The process of erecting a conduit for venting combustion byproducts from a heating appliance is a crucial aspect of home construction and renovation. This procedure, often involving specialized materials and techniques, ensures the safe and efficient removal of smoke, gases, and particulate matter from fireplaces, stoves, and furnaces. For example, accurately joining sections of stainless steel or insulated piping to create a continuous flue is a fundamental part of this practice.

Proper execution of this task safeguards occupants from carbon monoxide poisoning and reduces the risk of chimney fires. Historically, the correct and safe method for doing this has evolved significantly, from early clay flues to modern, engineered systems designed for optimal draft and longevity. The utilization of correct materials and adherence to building codes are central to ensuring the systems operational safety and regulatory compliance.

The following sections will delve into the various aspects of this operation, including selecting appropriate pipe materials, understanding relevant safety standards, and employing best practices for secure and effective assembly. Guidance will be provided on inspection procedures and maintenance to preserve optimal performance and safety throughout the lifespan of the system.

Guidance for Chimney Flue Construction

The following guidelines provide critical information for the safe and effective construction of a chimney flue. Strict adherence to these points is essential for the system’s proper function and the safety of the building occupants.

Tip 1: Select Approved Materials: Only use materials specifically listed and approved for chimney applications. This includes stainless steel, refractory cement, and insulation materials designed to withstand high temperatures and corrosive byproducts of combustion. Using unapproved materials can lead to premature failure and hazardous conditions.

Tip 2: Consult Local Building Codes: Prior to commencement, thoroughly review and understand all applicable local building codes and regulations pertaining to chimney construction. Codes dictate permissible materials, clearances to combustible materials, and required inspection procedures.

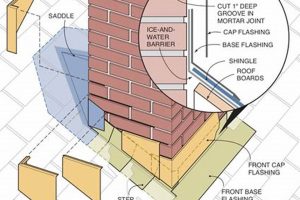

Tip 3: Maintain Proper Clearances: Ensure all sections maintain the required clearance from combustible materials such as wood framing, roofing, and insulation. Insufficient clearance is a primary cause of chimney fires.

Tip 4: Secure All Connections: Employ proper fasteners and sealing methods to ensure airtight and watertight connections between each section. Improperly sealed connections allow flue gases to escape into the building and reduce draft efficiency.

Tip 5: Ensure Adequate Support: Provide adequate structural support for the entire assembly, particularly for tall or heavy flue sections. Support mechanisms should be designed to withstand wind loads and seismic activity where applicable.

Tip 6: Install a Rain Cap: Terminate the flue with a properly sized rain cap to prevent water and debris from entering the chimney. Water intrusion can corrode the system and reduce its lifespan, while debris can obstruct the flow of flue gases.

Tip 7: Conduct a Thorough Inspection: Upon completion, conduct a comprehensive inspection of the entire system, checking for proper clearances, secure connections, and overall structural integrity. Address any deficiencies identified during the inspection prior to placing the system in service.

Proper construction requires careful planning, meticulous execution, and adherence to industry best practices. By diligently following these guidelines, the system will operate safely and efficiently for its intended lifespan.

The subsequent sections will address troubleshooting common issues and maintaining the integrity of the finished installation.

1. Proper Material Selection

The careful and deliberate selection of materials is paramount to a properly functioning and safe venting system. The chosen materials directly impact the system’s ability to withstand high temperatures, resist corrosion, and maintain structural integrity over its service life. Inadequate material choice will invariably lead to premature failure, creating hazardous conditions and necessitating costly repairs.

- Resistance to High Temperatures

Chimney flues are subjected to extreme temperatures during operation, particularly during periods of heavy use or in the event of a chimney fire. Materials must be capable of withstanding these temperatures without significant degradation or deformation. For example, stainless steel liners are commonly used due to their high melting point and resistance to thermal stress, whereas galvanized steel is unsuitable due to the potential for zinc coatings to vaporize and release toxic fumes at high temperatures.

- Corrosion Resistance

The byproducts of combustion, including acidic gases and moisture, are highly corrosive. The selected materials must be resistant to these corrosive elements to prevent deterioration and eventual failure. Stainless steel alloys, specifically those containing molybdenum, offer superior corrosion resistance compared to standard carbon steel. The use of incorrect materials can lead to rapid corrosion and the release of harmful gases into the living space.

- Compliance with Industry Standards

Material selection must adhere to relevant industry standards and building codes. These standards specify the minimum requirements for materials used in chimney construction, ensuring that they meet established safety and performance criteria. For instance, Underwriters Laboratories (UL) standards define the testing and certification requirements for chimney liners and components, ensuring that they have been evaluated for fire safety and structural integrity. Using non-compliant materials can void warranties and create legal liabilities.

- Material Compatibility

When installing or repairing a venting system, it is essential to ensure the selected materials are compatible with existing components and are designed to work together. Mismatched materials can lead to galvanic corrosion, thermal expansion differences, and other issues that compromise the system’s integrity. Mixing different grades of stainless steel, for example, can create a corrosive environment at the junction point. Consulting with a qualified professional is crucial when combining different materials or components.

The principles of correct material specification extend beyond merely choosing heat-resistant or corrosion-proof substances. The chosen materials must integrate harmoniously within the overall system design, taking into account factors such as flue gas temperatures, fuel type, and environmental conditions. Comprehensive consideration of these variables is essential for ensuring both long-term durability and compliance with safety standards.

2. Code Compliance

Code compliance forms a foundational pillar for any undertaking involving chimney construction. Adherence to established building codes is not merely a regulatory formality but a critical safeguard for both property and human life. These codes, developed through extensive research and practical experience, dictate specific requirements for materials, installation methods, and clearances, all of which are directly pertinent to the safety and efficiency of any chimney system. Failure to adhere to these regulations introduces significant risks, ranging from structural instability to carbon monoxide poisoning and devastating chimney fires. For instance, local building codes typically mandate specific clearances between a chimney and combustible materials, such as wood framing. Ignoring these requirements can create conditions ripe for ignition, particularly when high flue gas temperatures are present.

The practical significance of understanding and adhering to code is readily apparent in real-world scenarios. Consider the case of a homeowner who attempts to install a wood stove without the necessary permits or inspections. Without professional oversight, the chimney may not be properly sized for the stove, resulting in inadequate draft and the potential for back-drafting of dangerous gases into the home. Similarly, the use of unapproved chimney liners or connectors can compromise the system’s integrity, leading to leaks and the release of corrosive flue gases into the building structure. These examples highlight the crucial role that building codes play in preventing potentially life-threatening situations.

Therefore, a comprehensive understanding of relevant building codes and a commitment to strict adherence are non-negotiable aspects. Engaging qualified professionals who possess the necessary expertise and experience is crucial. These professionals are well-versed in local regulations and can ensure that the project meets all applicable safety and performance standards. Prioritizing code compliance serves not only to avoid legal penalties but also to protect the well-being of building occupants and preserve the integrity of the structure itself.

3. Adequate Clearance

The establishment and maintenance of adequate clearance between a chimney flue and adjacent combustible materials represents a critical safety imperative. This clearance, mandated by building codes and safety standards, is designed to prevent the ignition of surrounding structures due to the intense heat generated by the flue. Insufficient clearance constitutes a significant fire hazard, with documented instances of structural fires directly attributable to inadequate separation between the chimney and wood framing, insulation, or roofing materials. The principles of heat transfer dictate that close proximity to combustible materials increases the risk of reaching ignition temperatures, particularly during prolonged periods of high heat output.

The application of appropriate clearance principles necessitates careful planning and precise execution during construction. This involves meticulous adherence to manufacturer specifications for listed chimney systems, which provide detailed instructions on minimum clearance requirements based on the specific type of flue and its intended use. For example, a double-wall, air-insulated chimney system may require less clearance than a single-wall system due to its enhanced insulation properties. However, failure to install the chimney according to the manufacturer’s instructions, even with a seemingly adequate separation distance, can compromise the system’s safety. Additionally, regular inspections are essential to ensure that clearance distances remain consistent over time, as settling, shifting, or modifications to the building structure can inadvertently reduce clearances and create hazardous conditions.

In summary, maintaining adequate clearance constitutes an indispensable component of responsible construction and ongoing maintenance. It necessitates a thorough understanding of relevant building codes, adherence to manufacturer specifications, and diligent monitoring of the installation throughout its lifespan. Neglecting clearance requirements exposes building occupants to unacceptable fire risks, highlighting the profound practical significance of this seemingly straightforward concept. Proper clearance not only prevents potential catastrophes but also ensures the longevity and reliable performance of the chimney system itself.

4. Secure Connections

The establishment of secure connections represents a cornerstone of chimney construction. Integrity is paramount for functionality and safety in venting combustion byproducts from appliances. Failure to achieve securely joined components compromises the entire system, leading to potential hazards and performance degradation.

- Prevention of Leakage

Secure connections are essential to prevent the leakage of flue gases into the occupied space. Leaks introduce hazardous substances such as carbon monoxide, posing significant health risks to building occupants. Examples of compromised connections include improperly sealed joints or deteriorated gasket materials. Thoroughly checking each connection point during assembly is critical.

- Maintenance of Draft

Air-tight junctions contribute to maintaining proper draft within the chimney. An effective draft ensures the efficient removal of combustion byproducts, preventing back-drafting and promoting optimal appliance performance. Insecure connections allow ambient air to infiltrate the system, reducing draft effectiveness and potentially causing operational issues with the connected appliance.

- Structural Stability

Robust and secure connections are vital for the overall structural stability of the chimney system. The system must withstand wind loads, thermal expansion and contraction, and potential seismic activity. Weak connections can lead to component separation, compromising the chimney’s integrity and potentially creating a collapse hazard.

- Longevity and Durability

Properly executed connections enhance the longevity and durability of the system. Securely joined components minimize wear and tear, preventing premature degradation due to environmental factors and operational stresses. The use of appropriate fasteners, sealants, and connection methods is critical for long-term performance and reliability.

Collectively, securely connected components reinforce the chimney’s function. Compromised connections defeat the entire purpose, and increase safety hazard. Strict adherence to manufacturer’s instructions and best practices is indispensable to ensure both short and long-term reliability of this critical home component.

5. Structural Support

The provision of adequate structural support is inextricably linked to the process of erecting a chimney system. The inherent weight of the flue, combined with environmental factors such as wind and seismic activity, necessitates a robust support structure to ensure stability and prevent catastrophic failure. A chimney lacking adequate support poses a significant safety risk, potentially leading to collapse, damage to surrounding structures, and personal injury. For instance, a tall, unbraced chimney exposed to high winds may experience excessive stress, resulting in cracking, displacement, or complete collapse. Proper support mechanisms, such as steel bracing, masonry foundations, and secure anchoring, are essential for mitigating these risks and maintaining the system’s structural integrity throughout its lifespan.

The design and implementation of a suitable support system must account for various factors, including the height and weight of the flue, the local climate conditions, and the building’s structural characteristics. In regions prone to earthquakes, seismic bracing is crucial to prevent chimney collapse during ground movement. Similarly, in areas with high wind speeds, robust anchoring systems are necessary to resist wind loads. The selection of appropriate support materials and methods should be based on engineering principles and informed by professional assessment. A poorly designed or inadequately installed support structure can negate the benefits of a properly constructed flue, rendering the entire system vulnerable to failure.

In summary, structural support is not merely an ancillary consideration but an integral component of chimney construction. Its absence or inadequacy undermines the system’s safety and longevity, exposing building occupants to potential hazards. Employing sound engineering practices, adhering to relevant building codes, and engaging qualified professionals are essential for ensuring that the chimney system receives the necessary structural support to withstand environmental stresses and maintain its integrity over time.

6. Effective Termination

Effective flue termination constitutes the final and critical stage in the process of chimney construction. It directly influences the system’s ability to properly vent combustion byproducts, prevent the ingress of precipitation and debris, and maintain structural integrity over time. Improper termination negates the benefits of correctly installed components and introduces hazards. For example, a chimney lacking a properly sized rain cap allows water to enter the flue, leading to corrosion, reduced draft, and potential damage to the appliance connected to the system. Similarly, a termination point positioned too close to a roofline can create backdrafting issues, where combustion gases are drawn back into the building due to wind patterns.

The practical application of effective termination involves careful consideration of various factors, including local climate conditions, roof pitch, and proximity to surrounding structures. Building codes typically specify minimum heights for chimney terminations above the roofline to ensure adequate draft and prevent downdrafts. The selection of appropriate termination hardware, such as rain caps, spark arrestors, and animal guards, is crucial for protecting the system from environmental elements and preventing obstructions. Regular inspection and maintenance of the termination point are also essential for identifying and addressing potential issues before they escalate into significant problems. A rusted rain cap, for instance, can compromise its protective function and allow water intrusion, necessitating timely replacement.

In summary, effective termination is indispensable for safe operation. It protects from environmental elements and helps maintain efficient ventilation. Neglecting this aspect exposes the system to risks, reducing performance and safety. Following codes, using suitable hardware, and doing maintenance help ensure the finished process is done properly, safe-guarding properties and lives. Understanding the connection between effective termination and chimney system installation is crucial for maintaining a building’s safety and integrity.

Frequently Asked Questions

The following section addresses common inquiries regarding chimney flue establishment. It aims to clarify pertinent information and dispel potential misconceptions.

Question 1: What constitutes an acceptable material for chimney lining?

Acceptable materials are those listed and labeled for chimney lining applications, such as stainless steel (specifically 304 or 316 alloy) or clay tiles meeting ASTM C315 standards. Unapproved materials, such as galvanized steel or non-rated ceramic tiles, pose safety risks and violate building codes.

Question 2: How often should a chimney be inspected following pipe establishment?

A newly installed chimney should undergo an initial inspection immediately following completion to verify code compliance and proper functionality. Subsequent inspections should occur annually or more frequently if signs of damage or malfunction are observed.

Question 3: What is the required clearance to combustible materials?

Clearance requirements vary based on the type of chimney and local building codes. Typically, a minimum of 2 inches of clearance is required for listed factory-built chimneys, while masonry chimneys may require up to 12 inches. Consult local building codes for precise requirements.

Question 4: Can existing chimneys be relined with flexible stainless steel liners?

Yes, existing chimneys can often be relined with flexible stainless steel liners, provided the chimney is structurally sound and the liner is properly sized and installed. Relining is a common method for restoring damaged or deteriorated chimneys.

Question 5: What are the signs of a deteriorating or improperly established flue?

Signs of a failing or improperly established flue include visible cracks or gaps in the masonry, the presence of creosote buildup, water leaks, and evidence of backdrafting or carbon monoxide leaks. Any of these symptoms warrant immediate professional inspection.

Question 6: Are permits required prior to installing or relining a chimney?

Permits are typically required before commencing chimney installation or relining. Contact the local building department to determine specific permit requirements and inspection procedures.

The principles of careful materials selection, correct installation, and adherence to building codes are paramount for long-term safety.

The following section presents guidance for selecting a qualified contractor and overseeing the installation process.

Concluding Remarks

This exploration has underscored that installing chimney pipe is not a perfunctory task, but a procedure demanding meticulous attention to detail, code adherence, and material compatibility. The discussions on material selection, clearance maintenance, secure connections, structural support, and effective termination emphasize the multifaceted nature of chimney construction. Neglecting any of these elements can compromise system integrity and endanger building occupants.

Therefore, engaging qualified professionals and prioritizing safety standards are paramount. The longevity and proper function of the system hinges on responsible execution and continuous maintenance. Homeowners and building managers must recognize that establishing a secure ventilation system safeguards properties and lives and requires vigilance and sustained commitment to best practices. Only then can this critical home element offer safe, reliable operation.

![Protect with a Galvanized Chimney Cap: [Benefits] Chimney Works – Expert Chimney Repair, Cleaning & Installation Services Protect with a Galvanized Chimney Cap: [Benefits] | Chimney Works – Expert Chimney Repair, Cleaning & Installation Services](https://thechimneyworks.com/wp-content/uploads/2025/12/th-341-300x200.jpg)