These protective coverings are installed at the top of a chimney to prevent rain, snow, debris, and animals from entering the flue. They typically consist of a wire mesh or solid lid that covers the opening while allowing exhaust gases to escape freely. A common example is a stainless steel mesh cap fitted atop a brick chimney to deter birds and squirrels.

The utilization of these components offers several key advantages. Primarily, they safeguard the chimney interior from moisture damage, which can lead to costly repairs and structural deterioration. Furthermore, these devices prevent obstructions that could impede proper airflow, reducing the risk of dangerous backdrafts and improving heating system efficiency. Historically, simpler versions, often constructed from clay or stone, were used to mitigate downdrafts caused by wind.

The subsequent sections will delve into the various types available, the installation process, maintenance requirements, and common issues that might arise related to these essential chimney components.

Essential Considerations for Chimney Flue Caps

Optimizing the performance and longevity of these chimney components requires careful attention to selection, installation, and maintenance.

Tip 1: Material Selection. The choice of material significantly impacts durability. Stainless steel provides excellent resistance to corrosion in most environments. Copper offers superior longevity but carries a higher initial cost. Galvanized steel is a more economical option but may require more frequent replacement.

Tip 2: Sizing Accuracy. Precise measurements of the flue opening are critical. An improperly sized cap may fail to provide adequate protection or restrict airflow, potentially leading to carbon monoxide buildup.

Tip 3: Professional Installation. While DIY installation is possible, engaging a qualified professional ensures secure and proper fitting, minimizing the risk of damage to the chimney or the cap itself.

Tip 4: Regular Inspections. Conduct periodic inspections for signs of damage or deterioration, such as rust, corrosion, or loose fasteners. Address any issues promptly to prevent further degradation.

Tip 5: Debris Removal. Accumulated leaves, nests, and other debris can obstruct airflow. Regular cleaning, ideally performed annually, maintains optimal chimney function.

Tip 6: Animal Deterrents. For areas prone to animal intrusion, consider models specifically designed with animal deterrents, such as extended mesh or additional screening.

Tip 7: Local Codes and Regulations. Prior to installation, verify compliance with local building codes and regulations, which may specify requirements for materials, sizing, or installation methods.

Adhering to these considerations ensures the effective operation and prolonged lifespan of these protective devices, safeguarding both property and occupants.

The following sections will discuss troubleshooting common problems and determining when replacement is necessary.

1. Material Durability

Material durability is a paramount consideration in the selection and performance of chimney flue caps. Exposure to extreme weather conditions, corrosive flue gases, and potential animal interactions necessitates the use of robust materials to ensure long-term protection and functionality.

- Corrosion Resistance

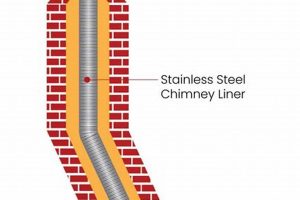

The primary role of durable materials lies in their ability to resist corrosion. Chimney flues are exposed to acidic byproducts of combustion, which can rapidly degrade less resistant materials. Stainless steel, particularly 304 grade or higher, provides excellent corrosion resistance in most residential applications. Copper offers superior corrosion resistance but is a more expensive option, typically reserved for high-end installations or historic preservation projects.

- Weather Endurance

Flue caps are perpetually exposed to the elements. Materials must withstand temperature fluctuations, precipitation, and ultraviolet radiation without significant degradation. Powder-coated steel offers improved resistance to UV damage compared to standard galvanized steel. The gauge or thickness of the material also contributes to weather endurance; thicker materials are generally more resistant to physical damage from hail or wind-borne debris.

- Structural Integrity

The structural integrity of the cap material is crucial for withstanding physical stresses. Strong winds, falling branches, or even climbing animals can compromise the cap if it is constructed from a weak or brittle material. Welded seams and reinforced construction techniques enhance structural integrity. The design of the cap, including the mesh size and support structures, also contributes to its ability to withstand external forces.

- Longevity and Cost-Effectiveness

While initial cost is a factor, the long-term cost-effectiveness of a flue cap is directly tied to its material durability. A cap constructed from a durable material will require less frequent replacement, resulting in lower overall costs over its lifespan. Investing in a higher-quality material upfront can prevent costly repairs and potential chimney damage down the line, making it a prudent long-term investment.

The interplay between corrosion resistance, weather endurance, structural integrity, and longevity defines the overall material durability of a chimney flue cap. Selecting a cap with appropriate material characteristics is essential for ensuring its continued protection of the chimney and the safety of the building’s occupants. For example, a coastal environment demands a higher grade of stainless steel due to increased salt exposure, illustrating the crucial link between environment and material choice.

2. Proper Sizing

Accurate dimensioning of chimney flue caps is paramount to their effective function and the overall safety of the chimney system. A mismatch in size can negate the protective benefits, leading to inefficiencies and potential hazards.

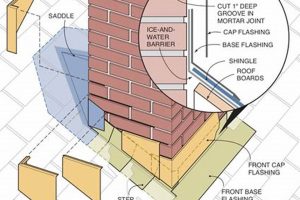

- Effective Weather Protection

An appropriately sized cap completely covers the flue opening, preventing rainwater, snow, and debris from entering the chimney. An undersized cap leaves portions of the flue exposed, allowing moisture intrusion that can damage the chimney lining. Oversizing, conversely, may result in unstable positioning, rendering the cap vulnerable to dislodgement by wind.

- Optimal Airflow Regulation

Correct sizing ensures unimpeded airflow, allowing for the efficient venting of combustion gases. A cap that is too small restricts airflow, potentially causing backdrafting and the accumulation of dangerous carbon monoxide within the dwelling. Conversely, a significantly oversized cap may create turbulence within the flue, affecting draft performance and potentially increasing creosote buildup.

- Secure Animal Deterrence

Proper sizing is essential for preventing animals, such as birds and squirrels, from entering the chimney. A cap that fits snugly prevents animals from squeezing past the edges. An improperly sized cap leaves gaps through which animals can gain access, potentially leading to blockages and fire hazards caused by nesting materials.

- Structural Stability and Longevity

Accurate sizing contributes to the overall structural stability of the chimney flue cap. A cap that fits securely resists dislodgement by wind or physical impact. A cap that is too large or too small may experience undue stress, potentially leading to premature failure and the need for replacement. Correct sizing, therefore, extends the lifespan of the cap and minimizes maintenance requirements.

The interplay between weather protection, airflow regulation, animal deterrence, and structural stability underscores the importance of proper sizing. Accurate measurement of the flue opening and selection of a cap with matching dimensions are critical steps in ensuring the effective and safe operation of the chimney system. Failure to adhere to proper sizing guidelines can have significant consequences, impacting both the structural integrity of the chimney and the safety of the building occupants.

3. Secure Installation

The correlation between secure installation and chimney flue caps is direct and consequential. Improperly installed caps offer diminished protection, increasing the risk of damage and hazardous conditions. For instance, a cap loosely affixed is susceptible to displacement by wind, negating its function of preventing rain ingress. Rainwater infiltration degrades the chimney’s interior structure, potentially necessitating costly repairs. Furthermore, a dislodged cap presents a physical hazard, possibly falling and causing property damage or injury. The secure attachment of a cap, therefore, is not merely a finishing touch but a fundamental aspect of its performance.

A real-world example illustrates the importance of secure installation: a homeowner neglected to properly secure a new cap. A moderate windstorm detached the cap, leading to significant water damage within the chimney. This, in turn, resulted in spalling of the brickwork and deterioration of the flue liner. The cost of repairing the damage far exceeded the initial expense of professional installation. This scenario highlights the economic prudence of ensuring secure installation from the outset.

In conclusion, secure installation is an indispensable element of chimney flue cap functionality. Failure to prioritize secure attachment can lead to a cascade of negative consequences, ranging from property damage to safety risks. The financial and practical benefits of professional, secure installation far outweigh the perceived savings of a less meticulous approach. This understanding is crucial for homeowners and professionals alike, ensuring both the longevity of the chimney and the safety of the occupants.

4. Regular Inspection

Consistent evaluation of chimney flue caps constitutes a critical aspect of maintaining the integrity and optimal performance of residential and commercial chimney systems. Periodic assessments facilitate the early detection of potential issues, mitigating the risk of costly repairs and hazardous conditions.

- Corrosion Detection

Regular visual inspections allow for the identification of rust or corrosion on the cap’s surfaces. Early detection prevents further deterioration, potentially averting structural failure. For instance, identifying minor surface rust on a galvanized steel cap enables timely application of a protective coating, extending its lifespan. Neglecting this can result in significant corrosion necessitating complete replacement.

- Structural Integrity Assessment

Inspections include assessing the cap’s physical condition for damage, such as dents, cracks, or loose fasteners. A damaged cap compromises its protective function, allowing water ingress and potentially obstructing flue gases. Examining weld points and support structures confirms their integrity, ensuring the cap can withstand environmental stresses. For example, a cracked weld on a stainless steel cap needs immediate repair to prevent total failure and subsequent chimney damage.

- Obstruction Identification

Routine checks reveal the presence of obstructions, such as leaves, nests, or debris, that impede airflow. Blockages can cause backdrafts and carbon monoxide accumulation within the building. Removing accumulated debris maintains proper ventilation and minimizes fire hazards. An example is the annual removal of bird nests from within the cap to ensure unimpeded exhaust flow from heating appliances.

- Animal Deterrent Evaluation

Regular inspection includes assessing the effectiveness of animal deterrents integrated into the cap’s design. Damage to the mesh or screening compromises its ability to prevent animal entry. Identifying and repairing breaches promptly prevents animals from nesting within the chimney, mitigating fire risks and structural damage. For instance, repairing a tear in the mesh of a cap deters squirrels from entering and building nests within the flue.

The collective impact of these inspection facets emphasizes the role of routine assessments in maintaining the protective function of chimney flue caps. By proactively identifying and addressing potential issues, property owners can safeguard their chimney systems and ensure the safety and well-being of building occupants. The long-term benefits of regular inspections far outweigh the minimal investment of time and resources required to conduct them.

5. Debris Management

The connection between debris management and chimney flue caps is fundamental to the safe and efficient operation of a chimney system. Flue caps are intentionally positioned to prevent the entry of various forms of debris into the chimney, including leaves, twigs, animal nests, and other foreign materials. Ineffective debris management, stemming from a damaged or absent cap, invariably leads to obstructions within the chimney flue, impacting airflow and posing significant safety risks.

Real-world examples underscore the importance of this relationship. Accumulations of dry leaves and twigs within a chimney flue, absent a functional cap, create a substantial fire hazard. A stray ember from the fireplace can ignite this debris, leading to a chimney fire that can spread to the building structure. Similarly, the nesting activities of birds and squirrels, unchecked by a properly fitted cap, can block the flue, leading to carbon monoxide buildup within the dwelling. This buildup is a silent killer, posing a serious threat to occupants. Furthermore, the weight of accumulated debris, especially when saturated with rainwater, can compromise the structural integrity of the chimney itself, leading to costly repairs. The practical significance of this understanding lies in the proactive maintenance of flue caps, ensuring their proper installation and routine inspection for damage or deterioration. Replacing damaged caps promptly is crucial in preventing debris-related hazards.

In conclusion, debris management is inextricably linked to the function and effectiveness of chimney flue caps. The absence of a cap, or the presence of a damaged one, undermines the chimney’s ability to vent safely and efficiently, creating fire hazards, carbon monoxide risks, and potential structural damage. Prioritizing debris management through the installation and maintenance of functional flue caps is an essential component of responsible homeownership and chimney safety.

6. Animal Deterrence

The capacity of chimney flue caps to prevent animal intrusion is a critical design feature directly impacting chimney system integrity and operational safety. The primary function of these protective devices extends beyond weatherproofing to include the exclusion of various animals that may seek shelter or nesting sites within chimney flues.

- Species-Specific Design Considerations

Effective animal deterrence necessitates accounting for the behaviors and physical characteristics of common chimney-invading species. For example, deterring birds typically involves mesh openings too small for them to enter, while preventing squirrels requires robust construction materials resistant to chewing. Larger animals, such as raccoons, necessitate heavier gauge materials and secure attachment mechanisms. The selection of appropriate materials and designs is crucial for species-specific protection.

- Mesh Material and Aperture Size

The mesh material and aperture size of the flue cap directly influence its effectiveness in preventing animal entry. Galvanized steel mesh offers a balance of cost and durability for general deterrence. Stainless steel mesh provides superior corrosion resistance, particularly in coastal environments. The aperture size must be small enough to exclude the target species without unduly restricting airflow. Excessive restriction of airflow can lead to backdrafting and carbon monoxide accumulation.

- Cap Height and Overhang

Cap height and overhang dimensions play a role in deterring animals that attempt to access the chimney from the roof. Adequate height prevents animals from reaching around the cap to gain entry, while sufficient overhang discourages climbing. Caps with extended skirts that cover the top portion of the chimney also deter climbing animals. These design features enhance the overall effectiveness of the cap in preventing animal intrusion.

- Attachment Security and Tamper Resistance

Secure attachment mechanisms are essential for preventing animals from dislodging or damaging the flue cap. Robust fasteners and tamper-resistant designs prevent animals from manipulating the cap to gain entry. Regular inspection of the attachment points is critical to ensure continued effectiveness. Compromised attachment security renders the cap vulnerable to animal interference, negating its protective function.

The design and implementation of effective animal deterrence measures in chimney flue caps require a comprehensive understanding of local wildlife and their behaviors. Proper selection, installation, and maintenance of these components are essential for safeguarding chimney systems from animal-related damage and hazards. Failure to address animal intrusion can result in significant repair costs, fire risks, and potential health hazards associated with carbon monoxide poisoning, underscoring the importance of robust deterrence strategies.

Frequently Asked Questions

This section addresses common inquiries concerning these essential chimney components, providing concise and informative answers to assist in their proper selection, maintenance, and understanding.

Question 1: What is the primary function of a chimney flue cap?

The primary function is to prevent the ingress of rain, snow, debris, and animals into the chimney flue, thereby protecting the chimney structure and preventing obstructions that could impede proper ventilation.

Question 2: What materials are commonly used in the construction of chimney flue caps, and what are their respective advantages?

Common materials include galvanized steel, stainless steel, and copper. Galvanized steel offers a cost-effective solution, while stainless steel provides enhanced corrosion resistance, and copper offers superior longevity and aesthetic appeal.

Question 3: How does one determine the appropriate size for a chimney flue cap?

The size is determined by measuring the outside dimensions of the chimney flue, ensuring the cap completely covers the opening without restricting airflow. Consult with a professional for precise measurements and sizing recommendations.

Question 4: What are the potential consequences of neglecting to install or maintain these protective devices?

Neglecting installation or maintenance can lead to water damage, flue blockages, increased risk of chimney fires, carbon monoxide buildup, and costly repairs to the chimney structure.

Question 5: How frequently should chimney flue caps be inspected and maintained?

Inspections should be conducted at least annually, preferably in the spring and fall. Maintenance should include the removal of any accumulated debris and the repair or replacement of damaged components.

Question 6: Can chimney flue caps be installed as a do-it-yourself project, or is professional installation recommended?

While DIY installation is possible, professional installation is strongly recommended to ensure proper fitting, secure attachment, and compliance with local building codes. Improper installation can negate the protective benefits and potentially create hazardous conditions.

These answers provide a foundational understanding of the importance and functionality of these devices, encouraging proactive maintenance and responsible chimney management.

The following section will explore common troubleshooting issues and potential solutions related to these chimney components.

Chimney Flue Caps

This exploration has illuminated the critical role these chimney components play in safeguarding residential and commercial properties. From material selection and proper sizing to secure installation and consistent maintenance, each facet contributes directly to the overall functionality and longevity of the chimney system. Their effectiveness in preventing water damage, deterring animal intrusion, and maintaining optimal airflow is paramount for both structural integrity and occupant safety.

The information presented underscores a vital responsibility: prioritizing chimney maintenance, including the proper installation and upkeep of these devices. Neglecting this crucial element can lead to significant financial burdens and, more importantly, pose serious health and safety risks. Therefore, a proactive approach to chimney care, centered around these components, is not merely advisable, but essential for responsible property management and the well-being of those within.