manufacturer’s instructions.

Tip 4: Use Appropriate Application Techniques: Apply a consistent bead of sealant along the flashing edges, ensuring full contact with both the chimney and roofing surfaces. Avoid gaps or thin spots, as these can create pathways for water intrusion. A caulk gun with adjustable flow can help maintain a consistent bead.

Tip 5: Tool the Sealant Joint: After applying the sealant, use a tool or gloved finger to smooth and press the sealant into the joint. This helps to create a watertight seal and improves the aesthetic appearance. Remove any excess sealant with a clean cloth.

Tip 6: Inspect Regularly and Reapply as Needed: Periodically inspect the sealant for signs of cracking, peeling, or degradation. Promptly address any issues by cleaning the area and reapplying sealant as necessary. Regular maintenance extends the lifespan of the flashing and prevents water damage.

Tip 7: Consider the Temperature Range: Select a sealant formulated to withstand the temperature fluctuations common in your region. Extreme temperatures can cause some sealants to become brittle or lose their adhesion. Check the manufacturer’s specifications for recommended temperature ranges.

Following these tips ensures the proper selection and application of sealant, contributing to a durable and effective barrier against water intrusion at the chimney flashing. Proactive measures minimize the risk of leaks and associated structural damage.

Implementing these strategies helps ensure long-term protection and addresses potential issues proactively, safeguarding the chimney and roof structure.

1. Adhesion Strength

Adhesion strength is a primary determinant of a sealant’s effectiveness in chimney flashing applications. The sealant must maintain a firm bond to dissimilar materials, typically masonry and roofing, to prevent water intrusion and ensure long-term protection.

- Surface Preparation and Bond Integrity

Effective adhesion relies heavily on proper surface preparation. Contaminants like dirt, grease, or old sealant residue must be thoroughly removed to allow the sealant to establish a strong molecular bond with the substrate. Failure to prepare the surface adequately compromises adhesion, potentially leading to premature sealant failure and water leaks. Some sealants require a primer to enhance adhesion on certain surfaces.

- Material Compatibility and Chemical Bonding

The chemical composition of the sealant must be compatible with both the chimney and roofing materials. Incompatibility can lead to chemical reactions that weaken the bond or cause the sealant to degrade over time. For instance, using a sealant that is not designed for masonry surfaces may result in poor adhesion and eventual separation. Sealants with strong chemical bonding capabilities, such as those based on modified polymers, generally exhibit superior adhesion across a wider range of materials.

- Flexibility and Movement Accommodation

Chimney flashing is subject to thermal expansion and contraction, as well as building movement. A sealant with sufficient flexibility is essential to maintain adhesion under these conditions. Rigid sealants are prone to cracking and separation as the chimney and roofing materials expand and contract at different rates. Flexible sealants, such as those based on polyurethane or silicone, can accommodate movement while maintaining a watertight seal.

- Environmental Factors and Long-Term Performance

Exposure to environmental factors such as UV radiation, temperature extremes, and moisture can degrade sealant adhesion over time. Sealants formulated with UV inhibitors and high resistance to temperature fluctuations are more likely to maintain their adhesive properties for extended periods. Regular inspections and maintenance, including resealing as needed, are crucial for preserving adhesion strength and preventing water damage.

The interplay of surface preparation, material compatibility, flexibility, and environmental resistance significantly influences the adhesive strength and overall effectiveness of any sealant used in chimney flashing. Selecting a product with high adhesion strength, appropriate for the specific materials and environmental conditions, is essential for ensuring a durable and watertight seal.

2. Weather Resistance

The capacity of a sealant to withstand environmental factors significantly determines its suitability for chimney flashing applications. Inadequate weather resistance directly correlates with premature degradation, compromising the seal and leading to water intrusion. Sunlight, temperature fluctuations, and precipitation exert continuous stress on the sealant. Sealants that fail to resist ultraviolet radiation become brittle and crack, while those susceptible to freeze-thaw cycles lose adhesion. For instance, a low-grade acrylic sealant applied in a region with severe winters would likely fail within a short timeframe due to cracking and loss of flexibility, necessitating costly repairs and potentially causing extensive water damage.

Effective weather resistance is engineered through specific formulations designed to mitigate environmental effects. Sealants incorporating UV inhibitors and stabilizers maintain their elasticity and tensile strength despite prolonged exposure to sunlight. Formulations based on modified polymers or high-quality silicones often exhibit superior resistance to temperature extremes, retaining their sealing properties across a wider range of conditions. The selection of a sealant should therefore prioritize its proven performance in comparable climatic conditions, referencing manufacturer specifications and independent testing data to assess its long-term durability. The absence of adequate weather resistance undermines the overall purpose of the sealant, regardless of other favorable attributes.

Ultimately, the relationship between weather resistance and the selection of an optimal sealant for chimney flashing is one of direct cause and effect. Choosing a product lacking this critical characteristic inevitably leads to compromised performance and premature failure. A thorough understanding of local weather patterns and the sealant’s ability to withstand them is paramount. Addressing this factor proactively ensures the long-term integrity of the chimney flashing, prevents water damage, and minimizes maintenance costs. Focusing on demonstrable weather resistance when selecting a sealant translates directly into a more durable and effective solution.

3. Material Compatibility

Material compatibility is a critical consideration in the selection of a suitable sealant for chimney flashing, with incompatibility resulting in compromised adhesion, accelerated degradation, and ultimately, failure of the seal. The principle governing this selection dictates that the sealant’s chemical properties must be inherently compatible with both the chimney’s masonry or metal components and the adjacent roofing materials, be they asphalt shingles, tiles, or metal panels. An inappropriate choice can lead to adverse reactions, such as the erosion of the sealant itself, or the corrosion of the materials it is intended to protect. For example, applying a sealant containing strong solvents to certain synthetic roofing membranes may dissolve or weaken the membrane, nullifying any protective benefit derived from the sealant.

The practical significance of understanding material compatibility lies in the prevention of costly repairs and the preservation of structural integrity. Different sealant formulations exhibit varying levels of compatibility with common building materials. Silicone-based sealants, while offering excellent weather resistance, may not adhere effectively to all masonry surfaces without proper priming. Polyurethane sealants, known for their durability and adhesion, can react negatively with certain metals, leading to corrosion over time. Therefore, a thorough assessment of the materials involved, coupled with a review of the sealant manufacturer’s specifications and compatibility charts, is essential prior to application. This assessment should consider not only the immediate interaction but also the long-term effects of prolonged contact under varying environmental conditions.

In conclusion, selecting the optimal sealant for chimney flashing necessitates a comprehensive understanding of material compatibility to ensure a durable, effective, and lasting seal. Challenges arise in complex installations involving multiple materials and varying environmental exposures. However, by prioritizing compatibility through informed selection and rigorous adherence to application guidelines, potential complications can be mitigated. This focus contributes directly to the overarching goal of maintaining a weathertight building envelope and preventing water damage associated with chimney flashing failure.

4. Application Ease

The ease with which a sealant can be applied directly impacts its effectiveness in protecting chimney flashing. Even the most chemically advanced sealant will fail if improperly applied, underscoring the significance of application ease as a critical factor in sealant selection.

- Viscosity and Tooling

The viscosity of the sealant directly affects its application. A sealant that is too thick may be difficult to extrude from a caulking gun, leading to uneven application and air pockets. Conversely, a sealant that is too thin may run or sag, compromising the seal’s integrity. Tooling characteristics, such as how easily the sealant can be smoothed and shaped, also contribute to application ease. Sealants that tool smoothly create a professional finish and ensure full contact with the substrate, minimizing potential weak points.

- Cure Time and Working Window

Cure time influences the working window available for application and correction. Sealants with excessively short cure times may not allow sufficient time for proper tooling and adhesion, while those with prolonged cure times may be susceptible to displacement or contamination before fully hardening. An optimal working window provides ample opportunity for precise application and correction, reducing the likelihood of errors and ensuring a durable seal. External conditions such as temperature and humidity will affect cure time.

- Surface Preparation Requirements

The complexity of surface preparation required for a sealant directly impacts application ease. Sealants requiring extensive cleaning, priming, or specialized surface treatments increase the time and effort involved in the application process. Sealants that adhere well to a variety of surfaces with minimal preparation offer greater application ease and reduce the potential for errors associated with improper surface preparation. Always follow manufacturer guidelines.

- Application Equipment Compatibility

Compatibility with standard application equipment, such as caulking guns and nozzles, is essential for ensuring ease of use. Sealants that require specialized equipment or techniques may be more challenging to apply, increasing the risk of improper application and reducing overall efficiency. Standardized equipment allows for consistent application and reduces the learning curve for installers, improving the likelihood of a successful seal.

Application ease is inextricably linked to the ultimate performance of a sealant used on chimney flashing. Sealants that are easy to apply, tool, and correct minimize the risk of errors and ensure a durable, weathertight seal. Choosing a sealant with consideration for these factors is paramount for achieving long-term protection against water damage.

5. Durability

Durability constitutes a paramount criterion in the selection of an optimal sealant for chimney flashing. The primary function of chimney flashing is to prevent water intrusion at the vulnerable junction where the chimney penetrates the roof. A sealant’s longevity and resistance to degradation directly correlate with its ability to maintain this protective barrier over time.

- Material Composition and Degradation Resistance

The inherent properties of the sealant’s material composition dictate its resistance to degradation from environmental stressors. Sealants formulated with high-quality polymers, UV inhibitors, and stabilizers exhibit superior longevity compared to those lacking these components. For instance, a polyurethane sealant with robust UV resistance will withstand prolonged exposure to sunlight without becoming brittle or cracking, whereas a lower-grade acrylic sealant may degrade rapidly under the same conditions. The implication is that selecting sealants with demonstrably superior resistance to degradation is crucial for ensuring long-term performance.

- Adhesion Longevity and Thermal Cycling

A sealant’s ability to maintain a secure bond with both the chimney and roofing materials is fundamental to its durability. Chimneys and roofs experience thermal cycling, expanding and contracting with temperature fluctuations. Sealants must possess sufficient flexibility to accommodate this movement without losing adhesion. Sealants with poor adhesion will eventually separate from the substrate, creating pathways for water infiltration. Consequently, choosing sealants that have been rigorously tested for adhesion under thermal cycling conditions is essential for ensuring a durable, watertight seal.

- Resistance to Chemical Exposure

Chimney flashing may be exposed to various chemical substances, including atmospheric pollutants, cleaning agents, and runoff from roofing materials. A durable sealant must exhibit resistance to these chemical exposures to prevent degradation and maintain its sealing properties. For example, sealants used on chimneys near industrial areas may be exposed to acidic pollutants, which can corrode or degrade certain sealant types. Therefore, assessing the potential for chemical exposure and selecting a sealant with appropriate resistance is vital for long-term durability.

- Abrasion and Physical Damage Resistance

While not the primary concern, chimney flashing sealants can be subject to physical abrasion and damage from falling debris, wildlife, or maintenance activities. A durable sealant should possess a degree of resistance to abrasion and physical impact to prevent tears or punctures that could compromise the seal. Sealants with higher tensile strength and tear resistance will generally withstand physical stressors better than those with lower ratings, contributing to increased longevity.

In summary, the durability of a sealant used on chimney flashing is a multifaceted characteristic influenced by material composition, adhesion strength, resistance to chemical exposure, and ability to withstand physical damage. Selecting a product that excels in these areas is essential for ensuring long-term protection against water intrusion and minimizing the need for frequent repairs. A durable sealant translates directly into reduced maintenance costs and a more reliable building envelope.

Frequently Asked Questions

This section addresses common inquiries regarding the selection and application of appropriate sealing materials for chimney flashing to promote informed decision-making and ensure optimal protection against water intrusion.

Question 1: What sealant type offers superior longevity in chimney flashing applications?

Polyurethane and modified polymer (SMP) sealants generally exhibit enhanced durability and weather resistance compared to silicone or acrylic alternatives. Their robust chemical structure provides greater resistance to UV degradation, temperature fluctuations, and abrasion, translating to extended service life.

Question 2: How critical is surface preparation prior to sealant application on chimney flashing?

Thorough surface preparation is paramount for ensuring adequate adhesion. Removal of all loose debris, dirt, and existing sealant residue is essential to create a clean, dry surface that promotes a strong bond between the sealant and the substrate. Failure to properly prepare the surface can compromise adhesion and lead to premature sealant failure.

Question 3: Can any sealant be used interchangeably on both the chimney masonry and roofing materials?

No, material compatibility is a crucial consideration. Sealants must be specifically formulated to adhere effectively to both the chimney’s masonry or metal components and the roofing materials. Incompatible sealants may exhibit poor adhesion or cause corrosion, compromising the seal’s integrity.

Question 4: Does sealant color affect its performance in chimney flashing applications?

Sealant color primarily affects aesthetics, with minimal impact on performance. However, darker colors may absorb more solar radiation, potentially leading to increased surface temperatures and accelerated degradation in some sealant types. Selection should prioritize performance characteristics over color alone.

Question 5: How often should chimney flashing sealant be inspected and re-applied?

Regular inspections are recommended at least annually, particularly after periods of extreme weather. Sealant exhibiting signs of cracking, peeling, or separation should be promptly addressed through cleaning and re-application to maintain a watertight seal.

Question 6: Are there specific sealant application techniques recommended for chimney flashing?

Yes, precise application is essential. Apply a continuous bead of sealant along the flashing edges, ensuring full contact with both the chimney and roofing surfaces. Tool the sealant joint to create a smooth, watertight seal, and promptly remove any excess sealant to prevent staining or discoloration.

Proper selection and application of sealant require careful consideration of multiple factors, including material compatibility, environmental conditions, and application techniques. Proactive maintenance is key to ensure long-term protection against water damage.

Explore further resources for detailed guidance on chimney maintenance and roofing best practices.

Conclusion

This exploration of the best sealant for chimney flashing underscores the critical role this material plays in protecting building structures. The optimal product must exhibit robust adhesion, exceptional weather resistance, material compatibility, ease of application, and long-term durability. Compromises in any of these areas can lead to premature sealant failure and subsequent water damage, necessitating costly repairs.

The selection and proper application of the best sealant for chimney flashing is not merely a maintenance task but a fundamental investment in the preservation of property. Continued vigilance, informed product choices, and adherence to best practices are essential for maintaining a watertight seal and safeguarding buildings against the damaging effects of water intrusion. Ongoing research and development efforts will likely lead to advancements in sealant technology, offering even greater protection and longevity in the future. Prioritizing quality and performance remains paramount.