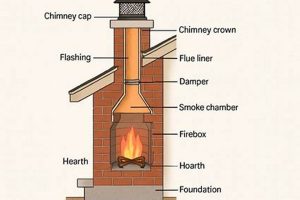

A dark-colored vertical structure extending above a building’s roofline, primarily designed for expelling smoke and combustion gases from a fireplace, furnace, or other heating appliance. This structure is typically constructed of brick, stone, or metal and its darkened appearance often results from the accumulation of soot and creosote, byproducts of burning fuel. As an example, a residence might feature this type of structure visibly projecting from its roof, indicating the presence of a wood-burning fireplace within.

These structures play a critical role in maintaining indoor air quality and preventing dangerous buildup of carbon monoxide. Their efficient design ensures proper draft, which is essential for effective combustion and the safe removal of harmful emissions. Historically, these components were vital elements of buildings relying on solid fuels for heating and cooking. Their presence signifies a connection to traditional heating methods and, in some cases, contributes to the architectural character of a building.

The following sections will explore the materials used in constructing these structures, the maintenance required to ensure their safe operation, and the regulations governing their installation and use. We will also consider the potential environmental impact and discuss modern alternatives that offer improved efficiency and reduced emissions.

Maintenance and Safety Tips

Proper maintenance and adherence to safety protocols are paramount for the safe and efficient operation of any such flue. Neglecting these aspects can lead to hazardous conditions, including chimney fires and carbon monoxide poisoning.

Tip 1: Schedule Annual Inspections. A qualified professional should inspect the structure annually to assess its condition and identify any potential issues, such as cracks, blockages, or deterioration of the liner.

Tip 2: Conduct Regular Cleaning. Creosote buildup is a significant fire hazard. Regular cleaning, ideally by a certified chimney sweep, removes this accumulation and reduces the risk of ignition.

Tip 3: Use Appropriate Fuel. Burning only seasoned, dry wood minimizes creosote production. Avoid burning trash, treated wood, or other materials that can create excessive smoke and harmful emissions.

Tip 4: Ensure Proper Ventilation. Adequate airflow is crucial for proper combustion and the safe removal of exhaust gases. Do not obstruct air intakes or vents.

Tip 5: Install Carbon Monoxide Detectors. Carbon monoxide is a colorless, odorless gas that can be deadly. Install carbon monoxide detectors on every level of the building, particularly near sleeping areas.

Tip 6: Be Aware of Warning Signs. Pay attention to potential warning signs, such as smoke backing up into the building, unusual odors, or a slow-burning fire. These indicators may suggest a problem requiring immediate attention.

Tip 7: Maintain Proper Clearance. Ensure that combustible materials, such as furniture, curtains, and firewood, are kept a safe distance from the heating appliance and the flue. Consult local building codes for specific clearance requirements.

Adhering to these maintenance and safety guidelines contributes significantly to the longevity and safe operation of these exhaust systems, protecting both property and occupants.

The following sections will delve into the specific types of fuel suitable for use and elaborate on the procedures for effective creosote removal.

1. Soot Accumulation

Soot accumulation, a direct consequence of incomplete combustion within heating appliances and fireplaces, is inextricably linked to the darkened appearance of flue structures. This accumulation not only alters the aesthetic of the structure but also presents significant operational and safety concerns.

- Composition and Formation

Soot comprises primarily unburned carbon particles, ash, and condensed volatile organic compounds. These byproducts are generated when fuel, typically wood, coal, or oil, does not undergo complete combustion. Factors contributing to incomplete combustion include insufficient oxygen supply, low combustion temperatures, and the presence of moisture in the fuel. These particles adhere to the interior surfaces of the flue during exhaust, gradually forming a dense, often flammable layer.

- Insulation and Draft Reduction

The accumulation of soot acts as an insulating layer within the flue, hindering heat transfer and reducing the draft efficiency. A reduced draft impairs the ability of the flue to effectively exhaust combustion gases, potentially leading to smoke backdraft into the living space and increasing the risk of carbon monoxide poisoning. This insulation effect can also elevate the flue temperature, increasing the likelihood of a chimney fire.

- Creosote Formation and Fire Hazard

Soot deposits, particularly those derived from wood burning, often contain creosote, a highly flammable substance. Creosote forms as volatile gases condense and solidify within the flue. The consistency of creosote can range from a flaky powder to a tar-like glaze. Regardless of its form, creosote presents a significant fire hazard. A chimney fire occurs when creosote ignites, rapidly escalating temperatures within the flue and potentially spreading to adjacent combustible materials in the building structure.

- Material Degradation and Structural Damage

Prolonged soot accumulation can contribute to the degradation of the flue’s materials, particularly in older structures constructed from brick or masonry. Soot deposits, especially when combined with moisture, can create acidic conditions that corrode mortar joints and weaken the overall structural integrity of the structure. This degradation can lead to cracks, spalling, and even collapse of the structure if left unaddressed.

The multifaceted impact of soot accumulation underscores the importance of regular flue inspections and cleaning. Professional chimney sweeps employ specialized tools and techniques to remove soot and creosote deposits, mitigating the associated safety hazards and preserving the structural integrity of the exhaust system. The visible darkness is a constant reminder of these risks, prompting necessary preventative measures.

2. Structural Integrity

The structural integrity of a flue structure is paramount to its safe and effective operation. Compromised integrity can lead to hazardous conditions, rendering the system incapable of containing combustion byproducts and potentially endangering occupants and the surrounding structure.

- Material Degradation and Cracking

Flues, whether constructed of brick, stone, metal, or clay liners, are subject to degradation from exposure to high temperatures, corrosive combustion gases, and the elements. Over time, thermal stress and chemical reactions can cause cracking, spalling, and erosion of the materials. Cracks compromise the flue’s ability to contain smoke and gases, allowing them to leak into the building structure. Deteriorated mortar joints in brick flues are a common example, creating pathways for flue gases to escape.

- Water Damage and Freeze-Thaw Cycles

Moisture penetration is a significant threat to the structural integrity of flue structures. Rainwater and melting snow can enter through cracks or damaged components, saturating the masonry and leading to freeze-thaw damage in colder climates. Repeated freezing and thawing cycles cause the water to expand and contract, exerting pressure on the surrounding materials and exacerbating existing cracks. This process weakens the overall structure and accelerates its deterioration. Chimney crowns, designed to prevent water ingress, are particularly susceptible to damage and require regular inspection and maintenance.

- Foundation Settlement and Shifting

The foundation upon which the flue structure rests plays a critical role in its stability. Uneven settlement of the foundation can cause the flue to shift, leading to cracks and structural instability. Factors contributing to foundation settlement include soil erosion, poor drainage, and inadequate soil compaction. Significant shifts can compromise the flue’s alignment, potentially causing it to lean or even collapse. Addressing foundation issues is essential for maintaining the long-term structural integrity of the exhaust system.

- Liner Deterioration and Failure

Many flues are equipped with liners, typically made of clay, metal, or concrete, to protect the surrounding masonry from the corrosive effects of combustion gases. Liners are particularly important in preventing the migration of carbon monoxide into the building. Over time, liners can crack, spall, or corrode, compromising their protective function. Damaged or missing liner sections allow flue gases to come into direct contact with the masonry, accelerating its deterioration and increasing the risk of carbon monoxide poisoning. Regular inspection and repair or replacement of damaged liners are crucial for maintaining the structural integrity of the entire system.

These factors highlight the complex interplay of elements that influence the structural integrity of darkened flue structures. Regular inspections, prompt repairs, and preventative maintenance are essential for ensuring their continued safe and effective operation. Addressing issues such as material degradation, water damage, foundation settlement, and liner deterioration proactively minimizes the risk of catastrophic failure and protects both property and occupants.

3. Draft Efficiency

Draft efficiency is a crucial determinant of the functional effectiveness and safety of any flue structure. This efficiency dictates the capacity of the structure to effectively expel combustion byproducts, ensuring proper heating appliance operation and minimizing the risk of hazardous emissions entering the living space.

- Stack Effect and Thermal Buoyancy

The stack effect, driven by thermal buoyancy, is the primary mechanism behind draft efficiency. Heated gases within the flue structure are less dense than the surrounding cooler air. This density difference creates a pressure differential, causing the hot gases to rise and exit through the top of the structure. The height of the structure directly influences the strength of the stack effect; taller structures generally exhibit greater draft efficiency. Insufficient height or obstructions within the flue can impede airflow and reduce draft.

- Flue Dimensions and Area

The cross-sectional area and shape of the flue influence its capacity to exhaust combustion gases effectively. An undersized flue restricts airflow, leading to incomplete combustion and increased creosote buildup. An oversized flue, on the other hand, may result in insufficient draft, allowing flue gases to cool and condense before exiting, also contributing to creosote formation. Proper sizing, based on the heating appliance’s specifications, is crucial for optimizing draft efficiency.

- Internal Surface Roughness and Obstructions

The smoothness of the internal flue surfaces impacts airflow resistance. Rough surfaces, caused by accumulated soot, creosote, or damaged liners, increase friction and impede the upward flow of gases. Obstructions, such as bird nests, debris, or collapsed liner sections, significantly reduce draft efficiency, potentially causing smoke backdraft into the building. Regular cleaning and maintenance are essential for maintaining smooth flue surfaces and removing obstructions.

- External Environmental Factors

External environmental conditions, such as wind and temperature variations, can influence draft efficiency. Strong winds can create downdrafts, pushing air down the flue and counteracting the stack effect. Cold outside temperatures can reduce the temperature differential between the flue gases and the ambient air, weakening the draft. Proper flue design, including the use of chimney caps and windbreaks, can mitigate the impact of these external factors.

The interplay of these facets underscores the importance of a well-maintained and properly designed flue structure. Reduced draft efficiency not only compromises the performance of heating appliances but also elevates the risk of carbon monoxide poisoning and chimney fires, highlighting the critical link between draft efficiency and the safe operation of the entire system.

4. Material Degradation

Material degradation is integrally linked to the performance and longevity of a dark-hued exhaust flue. The harsh operating conditions to which these structures are subjected, including high temperatures, corrosive gases, and cyclical exposure to the elements, accelerate the deterioration of their constituent materials. This degradation manifests in various forms, such as cracking, spalling, erosion, and chemical corrosion, significantly impacting the structure’s integrity and its ability to safely and efficiently vent combustion byproducts. For example, brick flues exposed to acidic condensation from improperly vented gas appliances often exhibit mortar joint erosion, weakening the overall structure and creating pathways for dangerous gases to escape. The darkness, resulting from accumulated soot, actually hides the degradation until it becomes severe.

The specific materials used in constructing the flue influence the nature and rate of degradation. Clay liners, while initially resistant to high temperatures, can crack under thermal stress, particularly when subjected to rapid temperature changes. Metal flues are susceptible to corrosion from acidic flue gases, leading to thinning and eventual perforation of the metal. Concrete flues may experience spalling and cracking due to moisture penetration and freeze-thaw cycles. Understanding the degradation mechanisms specific to each material is critical for implementing appropriate maintenance and repair strategies. A practical application of this understanding involves selecting appropriate flue liners for specific fuel types. For instance, stainless steel liners are often recommended for high-efficiency appliances that produce acidic condensate.

In summary, material degradation represents a substantial challenge to the continued safe operation of dark exhaust flues. Recognizing the causes and consequences of this degradation is essential for implementing proactive maintenance programs, selecting appropriate materials for new installations or repairs, and ultimately, ensuring the long-term performance and safety of these critical building components. Ignoring material degradation can lead to costly repairs, hazardous operating conditions, and, in extreme cases, structural failure, emphasizing the need for ongoing vigilance and informed decision-making.

5. Environmental Impact

The environmental consequences associated with flue structures, especially those darkened by soot and creosote accumulation, represent a critical concern in discussions of sustainable building practices and air quality management. The function of these structures in exhausting combustion byproducts directly links their operation to the release of pollutants into the atmosphere, necessitating careful consideration of their design, maintenance, and fuel sources.

- Particulate Matter Emissions

The primary environmental impact stems from the emission of particulate matter (PM), particularly PM2.5 and PM10, generated during the combustion of solid fuels such as wood and coal. These fine particles can penetrate deep into the respiratory system, contributing to respiratory illnesses, cardiovascular problems, and other adverse health effects. High concentrations of PM in urban areas are often directly correlated with the prevalence of these structures employing inefficient combustion processes. Regulations increasingly target PM emissions from residential heating sources to mitigate their impact on public health. For example, wood-burning stoves certified by environmental agencies are designed to minimize PM emissions compared to older, non-certified models.

- Greenhouse Gas Emissions

Combustion processes within heating appliances also release greenhouse gases (GHGs), including carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O), contributing to climate change. While CO2 emissions are inherent in the burning of carbon-based fuels, methane and nitrous oxide are potent GHGs with significantly higher global warming potentials. Incomplete combustion, often associated with poorly maintained or inefficient heating appliances, exacerbates the release of these gases. Shifting to alternative heating sources, such as natural gas or renewable energy, or implementing more efficient combustion technologies can substantially reduce GHG emissions. Moreover, using sustainably sourced wood as fuel offers a carbon-neutral approach, provided that the harvested trees are replaced through reforestation efforts.

- Volatile Organic Compound (VOC) Emissions

Incomplete combustion also leads to the release of volatile organic compounds (VOCs), which contribute to the formation of ground-level ozone and smog. VOCs react with nitrogen oxides in the presence of sunlight to produce ozone, a respiratory irritant and a major component of urban air pollution. Some VOCs are also classified as hazardous air pollutants (HAPs), posing direct health risks. Implementing cleaner burning technologies and using properly seasoned wood reduces VOC emissions. Additionally, certain types of wood emit fewer VOCs than others, influencing fuel selection as a mitigation strategy.

- Creosote Deposition and Soil Contamination

While primarily a safety hazard within the flue itself, creosote deposition can also pose an environmental risk if improperly handled during cleaning or maintenance. Creosote contains polycyclic aromatic hydrocarbons (PAHs), some of which are carcinogenic and can contaminate soil and water resources if disposed of improperly. Proper disposal methods, such as collecting creosote in sealed containers and delivering it to hazardous waste facilities, are essential to prevent environmental contamination. Furthermore, using creosote-reducing additives in wood stoves can minimize creosote formation and reduce the risk of environmental contamination during cleaning.

These facets collectively highlight the diverse environmental implications associated with these structures. Mitigating these impacts requires a multi-faceted approach encompassing cleaner fuel sources, more efficient combustion technologies, regular maintenance, and responsible waste disposal practices. Public awareness campaigns promoting these measures are crucial for reducing the overall environmental footprint associated with these essential, yet potentially polluting, building components.

Frequently Asked Questions About “Black Chimneys”

This section addresses common inquiries regarding the nature, function, and maintenance of flue structures darkened by soot and creosote accumulation. The intent is to provide clarity and dispel misconceptions surrounding these important building components.

Question 1: What causes a “black chimney?”

The darkened appearance typically results from the accumulation of soot and creosote, byproducts of incomplete combustion within fireplaces, wood stoves, and furnaces. These substances adhere to the interior surfaces of the structure over time, leading to the characteristic discoloration.

Question 2: Is a “black chimney” necessarily dangerous?

While the discoloration itself is not inherently dangerous, it signifies the presence of combustible materials, particularly creosote, that pose a significant fire hazard. Accumulation also reduces draft efficiency, potentially leading to carbon monoxide exposure.

Question 3: How often should a “black chimney” be cleaned?

The frequency of cleaning depends on usage and fuel type. However, annual inspections by a qualified professional are recommended. If significant creosote buildup is observed, more frequent cleaning is necessary.

Question 4: Can the color of a “black chimney” be reversed?

While the internal deposits can be removed through professional cleaning, external discoloration may be permanent, depending on the materials and the extent of staining. Emphasis should be placed on preventing further accumulation, rather than reversing existing staining.

Question 5: Are there alternative chimney designs that minimize blackening?

Properly sized and insulated flues promote more complete combustion, reducing soot and creosote production. Modern, high-efficiency appliances also contribute to cleaner burning. Regular maintenance is critical, regardless of the design.

Question 6: What are the long-term consequences of neglecting a “black chimney?”

Neglecting a darkened flue structure increases the risk of chimney fires, structural damage, and carbon monoxide poisoning. Regular inspections and cleaning are essential for mitigating these risks and ensuring the safety of the building and its occupants.

In conclusion, the presence of a “black chimney” necessitates vigilance and proactive maintenance to ensure its safe and efficient operation. Addressing the underlying causes of soot and creosote accumulation is paramount.

The following section will explore regulations and code compliance as they pertain to flue structures and heating appliances.

Conclusion

This exploration has detailed the multifaceted aspects of flues darkened by combustion byproducts. The accumulation of soot and creosote signifies not only aesthetic alteration but also potential hazards related to structural integrity, draft efficiency, and environmental impact. Mitigation strategies, including regular inspections, professional cleaning, and informed fuel selection, are crucial for ensuring safe and efficient operation.

The enduring presence of these structures in the built environment necessitates a continued commitment to responsible maintenance and adherence to evolving safety standards. By prioritizing proactive measures, property owners and building professionals can safeguard against the inherent risks and contribute to improved air quality and environmental stewardship.